Introduction: Navigating the Global Market for co2 laser metal cutting

In today’s competitive landscape, sourcing effective CO2 laser metal cutting solutions can be a daunting task for international B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. With a variety of technologies available, including CO2 and fiber lasers, organizations must navigate a complex array of options to find the right fit for their operational needs. This guide serves as a comprehensive resource, detailing the types of CO2 laser cutters, their applications across different materials, and critical supplier vetting processes to ensure quality and reliability.

Furthermore, we delve into the cost implications associated with CO2 laser metal cutting, providing insights that empower decision-makers to make informed purchasing choices. By exploring various factors such as cutting speeds, material compatibility, and maintenance requirements, this guide equips buyers with the knowledge needed to enhance productivity and reduce operational costs.

As the global market continues to evolve, understanding the intricacies of CO2 laser technology is essential for businesses looking to stay ahead. Whether you are in Germany, Vietnam, or elsewhere, our guide offers actionable insights tailored to your region, ensuring that you can confidently invest in the right laser cutting solutions that align with your manufacturing goals.

Understanding co2 laser metal cutting Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard CO2 Laser Cutting | Utilizes a gas-filled tube; versatile for various materials. | General manufacturing, signage, engraving | Pros: Versatile, good for thick materials. Cons: Higher operational costs, slower than fiber lasers. |

| High-Power CO2 Laser Cutting | Enhanced power output for faster cutting of thick metals. | Heavy industries, automotive, aerospace | Pros: Fast piercing and cutting of thick materials. Cons: Increased maintenance and energy costs. |

| CO2 Laser Engraving | Focuses on engraving applications with precision. | Custom signage, artistic applications | Pros: High detail, smooth finishes. Cons: Limited to engraving; not ideal for cutting. |

| Hybrid CO2 Laser Systems | Combines CO2 and fiber technologies for increased versatility. | Complex manufacturing environments | Pros: Flexible, efficient for diverse tasks. Cons: Higher initial investment, requires skilled operators. |

| CO2 Laser Cutting with Assist Gases | Utilizes nitrogen or oxygen for improved cutting quality. | Metal fabrication, sheet metal processing | Pros: Enhanced edge quality, faster cutting speeds. Cons: Requires gas supply management and costs. |

What Are the Characteristics of Standard CO2 Laser Cutting?

Standard CO2 laser cutting systems are characterized by their use of a gas-filled tube, which produces a highly concentrated beam of light. This technology is versatile, capable of cutting a wide range of materials, including various metals and plastics. It is particularly suitable for applications in general manufacturing, signage, and engraving. When considering this option, buyers should weigh the benefits of its versatility against its higher operational costs and relatively slower cutting speeds compared to fiber lasers.

How Does High-Power CO2 Laser Cutting Differ from Other Types?

High-power CO2 laser cutting systems are designed for heavy-duty applications, featuring enhanced power outputs that allow for faster cutting of thicker metals. These systems are essential in industries such as automotive and aerospace, where precision and speed are critical. Buyers should consider the initial investment and maintenance requirements, as these systems can lead to increased energy costs. However, their ability to quickly pierce and cut thick materials makes them a valuable asset for businesses that require high productivity.

What Are the Advantages of CO2 Laser Engraving?

CO2 laser engraving systems focus on creating detailed engravings rather than cutting through materials. They are ideal for custom signage and artistic applications, delivering high precision and smooth finishes. While these systems excel in engraving, they are not suitable for cutting tasks. Buyers should evaluate their specific needs for detailed work against the limitations of this technology, including its inability to handle cutting applications.

What Makes Hybrid CO2 Laser Systems Unique?

Hybrid CO2 laser systems combine the strengths of both CO2 and fiber laser technologies, offering increased versatility for complex manufacturing environments. These systems can handle a variety of tasks, from cutting to engraving, making them suitable for businesses that require flexibility in their operations. However, the initial investment is higher, and skilled operators are necessary to maximize their potential. Buyers should assess whether the benefits of versatility align with their operational goals.

How Do CO2 Laser Cutting Systems with Assist Gases Enhance Performance?

CO2 laser cutting systems that utilize assist gases like nitrogen or oxygen significantly improve cutting quality and speed. Nitrogen helps expel molten material quickly, while oxygen facilitates faster cutting speeds and enhanced edge quality, especially on thicker materials. These systems are particularly effective in metal fabrication and sheet metal processing. Buyers must consider the management of gas supplies and associated costs but can benefit from improved efficiency and quality in their cutting processes.

