Introduction: Navigating the Global Market for convert dxf to stl

In today’s competitive landscape, the ability to convert DXF files to STL format efficiently is critical for businesses aiming to streamline their design-to-manufacturing processes. Many international B2B buyers face the challenge of navigating diverse software solutions that promise seamless conversion but often fall short in accuracy and speed. This guide offers a comprehensive overview of the various methods and tools available for converting DXF to STL, tailored specifically for professionals across Africa, South America, the Middle East, and Europe, including regions like Saudi Arabia and Nigeria.

Throughout this guide, we will explore the types of DXF and STL files, their applications in industries such as 3D printing and CAD modeling, and the criteria for vetting reliable suppliers. Additionally, we will address cost considerations and the importance of selecting the right tools to ensure precision in conversions. By empowering B2B buyers with actionable insights and a clear understanding of the conversion landscape, this resource aims to facilitate informed purchasing decisions. With this knowledge, businesses can enhance their operational efficiency, reduce time-to-market, and ultimately gain a competitive edge in the global market.

Understanding convert dxf to stl Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

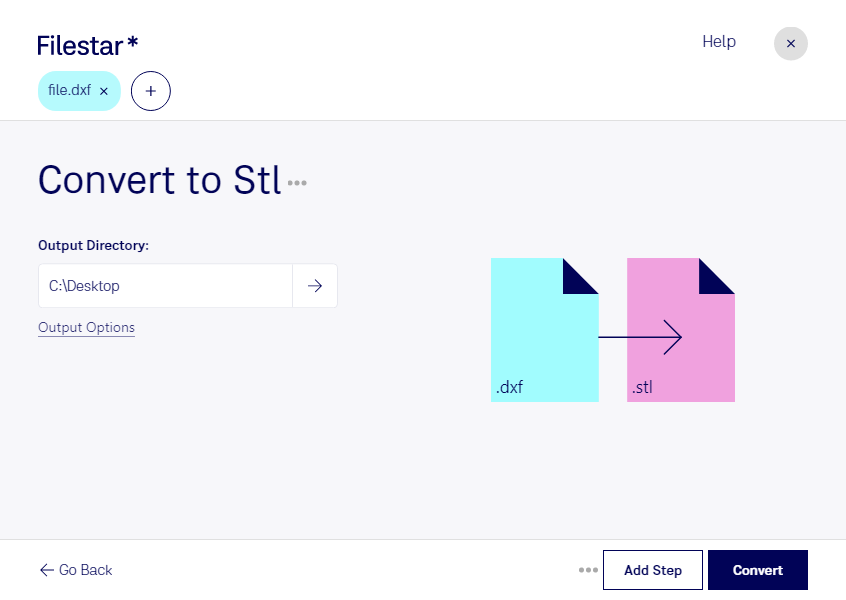

| Online Conversion Tools | Quick, no installation required, browser-based access | Rapid prototyping, small-scale production | Pros: Easy to use, accessible from any device. Cons: Limited features and control over output quality. |

| Desktop Software Solutions | Comprehensive features, offline use, customizable settings | Large-scale manufacturing, detailed design | Pros: High precision, extensive editing capabilities. Cons: Higher cost, requires installation and maintenance. |

| API Integration Services | Programmatic access, automation capabilities | Software development, integration in workflows | Pros: Streamlines processes, scalable. Cons: Technical expertise required for integration. |

| Batch Conversion Services | Converts multiple files simultaneously | Bulk production, archiving | Pros: Time-efficient for large projects. Cons: May require higher processing power and internet speed. |

| Cloud-Based Storage Solutions | Storage and conversion in one platform | Remote collaboration, data management | Pros: Accessible from anywhere, easy sharing. Cons: Dependent on internet connectivity and potential security concerns. |

What are Online Conversion Tools for DXF to STL?

Online conversion tools provide a straightforward solution for converting DXF files to STL format without the need for software installation. These tools are particularly suitable for businesses that require quick prototyping or small-scale production. The ease of use and accessibility from any device are significant advantages. However, buyers should consider the limitations in features and output quality, which may not meet the demands of more complex projects.

How do Desktop Software Solutions Enhance DXF to STL Conversion?

Desktop software solutions offer a robust set of features for converting DXF to STL, including customizable settings and offline functionality. These tools are ideal for companies engaged in large-scale manufacturing or detailed design processes, where precision is paramount. While they provide extensive editing capabilities, the higher cost and need for installation can be drawbacks for some businesses, especially smaller firms.

What Benefits do API Integration Services Offer for DXF to STL Conversion?

API integration services allow businesses to automate the conversion process, making it easier to incorporate DXF to STL conversions into existing workflows. This is particularly beneficial for software developers looking to enhance their applications with 3D capabilities. While the scalability and efficiency of these services are appealing, they do require technical expertise for proper integration, which may pose a challenge for non-technical teams.

Why Choose Batch Conversion Services for DXF to STL?

Batch conversion services are designed to handle multiple files simultaneously, making them a time-efficient choice for businesses with large projects or archiving needs. This capability is particularly advantageous in environments where speed and efficiency are critical. However, buyers should be aware that these services may require higher processing power and stable internet connections to function optimally.

How do Cloud-Based Storage Solutions Facilitate DXF to STL Conversion?

Cloud-based storage solutions combine file storage and conversion capabilities, enabling remote collaboration and efficient data management. These platforms are especially useful for teams working across different locations, as they provide easy access to files and facilitate sharing among stakeholders. However, businesses must consider the reliance on internet connectivity and potential security concerns when using cloud-based services.

