Introduction: Navigating the Global Market for convert jpeg to stl

In today’s competitive landscape, converting JPEG to STL files presents a critical challenge for businesses seeking to leverage 3D printing technology. As companies globally strive to innovate their product offerings, the ability to transform 2D images into tangible 3D models can unlock new avenues for creativity and efficiency. This comprehensive guide delves into the various methods and tools available for converting JPEG files into STL format, highlighting applications across industries such as manufacturing, design, and education.

International B2B buyers from regions like Africa, South America, the Middle East, and Europe will find value in understanding the nuances of this conversion process. The guide encompasses essential topics such as different conversion techniques, types of software tools, key considerations for supplier vetting, and cost implications. By equipping decision-makers with the necessary insights and best practices, this resource empowers them to make informed purchasing decisions that can enhance their operational capabilities.

Whether you’re a manufacturer looking to streamline prototyping or a designer aiming to bring your artistic visions to life, navigating the global market for converting JPEG to STL can position your business for growth. With the right knowledge and resources at your disposal, you can harness the power of 3D printing to drive innovation and meet the evolving demands of your customers.

Understanding convert jpeg to stl Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Conversion | Converts JPEG images into heightmap-style STL models based on brightness levels. | Architectural visualizations, terrain modeling | Pros: Easy to use; suitable for landscapes. Cons: Limited detail; may not suit complex images. |

| Color Extrusion | Creates 3D models by layering colors, maintaining distinct color elements. | Product design, branding, prototypes | Pros: Captures color details; ideal for logos. Cons: May require more processing power. |

| Basic Extrusion | Generates a 3D model by extruding the JPEG image into distinct layers without color. | Manufacturing, tooling, 3D printing | Pros: Simple and effective for shapes; quick conversion. Cons: Lacks color detail; less aesthetic. |

| Heightmap Conversion | Utilizes grayscale values to create a textured surface that reflects the image’s depth. | Art installations, gaming assets | Pros: High-detail representation; effective for artistic designs. Cons: Complexity in setup; may need adjustments. |

| Batch Conversion | Enables the processing of multiple JPEG files into STL formats simultaneously. | Mass production, rapid prototyping | Pros: Saves time; efficient for large projects. Cons: Requires more advanced software; potential for errors. |

What are the Characteristics and Suitability of Standard Conversion?

Standard conversion is a straightforward method that transforms JPEG images into STL models by interpreting brightness levels. This process is particularly suitable for creating terrain models or architectural visualizations, where a heightmap representation is beneficial. B2B buyers should consider the simplicity and ease of use, but also note that this method may not capture intricate details, making it less ideal for complex images.

How Does Color Extrusion Differ from Other Methods?

Color extrusion distinguishes itself by layering colors from the JPEG image, preserving distinct color elements in the final STL model. This approach is particularly advantageous for product design and branding, where color fidelity is crucial. Buyers should weigh the benefits of high visual appeal against potential processing power requirements, as this method can be resource-intensive.

Why Choose Basic Extrusion for Manufacturing Needs?

Basic extrusion is a practical choice for generating 3D models by simply extruding JPEG images into distinct layers without color considerations. This method is effective for manufacturing applications, tooling, and 3D printing, where the focus is on the shape rather than aesthetics. Buyers will appreciate the quick conversion and simplicity, but should be aware of its limitations in capturing color details.

What Advantages Does Heightmap Conversion Offer for Artistic Projects?

Heightmap conversion utilizes grayscale values to create textured surfaces, making it an excellent choice for artistic applications, such as art installations or gaming assets. This method allows for a high level of detail and depth representation. B2B buyers should consider the artistic potential, while also being prepared for a more complex setup that may require adjustments for optimal results.

How Can Batch Conversion Enhance Production Efficiency?

Batch conversion enables users to process multiple JPEG files into STL formats at once, significantly enhancing production efficiency for businesses engaged in mass production or rapid prototyping. This method saves time and streamlines workflow but requires more advanced software to handle the processes effectively. Buyers should also be cautious of potential errors that could arise when processing large quantities of files.

Key Industrial Applications of convert jpeg to stl

| Industry/Sector | Specific Application of convert jpeg to stl | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Custom Product Design using Logos | Enables rapid prototyping of custom products with brand logos | Quality of conversion tool, compatibility with CAD software, cost |

| Architecture | Architectural Visualization | Transforms 2D architectural plans into 3D models for client presentations | Detail level in conversion, ease of integration with design software |

| Education | Educational Models for Teaching | Converts educational images into 3D models for interactive learning | Reliability of conversion, support for various image formats |

| Advertising & Marketing | Promotional Material Development | Creates 3D representations of marketing materials for campaigns | Speed of conversion, customization options, and export formats |

| Art & Design | 3D Art Creation from Illustrations | Facilitates the transformation of artistic images into 3D sculptures | Precision of detail, ability to handle complex images, cost-effectiveness |

How is ‘convert jpeg to stl’ utilized in Manufacturing?

In the manufacturing sector, the conversion of JPEG images to STL files is essential for creating custom product designs that incorporate company logos or specific artwork. This process allows businesses to rapidly prototype products, enabling them to test designs before mass production. Buyers in this sector must consider the quality of the conversion tool and ensure compatibility with their existing CAD software, as well as the overall cost of the conversion process.

What are the benefits of ‘convert jpeg to stl’ in Architecture?

Architects leverage the conversion of JPEG to STL for architectural visualization, transforming 2D plans into engaging 3D models that can be presented to clients. This capability enhances client understanding and approval of designs. For international buyers, particularly in regions with diverse architectural styles, the detail level in the conversion and ease of integration with design software are crucial factors when sourcing these services.

How does ‘convert jpeg to stl’ enhance Education?

In the educational sector, converting JPEG images into STL files is used to create interactive 3D models for teaching purposes. This method helps students engage more deeply with the material, particularly in subjects like science and art. Buyers from educational institutions should prioritize the reliability of the conversion tool and its support for various image formats, ensuring that it meets the diverse needs of their curriculum.