Key Industrial Applications of co2 laser metal cutting

| Industry/Sector | Specific Application of CO2 Laser Metal Cutting | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Cutting complex parts for vehicle assemblies | High precision and repeatability in part production | Reliability of equipment and availability of parts |

| Aerospace | Fabricating components for aircraft structures | Lightweight, strong parts that meet stringent specs | Compliance with industry standards and certifications |

| Electronics | Producing enclosures and circuit boards | Enhanced design flexibility and reduced waste | Material compatibility and precision requirements |

| Construction | Custom metal fittings and structural components | Faster project turnaround and reduced labor costs | Sourcing quality materials and machine capabilities |

| Furniture Design | Creating intricate metal designs for furniture | Unique aesthetic appeal and customization options | Design software compatibility and post-processing needs |

How is CO2 Laser Metal Cutting Used in Automotive Manufacturing?

In the automotive sector, CO2 laser metal cutting is utilized to create intricate components for vehicle assemblies, such as brackets, chassis, and panels. This technology allows manufacturers to achieve high precision and repeatability, essential for safety and performance. International buyers should focus on the reliability of the equipment, as downtime can significantly impact production schedules. Additionally, sourcing spare parts and maintenance services is crucial to ensure uninterrupted operations.

What Role Does CO2 Laser Cutting Play in Aerospace Fabrication?

The aerospace industry relies on CO2 laser cutting for fabricating lightweight and robust components for aircraft structures. This method meets stringent aerospace specifications while ensuring a high-quality finish. Buyers in this sector must consider compliance with industry standards and certifications, as any deviation can lead to costly delays or safety issues. Furthermore, sourcing equipment that offers flexibility in cutting various materials is beneficial for adapting to different project needs.

How is CO2 Laser Cutting Beneficial in Electronics Manufacturing?

In electronics, CO2 laser metal cutting is employed to produce enclosures and circuit boards with high precision. This technology reduces material waste and enhances design flexibility, allowing for more intricate designs that can improve product performance. Buyers must prioritize material compatibility, as different metals and composites may require specific cutting settings. Additionally, precision is crucial, so sourcing high-quality machines with advanced features is essential.

Why is CO2 Laser Cutting Important for Construction Projects?

For the construction industry, CO2 laser cutting facilitates the creation of custom metal fittings and structural components. This method accelerates project turnaround times, ultimately reducing labor costs and increasing overall efficiency. International buyers should focus on sourcing quality materials that can withstand environmental conditions, as well as ensuring that the cutting machines have the necessary capabilities to handle diverse construction needs.

What Advantages Does CO2 Laser Cutting Offer in Furniture Design?

In furniture design, CO2 laser cutting is used to create intricate metal designs that enhance aesthetic appeal and allow for customization. This technology provides designers with the flexibility to experiment with unique shapes and patterns, which can distinguish their products in the marketplace. Buyers should consider the compatibility of design software with cutting machines to streamline the production process and ensure that post-processing needs are met for a polished final product.

3 Common User Pain Points for ‘co2 laser metal cutting’ & Their Solutions

Scenario 1: High Operational Costs with CO2 Laser Cutting

The Problem: B2B buyers often encounter the challenge of elevated operational costs associated with CO2 laser cutting systems. These costs can stem from high electricity consumption, expensive consumables, and maintenance requirements. For businesses operating in regions where energy prices are volatile, this unpredictability can strain budgets. Additionally, manufacturers may struggle with the cost-effectiveness of production runs, leading to squeezed profit margins.

The Solution: To address high operational costs, buyers should consider investing in energy-efficient CO2 laser cutting systems. Opting for machines that utilize advanced technology, such as optimized beam delivery and improved gas management, can significantly reduce energy consumption. Additionally, sourcing reliable suppliers that offer competitive pricing on consumables and parts can further mitigate costs. Implementing regular maintenance schedules can prevent breakdowns and costly repairs, ensuring that the machinery operates at peak efficiency. Buyers should also explore automation solutions that minimize manual input and maximize throughput, thereby enhancing overall productivity and reducing the cost per part.

Scenario 2: Limited Material Versatility in CO2 Laser Cutting

The Problem: Many B2B manufacturers face limitations when using CO2 laser cutting systems, particularly when dealing with diverse materials. While CO2 lasers are adept at cutting thicker metals, they may not perform as well on certain materials, such as reflective metals (like copper or brass), which can lead to suboptimal cutting results. This lack of versatility can hinder a company’s ability to meet varied customer demands, ultimately impacting sales and growth.