Key Industrial Applications of convert dxf to stl

| Industry/Sector | Specific Application of convert dxf to stl | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Tooling and Mold Design | Enhances precision in creating molds, reducing material waste and production time. | Compatibility with existing CAD systems and software integration. |

| Architecture & Construction | 3D Printing of Architectural Models | Facilitates rapid prototyping, allowing for quick design iterations and client presentations. | Quality of conversion to ensure accurate representation of designs. |

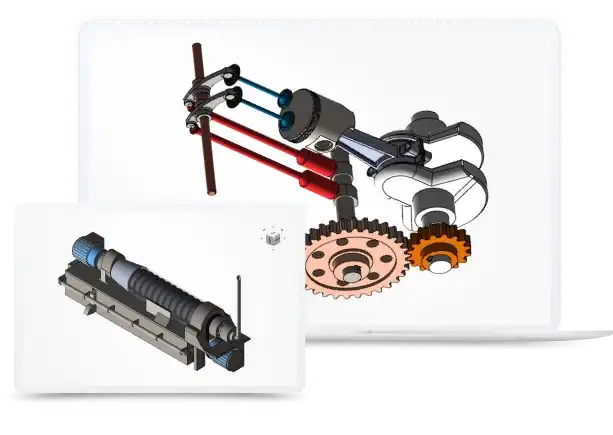

| Automotive | Component Design for Prototyping | Speeds up the design process and allows for testing of parts before full production. | Ability to handle complex geometries and large file sizes effectively. |

| Aerospace | Lightweight Structural Components | Supports the creation of lightweight, strong components, crucial for efficiency and performance. | Compliance with industry standards for safety and performance. |

| Education | Teaching Aids in CAD Courses | Provides students with hands-on experience in 3D modeling and printing, enhancing learning outcomes. | User-friendly tools that are accessible for both educators and students. |

How is ‘convert dxf to stl’ used in Manufacturing?

In the manufacturing sector, converting DXF files to STL is essential for tooling and mold design. Businesses can create precise molds for various products, which minimizes material waste and enhances production efficiency. This conversion allows manufacturers to quickly iterate designs, ensuring that the final product meets specifications. For international buyers, particularly in regions like Africa and South America, sourcing tools that integrate seamlessly with existing CAD systems is crucial for maintaining workflow efficiency.

What are the benefits for Architecture & Construction?

In architecture and construction, converting DXF to STL enables the rapid 3D printing of architectural models. This process allows architects to present their designs effectively to clients, facilitating quick feedback and design iterations. The ability to visualize projects in three dimensions helps in identifying potential design flaws early in the process, saving time and costs. For buyers in the Middle East and Europe, ensuring the quality of the conversion process is vital to accurately represent complex architectural designs.

How does this conversion aid the Automotive industry?

The automotive industry benefits significantly from converting DXF to STL files for component design and prototyping. This conversion accelerates the design phase, enabling engineers to create and test parts before full-scale production. By identifying potential issues early, companies can avoid costly revisions later in the manufacturing process. Buyers in regions like Saudi Arabia and Nigeria should consider the converter’s ability to handle complex geometries and large file sizes to support their specific design needs.

What role does it play in Aerospace applications?

In aerospace, the conversion from DXF to STL is crucial for designing lightweight structural components. These components must meet rigorous performance and safety standards while minimizing weight to enhance fuel efficiency. The conversion process supports the development of intricate designs that are essential for high-performance applications. International buyers in this sector need to ensure that their selected tools comply with industry standards to maintain safety and quality.

How is ‘convert dxf to stl’ utilized in Education?

In educational settings, converting DXF files to STL is a valuable tool for teaching CAD and 3D modeling. It allows students to engage in hands-on projects, enhancing their learning experience through practical application. By providing access to user-friendly conversion tools, educational institutions can foster creativity and innovation among students. For B2B buyers in Europe and beyond, selecting tools that are accessible and easy to use is key to effective learning outcomes.

3 Common User Pain Points for ‘convert dxf to stl’ & Their Solutions

Scenario 1: Difficulty in Maintaining Precision During Conversion

The Problem: B2B buyers, especially in industries like manufacturing and engineering, often face challenges when converting DXF files to STL. The intricacies of the original designs can be lost during conversion, leading to inaccuracies in measurements and details. This is particularly concerning for companies that rely on precision in 3D printing or CNC machining, where even minor discrepancies can result in costly errors or rework. The need for exact specifications, especially when dealing with complex geometries, adds a layer of stress to the conversion process.

The Solution: To ensure precision during the conversion from DXF to STL, buyers should opt for advanced conversion tools that offer customizable settings. Look for software that allows you to specify parameters such as extrusion height, mesh quality, and tolerance levels before initiating the conversion. Tools like ImageToStl and Aspose provide these features, allowing users to adjust settings based on the complexity of their DXF files. Additionally, conducting a thorough review of the STL file post-conversion using a 3D modeling software like Blender or MeshLab can help identify any inaccuracies. This step is crucial; by visualizing the model, businesses can verify that the conversion maintains the integrity of the original design before proceeding to production.

Scenario 2: Limited Support for Batch Conversions

The Problem: For many B2B companies, especially those in product design and prototyping, the need to convert multiple DXF files to STL format is a common requirement. However, many online conversion tools limit users to single-file uploads or have cumbersome processes for batch conversions. This can lead to significant time loss, especially for businesses that need to quickly iterate on designs and produce multiple prototypes. The inability to efficiently handle batch conversions can slow down project timelines and increase operational costs.