In what ways does ‘convert jpeg to stl’ support Advertising & Marketing?

Advertising and marketing professionals utilize the conversion of JPEG images to STL files to develop promotional materials that stand out. By creating 3D representations of marketing assets, businesses can effectively capture the attention of potential customers. When sourcing these services, factors such as the speed of conversion and available customization options are important for ensuring timely and impactful marketing campaigns.

How is ‘convert jpeg to stl’ beneficial for Art & Design?

Artists and designers use the conversion of JPEG images into STL files to create 3D art from their illustrations, allowing for the production of sculptures and other physical artworks. This process provides artists with new avenues for expression and commercialization of their work. Buyers in this sector should focus on the precision of detail in the conversion, the tool’s ability to handle complex images, and overall cost-effectiveness to maximize their investment in 3D art creation.

3 Common User Pain Points for ‘convert jpeg to stl’ & Their Solutions

Scenario 1: Difficulty in Achieving Accurate 3D Representations from JPEG Images

The Problem: Many B2B buyers, particularly those in design and manufacturing sectors, encounter challenges when converting JPEG images into STL files that accurately reflect the original design. JPEG images often lose important details due to their lossy compression, leading to 3D models that do not capture the intended features. This can result in wasted time and resources during the product development cycle, as stakeholders may need to repeatedly refine their designs or engage in time-consuming revisions.

The Solution: To overcome this issue, it’s crucial to select a conversion tool that offers various customization options during the JPEG to STL conversion process. Look for tools that allow you to adjust the detail level, specify dimensions, and control features like background removal and color merging. For instance, using a tool that offers a “High Detail” setting can help retain intricate design elements. Additionally, ensure that the conversion process allows for a preview option, enabling users to assess the model before finalizing the output. Engaging in a thorough review of the STL file against the original JPEG can also provide insights into any discrepancies, allowing for quick adjustments before proceeding to production.

Scenario 2: Managing File Size and Complexity in STL Models

The Problem: B2B buyers often face challenges related to the size and complexity of STL files generated from JPEG conversions. Large file sizes can lead to slow processing times and difficulties in handling during 3D printing or CAD modeling. Additionally, overly complex models with excessive polygons can create issues in rendering and may require significant computational resources to manipulate. This can be particularly problematic for companies that need to share files with clients or partners who may not have access to advanced software or hardware.

The Solution: To effectively manage file size and complexity, buyers should seek out conversion tools that include options for simplifying the mesh and controlling the number of segments during the conversion process. Features such as “Merges Similar Colors” and adjustable “Width Segments” and “Height Segments” can significantly reduce the number of polygons in the STL file without sacrificing essential details. It’s also advisable to explore tools that offer batch conversion capabilities to streamline processes when converting multiple JPEG files at once. Implementing these strategies not only enhances efficiency but also ensures that the resulting STL files are more manageable and compatible with various 3D printing technologies.

Scenario 3: Ensuring Consistency in Color and Texture During Conversion

The Problem: For businesses that rely on brand consistency, converting JPEG logos or color images into STL files can lead to challenges in maintaining accurate color representation. The conversion process can sometimes distort colors or fail to capture the intended textural details, resulting in a 3D model that does not align with the brand’s visual identity. This inconsistency can undermine the professional appearance of products, especially in markets that value aesthetic quality.

The Solution: To maintain color and texture fidelity, it’s important to choose conversion tools that allow for detailed color specifications and texture overlays. Buyers should utilize options such as “Specify Color” and “Color Overlay” to ensure that the correct colors are applied during the conversion. Additionally, employing a tool that supports color STL formats can enhance the visual quality of the final model. Before finalizing the STL file, conducting a comparison between the original JPEG and the 3D model in a capable viewing software can help identify any discrepancies in color and texture, allowing for necessary adjustments. By prioritizing these features in the conversion process, businesses can achieve higher levels of brand integrity in their 3D printed products.

Strategic Material Selection Guide for convert jpeg to stl

What Are the Key Materials for Converting JPEG to STL and Their Properties?

When converting JPEG images to STL files for 3D printing, the choice of material used in the final product is critical. Different materials offer various properties that can significantly affect the performance, durability, and overall suitability of the end product. Below, we analyze four common materials used in this context: PLA, ABS, PETG, and Nylon.

How Does PLA Perform in 3D Printing Applications?

Polylactic Acid (PLA) is one of the most widely used materials in 3D printing, particularly for applications derived from STL files. It is biodegradable and derived from renewable resources, making it an environmentally friendly option. PLA has a relatively low melting temperature, typically around 180-220°C, which makes it easy to print.

Pros: PLA is known for its excellent print quality and detail, making it ideal for intricate designs. It is also cost-effective and readily available, which is a significant advantage for businesses looking to minimize expenses.

Cons: However, PLA has lower heat resistance and can deform under high temperatures, which limits its applications in environments where thermal stability is critical. Additionally, it is less durable compared to other materials, making it unsuitable for functional parts that require strength.

Impact on Application: PLA is compatible with a wide range of 3D printers and is often preferred for prototyping and aesthetic models.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider local availability and compliance with environmental standards, as PLA’s biodegradable nature may align with sustainability initiatives.

What Are the Advantages of Using ABS?

Acrylonitrile Butadiene Styrene (ABS) is another popular material for 3D printing, known for its toughness and impact resistance. It has a higher melting point than PLA, typically around 210-250°C, making it suitable for functional parts that may experience stress.

Pros: ABS is durable and can withstand higher temperatures, making it ideal for applications requiring strength and longevity. It also has good chemical resistance, which is beneficial in various industrial applications.

Cons: On the downside, ABS can be more challenging to print due to its tendency to warp and emit fumes during the printing process, necessitating good ventilation and a controlled printing environment.

