Contents

Manufacturing Insight: Cold Rolled Steel Versus Hot Rolled Steel

Material Selection Precision for Your CNC Machined Components

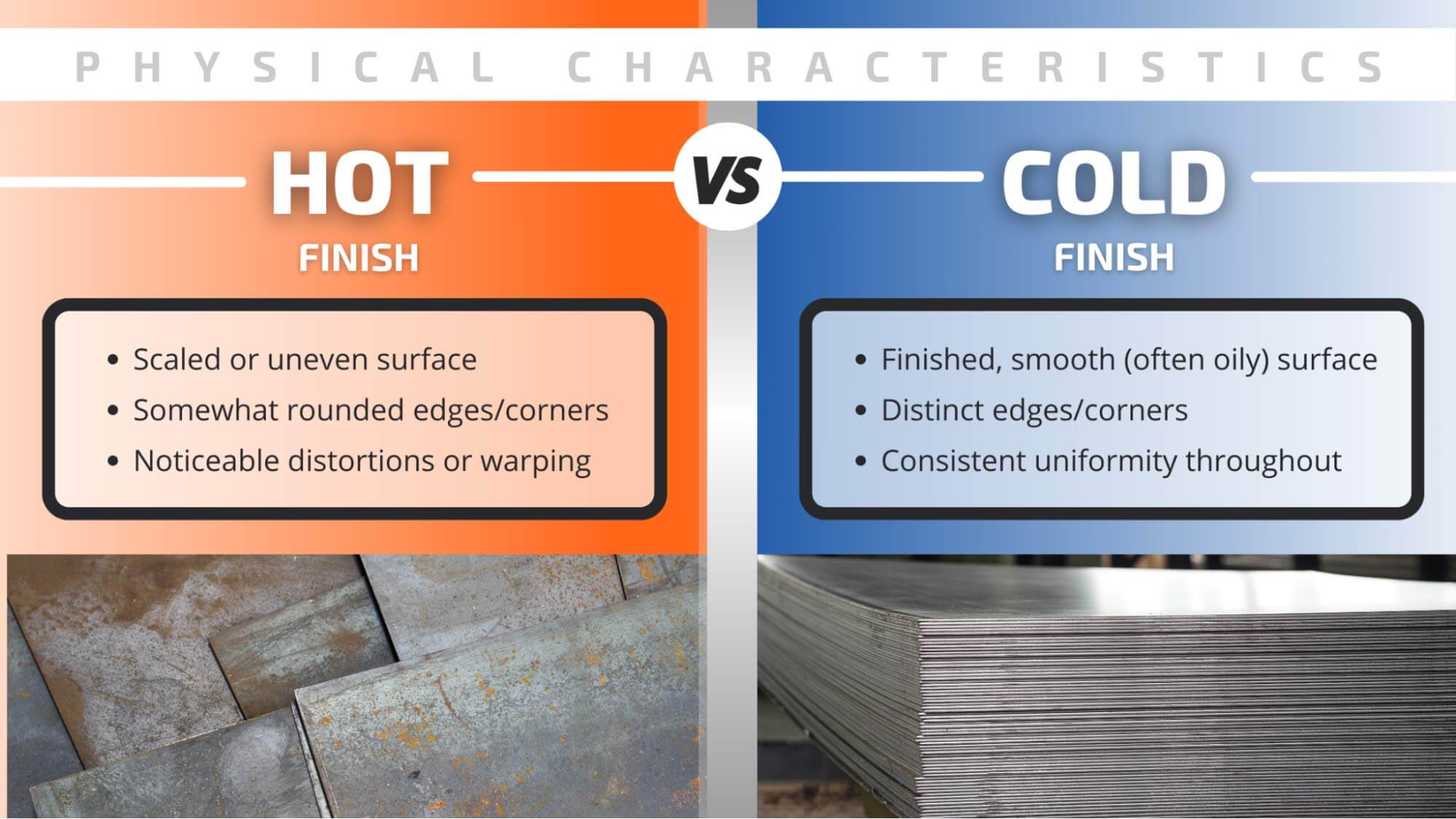

Understanding the fundamental differences between cold rolled steel and hot rolled steel is critical for achieving optimal part performance, dimensional accuracy, and cost efficiency in precision manufacturing. At Honyo Prototype, our CNC machining expertise directly addresses how these material properties impact your final component. Hot rolled steel, formed above its recrystallization temperature, offers cost-effective bulk formability but exhibits mill scale, slightly rounded edges, and looser dimensional tolerances. Conversely, cold rolled steel undergoes additional processing at room temperature, yielding superior surface finish, tighter tolerances, enhanced strength, and improved machinability—making it ideal for applications demanding high precision and aesthetic quality.