The Solution: To improve material versatility, businesses should evaluate their current CO2 laser cutting system’s capabilities against their material requirements. Investing in specialized optics or additional assist gases can enhance performance on reflective materials. Buyers might also consider hybrid systems that combine CO2 and fiber laser technologies, allowing for greater flexibility in processing a wider range of materials without sacrificing quality. Regularly updating the laser cutting software can also improve settings tailored to different materials, ensuring consistent quality and efficiency. Collaborating with suppliers who can offer insights into material compatibility and cutting techniques can also provide valuable support.

Scenario 3: Inconsistent Cutting Quality and Precision

The Problem: Inconsistent cutting quality is a common concern for B2B buyers using CO2 laser cutting systems. Fluctuations in cut edge quality can result from various factors, including machine calibration, material inconsistencies, or improper settings. This inconsistency not only affects the final product but can also damage a company’s reputation for reliability and precision in manufacturing.

The Solution: To achieve consistent cutting quality, businesses should prioritize regular calibration and maintenance of their CO2 laser systems. Implementing a robust quality assurance process that includes routine inspections of machinery and materials can help identify potential issues before they affect production. Additionally, investing in advanced monitoring technologies that track performance metrics in real-time can provide insights into cutting efficiency and quality. Training operators on best practices for setup and adjustments can also minimize errors and ensure optimal results. Finally, establishing a feedback loop with customers regarding their quality expectations can guide improvements and enhance satisfaction with the final product.

Strategic Material Selection Guide for co2 laser metal cutting

What Are the Key Materials for CO2 Laser Metal Cutting?

When selecting materials for CO2 laser metal cutting, understanding the properties, advantages, and limitations of each material is crucial for optimizing production processes and meeting specific application requirements. Below is an analysis of four common materials used in CO2 laser cutting, focusing on their performance characteristics and implications for international B2B buyers.

How Does Mild Steel Perform in CO2 Laser Cutting?

Mild steel is one of the most commonly used materials in CO2 laser cutting due to its excellent machinability and cost-effectiveness. This material has good weldability and can withstand high temperatures, making it suitable for various applications, including structural components and automotive parts.

Pros: Mild steel offers high durability and strength, along with relatively low material costs. The cutting process yields smooth edges and high-quality finishes, which are essential for aesthetic applications.

Cons: While it is less expensive, mild steel is prone to rust and corrosion if not properly treated, which may limit its use in outdoor or high-humidity environments. Additionally, its weight can be a factor in transportation and handling.

Impact on Application: Mild steel is compatible with various coatings and treatments, enabling its use in diverse environments. However, B2B buyers must consider local climate conditions that may affect the longevity of the final product.

What Are the Benefits of Stainless Steel in CO2 Laser Cutting?

Stainless steel is renowned for its corrosion resistance and durability, making it a popular choice for applications requiring hygiene and aesthetic appeal, such as kitchenware, medical devices, and architectural elements.

Pros: The primary advantage of stainless steel is its resistance to rust and staining, which extends the lifespan of products. It also maintains structural integrity at high temperatures and is easy to clean.

Cons: The cost of stainless steel is generally higher than that of mild steel, which can impact overall project budgets. Additionally, cutting thicker sections may require higher power settings, leading to increased operational costs.

Impact on Application: Stainless steel’s compatibility with food and medical applications often requires adherence to specific international standards, such as ASTM or ISO certifications, which can vary by region.

How Does Aluminum Compare in CO2 Laser Cutting Applications?

Aluminum is lightweight and has excellent thermal conductivity, making it ideal for applications in the aerospace and automotive industries. Its ability to be anodized adds to its appeal for decorative and functional uses.

Pros: The lightweight nature of aluminum allows for easier handling and transportation, which can reduce shipping costs. It also provides good corrosion resistance and is highly recyclable.

Cons: Aluminum can be more challenging to cut than steel due to its reflective surface, which may require specialized settings or assist gases. Additionally, the initial cost can be higher compared to mild steel.

Impact on Application: B2B buyers should be aware that aluminum’s properties may necessitate specific cutting techniques and equipment, particularly in regions with varying manufacturing standards.

What Role Does Copper Play in CO2 Laser Cutting?

Copper is primarily used in electrical applications due to its excellent conductivity. It is also utilized in decorative items and heat exchangers.

Pros: Copper’s high thermal and electrical conductivity makes it ideal for applications requiring efficient heat transfer. It also has antimicrobial properties, making it suitable for medical and food applications.

Cons: The reflective nature of copper can lead to challenges in laser cutting, requiring more precise settings and potentially higher operational costs. It is also more expensive than other metals.

Impact on Application: Buyers must consider the specific requirements of their applications, such as electrical standards and compliance with local regulations, which can vary significantly across regions.