Impact on Application: ABS is often used for creating prototypes, automotive parts, and consumer goods where durability is essential.

Considerations for International Buyers: Compliance with safety standards, such as ASTM and ISO, is crucial when sourcing ABS. Buyers in regions like the Middle East may need to consider the availability of ABS in local markets.

How Does PETG Compare to Other Materials?

Polyethylene Terephthalate Glycol (PETG) is a versatile material that combines the best properties of both PLA and ABS. It has a melting point similar to ABS but offers greater ease of printing and is less prone to warping.

Pros: PETG is known for its excellent clarity and strength, making it suitable for functional parts and prototypes that require transparency. It is also more resistant to moisture and chemicals than PLA and ABS.

Cons: However, PETG can be more expensive than both PLA and ABS, which may be a consideration for budget-conscious businesses.

Impact on Application: PETG is often used in applications where clarity and durability are essential, such as in packaging and medical devices.

Considerations for International Buyers: Buyers should ensure that PETG complies with local regulations regarding food safety and medical applications, particularly in Europe where stringent standards exist.

What Are the Benefits of Using Nylon in 3D Printing?

Nylon is a strong and flexible material that is increasingly popular in 3D printing, particularly for functional parts that require durability and resilience. It has a higher melting point than the other materials discussed, typically around 220-260°C.

Pros: Nylon is highly durable and resistant to abrasion, making it suitable for parts that undergo wear and tear. Its flexibility allows for the creation of complex geometries that can withstand stress.

Cons: The main drawback of Nylon is its hygroscopic nature, meaning it absorbs moisture from the air, which can affect print quality. It also requires a more advanced printing setup, which may not be accessible for all businesses.

Impact on Application: Nylon is often used in applications such as gears, bearings, and other mechanical parts where strength and flexibility are crucial.

Considerations for International Buyers: Businesses in regions like Vietnam should be aware of the specific storage and handling requirements for Nylon to ensure optimal print quality.

Summary Table of Material Selection for JPEG to STL Conversion

| Material | Typical Use Case for convert jpeg to stl | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PLA | Prototyping, aesthetic models | Excellent print quality | Low heat resistance | Low |

| ABS | Functional parts, automotive components | High durability | Warping during printing | Medium |

| PETG | Transparent prototypes, medical devices | Good moisture resistance | Higher cost | Medium |

| Nylon | Mechanical parts, gears | High strength and flexibility | Hygroscopic, requires advanced setup | High |

This strategic material selection guide provides valuable insights for B2B buyers looking to convert JPEG images to STL files for 3D printing, ensuring they choose the most suitable material for their specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for convert jpeg to stl

What Are the Main Stages of Manufacturing Processes for Converting JPEG to STL?

The process of converting JPEG images to STL files for 3D printing involves several key manufacturing stages, each essential for ensuring the final product’s quality and usability.

Material Preparation: What Initial Steps Are Needed?

The first step in the manufacturing process is the preparation of the JPEG image. This includes selecting an appropriate image that can be effectively converted into a 3D model. Factors such as resolution and clarity are critical; higher quality images yield better STL outputs.

Once the image is selected, it may require editing to enhance contrast, remove backgrounds, or adjust colors. This stage often utilizes software tools that allow users to manipulate the image before conversion. Ensuring the image is in a compatible format (JPEG) and meets the size requirements is crucial for smooth processing.

How Is the Forming Stage Conducted During Conversion?

The forming stage involves the actual conversion of the JPEG file into an STL model. This is typically achieved through software applications that utilize algorithms to interpret the image data and generate a 3D mesh.

Key techniques used in this stage include:

- Height Mapping: This technique converts pixel brightness into height variations, creating a topographical representation of the image.

- Extrusion: This involves layering the image to create depth, where the software adds layers based on the image’s features.

Users can often adjust parameters such as dimensions, detail levels, and color handling during this stage, allowing for customization of the final STL output.

What Assembly Processes Are Involved in Finalizing the STL Model?

In the context of JPEG to STL conversion, the assembly process is somewhat abstract. Once the STL file is generated, it can be assembled with other digital models or printed directly.

If the STL model is part of a larger project involving multiple components, proper alignment and integration with other models are essential. This requires ensuring that all components fit correctly together in the 3D space, which can be verified using CAD software prior to printing.

How Is the Finishing Process Handled Post-Conversion?

The finishing stage involves finalizing the STL file for 3D printing or further digital manipulation. This may include:

- Smoothing: Applying algorithms to reduce rough edges or spikes in the model.

- Optimization: Adjusting the file size and complexity for efficient printing, ensuring that it meets the requirements of the chosen 3D printer.

Finally, the STL file is saved in the desired format, ready for downloading and subsequent use in 3D printing.

What Quality Assurance Measures Are Essential for JPEG to STL Conversion?

Quality assurance (QA) is critical in the manufacturing process of converting JPEG images to STL files. This ensures that the resulting 3D models meet international standards and industry-specific requirements.

Which International Standards Should B2B Buyers Be Aware Of?

For businesses engaged in this process, adherence to international quality standards such as ISO 9001 is vital. ISO 9001 outlines criteria for a quality management system and emphasizes customer satisfaction, process improvement, and regulatory compliance.

Additionally, industry-specific certifications like CE marking (indicating compliance with European safety standards) may also be relevant, depending on the intended application of the STL files.

What Are the Key Quality Control Checkpoints in the Process?

Quality control (QC) checkpoints are established throughout the JPEG to STL conversion process. These typically include:

- Incoming Quality Control (IQC): Assessing the quality of the JPEG images before conversion. This includes checking for resolution, contrast, and overall suitability for conversion.

- In-Process Quality Control (IPQC): Monitoring the conversion process itself to ensure that parameters are set correctly and the output meets the expected specifications.

