Guide Contents

Project Insight: Cold Rolled Steel Versus Hot Rolled Steel

Manufacturing Insight: Cold Rolled Steel vs. Hot Rolled Steel

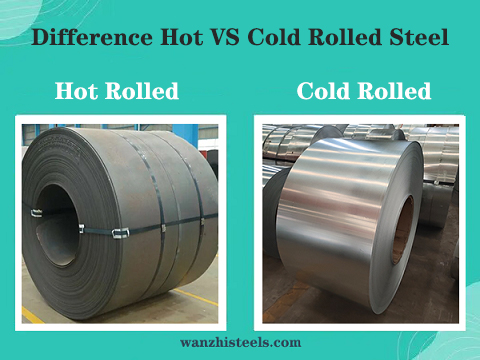

Understanding the Core Differences Between Hot Rolled and Cold Rolled Steel

Cost & Processing: Hot rolled steel is typically 30% more cost-effective (e.g., $270 vs. $400+ for standard sheets), ideal for early-stage prototypes where budget efficiency matters. Cold rolled steel involves additional steps (pickling, annealing), increasing costs but delivering superior precision and surface quality.

Tolerance & Surface Finish: Hot rolled steel has looser tolerances (±0.1mm) and a rougher scale finish; cold rolled offers tighter tolerances (±0.05mm) and smooth, mill-finished surfaces critical for high-precision assemblies.

Internal Stress: Cold rolled steel undergoes strain hardening, reducing internal stresses for better machinability and dimensional stability—key for complex parts requiring tight tolerances.

Why Speed and Precision Matter in Early-Stage Product Development

Hardware startups face intense pressure to validate designs rapidly. Delays from material selection errors or slow turnaround can derail timelines and increase costs.

Precision isn’t just about fit—it’s about function. A single misaligned component can compromise entire systems, especially in electronics or medical devices.

The right material choice at the right stage accelerates iteration cycles. Honyo’s expertise ensures you select the optimal steel type without compromising speed.

Honyo Prototype: Accelerating Your Design-to-Reality Journey

Online Instant Quote: Get real-time pricing for both hot rolled and cold rolled steel within seconds. Our AI-driven platform analyzes your design specs to recommend the most cost-effective and precise material for your stage of development.

AI-Powered Platform: Smart recommendations for material selection based on your application, tolerances, and timeline. No more guesswork—just data-driven insights to optimize your supply chain.

Fast Turnaround: From prototype to production, leverage our integrated digital manufacturing ecosystem to deliver parts in as little as 3 days. Scale seamlessly from initial prototypes to full production runs without switching suppliers.

“At Honyo, we don’t just manufacture parts—we engineer solutions. Whether you need a fast, affordable hot rolled prototype or a precision cold rolled final part, our digital ecosystem turns your vision into reality, faster and smarter.”

— Susan Leo, Founder

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities for Steel Solutions

At Honyo Prototype, we empower hardware startups and product engineers with a seamless digital manufacturing ecosystem that delivers both cold rolled and hot rolled steel solutions—optimized for precision, cost-efficiency, and speed. From prototype to production, our AI-powered platform ensures you get the right material choice with real-time pricing and lead times.

Cold Rolled Steel: Precision Engineered for Critical Applications

Tight Tolerances & Surface Finish: Achieve ±0.05mm dimensional accuracy and mirror-like surface quality for high-precision components like medical devices and automotive parts.

AI-Optimized Processing: Our digital ecosystem automatically adjusts annealing and pickling parameters, reducing lead times by up to 40% while maintaining superior mechanical properties.

Stress-Reduced Manufacturing: Minimized internal stresses ensure consistent performance in high-load applications, validated by ISO 9001-certified quality checks.

Competitive Pricing: Transparent cost breakdowns with real-time quotes—cold rolled steel optimized for your specific requirements to maximize ROI.