Summary Table of Material Selection for CO2 Laser Metal Cutting

| Material | Typical Use Case for CO2 Laser Metal Cutting | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mild Steel | Structural components, automotive parts | Cost-effective and durable | Prone to rust | Low |

| Stainless Steel | Kitchenware, medical devices, architectural elements | Corrosion resistant and durable | Higher cost | Med |

| Aluminum | Aerospace, automotive, decorative applications | Lightweight and recyclable | Challenging to cut | Med |

| Copper | Electrical applications, decorative items | Excellent conductivity | Reflective, higher cost | High |

This guide provides essential insights into material selection for CO2 laser metal cutting, helping B2B buyers make informed decisions tailored to their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for co2 laser metal cutting

What Are the Main Stages of the Manufacturing Process for CO2 Laser Metal Cutting?

The manufacturing process for CO2 laser metal cutting involves several critical stages that ensure the final product meets the required specifications. These stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the CO2 laser cutting process is material preparation. This involves selecting the appropriate type and thickness of metal, which can range from mild steel to stainless steel, aluminum, and even non-metal materials. Pre-cutting processes may include cleaning the surface to remove contaminants such as oils or dust, which can interfere with the cutting quality. Additionally, the material is often cut into manageable sheets that fit the dimensions of the laser cutter.