- Final Quality Control (FQC): Conducting a thorough review of the final STL file, including visual inspections and software checks to confirm that the model is free of defects and ready for printing.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should actively verify the QC measures of suppliers to ensure reliability and quality. This can be achieved through:

- Supplier Audits: Conducting on-site audits to review the supplier’s processes and adherence to quality standards.

- Quality Reports: Requesting detailed reports that outline the QC procedures in place, including any certifications obtained.

- Third-Party Inspections: Engaging independent inspection services to evaluate the quality of the STL files and the conversion processes.

What QC and Certification Nuances Should International B2B Buyers Consider?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of the nuances related to quality assurance.

Different regions may have varying compliance requirements and standards, which can affect the acceptance of STL files in specific markets. Understanding these regional standards and ensuring that suppliers meet them is crucial for avoiding complications in product acceptance.

Additionally, cultural differences in business practices can influence communication and expectations regarding quality assurance. It is advisable for buyers to establish clear communication channels and set explicit quality expectations with suppliers.

Conclusion: Ensuring Quality in the JPEG to STL Conversion Process

The conversion of JPEG images to STL files involves a meticulous manufacturing process that requires careful attention to quality assurance. By understanding the key stages of manufacturing and the relevant QC measures, B2B buyers can make informed decisions, ensuring they receive high-quality STL files suitable for their 3D printing needs. Engaging with suppliers who adhere to international standards and implementing rigorous QC checks will ultimately lead to successful outcomes in the competitive B2B landscape.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘convert jpeg to stl’

Introduction

This practical guide serves as a comprehensive checklist for B2B buyers seeking to procure services or tools for converting JPEG images to STL files. Whether for product prototyping, 3D printing, or digital modeling, understanding the conversion process and selecting the right supplier is crucial for achieving high-quality results. This checklist will help you navigate the essential steps involved in sourcing effective conversion solutions tailored to your business needs.

Step 1: Define Your Technical Specifications

Before initiating your search for conversion services, it’s essential to clearly outline your technical requirements. Specify the image dimensions, desired resolution, and any particular features needed in the STL files, such as color fidelity or surface detail. A well-defined specification helps in aligning your expectations with potential suppliers.

- Consider the complexity of your JPEG images and the level of detail you want in the STL files.

- Determine if you need support for high-resolution images or specific formats for your industry.

Step 2: Research Available Conversion Tools and Services

Conduct thorough research to identify the various tools and services available for JPEG to STL conversion. Look for online platforms, software applications, or local service providers that specialize in 3D modeling.

- Evaluate the features offered, such as batch processing capabilities, background removal options, and color management.

- Read user reviews and case studies to gauge the reliability and quality of the conversion services.

Step 3: Evaluate Potential Suppliers

Assess potential suppliers carefully before making a commitment. Request detailed company profiles, including their experience in the industry and examples of past projects that align with your needs.

- Seek references from other businesses, particularly those in your region or industry, to validate the supplier’s credibility.

- Consider suppliers that offer customer support and consultation, ensuring you can address any technical queries.

Step 4: Review Pricing Structures and Payment Terms

Understanding the pricing models of different suppliers is vital for budgeting purposes. Compare costs associated with various conversion methods, such as pay-per-file or subscription models.

- Inquire about any additional fees for special features or high-volume conversions.

- Ensure the payment terms are clear, including any upfront costs or potential discounts for bulk orders.

Step 5: Verify Data Security and Confidentiality Measures

Given the sensitivity of proprietary designs, ensure that the suppliers have robust data security measures in place. It’s crucial to verify how they handle your files and what protocols they follow to protect your intellectual property.

- Look for suppliers that offer secure file transfer options and confidentiality agreements.

- Ensure they have a clear data retention policy that outlines how long your files will be stored.

Step 6: Request a Trial or Sample Conversion

Before finalizing your decision, consider requesting a trial or sample conversion of a JPEG image to STL. This step allows you to assess the quality of the output and the efficiency of the supplier’s process.

- Use this opportunity to evaluate the level of detail, accuracy, and any other specific requirements you may have.

- Analyze the turnaround time and customer service responsiveness during this trial phase.

Step 7: Establish Clear Communication Channels

Once you have selected a supplier, establish clear lines of communication for ongoing projects. Regular updates and feedback loops are essential for ensuring the final STL files meet your expectations.

- Schedule periodic check-ins to discuss project progress and address any concerns promptly.

- Ensure that the supplier is receptive to feedback and willing to make adjustments as necessary.

By following this checklist, B2B buyers can effectively navigate the process of sourcing JPEG to STL conversion services, ensuring they make informed decisions that align with their technical needs and business objectives.

Comprehensive Cost and Pricing Analysis for convert jpeg to stl Sourcing

What Are the Key Cost Components for JPEG to STL Conversion?

When analyzing the cost structure for converting JPEG files to STL formats, several components come into play. Materials primarily refer to the digital resources needed for the conversion process, including software licenses and storage solutions. While these costs can be minimal for online tools, bespoke software solutions may incur higher expenses.

Labor costs involve the personnel required to manage and operate the conversion tools. Depending on the complexity of the task, skilled labor may be necessary to ensure high-quality results. Additionally, manufacturing overhead covers expenses related to utilities, maintenance of the conversion systems, and other operational costs.

Tooling refers to the software and hardware used in the conversion process. The choice between proprietary and open-source tools can significantly affect overall costs. Furthermore, quality control (QC) measures are essential, especially for B2B transactions, to ensure that the final STL files meet specific standards and requirements.

Lastly, logistics costs may arise if the files need to be transferred across borders or if physical products are involved, such as 3D prints derived from the STL files. Adding a margin for profit is crucial for service providers, typically ranging from 10% to 30%, depending on the market.

How Do Price Influencers Affect JPEG to STL Conversion Costs?

Several factors can influence the pricing of JPEG to STL conversion services. Volume and minimum order quantity (MOQ) play a significant role; larger orders often lead to discounted rates, making it economically viable for businesses looking to convert multiple files.