The Solution: To tackle this issue, B2B buyers should seek out conversion platforms that support batch processing of DXF files. Tools like ImageToStl allow users to upload up to 25 DXF files simultaneously, streamlining the workflow and saving valuable time. When selecting a tool, ensure that it not only supports batch conversions but also maintains high-quality output for each file. After conversion, it’s advisable to organize the STL files systematically, possibly by project or date, to facilitate easy retrieval. Implementing a standardized naming convention for the converted files can also enhance workflow efficiency and reduce confusion during later stages of the design process.

Scenario 3: Concerns Over Data Security and File Privacy

The Problem: In an increasingly digital landscape, data security is a paramount concern for B2B buyers, particularly those in sectors like architecture or engineering, where proprietary designs and sensitive information are at stake. Many online conversion services may not provide clear assurances regarding the handling and storage of uploaded files, leading to hesitance in using these platforms. The fear of intellectual property theft or data breaches can hinder companies from leveraging convenient online tools for DXF to STL conversions.

The Solution: To alleviate these concerns, it is essential for businesses to choose conversion tools that prioritize data security. Look for services that explicitly state their data retention policies, such as temporary file storage and prompt deletion after processing. Platforms like Aspose and ImageToStl have measures in place to ensure that uploaded files are deleted shortly after conversion, reducing the risk of unauthorized access. Additionally, consider using a secure, private network when conducting conversions to further safeguard sensitive data. For companies with heightened security needs, investing in desktop conversion software may provide an added layer of control over their files while still facilitating the necessary conversions without internet exposure.

Strategic Material Selection Guide for convert dxf to stl

What Are the Key Materials for Converting DXF to STL?

When converting DXF files to STL format for 3D printing or modeling, the choice of material significantly influences the end product’s performance, durability, and cost-effectiveness. Below, we analyze four common materials used in conjunction with STL files, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does PLA (Polylactic Acid) Perform in 3D Printing from STL Files?

PLA is a biodegradable thermoplastic made from renewable resources like cornstarch. It is widely used in 3D printing due to its ease of use and low warping tendencies.

- Key Properties: PLA has a melting temperature of around 180-220°C and exhibits good rigidity, making it suitable for detailed prints.

- Pros: It is cost-effective, environmentally friendly, and compatible with most 3D printers. Its low shrinkage factor contributes to high dimensional accuracy.

- Cons: PLA is less durable than other materials, with limited heat resistance and lower impact strength, making it unsuitable for high-stress applications.

- Impact on Application: PLA is ideal for prototypes, decorative items, and educational models but may not withstand high temperatures or mechanical stress.

- International Considerations: Compliance with environmental regulations is crucial, especially in regions like Europe where sustainability is prioritized. Buyers should ensure that PLA suppliers adhere to relevant standards like ASTM D6400 for compostability.

What Role Does ABS (Acrylonitrile Butadiene Styrene) Play in STL Conversions?

ABS is a strong thermoplastic commonly used in various applications, including automotive parts and consumer goods.

- Key Properties: It has a melting temperature of approximately 220-250°C and offers good impact resistance and toughness.

- Pros: ABS is known for its durability and ability to withstand higher temperatures compared to PLA. It can be easily post-processed, allowing for sanding and painting.

- Cons: It emits fumes during printing, necessitating proper ventilation. ABS also has a higher tendency to warp, requiring a heated bed for optimal printing.

- Impact on Application: ABS is suitable for functional parts, toys, and components that require durability and heat resistance.

- International Considerations: Buyers in regions like Saudi Arabia and Nigeria should consider local regulations regarding emissions and material safety. Compliance with standards such as ISO 527 for mechanical properties is also important.

Why Choose PETG (Polyethylene Terephthalate Glycol) for STL Files?

PETG is a copolyester that combines the ease of printing of PLA with the durability of ABS.

- Key Properties: PETG has a melting temperature of around 230-250°C and is known for its excellent layer adhesion and flexibility.

- Pros: It is impact-resistant, food-safe, and exhibits low shrinkage, making it a versatile option for various applications.

- Cons: PETG can be more expensive than PLA and may require fine-tuning of printer settings to achieve optimal results.

- Impact on Application: It is ideal for functional prototypes, mechanical parts, and items requiring transparency.

- International Considerations: Buyers should ensure compliance with food safety standards (e.g., FDA regulations) if PETG is used for food-related applications, particularly in regions with strict health regulations like Europe.

How Does Nylon (Polyamide) Compare for STL Conversions?

Nylon is a versatile synthetic polymer known for its strength and flexibility.

- Key Properties: It has a high melting temperature (around 220-260°C) and excellent abrasion resistance, making it suitable for demanding applications.

- Pros: Nylon is durable, flexible, and resistant to chemicals, making it ideal for functional parts and mechanical components.

- Cons: It can be challenging to print due to warping and moisture absorption. Specialized printers may be required for optimal results.

- Impact on Application: Nylon is often used in engineering applications, gears, and functional prototypes that require high strength and flexibility.

- International Considerations: Buyers in regions like South America and the Middle East should be aware of local standards for material safety and performance, such as ASTM D638 for tensile properties.

Summary Table of Material Selection for DXF to STL Conversion

| Material | Typical Use Case for convert dxf to stl | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PLA | Prototypes, decorative items | Biodegradable and easy to print | Limited durability and heat resistance | Low |

| ABS | Functional parts, toys | High durability and heat resistance | Emits fumes, requires ventilation | Medium |

| PETG | Functional prototypes, mechanical parts | Impact-resistant and food-safe | More expensive, requires fine-tuning | Medium |

| Nylon | Engineering applications, gears | High strength and flexibility | Difficult to print, moisture absorption | High |

This analysis provides valuable insights for international B2B buyers considering material selection for converting DXF files to STL format, ensuring they make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for convert dxf to stl

What Are the Key Stages in the Manufacturing Process for Converting DXF to STL?