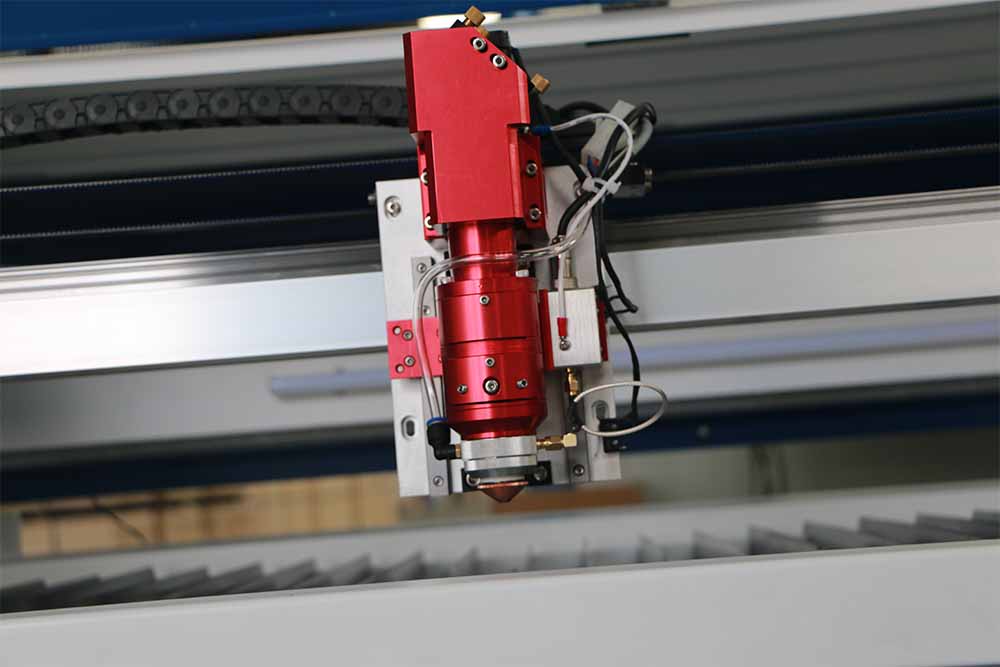

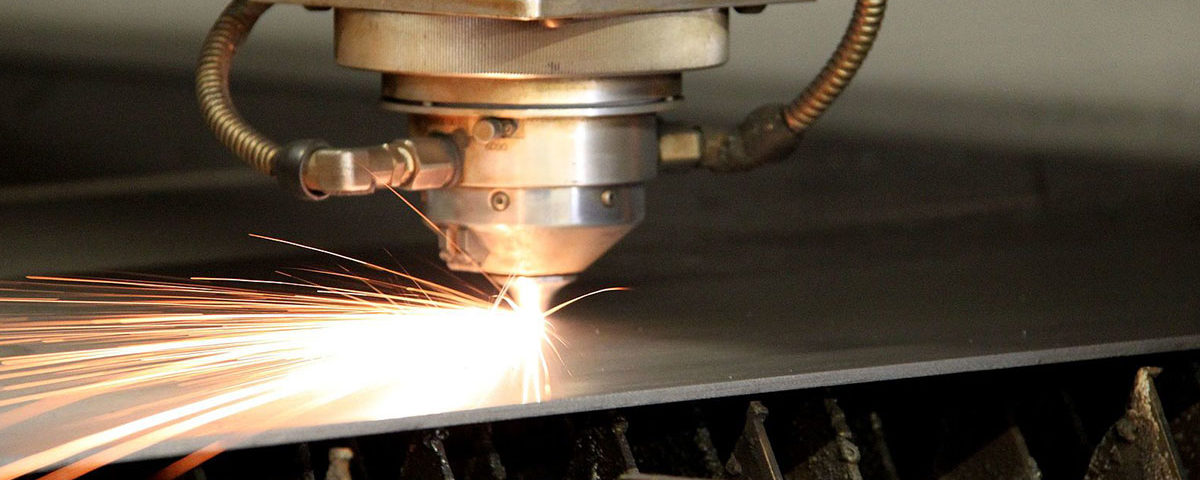

Forming

Once the material is prepared, the next stage is forming. This is where the actual cutting takes place. The CO2 laser cutter generates a high-intensity beam that is focused onto the metal surface. The laser beam melts or vaporizes the material along the programmed path, guided by a CNC system. The precision of this process allows for intricate designs and tight tolerances, making CO2 laser cutting suitable for various applications, from automotive components to decorative metalwork.

Assembly

After cutting, the components may undergo an assembly process, especially if they are part of a larger product. This could involve welding, riveting, or fastening parts together. The accuracy of the CO2 laser cutting process contributes significantly to the ease of assembly, as the parts are cut to precise dimensions that minimize the need for additional adjustments.

Finishing

The final stage is finishing, which may include deburring, polishing, or applying protective coatings to enhance the appearance and durability of the cut parts. Finishing processes are crucial for ensuring that the components not only meet aesthetic standards but also adhere to functional requirements, such as corrosion resistance.

How Is Quality Assurance Implemented in CO2 Laser Metal Cutting?

Quality assurance (QA) is vital in the manufacturing process of CO2 laser cutting, ensuring that products meet both international standards and customer specifications. Here are some key aspects of QA in this context.

What International Standards Are Relevant for Quality Assurance?

International standards such as ISO 9001 provide a framework for quality management systems across various industries, including metal cutting. Compliance with these standards assures B2B buyers that suppliers follow best practices in manufacturing and quality control.

In addition to ISO certifications, industry-specific standards may apply, such as CE marking for European markets, which indicates compliance with health, safety, and environmental protection standards. For sectors like oil and gas, API (American Petroleum Institute) certifications might be required to ensure the reliability and safety of components.

What Are the Key Quality Control Checkpoints?

Quality control (QC) in the CO2 laser cutting process typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for conformity to specifications before they enter the production line. It helps prevent defective materials from affecting the final product quality.

-

In-Process Quality Control (IPQC): During the manufacturing process, real-time monitoring is performed to ensure that the cutting parameters are within acceptable limits. This could include measuring cutting speed, power settings, and gas flow rates.

-

Final Quality Control (FQC): After the cutting and finishing processes, a thorough inspection is conducted to verify that the parts meet design specifications. This may involve dimensional checks, visual inspections, and functional tests.

What Common Testing Methods Are Used in Quality Assurance?

Several testing methods are employed to ensure the quality of CO2 laser-cut components:

-

Dimensional Inspection: Utilizing calipers and gauges to measure the dimensions of cut parts against specifications.

-

Visual Inspection: Inspecting for surface defects, burrs, or inconsistencies in finish.

-

Functional Testing: Conducting tests to ensure that the parts perform as intended, especially in assemblies where operational reliability is critical.

-

Material Testing: In some cases, additional tests such as tensile strength or hardness may be performed to verify material properties.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are some actionable steps:

-

Conduct Supplier Audits: Regular audits of suppliers can help verify compliance with quality standards and assess their manufacturing processes. This should include reviewing their quality management systems, certifications, and historical performance.

-

Request Quality Reports: Suppliers should provide detailed quality reports that outline their QC processes, including any corrective actions taken in response to past issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality practices. These services can conduct audits and inspections to validate compliance with industry standards.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers should be aware of specific nuances in quality control and certification:

-

Regional Standards Compliance: Different regions may have varying standards and regulations. For example, European buyers may prioritize CE compliance, while buyers in the Middle East might look for ISO certifications.

-

Understanding Local Practices: Familiarity with local manufacturing practices and standards can help buyers assess the credibility of suppliers. This knowledge can inform decisions regarding supplier selection and negotiation.

-

Cultural Considerations: Building relationships with suppliers may require an understanding of cultural practices in the supplier’s country, which can influence business negotiations and quality expectations.