Specifications and customization can also impact costs. Customized solutions that require specific settings or additional features may incur higher fees compared to standard conversions. The choice of materials used in post-conversion processes, such as different types of filaments for 3D printing, will further influence overall pricing.

Quality and certifications are critical, particularly for international buyers who may need to meet specific industry standards. Suppliers offering certified services may charge a premium, but this often translates to better quality and reliability.

Supplier factors such as reputation, experience, and geographic location can also affect pricing. Suppliers in regions with higher operational costs may offer services at a premium compared to those in lower-cost regions. Finally, Incoterms dictate how costs are allocated during shipping and handling, which can significantly impact the total expenditure for international transactions.

What Tips Can Help Buyers Optimize Costs in JPEG to STL Conversions?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, negotiating effectively can lead to substantial savings. Engage suppliers in discussions about volume discounts, payment terms, and potential for future partnerships to leverage better pricing.

Understanding total cost of ownership (TCO) is essential. This includes not just the initial conversion cost but also ongoing expenses related to storage, maintenance, and potential reworks. Evaluating the long-term implications of pricing can lead to more informed purchasing decisions.

Buyers should also be aware of pricing nuances in different markets. For instance, suppliers from Africa may offer competitive rates due to lower labor costs, while European suppliers might offer higher quality due to advanced technology. It’s crucial to assess the balance between cost and quality to avoid future expenses related to rework or dissatisfaction.

Lastly, consider the impact of currency fluctuations on pricing for international transactions. Establishing contracts in stable currencies can mitigate risks associated with exchange rate changes, providing a clearer budgetary framework.

Conclusion

The landscape for converting JPEG files to STL formats encompasses a variety of costs and pricing influencers. By understanding these dynamics, B2B buyers can make informed decisions that align with their operational needs and budget constraints. It is essential to remain vigilant about market conditions and supplier capabilities to ensure optimal cost-effectiveness in sourcing these services.

Alternatives Analysis: Comparing convert jpeg to stl With Other Solutions

Exploring Alternatives for Converting JPEG to STL

In the realm of 3D modeling and printing, converting JPEG images to STL files is a common requirement. However, various solutions exist that provide similar functionalities, each with distinct advantages and limitations. This analysis will compare the conversion of JPEG to STL against two notable alternatives: vectorization software and manual 3D modeling techniques. Understanding these alternatives will help B2B buyers make informed decisions based on their specific needs.

| Comparison Aspect | Convert JPEG to STL | Vectorization Software | Manual 3D Modeling Techniques |

|---|---|---|---|

| Performance | Fast conversion for simple images; results may vary with complex images. | High accuracy and detail, especially for logos and shapes. | Time-consuming but allows for complete control over design. |

| Cost | Free to use online tools; may incur costs for advanced features. | Licensing fees for professional software can be high. | Cost of skilled labor and software licenses. |

| Ease of Implementation | User-friendly; requires minimal technical skills. | Requires knowledge of vector graphics; moderate learning curve. | Requires expertise in 3D modeling software; steep learning curve. |

| Maintenance | Low; primarily one-off use. | Moderate; updates and learning new features needed. | High; ongoing skill development and software updates. |

| Best Use Case | Quick conversions of JPEG images for prototyping. | Creating detailed, scalable vector graphics from images. | Custom 3D models for unique applications like prototyping or art. |

What Are the Advantages and Disadvantages of Vectorization Software?

Vectorization software converts raster images (like JPEG) into vector graphics, which can then be exported as STL files. Pros include high accuracy and the ability to create clean lines and shapes, making it ideal for logos and designs that require precision. However, the cost can be prohibitive for smaller businesses, and users need a moderate level of graphic design knowledge to effectively utilize these tools. This method is best for projects that require high detail and quality, particularly in branding or product design.

How Do Manual 3D Modeling Techniques Compare?

Manual 3D modeling involves using software to create models from scratch based on design specifications. While this method allows for unparalleled control and customization, it is labor-intensive and requires significant expertise in 3D modeling tools. Additionally, the cost associated with hiring skilled designers can be substantial. This approach is most beneficial for unique projects where standard conversions do not suffice, such as bespoke product designs or artistic endeavors.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the appropriate method for converting JPEG to STL largely depends on the specific requirements of a business. For companies seeking quick and cost-effective solutions for simple images, online conversion tools are ideal. On the other hand, businesses needing high-quality, detailed designs may find vectorization software or manual modeling more suitable, despite the higher costs and learning curves involved. Ultimately, understanding the nuances of each option will empower B2B buyers to choose the solution that aligns best with their operational goals and project needs.

Essential Technical Properties and Trade Terminology for convert jpeg to stl

What Are the Key Technical Properties in Converting JPEG to STL?

When converting JPEG files to STL formats for 3D modeling and printing, several technical properties are vital for ensuring quality and compatibility. Understanding these properties allows businesses to make informed decisions regarding their projects.

-

Extrusion Depth: This property determines how far the JPEG image is extruded into the 3D space. It affects the model’s dimensionality and is crucial for achieving the desired visual impact. Businesses should consider the intended application of the 3D model—whether for prototyping, product displays, or end-use products—when setting this parameter.

-

Detail Level: The detail level can significantly impact the final STL model. It is often adjustable, with options ranging from low to high resolution. Higher detail settings may produce more intricate models but can also increase file size and complexity. Companies must balance detail with file manageability, especially when working with limited processing capabilities in 3D printers.

-

Background Removal Tolerance: This setting controls the sensitivity of the tool when determining what constitutes the background in the JPEG. A higher tolerance can lead to cleaner models by removing unnecessary elements, which is particularly important for logos or images with intricate designs. This property is critical for ensuring that the final output meets aesthetic and functional requirements.

-

Color Specification: The capability to specify colors from the JPEG file is essential for creating visually accurate models. Options may include merging similar colors or defining a specific background color. This is particularly valuable for branding purposes in B2B contexts, as accurate color representation can enhance product appeal.