The conversion of DXF (Drawing Exchange Format) files to STL (Standard Triangle Language) files involves several critical manufacturing stages, each contributing to the overall quality of the final product. Understanding these processes is vital for B2B buyers, particularly when sourcing from international suppliers.

1. Material Preparation: How Are DXF Files Organized for Conversion?

The initial stage in the DXF to STL conversion process involves preparing the DXF files. This includes ensuring that the CAD files are free from errors and properly formatted. Various CAD software tools, such as AutoCAD, may be utilized to modify the DXF files before conversion. Buyers should ensure that their suppliers can handle various file complexities and that the DXF files adhere to industry standards. This step often involves validating the integrity of the drawing entities, ensuring that all necessary components are included and that the file is optimized for conversion.

2. Forming: What Techniques Are Used for File Conversion?

The actual conversion from DXF to STL is where the forming process takes place. This typically involves using specialized software tools that interpret the DXF file’s vector data and convert it into a mesh structure suitable for 3D printing. Common techniques employed in this stage include:

- Extrusion: This method converts 2D shapes in the DXF file into 3D geometries by extending them along a specified axis.

- Surface Reconstruction: This technique involves generating a mesh surface from the curves and lines defined in the DXF file, ensuring that the mesh accurately reflects the original design.

Buyers should inquire about the software tools used by their suppliers, as the choice of software can significantly impact the quality of the STL file produced.

3. Assembly: Are Multiple DXF Files Being Combined?

In cases where multiple DXF files are involved, an assembly process may be necessary. This stage ensures that all components fit together seamlessly in the final STL file. Batch conversion capabilities are essential for businesses needing to convert multiple files simultaneously. Suppliers should demonstrate their ability to handle complex assemblies and provide evidence of successful previous projects.

4. Finishing: How Is the Final STL File Optimized?

The finishing stage focuses on refining the STL file for optimal performance in 3D printing. This may include reducing the file size, optimizing mesh quality, and ensuring compatibility with various 3D printing technologies. Techniques such as mesh simplification and error correction are often applied to enhance the final output. B2B buyers should ensure that their suppliers have robust quality checks during this stage to guarantee a high-quality STL file.

What Quality Control Measures Should B2B Buyers Expect?

Quality assurance is crucial in the DXF to STL conversion process. B2B buyers must understand the relevant international standards and quality control practices that suppliers should follow.

Relevant International Standards: Which Certifications Matter?

For B2B buyers, certifications such as ISO 9001 are fundamental indicators of a supplier’s commitment to quality management systems. This standard ensures that suppliers consistently meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in the European market or API (American Petroleum Institute) standards for certain industrial applications may also be relevant.

Quality Control Checkpoints: What Processes Are in Place?

Quality control typically involves several checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): This initial stage verifies the quality of the DXF files before conversion begins. It involves checking for file integrity and compliance with specifications.

- In-Process Quality Control (IPQC): During the conversion, continuous monitoring is essential to catch any errors or discrepancies in real-time.

- Final Quality Control (FQC): After conversion, the STL files undergo rigorous testing to ensure they meet all required specifications. This may include visual inspections and software-based checks for mesh integrity.

B2B buyers should request documentation of these quality control processes and any associated testing results to verify the reliability of their suppliers.

Common Testing Methods: How Are STL Files Verified?

Several testing methods can be employed to ensure the quality of the STL files:

- Visual Inspection: This involves manually reviewing the STL files for obvious defects or irregularities.

- Software Validation: Using specialized software tools to analyze the mesh structure for any errors, such as non-manifold edges or inverted normals, is crucial.

- 3D Printing Trials: Conducting test prints of the STL files can reveal any issues that may not be apparent in software analysis.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality assurance measures of their suppliers. Here are some effective strategies:

- Audits: Conducting regular audits of suppliers can help ensure that quality control measures are being adhered to. This can include both on-site inspections and remote assessments.

- Quality Reports: Requesting detailed quality reports and documentation from suppliers provides insight into their quality control processes and outcomes.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality management systems and product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances. These may include:

- Regulatory Compliance: Ensuring that suppliers comply with local regulations and international standards is essential, particularly when dealing with cross-border transactions.

- Cultural Differences: Different regions may have varying standards for quality and manufacturing practices. Understanding these differences can help in establishing effective partnerships.

- Supply Chain Transparency: Buyers should prioritize suppliers who provide transparency in their manufacturing and quality control processes, as this builds trust and ensures accountability.

By understanding the manufacturing processes and quality assurance measures involved in converting DXF to STL, B2B buyers can make informed decisions when selecting suppliers, ultimately ensuring the success of their projects.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘convert dxf to stl’

To assist B2B buyers in successfully procuring services or tools for converting DXF files to STL, this guide outlines essential steps to ensure a smooth and efficient process. By following this checklist, businesses can enhance their operational efficiency and reduce potential pitfalls in sourcing.

Step 1: Define Your Technical Specifications

Clearly outline your specific requirements for converting DXF to STL. This includes understanding the types of DXF files you’ll be working with, the expected output quality, and any additional features such as batch processing capabilities. Having precise specifications helps in identifying the right tools or services that meet your business needs.

Step 2: Research Available Conversion Tools

Conduct thorough research on various DXF to STL conversion tools available in the market. Look for both online and software-based solutions, and consider factors such as ease of use, processing speed, and support for different DXF formats. Pay attention to user reviews and case studies that highlight the effectiveness and reliability of these tools in real-world applications.

Step 3: Evaluate Potential Suppliers

Before making a commitment, vet potential suppliers extensively. Request company profiles, case studies, and references from businesses in similar industries or regions. This due diligence is crucial to ensure that the supplier has a proven track record and can deliver the quality and reliability you require.