The choice between these materials significantly influences CNC machining strategy, tool wear, cycle time, and secondary operations. Honyo Prototype leverages decades of metallurgical insight and advanced CNC capabilities to optimize machining parameters for both steel types, ensuring consistent part integrity whether you require the economical robustness of hot rolled steel or the refined precision of cold rolled variants. Our engineers proactively address material-specific challenges, such as scale removal for hot rolled stock or managing work hardening in cold rolled grades, to deliver components that meet exact specifications without unnecessary rework.

Key comparative attributes relevant to machinability and end-use performance include:

| Property | Hot Rolled Steel | Cold Rolled Steel |

|---|---|---|

| Surface Condition | Mill scale present | Smooth, scale-free |

| Dimensional Tolerance | ±0.5mm typical | ±0.1mm typical |

| Surface Roughness (Ra) | 3.2–6.3 µm | 0.8–1.6 µm |

| Yield Strength | Lower | 20–30% higher |

| Machining Consideration | Scale removal required | Optimized for fine cuts |

When your project demands the right balance of performance, lead time, and cost, Honyo Prototype provides the technical partnership to navigate these material decisions. Explore how our CNC machining services transform your steel selection into precision-engineered reality—validate timelines and pricing instantly using our Online Instant Quote platform, designed for engineers who value speed without sacrificing technical rigor. Submit your CAD file today to experience seamless prototyping and low-volume production.

Technical Capabilities

Cold rolled steel and hot rolled steel differ significantly in mechanical properties, dimensional accuracy, and surface finish—factors that directly impact machining performance in precision applications such as 3-, 4-, and 5-axis milling and turning. These processes often require tight tolerances (±0.0005″ to ±0.005″), especially in industries like aerospace, medical, and automation. Material selection plays a critical role in achieving these tolerances, with aluminum, steel (both cold and hot rolled), ABS, and nylon each offering distinct advantages and limitations.

Cold rolled steel is processed at room temperature, resulting in improved surface finish, tighter dimensional control, and higher yield strength compared to hot rolled steel, which is formed at high temperatures and exhibits scale, warpage, and looser tolerances. For high-precision CNC operations, cold rolled steel is preferred when dimensional consistency and smoother finishes are required. Hot rolled steel may require additional machining stock to account for irregularities, increasing cycle time and tool wear.

Aluminum alloys (e.g., 6061, 7075) are lightweight, exhibit excellent machinability, and are ideal for tight-tolerance parts in dynamic applications. ABS and nylon, as engineering thermoplastics, are easier to machine than metals but require careful thermal management due to lower glass transition temperatures and higher thermal expansion.

Below is a comparative table summarizing key technical specifications relevant to multi-axis milling, turning, and tight-tolerance manufacturing:

| Property / Material | Cold Rolled Steel | Hot Rolled Steel | Aluminum (6061-T6) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (PA6/PA66) |

|---|---|---|---|---|---|

| Tensile Strength (MPa) | 440–550 | 400–500 | 310 | 40–50 | 70–85 |

| Yield Strength (MPa) | 370–420 | 250–350 | 276 | 30–40 | 50–70 |

| Elongation at Break (%) | 10–15 | 15–25 | 8–12 | 3–50 (varies by grade) | 20–50 |

| Density (g/cm³) | 7.85 | 7.85 | 2.70 | 1.04–1.06 | 1.13–1.15 |

| Surface Finish (as-machined) | 32–64 μin | 64–125 μin | 16–32 μin | 32–64 μin | 32–64 μin |

| Dimensional Consistency | High | Moderate to Low | High | Moderate | Low to Moderate |

| Machinability Rating | 55–65% (Fair) | 50–60% (Fair) | 90–100% (Excellent) | 80–90% (Good) | 70–80% (Good) |

| Typical Tolerance Capability | ±0.0005″ to ±0.002″ | ±0.005″ to ±0.010″ | ±0.0005″ to ±0.002″ | ±0.005″ to ±0.010″ | ±0.005″ to ±0.020″ |

| Thermal Stability | High | High | Moderate | Low | Moderate |

| Tool Wear (Relative) | High | High | Low | Very Low | Moderate |

| Best Suited For | Precision shafts, gears, structural components requiring tight tolerances | Non-critical structural parts, weldments | Enclosures, brackets, aerospace components | Housings, prototypes, jigs | Wear strips, gears, bushings |

Notes on Machining Performance:

In 3-, 4-, and 5-axis milling and turning, cold rolled steel provides superior repeatability due to consistent stock dimensions and reduced internal stresses compared to hot rolled steel. This allows for finer finishes and tighter tolerances without excessive corrective machining.