-

File Format Compatibility: The output format (binary or text for STL) can impact how the model interacts with various 3D printing software and hardware. Businesses must ensure that the chosen format aligns with their existing workflow and equipment to avoid compatibility issues.

-

Units of Measurement: The ability to set units (e.g., inches, millimeters) is crucial for accurate scaling of the model. Understanding the measurement systems used in the target market can help avoid discrepancies in the final product, especially for international transactions.

What Are Common Trade Terms Related to JPEG to STL Conversion?

Familiarity with industry terminology is essential for effective communication and negotiations in B2B transactions involving JPEG to STL conversions.

-

OEM (Original Equipment Manufacturer): In the context of 3D printing, OEM refers to companies that produce parts or products based on the specifications provided by another company. Understanding OEM relationships is vital for businesses looking to outsource their 3D printing needs.

-

MOQ (Minimum Order Quantity): This term defines the smallest number of units a supplier is willing to produce or sell. When converting JPEG to STL for mass production, knowing the MOQ helps businesses plan their budgets and inventory effectively.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting a price estimate for specific services, such as converting a batch of JPEG files to STL. Including detailed specifications can lead to more accurate quotes, streamlining the procurement process.

-

Incoterms (International Commercial Terms): These are standardized trade terms used in international transactions, defining responsibilities between buyers and sellers. Understanding Incoterms can help businesses navigate shipping and delivery logistics, especially when dealing with international partners.

-

CAD (Computer-Aided Design): This refers to software used for creating precise drawings and technical illustrations. Knowing how CAD fits into the JPEG to STL conversion process helps businesses align their design efforts with production capabilities.

-

Tolerance: In 3D printing and modeling, tolerance refers to the allowable deviation from a specified dimension. Understanding tolerances is crucial for ensuring that the final product meets functional requirements, particularly in industries like manufacturing and engineering.

By grasping these technical properties and trade terms, businesses can optimize their processes and make more strategic decisions in their JPEG to STL conversion projects.

Navigating Market Dynamics and Sourcing Trends in the convert jpeg to stl Sector

What Are the Key Market Dynamics and Trends Affecting the Convert JPEG to STL Sector?

The convert JPEG to STL sector is experiencing robust growth driven by the increasing adoption of 3D printing technologies across various industries. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking efficient solutions to transform 2D images into 3D models for applications ranging from prototyping to custom manufacturing. The emergence of online conversion tools has simplified the process, enabling even small businesses to access this technology without significant upfront investments in software or expertise.

A notable trend is the integration of advanced features in conversion tools, such as customizable extrude options, color merging, and background removal capabilities. This adaptability caters to diverse customer needs, allowing users to create high-quality STL files that meet specific project requirements. Moreover, the rise of digital marketplaces has created a competitive landscape where providers must continuously innovate to differentiate their offerings.

Sourcing strategies are also evolving, with international buyers increasingly prioritizing suppliers that demonstrate technological agility and customer-centric approaches. The demand for comprehensive support services, including tutorials and customer assistance, is rising as businesses look to maximize the value from their conversions. Buyers are encouraged to evaluate potential suppliers based on their ability to deliver reliable, high-quality outputs while also considering turnaround times and service responsiveness.

How Is Sustainability and Ethical Sourcing Impacting the Convert JPEG to STL Sector?

Sustainability is becoming a critical consideration for B2B buyers in the convert JPEG to STL sector, particularly as environmental concerns gain prominence globally. The conversion process itself has a relatively low environmental impact, especially when compared to traditional manufacturing methods, as it often involves less material waste. However, the sourcing of raw materials for 3D printing and the operational practices of conversion tool providers play a significant role in shaping the industry’s ecological footprint.

Buyers are increasingly seeking suppliers who adhere to ethical sourcing practices and offer ‘green’ certifications. This includes using eco-friendly materials for 3D printing, such as biodegradable filaments or recycled plastics. Furthermore, transparency in the supply chain is crucial; buyers want assurance that their suppliers are committed to reducing carbon emissions and promoting sustainable production practices.

The demand for ethical sourcing not only reflects a shift in consumer preferences but also aligns with regulatory trends in various regions, where compliance with environmental standards is becoming mandatory. Suppliers who prioritize sustainability and can demonstrate their commitment through certifications will likely gain a competitive advantage in the market.

How Has the Convert JPEG to STL Sector Evolved Over Time?

The evolution of the convert JPEG to STL sector has been marked by significant technological advancements and shifting market demands. Initially, converting JPEG images to STL files required specialized software and technical expertise, limiting access primarily to large organizations and experienced professionals. However, with the advent of user-friendly online tools, the process has been democratized, enabling a broader range of businesses to leverage 3D modeling capabilities.

The rise of 3D printing in various sectors, including manufacturing, education, and healthcare, has further propelled the need for efficient conversion solutions. As industries seek to innovate and reduce time-to-market, the ability to quickly transform images into 3D models has become a valuable asset. Consequently, the sector continues to grow, driven by advancements in technology, increasing accessibility, and a growing emphasis on sustainability and ethical practices among B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of convert jpeg to stl

-

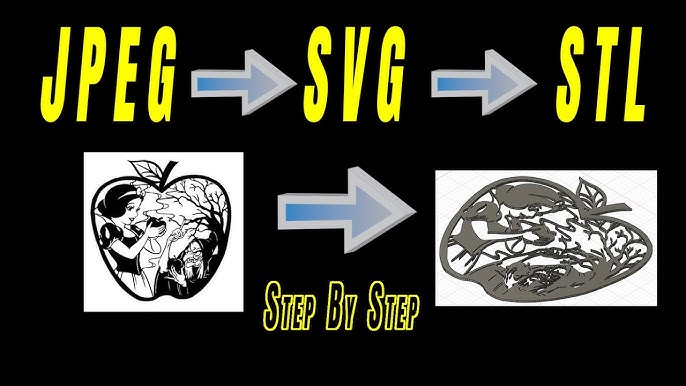

How do I convert a JPEG image to an STL file for 3D printing?