Conclusion

In summary, understanding the manufacturing processes and quality assurance protocols in CO2 laser metal cutting is crucial for B2B buyers. By familiarizing themselves with the stages of manufacturing, quality control checkpoints, testing methods, and the nuances of international standards, buyers can make informed decisions and ensure they partner with reliable suppliers. This knowledge not only enhances product quality but also fosters long-term business relationships built on trust and transparency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘co2 laser metal cutting’

Introduction

This guide serves as a comprehensive checklist for B2B buyers considering the procurement of CO2 laser metal cutting systems. It outlines essential steps to ensure that your investment aligns with operational needs, quality standards, and financial considerations. Following this checklist will help you make informed decisions, optimize your sourcing process, and ultimately enhance your manufacturing capabilities.

Step 1: Define Your Technical Specifications

Before exploring suppliers, clarify your technical requirements. Identify the types of metals you will be cutting, the thickness ranges, and the specific applications. This step is crucial as it influences the type of CO2 laser cutting machine you need, ensuring it meets your production demands.

- Material Types: Consider if you will be cutting mild steel, stainless steel, aluminum, or other materials.

- Thickness Requirements: Determine the maximum thickness of metal you intend to process, as different machines have varying capabilities.

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers specializing in CO2 laser cutting systems. A well-informed selection process can prevent costly mistakes and ensure you partner with reputable manufacturers.

- Supplier Reputation: Look for reviews, testimonials, and case studies from other B2B buyers in your region.

- Industry Experience: Choose suppliers with a proven track record in your specific industry to ensure they understand your unique challenges.

Step 3: Evaluate Supplier Certifications and Compliance

Verify that your potential suppliers hold relevant certifications and comply with industry standards. This ensures the machines are built to last and operate safely and efficiently.

- Quality Certifications: Check for ISO certifications or other relevant quality assurance credentials.

- Safety Standards: Ensure compliance with local and international safety regulations to mitigate risks in your operations.

Step 4: Request Detailed Proposals and Quotations

Once you have narrowed down your list of suppliers, request detailed proposals and quotations. This step allows you to compare offerings comprehensively and assess which supplier can meet your needs most effectively.

- Breakdown of Costs: Ensure quotations include a detailed breakdown of costs, including installation, training, and maintenance.

- Machine Specifications: Verify that the proposed machines meet your defined technical specifications.

Step 5: Inquire About After-Sales Support and Maintenance

After-sales support is critical for maintaining operational efficiency. Evaluate the level of support each supplier offers post-purchase, as this can significantly impact your long-term satisfaction.

- Technical Support: Confirm the availability of technical support and training for your staff.

- Maintenance Services: Understand the maintenance options and response times for repairs and servicing.

Step 6: Visit Supplier Facilities if Possible

If feasible, arrange visits to the suppliers’ facilities. Seeing the machines in action can provide valuable insights into their capabilities and the supplier’s operations.

- Operational Demonstrations: Request demonstrations of the cutting machines to evaluate their performance firsthand.

- Quality Control Processes: Observe the supplier’s quality control measures to ensure they meet industry standards.

Step 7: Finalize Contract Terms Carefully

Before signing any agreements, review the contract terms meticulously. Pay attention to warranties, payment terms, and delivery timelines to avoid potential issues down the line.

- Warranties and Guarantees: Ensure you understand the warranty coverage for the machinery and any guarantees related to performance.

- Delivery and Installation: Confirm the expected delivery dates and installation support included in the agreement.

By following this checklist, B2B buyers can navigate the complex process of sourcing CO2 laser metal cutting systems with confidence, ultimately leading to a more successful procurement experience.

Comprehensive Cost and Pricing Analysis for co2 laser metal cutting Sourcing

What Are the Key Cost Components in CO2 Laser Metal Cutting?

When evaluating the cost structure of CO2 laser metal cutting, several components significantly influence pricing. These include:

-

Materials: The choice of materials directly affects costs. CO2 lasers can cut a variety of metals, including mild steel, stainless steel, and aluminum. Prices for these materials can vary widely based on market demand and availability. Additionally, thickness and quality of the metal play a crucial role; thicker materials generally incur higher costs due to increased cutting time and wear on the equipment.

-

Labor: Skilled labor is essential in operating CO2 laser systems, programming the machines, and ensuring quality control. Labor costs can differ greatly depending on the region. For instance, labor in Europe may be more expensive than in parts of Africa or South America, impacting the overall pricing of cutting services.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment maintenance. CO2 laser cutting systems, while generally reliable, require periodic maintenance and consumables (like gases), adding to the overhead.