Hot Rolled Steel: Cost-Optimized Structural Solutions

Rapid Production Cycles: From prototype to 10,000+ parts in as little as 3 days, leveraging energy-efficient hot rolling processes for maximum speed.

Scalable Volume Handling: Seamlessly scale production with automated tooling adjustments—no setup fees for small batches or large runs.

Structural Integrity: Consistent strength and durability for frameworks, brackets, and heavy-duty applications, backed by ISO-certified material testing.

Cost Efficiency: Up to 30% lower costs than competitors for structural components, with transparent pricing via our AI-powered platform.

Integrated Digital Ecosystem for Seamless Execution

Online Instant Quote: Upload your CAD file to get real-time pricing and lead times for CR/HR steel within seconds—no manual quotes required.

AI-Powered Design Guidance: Receive instant DFM feedback and material recommendations tailored to your project’s performance and budget needs.

End-to-End Visibility: Track every step of your order from raw material sourcing to delivery through our digital dashboard.

Global Supply Chain: Access certified steel suppliers with guaranteed consistency and sustainability compliance across all orders.

Why Honyo?

“We don’t just manufacture steel—we engineer solutions. Whether you need micron-level precision for a medical implant or rugged structural frames for industrial equipment, our digital ecosystem turns complexity into simplicity.”

— Susan Leo, Founder of Honyo Prototype

Materials & Surface Finishes

Material Options & Finishes

At Honyo Prototype, our digital manufacturing ecosystem empowers you to optimize every design decision—from material selection to final finish. With an AI-powered platform that delivers instant quotes, 3–5 day prototyping, and seamless scaling from prototype to production, we eliminate guesswork and accelerate your innovation cycle.

Comprehensive Material Library

Metals:

Aluminum (6061-T6, 7075-T6)

Stainless Steel (304, 316L)

Carbon Steel (Hot Rolled, Cold Rolled)

Titanium (Gr5), Brass, Copper

Plastics:

ABS, PLA, Nylon (PA6, PA66), POM (Acetal), PC, PETG, PEEK

Precision Surface Finishes

Metals:

Anodizing (Type II/III, 20+ colors)

Powder Coating (200+ RAL options, matte/gloss)

Electroplating (Nickel, Zinc, Chrome)

Mirror/Satin Polishing (Ra 0.1–0.8μm)

Passivation (Stainless steel)

Plastics:

Paint (Custom color matching)

Texturing (Matte, gloss, leather grain)

Laser Engraving & Deburring

Cold Rolled vs. Hot Rolled Steel: Strategic Selection Guide

⚖️ Cost & Process Efficiency

Hot Rolled Steel:

~30% lower cost ($270/sheet avg.) due to high-temperature rolling (no secondary processing).

Ideal for budget-sensitive projects where dimensional precision is secondary.

Cold Rolled Steel:

Higher cost ($400+/sheet avg.) from additional steps: pickling, annealing, and cold rolling.

Justified for applications requiring tight tolerances, superior strength, or aesthetic finishes.

📏 Performance & Applications

| Property | Hot Rolled Steel | Cold Rolled Steel |

|---|---|---|

| Tolerances | ±0.03″ (looser) | ±0.001″ (precision-grade) |

| Surface Finish | Rough (Ra 1.6–3.2μm), scale layer | Smooth (Ra 0.4–0.8μm), uniform |

| Internal Stress | Higher residual stress | Reduced stress (annealed) |

| Best For | Structural frames, agricultural equipment, heavy machinery | Automotive parts, medical devices, precision machinery, consumer electronics |

💡 When to Choose Which?

Choose Hot Rolled Steel if:

Your project prioritizes cost efficiency over surface quality.

Components require welding or forging (e.g., structural beams, trailer frames).

Tolerances of ±0.03″ are acceptable (e.g., non-critical load-bearing parts).

Choose Cold Rolled Steel if:

Precision machining is needed (e.g., shafts, gears, tight-fit assemblies).

Aesthetic finish matters (e.g., visible components in consumer products).