To convert a JPEG image to an STL file, you can use online conversion tools that simplify the process. Start by uploading your JPEG file, then select the desired conversion options such as dimensions, detail level, and color settings. After configuring the settings, initiate the conversion. Once completed, download the STL file to use it in your 3D printing projects. Ensure your image is high-quality for the best results. -

What is the best software for converting JPEG to STL?

Several software options are available for converting JPEG to STL, with online tools being the most accessible. Platforms like ImageToStl and 3DPEA provide user-friendly interfaces for quick conversions. For more complex needs, desktop software like Blender or specialized CAD programs offer advanced features. Choose a tool based on your specific requirements, such as ease of use, customization options, and the level of detail needed in the final model. -

What are the common challenges when converting JPEG to STL?

Common challenges include loss of detail in low-resolution images, improper color interpretation, and background noise affecting the final model. To mitigate these issues, ensure your JPEG is of high quality and consider using settings that merge similar colors or adjust tolerance levels for background removal. Testing different conversion options can also help you achieve a better result by refining the model’s detail and accuracy. -

How can I ensure quality control when sourcing JPEG to STL conversion services?

When sourcing conversion services, review the provider’s portfolio and customer testimonials to gauge their quality. Request sample conversions to assess the output quality before making a commitment. Additionally, inquire about their quality assurance processes, such as checks for accuracy, detail, and adherence to your specifications. Establish clear communication to discuss your requirements and ensure they understand your expectations. -

What payment terms should I consider when working with international suppliers?

When dealing with international suppliers, it’s essential to negotiate payment terms that protect both parties. Common options include upfront payments, milestone payments based on project phases, or payment upon delivery. Consider using secure payment methods like letters of credit or escrow services to mitigate risks. Ensure that the agreed terms are documented in the contract to avoid misunderstandings later. -

What are the minimum order quantities (MOQs) for converting JPEG to STL?

MOQs can vary widely among suppliers depending on their business model and capabilities. Some online services may not have an MOQ, allowing you to convert single files, while others may require a minimum number of conversions to justify production costs. Always clarify MOQs before placing an order to ensure they align with your project needs and budget. -

How can I customize the STL file output from a JPEG?

Customization options typically include adjusting dimensions, detail level, and color settings during the conversion process. Many tools allow you to specify whether to extrude the image or use heightmap techniques, which affects the model’s depth and appearance. Additionally, you can choose to add bases or modify tolerances for background removal. Explore the available settings in your chosen conversion tool to tailor the output to your specifications. -

What logistics considerations should I keep in mind when sourcing conversion services internationally?

When sourcing conversion services internationally, consider shipping times, costs, and customs regulations that may affect delivery. Assess the supplier’s ability to meet deadlines and whether they offer digital delivery options for faster turnaround. Additionally, confirm their policies regarding revisions and post-delivery support to address any potential issues with the final STL files.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 10 Convert Jpeg To Stl Manufacturers & Suppliers List

1. ImageToSTL – JPEG to STL Converter

Domain: imagetostl.com

Registered: 2019 (6 years)

Introduction: Convert JPEG to STL for free using an online tool. Upload JPEG files up to 100MB, set conversion options, and download the STL file. Options include extruding the image into 3D space, applying heightmap processes, adjusting detail levels, adding a solid base, removing backgrounds, specifying colors, and more. Supports both text and binary STL formats. Ideal for 3D printing and compatible with vari…

2. 3D PEA – JPEG to STL Converter

Domain: 3dpea.com

Registered: 2020 (5 years)

Introduction: Convert JPEG to STL Online For Free – Easily convert your JPEG image into a STL 3D model file suitable for 3D printing in seconds. Supported formats include JPEG, JPG, PNG, SVG, and more. Features include options for model creation (Stander, Stander Color, Extrude, Extrude Color), dimension settings (Width, Height, Depth), and additional features like merging similar colors, transparency conversio…

3. AnyConv – JPEG to STL Converter

Domain: anyconv.com

Registered: 2019 (6 years)

Introduction: Convert JPEG to STL Online — Free & Fast | AnyConv

– Quickly convert multiple JPEG files to STL for free and online.

– Supports file uploads up to 100 MB.

– Works on all devices: Windows, Mac, Linux, iPhone, Android.

– Simple conversion process: Upload JPEG, click ‘Convert’, and download STL.

– No registration required for conversion.

– Files are securely handled and deleted after 1 hour.

– Batch …

4. Meshy.ai – JPG to STL Converter

Domain: meshy.ai

Registered: 2023 (2 years)

Introduction: Convert 3D Models from JPG to STL Online for Free – Fast and free online tool to convert your 3D models from JPG to STL format in seconds. No software installation needed. Supports popular formats including PNG, JPEG, and WEBP files with a maximum file size of 20MB. Generates aligned geometry and detailed textures during conversion. Allows further editing in most 3D software or upload to Meshy for…

5. Aspose – JPEG to STL Converter

Domain: products.aspose.app

Introduction: JPEG to STL is a free online converter that allows users to convert JPEG files to STL format without the need for specialized software. The application is accessible via web browsers on various operating systems including Windows, Linux, MacOS, and mobile devices. Users can upload files by dragging and dropping them into the upload area or by selecting them directly. The conversion process is quic…

6. Embossify – JPEG to STL Converter

Domain: embossify.com

Registered: 2013 (12 years)

Introduction: Convert JPEG images into STL 3D mesh files suitable for 3D printing or CNC routing. Features include: converting 2D images to 3D objects, creating lithophanes and reliefs, free low resolution renderings (~108k facets), $5 for high resolution renderings, perfectly enclosed tessellation of rendered 3D mesh, depth adjustments based on pixel brightness, and bulk purchase options for savings.