-

Tooling and Setup: Initial setup costs for CO2 laser cutting can be significant, especially if customized tooling is required for specific projects. This includes the costs associated with designing and fabricating any necessary jigs or fixtures.

-

Quality Control (QC): Ensuring that cuts meet specified tolerances and quality standards requires rigorous QC processes. This may involve additional testing and inspection, which can increase labor and material costs.

-

Logistics: Shipping and handling costs can vary based on the distance and the chosen Incoterms. For international transactions, these costs can be substantial, particularly if the materials or finished products need to be transported across borders.

-

Margin: Finally, suppliers will include a profit margin in their pricing, which can vary based on market competition and the perceived value of the service.

How Do Price Influencers Affect CO2 Laser Metal Cutting Costs?

Several factors can influence pricing in CO2 laser metal cutting:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs. Suppliers may offer discounts for bulk purchases, enabling buyers to negotiate better terms.

-

Specifications and Customization: Unique project requirements, such as specific tolerances or custom designs, can drive up costs. Buyers should clearly communicate their needs to avoid unforeseen expenses.

-

Material Quality and Certifications: Higher-quality materials or those with specific certifications (e.g., ISO standards) may come at a premium. Buyers should weigh the benefits of quality against budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record and better customer service.

-

Incoterms: Understanding Incoterms is crucial for international buyers. These terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, affecting overall costs.

What Are the Best Negotiation Tips for B2B Buyers?

When sourcing CO2 laser cutting services, international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider these tips:

-

Research the Market: Understanding the market rates for CO2 laser cutting in your region can provide leverage during negotiations. Use this information to benchmark prices and identify competitive suppliers.

-

Emphasize Total Cost of Ownership (TCO): Focus not just on the upfront price but also on long-term costs, including maintenance, energy consumption, and labor. A supplier with a slightly higher initial price but lower operational costs may ultimately provide better value.

-

Request Quotes from Multiple Suppliers: Gathering quotes from several suppliers can reveal pricing trends and give you negotiating power. Use this information to negotiate better terms.

-

Be Transparent About Your Needs: Clearly communicate your project specifications and budget constraints. This can help suppliers provide more tailored solutions that align with your financial and operational goals.

-

Consider Long-term Partnerships: Building a relationship with a supplier can lead to better pricing and service over time. Suppliers may be more willing to negotiate on price if they see potential for ongoing business.

Conclusion: Why Understanding CO2 Laser Cutting Costs is Crucial for Your Business

Understanding the cost structure and pricing dynamics of CO2 laser metal cutting is essential for making informed purchasing decisions. By analyzing the various cost components and price influencers, B2B buyers can optimize their sourcing strategies, negotiate effectively, and ultimately enhance their operational efficiency. As always, it’s advisable to approach pricing discussions with a clear understanding of your specific needs and market conditions, ensuring that you secure the best possible deal for your business.

Disclaimer: Prices and costs referenced are indicative and may vary based on market conditions, supplier capabilities, and specific project requirements. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing co2 laser metal cutting With Other Solutions

When considering laser metal cutting technologies, CO2 laser cutting stands as a popular choice among manufacturers. However, it is essential to evaluate alternative solutions to determine the most suitable method for specific operational needs. This analysis will compare CO2 laser cutting with fiber laser cutting and plasma cutting, two viable alternatives that have gained traction in the industry.

| Comparison Aspect | Co2 Laser Metal Cutting | Fiber Laser Cutting | Plasma Cutting |

|---|---|---|---|

| Performance | Effective for a wide range of materials, excels in thicker metals | Faster cutting speeds, optimal for thinner metals | Suitable for thick materials, but less precise than lasers |

| Cost | Higher operational costs, especially for power and maintenance | Generally lower operational costs; initial investment can be higher | Lower initial costs, but operational costs vary with gas prices |

| Ease of Implementation | Established technology, widely understood | Requires training for optimal use; newer technology | Easy to set up and operate, less technical training needed |

| Maintenance | Higher maintenance requirements due to optics | Minimal maintenance with no mirrors or lenses | Moderate maintenance; wear parts need regular replacement |

| Best Use Case | Ideal for diverse materials and thicker sections | Best for high-speed production of thinner metals like stainless steel | Suitable for heavy-duty applications in construction and metal fabrication |

How Does Fiber Laser Cutting Compare to CO2 Laser Cutting?