Step 4: Assess Customer Support and Service Levels

Evaluate the level of customer support offered by the suppliers. It’s essential to have access to timely assistance, especially if you encounter issues during the conversion process. Look for suppliers that provide multiple support channels, such as email, chat, and phone support, and check their response times for inquiries.

Step 5: Verify Compliance and Security Measures

Ensure that the suppliers you consider comply with relevant industry standards and regulations, particularly regarding data security. Since DXF files may contain sensitive information, it’s vital to confirm that the conversion process adheres to best practices for data protection. Look for suppliers that clearly outline their security measures and data handling policies.

Step 6: Request a Demonstration or Trial

Before finalizing your choice, request a demonstration or trial of the conversion tool. This allows you to assess its functionality and ease of use firsthand. A trial can also help identify any potential issues or limitations that may affect your workflow, ensuring that you make an informed decision.

Step 7: Evaluate Pricing and Payment Terms

Finally, review the pricing structures and payment terms of the suppliers. Compare costs while considering the value provided by each solution. Look for transparency in pricing—ensure there are no hidden fees and that you understand the payment schedule, especially if opting for subscription-based services.

By following these steps, B2B buyers can effectively navigate the process of sourcing DXF to STL conversion solutions that align with their operational needs, ensuring quality, efficiency, and security in their projects.

Comprehensive Cost and Pricing Analysis for convert dxf to stl Sourcing

What Are the Key Cost Components in DXF to STL Conversion?

When evaluating the cost structure for converting DXF files to STL formats, several components must be taken into account:

-

Materials: In the context of digital file conversion, materials refer to the computational resources used during the conversion process. This includes server uptime and bandwidth, which can significantly impact costs, especially for high-volume conversions or more complex files.

-

Labor: While automated tools are prevalent, skilled personnel are necessary for quality control and troubleshooting. The expertise required for effective management of conversion processes can contribute to labor costs, particularly in regions with higher wage standards.

-

Manufacturing Overhead: This encompasses the costs associated with maintaining the digital infrastructure, including software licenses, server maintenance, and data storage solutions. Efficient management of these overheads can lead to cost savings.

-

Tooling: Depending on the service provider, specialized software or conversion tools may incur licensing fees, adding to the overall cost of service.

-

Quality Control (QC): Ensuring the accuracy of the conversion is critical, especially for industries that rely on precision, such as engineering and architecture. QC processes may include additional checks and balances, further influencing costs.

-

Logistics: While less tangible in digital file conversion, logistics can refer to the speed of service delivery and the ability to handle large file sizes efficiently. Providers that offer rapid turnaround times may charge a premium.

-

Margin: Finally, the profit margin that service providers add to their costs will vary. It’s essential for buyers to understand the pricing structure to negotiate better terms.

What Influences Pricing for DXF to STL Conversion Services?

Several factors can influence the pricing of DXF to STL conversion services:

-

Volume/MOQ (Minimum Order Quantity): Bulk conversions often come with discounts. Understanding the provider’s pricing tiers based on volume can lead to significant savings.

-

Specifications/Customization: Custom specifications, such as specific file formats or additional features, can increase costs. Buyers should clarify their needs upfront to avoid unexpected charges.

-

Materials and Quality Certifications: Providers offering higher-quality outputs or certified services may charge more. Buyers should assess whether the additional costs align with their quality requirements.

-

Supplier Factors: The reputation and location of the supplier can also affect pricing. Providers in high-cost regions may charge more than those in emerging markets, but this can also correlate with service quality and reliability.

-

Incoterms: Understanding Incoterms is crucial, especially for international buyers. These terms dictate the responsibilities of buyers and sellers, influencing overall costs related to shipping and handling.

How Can Buyers Negotiate for Better Pricing in DXF to STL Services?

-

Leverage Volume Discounts: When possible, consolidate conversion needs to meet minimum order quantities, allowing for better pricing negotiations.

-

Clarify Specifications Early: Providing detailed project specifications upfront can prevent misunderstandings and potential cost overruns later in the process.

-

Assess Total Cost of Ownership (TCO): Beyond initial conversion costs, consider the long-term implications of using the converted files, including any additional editing or rework that may be required.

-

Understand Pricing Nuances for International Buyers: Factors such as currency fluctuations, import duties, and regional pricing strategies can impact overall costs. Engaging with local suppliers may mitigate some of these expenses.

-

Build Relationships with Suppliers: Establishing a long-term partnership can lead to better pricing and service terms over time.

What Should International Buyers Consider When Sourcing DXF to STL Conversion?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of several unique challenges and opportunities:

-

Cultural Differences: Understanding cultural norms and business practices in different regions can enhance negotiations.

-

Regulatory Environment: Familiarize yourself with local regulations that may affect data handling and file sharing, particularly in sensitive industries.

-

Supplier Location: Consider the geographical proximity of suppliers, as this can influence shipping costs and turnaround times.

-

Language Barriers: Effective communication is critical. Ensure that language differences do not hinder project specifications or negotiations.

Disclaimer on Indicative Prices

The prices associated with DXF to STL conversion services can vary widely based on the factors discussed. It is crucial for buyers to obtain quotes tailored to their specific needs and to understand that the final costs may differ from initial estimates due to various influencing factors.