7. 3D Medallion Maker – JPEG to STL Converter

Domain: reddit.com

Registered: 2005 (20 years)

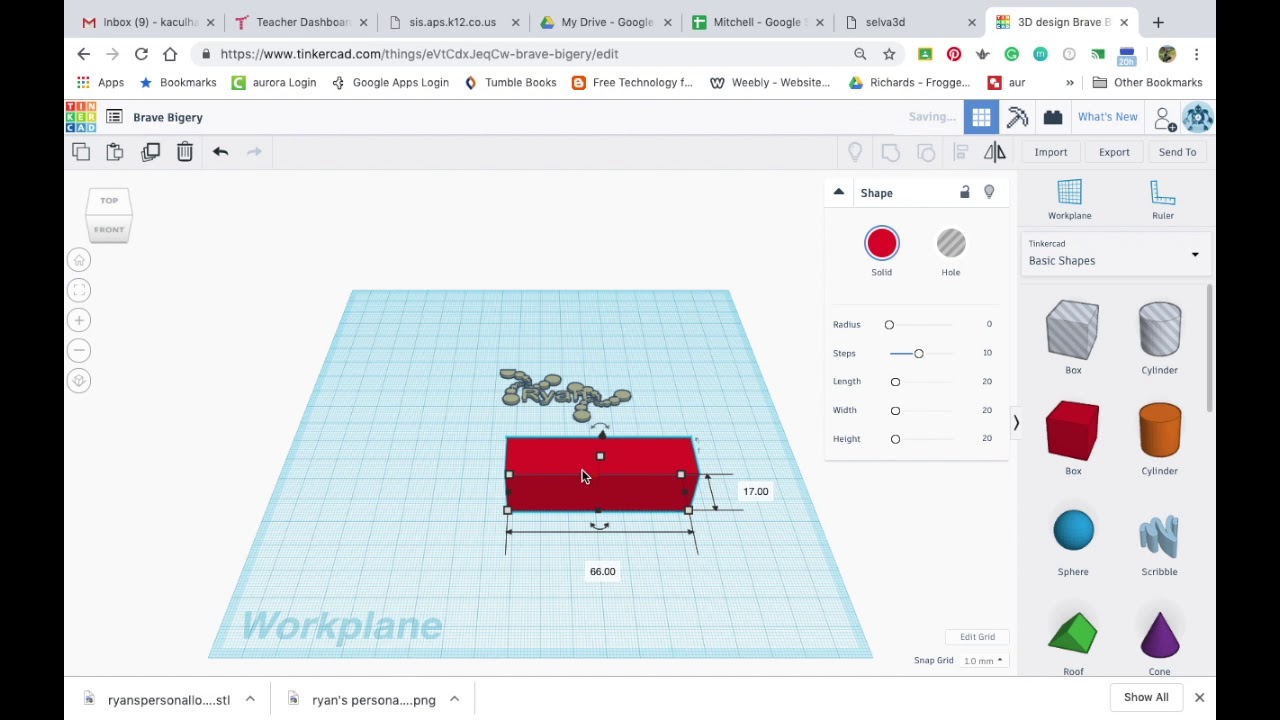

Introduction: Looking for a good converter for JPEG to STL files. The user is specifically interested in creating 3D medallions for a local sports team’s logo and is struggling with existing tools that only produce solid boxes or require extensive modeling skills. Suggestions include using TinkerCAD, 3D Builder (built into Windows 10), and online converters to change JPEGs to SVGs before converting to STL.

8. Bambu Lab – X1 Series STL Conversion

Domain: forum.bambulab.com

Registered: 2019 (6 years)

Introduction: The discussion revolves around converting images to STL files for 3D printing, particularly focusing on the Bambu Lab X1 Series. Users share various methods and tools for this conversion, including:

1. Bambu’s “Make my Sign” feature.

2. Online converters for PNG/JPEG to STL/OBJ/3MF.

3. Converting images to vector graphics (SVG) before importing into CAD software like Fusion 360 or Tinkercad.

4. Us…

9. Dorchester 3D – JPEG to STL Converter

Domain: dorchester3d.com

Registered: 2014 (11 years)

Introduction: Free online JPEG to STL converter that converts JPEG image files into 3D models in STL format using heightmap or extrusion processes. Supports batch conversion of up to 20 JPEG files at once, with a maximum file size of 100MB per file. Offers options for mode selection (heightmap or extrude), dimensions, and smoothing. Uploaded JPEG files are deleted 15 minutes after upload. The tool processes con…

10. FabConvert – JPEG to STL Converter

Domain: fabconvert.com

Registered: 2021 (4 years)

Introduction: Free online JPEG to STL converter that allows users to convert JPEG image files into 3D heightmap models. Supports batch conversion of up to 20 JPEG files at once, with a maximum file size of 100MB per file. The conversion process typically takes around 5 seconds. Users can fine-tune conversion settings, including the choice between Heightmap or Extrude algorithms, and control the size and detail …

Strategic Sourcing Conclusion and Outlook for convert jpeg to stl

In today’s competitive landscape, the ability to convert JPEG files to STL formats represents a significant opportunity for businesses in various sectors, including manufacturing, design, and 3D printing. By leveraging online tools that streamline this conversion process, companies can optimize their workflows, reduce operational costs, and enhance product offerings. Key considerations include understanding the various settings available for customization, such as detail level, color management, and model dimensions, which can significantly impact the final output’s quality.

Strategic sourcing of these conversion services is vital, especially for international buyers from regions like Africa, South America, the Middle East, and Europe. By choosing reliable platforms that provide high-quality, user-friendly tools, businesses can ensure they remain agile and responsive to market demands.

Looking ahead, the increasing integration of 3D printing technologies across industries will only amplify the need for efficient JPEG to STL conversions. Now is the time for B2B buyers to explore these solutions and invest in tools that can elevate their design capabilities. Embrace this transformative opportunity to stay ahead in your market—your next innovation could be just a conversion away.