Consistent grain structure and minimal stress prevent warping during secondary processing.

Why Honyo Prototype Delivers Steel Solutions Faster

AI-Powered Material Optimization: Our platform cross-references your design specs with real-time cost, lead time, and performance data—so you choose the right steel in seconds.

One-Stop Precision: From raw material sourcing to final finish, we handle everything under one roof—no coordination headaches.

Fast-Track Prototyping: Get cold/hot rolled steel prototypes in 3–5 days and scale to production in 1–2 weeks.

Engineer-Backed Guidance: Our team of manufacturing experts reviews your design to eliminate material mismatches before production starts.

“At Honyo, we don’t just supply materials—we engineer solutions. Whether you’re building a prototype or scaling to 10,000 units, our digital ecosystem ensures you get the perfect balance of cost, quality, and speed.”

— Susan Leo, Founder

From Quote to Part: Our Process

How It Works: From CAD to Part

At Honyo Prototype, we’ve redefined manufacturing with a seamless digital workflow that turns your ideas into reality faster than ever. Our AI-powered platform ensures precision, transparency, and speed at every step—no matter the complexity of your project.

Step 1: Upload Your CAD File

Simple & Secure: Upload any CAD format (STEP, STL, IGES, etc.) via our intuitive interface

Real-Time Validation: Instant checks for printability, tolerances, and manufacturability

Zero Setup Time: No manual file preparation—just upload and go

Step 2: Get Instant AI-Powered Quote

Real-Time Pricing: AI analyzes geometry, material (e.g., hot rolled vs. cold rolled steel), quantity, and finishes to deliver an accurate quote in seconds

Transparent Breakdown: See cost components clearly—no hidden fees or surprises

Optimized for Cost: Our system identifies cost-saving opportunities without compromising quality

Step 3: Smart DFM Analysis

Automated Feedback: AI-driven design-for-manufacturing review highlights potential improvements

Material-Specific Insights: Recommendations for optimal material selection (e.g., choosing cold rolled for tighter tolerances or hot rolled for cost efficiency)

Proactive Optimization: Suggestions to enhance structural integrity, reduce waste, and accelerate production

Step 4: Seamless Production & Delivery

End-to-End Tracking: Monitor your project in real-time from machining to shipping

On-Demand Manufacturing: Flexible scaling from prototypes to high-volume production

Guaranteed Timelines: Rigorous quality control and logistics partnerships ensure on-time delivery

With Honyo’s digital manufacturing ecosystem, you get a true one-stop solution—where innovation meets efficiency, and every step is designed to accelerate your time-to-market.

Start Your Project with Honyo

Start Your Project with Honyo

Optimize Your Steel Strategy with Precision Manufacturing

Whether you need cost-efficient hot rolled steel for structural applications or high-precision cold rolled steel for critical components, Honyo’s digital manufacturing ecosystem delivers tailored solutions with unmatched speed and quality.

AI-Powered Instant Quotes

Get real-time pricing, material options, and lead times in seconds—no manual quotes, no delays. Our platform analyzes your specs to recommend the perfect steel type for your project’s budget and performance needs.

3-5 Day Prototypes to Production

From Shenzhen/Dongguan facilities, we deliver prototypes in 3–5 days and scale seamlessly to volume production—no setup fees, no bottlenecks.

End-to-End Precision

One-stop solution from material selection to finishing: tighter tolerances (<±0.05mm), stress-free procurement, and consistent grain structure for machinability.

“At Honyo, we don’t just manufacture—we engineer efficiency. Whether you’re prototyping a drone frame or scaling a medical device, our digital ecosystem turns steel choices into competitive advantages.”

— Susan Leo, Founder & CEO

Ready to Build Smarter?

📧 [email protected]

📞 +86 139 2843 8620

📍 Visit our Shenzhen/Dongguan facilities for a personalized consultation

Innovation starts with the right material. Let’s make it happen.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.