Alternatives Analysis: Comparing convert dxf to stl With Other Solutions

Exploring Alternatives to Converting DXF to STL

When it comes to converting DXF (Drawing Exchange Format) files to STL (Standard Triangle Language) files, businesses may find themselves weighing various alternatives. Different solutions can offer unique advantages and drawbacks, depending on specific operational needs, budget constraints, and the level of technical expertise available. Below is a comparative analysis of the conventional DXF to STL conversion against two alternative solutions: dedicated software applications and 3D modeling services.

| Comparison Aspect | Convert DXF to STL | Dedicated Software (e.g., AutoCAD) | 3D Modeling Services (Freelancers) |

|---|---|---|---|

| Performance | Fast, typically under 10 seconds for smaller files; batch processing available. | High performance for complex files; may require significant computational resources. | Variable performance based on the service provider; could take days depending on workload. |

| Cost | Free or low-cost online tools; no additional costs for software. | Requires a software license; can be expensive (often hundreds of dollars). | Varies widely; can be cost-effective for one-off projects but may add up for ongoing needs. |

| Ease of Implementation | Extremely user-friendly; no installation needed. | Requires installation and learning curve; may be complex for new users. | Simple to engage but may require clear communication of needs and expectations. |

| Maintenance | Minimal; online tools are maintained by service providers. | Regular updates needed; requires IT support for troubleshooting. | No maintenance required; however, consistency in service quality can vary. |

| Best Use Case | Ideal for quick conversions and small businesses. | Best for large organizations with frequent, complex conversions. | Suitable for companies needing custom solutions or design work beyond simple conversions. |

What Are the Advantages and Disadvantages of Using Dedicated Software for Conversion?

Dedicated software like AutoCAD provides robust functionality for a wide range of design tasks, including the conversion of DXF files to STL. The primary advantage is its high performance and capability to handle complex designs effectively. However, the cost of licensing can be a barrier for smaller businesses. Additionally, the software’s complexity may require extensive training, making it less accessible for teams with limited technical expertise.

How Do 3D Modeling Services Compare to Direct Conversion Tools?

3D modeling services, often offered by freelancers or specialized agencies, can provide tailored solutions that go beyond mere file conversion. These services can create intricate 3D models based on DXF files, ensuring high levels of detail and customization. While this method can be more expensive and time-consuming, it is beneficial for businesses that require unique designs or modifications that online converters cannot provide. However, the variability in service quality means businesses must carefully vet providers to ensure they meet their standards.

Conclusion: Which DXF to STL Solution is Right for Your Business?

Choosing the right solution for converting DXF files to STL largely depends on your specific business needs. For companies that require quick, cost-effective conversions without the need for additional features, online tools present an excellent option. On the other hand, businesses that frequently engage in complex design tasks may find investing in dedicated software more beneficial. Lastly, if your project demands custom 3D modeling, engaging a freelancer could provide the tailored results you need, albeit at a higher cost. By evaluating these options against your operational requirements, budget, and expertise, you can make an informed decision that aligns with your business goals.

Essential Technical Properties and Trade Terminology for convert dxf to stl

What Are the Key Technical Properties to Consider When Converting DXF to STL?

When converting DXF files to STL, several technical properties are crucial for ensuring the output meets your project’s requirements. Understanding these properties can significantly affect the quality of your final 3D model and its suitability for applications like 3D printing or further digital manipulation.

-

Mesh Geometry

Mesh geometry refers to the arrangement of vertices, edges, and faces that define the shape of a 3D object. In the context of DXF to STL conversion, it’s essential to ensure that the mesh is accurately generated to reflect the original design. Poor mesh geometry can lead to printing errors or structural weaknesses in the final product. B2B buyers should prioritize converters that produce high-quality mesh geometry to minimize post-processing adjustments. -

File Size Limitations

The size of the DXF file can impact the conversion process. Many online converters impose file size limits (often around 100MB), which can restrict the complexity of designs that can be processed. Understanding these limitations is vital for businesses, especially those dealing with intricate designs. Opting for tools that support larger file sizes or batch processing can enhance efficiency and productivity. -

Extrusion Settings

During the conversion, extrusion settings dictate the depth or height of the 3D model derived from the 2D DXF file. The ability to adjust these settings is critical for achieving the desired dimensions in the final STL file. Companies should look for conversion tools that allow customization of extrusion values to ensure that the output aligns with specific project requirements. -

Color Information Retention

While the standard STL format does not support color data, some converters offer options to retain color information through non-standard formats like VisCAM or SolidView. For businesses that require visually accurate models for presentations or marketing, this capability can be a significant advantage. Understanding the implications of color retention can help businesses make informed choices about their conversion tools. -

Compatibility with 3D Software

The output STL files must be compatible with various 3D modeling and printing software. Ensuring that the converted files can be easily imported into programs like Blender, AutoCAD, or MeshLab is essential for seamless workflows. B2B buyers should inquire about compatibility options when selecting conversion services.

What Are Common Trade Terms Associated with DXF to STL Conversion?

Familiarity with specific industry terms can enhance communication and streamline processes for businesses involved in CAD design and 3D printing. Here are some key terms to be aware of:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of DXF to STL conversion, OEMs often require precise models for components that will be integrated into larger systems. Understanding OEM specifications can help ensure that conversions meet the necessary standards for integration. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. In the realm of 3D printing and CAD services, knowing the MOQ can be crucial for businesses looking to optimize their supply chain and production processes. This term is particularly relevant when ordering customized parts or components. -

RFQ (Request for Quotation)

An RFQ is a document that businesses send to suppliers to request pricing information for specific products or services. In the context of DXF to STL conversion, issuing an RFQ can help companies compare different service providers based on price, turnaround time, and technical capabilities. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in the shipping process. Understanding these terms can help businesses navigate international shipping and logistics when transporting 3D printed parts or CAD files across borders. -

3D Printing

This term refers to the process of creating three-dimensional objects from digital files. As a direct application of STL files, understanding the 3D printing process and its requirements is essential for businesses that rely on this technology for prototyping or production.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when converting DXF files to STL, ultimately leading to better project outcomes and enhanced operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the convert dxf to stl Sector

What Are the Key Market Drivers for DXF to STL Conversion?