Aluminum remains the preferred choice for high-speed, complex geometries due to its low density and excellent chip evacuation. ABS and nylon are suitable for non-structural, lightweight components but require reduced feed rates and sharp tooling to prevent melting or deformation.

For tight-tolerance applications, pre-hardened or stress-relieved materials are recommended to minimize distortion during machining. Cold rolled steel and T6-tempered aluminum are typically supplied in stress-relieved conditions, enhancing dimensional stability during precision operations.

From CAD to Part: The Process

Honyo Prototype applies a structured engineering workflow to material selection between cold rolled steel and hot rolled steel, ensuring optimal manufacturability and cost efficiency. Our process integrates material-specific analysis at each stage rather than treating steel types generically.

Upon CAD file upload, our system validates geometry against material constraints. Cold rolled steel (typically AISI 1008-1026) is flagged for thickness limitations (generally under 0.25 inches) and tight tolerance requirements, while hot rolled steel (e.g., ASTM A36) triggers checks for scale removal allowances and minimum bend radii. Incomplete material specifications in the CAD file prompt immediate client consultation to avoid downstream rework.

The AI Quote engine calculates cost differentials using real-time material pricing and processing variables. Key factors include:

| Parameter | Cold Rolled Steel | Hot Rolled Steel | Impact on Quote |

|---|---|---|---|

| Base Material Cost | 15-25% higher | Standard baseline | Direct material cost delta |

| Machining Time | Longer (harder surface) | Shorter (softer scale) | Labor/cutter wear adjustment |

| Surface Prep | Minimal (smooth finish) | Required (descale/prime) | Secondary operation cost inclusion |

| Tolerance Control | ±0.005″ achievable | ±0.020″ typical | Precision machining surcharge assessment |

During DFM analysis, our engineers evaluate material-specific manufacturability. Cold rolled steel’s consistent surface and tighter tolerances enable direct machining for precision components but require stress-relief considerations for complex geometries. Hot rolled steel necessitates aggressive initial machining to remove mill scale and account for dimensional variance, with recommendations for post-process straightening if flatness exceeds 0.005″/inch. We explicitly document whether the design leverages cold rolled steel’s finish for cosmetic parts or hot rolled steel’s weldability for structural assemblies.

In production, material choice dictates machine parameters. Cold rolled steel parts undergo optimized CNC feeds/speeds to manage work hardening, with in-process CMM checks at critical features. Hot rolled steel components receive dedicated descaling (e.g., abrasive blasting) before machining, and final dimensions are verified after stress-relief heat treatment if specified. Both materials follow our ISO 9001-certified process control, but with distinct inspection protocols: cold rolled focuses on surface integrity and tolerance compliance, while hot rolled emphasizes dimensional stability post-machining.

Delivery includes material-specific documentation: Mill test reports for both variants, with cold rolled shipments accompanied by surface roughness validation and hot rolled parts including post-machining flatness certification. We proactively advise clients on secondary operations—such as powder coating suitability for cold rolled steel’s uniform surface versus the need for enhanced primers on hot rolled steel—to prevent field failures.

This integrated approach ensures material selection aligns with functional requirements rather than defaulting to lowest cost. Honyo’s engineers provide data-driven recommendations during DFM to justify cold rolled steel for high-precision assemblies or hot rolled steel for cost-sensitive structural applications, directly linking material properties to manufacturability and total project value.

Start Your Project

Understanding the differences between cold rolled steel and hot rolled steel is critical for achieving the desired strength, finish, and dimensional accuracy in your manufacturing projects. Cold rolled steel offers superior surface quality and tighter tolerances, making it ideal for precision components, while hot rolled steel provides excellent toughness and cost-efficiency for structural applications.

To determine the best material option for your next project, contact Susan Leo at [email protected]. With our advanced manufacturing facility located in Shenzhen, Honyo Prototype delivers high-quality steel fabrication with fast turnaround and strict quality control—ensuring your parts meet exact specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.