The global demand for 3D printing and additive manufacturing is accelerating the need for efficient file conversion tools, particularly for converting DXF (Drawing Exchange Format) files to STL (Standard Triangle Language) files. This trend is driven by industries such as architecture, engineering, and manufacturing, where 3D models play a crucial role in prototyping and production. Emerging markets in Africa, South America, the Middle East, and Europe are seeing increased investments in technology that streamline design processes. For instance, countries like Nigeria and Saudi Arabia are enhancing their technological infrastructure, leading to a growing pool of businesses seeking advanced CAD solutions.

The rise of cloud-based conversion tools is another significant trend. These solutions offer users the convenience of converting files without the need for high-spec hardware, making them accessible to small and medium-sized enterprises (SMEs). Additionally, batch conversion capabilities allow businesses to optimize their workflows, reducing the time and costs associated with file handling. As the market evolves, international B2B buyers should focus on tools that offer scalability, user-friendly interfaces, and robust customer support to facilitate their design processes.

How Is Sustainability Impacting the DXF to STL Conversion Sector?

Sustainability is becoming a central concern in the B2B landscape, influencing sourcing decisions across various sectors, including digital file conversion. The environmental impact of 3D printing, particularly concerning material waste and energy consumption, is prompting companies to adopt more sustainable practices. This includes selecting suppliers who prioritize eco-friendly materials and processes in their offerings.

Ethical sourcing is equally important, as companies are increasingly held accountable for their supply chain practices. Buyers are encouraged to look for conversion tools that are compliant with sustainability certifications or that utilize renewable energy in their operations. Moreover, companies should consider using biodegradable or recyclable materials for their 3D printing needs, aligning with broader sustainability goals. By prioritizing these factors, international buyers can not only meet their corporate social responsibility (CSR) objectives but also enhance their brand reputation in the global market.

How Has the DXF to STL Conversion Process Evolved Over Time?

The evolution of the DXF to STL conversion process reflects broader technological advancements in the CAD and 3D printing industries. Initially, DXF files were primarily used for 2D designs in AutoCAD, with limited support for 3D modeling. However, as 3D printing gained traction in the late 20th century, the need for converting 2D designs into 3D models became essential. This led to the development of specialized software tools that could handle complex conversions, including batch processing capabilities.

The introduction of online conversion platforms has further democratized access to these tools, enabling users from various sectors to convert DXF files to STL format without needing specialized software installations. This shift has made it easier for businesses, especially SMEs in emerging markets, to integrate 3D printing into their operations, fostering innovation and efficiency. As technology continues to advance, the focus on user experience and integration with other digital tools will likely shape the future of DXF to STL conversion solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of convert dxf to stl

-

How do I solve issues with DXF file compatibility during conversion to STL?

To resolve compatibility issues, first ensure that your DXF file adheres to the latest specifications and does not contain unsupported features. Use a reliable converter that supports a wide range of DXF versions and features. If problems persist, consider simplifying your DXF file by removing complex elements or layers that may not translate well. Additionally, testing the conversion process with smaller files can help identify specific issues before moving on to larger, more complex designs. -

What is the best method for converting DXF to STL for 3D printing?

The optimal method involves using a specialized online converter that can handle both DXF and STL formats efficiently. Look for a tool that supports batch conversions to save time, especially if you have multiple files. Ensure the converter maintains the integrity of the design, including mesh geometry and any color information, which can be crucial for accurate 3D printing. Lastly, verify that the STL file adheres to 3D printing standards, such as being manifold and properly scaled. -

How can I ensure the accuracy of my DXF to STL conversion?

To ensure accuracy, choose a conversion tool that utilizes advanced algorithms for translating 2D CAD data into 3D mesh geometry. Before finalizing your conversion, review the output STL file in a 3D viewer or modeling software to check for errors or distortions. It may also be beneficial to conduct test prints using lower-quality settings to verify that the geometry translates correctly before committing to final prints. -

What should I consider when vetting suppliers for DXF to STL conversion services?

When vetting suppliers, assess their experience and expertise in CAD file conversions, specifically DXF to STL. Review their portfolio and client testimonials to gauge the quality of their work. Additionally, inquire about their turnaround times, quality assurance processes, and customer support. Ensure they have robust data security measures in place to protect your proprietary designs during the conversion process. -

Are there minimum order quantities (MOQ) for DXF to STL conversion services?

Many suppliers may have flexible policies regarding minimum order quantities for DXF to STL conversions, especially for batch processing. It is advisable to clarify this with potential suppliers, as some may allow single-file conversions while others may prefer larger batches to optimize their workflow. Discussing your specific needs can help negotiate favorable terms that align with your project requirements. -

What payment terms are commonly offered by suppliers for DXF to STL conversion?

Payment terms can vary widely among suppliers, but common options include upfront payment, partial payment upon order confirmation, or payment upon delivery of the final STL files. Some suppliers may also offer discounts for larger orders or repeat business. It is essential to clearly communicate your preferences and establish mutually agreeable terms before proceeding with any conversion services. -

How do logistics work for delivering converted STL files internationally?

Most online conversion services provide digital delivery of STL files, which simplifies logistics significantly. After conversion, you typically receive a download link via email. Ensure that the supplier can deliver files in a format compatible with your local 3D printing systems. If physical components are involved, discuss shipping options, delivery times, and customs clearance procedures to avoid delays. -

What quality assurance measures should I expect from DXF to STL conversion services?

Reputable conversion services should implement rigorous quality assurance measures, such as file validation processes and error-checking protocols. They should provide a preview of the converted STL file and allow for revisions if the initial output does not meet your specifications. Inquire about their process for handling file corrections and whether they offer any guarantees on the quality of their conversions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Convert Dxf To Stl Manufacturers & Suppliers List

1. ImageToSTL – DXF to STL Converter

Domain: imagetostl.com

Registered: 2019 (6 years)

Introduction: Free online tool to convert DXF CAD files to STL. Supports batch conversion of up to 25 files at a time. Maximum file size for upload is 100MB. Converts DXF files to STL format suitable for 3D editing and printing. DXF format is a CAD file type, while STL is a standard for 3D models. The tool processes files on dedicated servers, requiring no high-spec computer. Compatible with any system with a m…

2. Aspose – DXF to STL Converter

Domain: products.aspose.app

Introduction: DXF to STL: online DXF to STL converter for free. Convert DXF files to STL format without installing specialized software. Accessible via web browser on any operating system (Windows, Linux, MacOS, Android). Supports drag and drop file upload. Conversion is fast, taking only a few seconds. Files are processed on Aspose servers, ensuring safety and privacy (files deleted after 24 hours). Supports m…

3. Reddit – DXF to STL Conversion Tools

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around converting DXF files to STL format for 3D printing. Users suggest using software like FreeCAD and Tinkercad for the conversion process. One user mentions successfully using Fusion 360 to extrude 2D shapes from DXF files into 3D models. It is noted that DXF files primarily contain 2D data and may not be suitable for 3D printing without additional modeling.

4. 3D Convert – DXF to STL Converter

Domain: 3d-convert.com

Registered: 2019 (6 years)

Introduction: Convert DXF to STL online for free at 3d-convert.com. The converter supports over 12 formats including STL, OBJ, Blend, FBX, and PLY, with a total of 627 conversion possibilities. The process involves three steps: 1) Upload a DXF file (max 50MB), 2) Select the output format, and 3) Start the conversion. Converted files are available for download for 24 hours after conversion. The service is free, …

5. eMachineShop – Free Online CAD File Converter

Domain: convert.emachineshop.com

Registered: 1999 (26 years)

Introduction: Free Online CAD File Converter for DXF, IGES, STEP, and STL. Convert CAD files online for free with no software download or signup required. Compatible with Solidworks, AutoCAD, Fusion 360, CATIA, Solid Edge, NX, Creo, FreeCAD, TurboCAD, Rhino, and more. Works on mobile and desktop devices (Windows, Apple, Linux, Android, iOS). Supports various file types including STEP AP-214, STEP AP-203, IGES, …

6. All3DP – DXF to STL Conversion Guide

Domain: all3dp.com

Registered: 2013 (12 years)

Introduction: This article discusses how to convert DXF files to STL format, which is essential for 3D printing. It presents three simple methods for this conversion, highlighting the importance of DXF files in CAD and STL files in 3D printing.

7. 3DPEA – DXF to STL Converter

Domain: 3dpea.com

Registered: 2020 (5 years)

Introduction: Convert DXF to STL Online For Free – Effortlessly convert your DXF files to STL for 3D printing with our powerful online 3D file conversion tool. No downloads or installations required. The conversion process is quick, typically taking about 5 seconds, though complex files may take longer. The tool supports various formats including DXF, STL, 3MF, OBJ, and more. Users can upload their DXF files, s…

8. AnyConv – DXF to STL Converter

Domain: anyconv.com

Registered: 2019 (6 years)

Introduction: Convert DXF to STL Online — Free & Fast | AnyConv

– Quickly convert multiple DXF files to STL for free and online.

– Supports file uploads up to 100 MB.

– Works on all devices: Windows, Mac, Linux, iPhone, Android.

– Simple conversion process: Upload DXF file, click ‘Convert’, and download STL file.

– DXF (Drawing Exchange Format) is developed by Autodesk for data interoperability in CAD tools, st…

9. Cadsoft Tools – ABViewer

Domain: cadsofttools.com

Registered: 2003 (22 years)

Introduction: ABViewer is a feature-rich software that supports over 30 popular formats, enabling conversion from DXF and other formats to STL. It offers a 30-day free trial, batch conversion feature, and measurement tools for 3D models, allowing users to measure distance, length, radius, area, volume, and coordinates. Users can create section views of 3D models without altering the geometry. The software suppo…

Strategic Sourcing Conclusion and Outlook for convert dxf to stl

Why is Strategic Sourcing Essential for Converting DXF to STL?

In the evolving landscape of 3D modeling and printing, the ability to convert DXF files to STL format is pivotal for businesses aiming to enhance their design workflows and production efficiency. Strategic sourcing of reliable conversion tools not only ensures accuracy and quality but also facilitates quick turnaround times, which are crucial for maintaining competitive advantage in diverse markets across Africa, South America, the Middle East, and Europe.

By leveraging online conversion tools, businesses can significantly reduce operational costs and time delays associated with traditional conversion methods. The availability of batch conversion options allows companies to streamline their processes, making it easier to manage multiple projects simultaneously. Furthermore, ensuring compatibility with various CAD applications enhances collaboration across international teams, fostering innovation and responsiveness to market demands.

As you consider your sourcing strategies, prioritize tools that offer user-friendly interfaces, robust support for various file formats, and compliance with data security standards. Embrace these advancements to position your business for growth in the dynamic world of 3D modeling. Start exploring your options today and unlock the full potential of your design capabilities in a global marketplace.