Fiber laser cutting technology utilizes solid-state lasers, which provide a more concentrated beam that is absorbed by metals more efficiently. This technology allows for significantly faster cutting speeds, especially on thinner materials, making it a preferred choice for high-volume production environments. Fiber lasers typically have lower operational costs due to reduced power consumption and minimal maintenance requirements, as they lack the mirrors and lenses that CO2 systems have. However, fiber lasers may not perform as well on thicker materials compared to CO2 systems, which can handle a broader range of thicknesses and materials.

What Are the Advantages of Plasma Cutting Over CO2 Laser Cutting?

Plasma cutting is a versatile method that employs a high-velocity jet of ionized gas to cut through conductive materials. This technology is particularly effective for thicker metals and offers lower initial equipment costs compared to both CO2 and fiber lasers. The setup for plasma cutting is generally straightforward, making it accessible for a range of applications. However, plasma cutting does come with trade-offs, including lower precision and quality of cuts compared to laser systems, which can affect the aesthetic finish of the final product.

How Can B2B Buyers Decide on the Right Laser Cutting Technology?

Choosing the right cutting technology involves a thorough analysis of specific operational requirements. B2B buyers should consider factors such as material types and thicknesses, production volume, cost constraints, and desired cut quality. For businesses focused on high-speed production of thinner metals, fiber laser cutting may be the best choice. Conversely, those working with a diverse range of materials and thicknesses may find CO2 laser cutting more beneficial. Plasma cutting may appeal to industries requiring heavy-duty cutting at lower costs, albeit with some compromises in precision. Ultimately, understanding the strengths and limitations of each technology will empower buyers to make informed decisions tailored to their unique needs.

Essential Technical Properties and Trade Terminology for co2 laser metal cutting

Understanding the technical properties and terminology related to CO2 laser metal cutting is crucial for B2B buyers looking to make informed purchasing decisions. This section outlines essential specifications and industry jargon that can help streamline the evaluation process.

What Are the Key Technical Properties of CO2 Laser Metal Cutting?

1. Material Grade

Material grade refers to the classification of metals based on their composition and properties, such as tensile strength and corrosion resistance. Common materials for CO2 laser cutting include mild steel, stainless steel, aluminum, and brass. Understanding the material grade is vital for ensuring that the chosen laser cutting system can effectively process the intended materials, leading to optimal results and minimizing waste.

2. Cutting Thickness

The cutting thickness is the maximum depth of material that a laser can effectively penetrate. CO2 lasers excel in cutting thicker materials, often exceeding 5mm. This property is particularly important for industries requiring robust components, such as automotive or aerospace, where precision and strength are critical. Buyers should evaluate their specific needs to select a laser cutter capable of handling the required thickness.

3. Tolerance

Tolerance is the permissible limit of variation in a physical dimension, crucial in manufacturing to ensure parts fit together properly. CO2 laser cutting typically offers tolerances of ±0.1 mm, which is essential for precision applications. Understanding tolerance levels helps buyers ensure that their projects meet quality standards, which can affect product performance and customer satisfaction.

4. Beam Quality

Beam quality, often measured by the M² factor, indicates the effectiveness of the laser beam in cutting materials. A lower M² value signifies a higher quality beam, leading to cleaner cuts and better edge finishes. For B2B buyers, selecting a CO2 laser with superior beam quality can enhance production efficiency and reduce the need for secondary finishing processes.

5. Power Output

The power output of a CO2 laser, measured in watts, determines its cutting speed and capability. Higher wattage typically allows for faster cutting and the ability to handle thicker materials. B2B buyers should consider their production volume and material types when assessing the required power output to ensure the chosen system aligns with operational goals.

What Are Common Trade Terms in CO2 Laser Metal Cutting?

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of CO2 laser systems, buyers often engage with OEMs for customized solutions tailored to specific industrial needs. Understanding OEM relationships can lead to better pricing and support options.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. In the laser cutting industry, this term is significant for B2B buyers as it can affect procurement strategies, inventory management, and overall project costs. Knowing the MOQ helps in planning purchases and budgeting effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products or services. Utilizing RFQs in the laser cutting procurement process ensures that buyers receive competitive offers, enabling better decision-making and budget management.

4. Incoterms

Incoterms (International Commercial Terms) are predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers in understanding shipping responsibilities, risk transfer, and cost allocation, which can impact the overall project timeline and budget.

5. CAD (Computer-Aided Design)

CAD refers to software used for creating precision drawings or technical illustrations. In the context of CO2 laser cutting, CAD files are essential for programming the laser cutter to accurately produce components. Understanding CAD’s role can streamline the design-to-production workflow, enhancing efficiency and reducing errors.

By grasping these technical properties and trade terminologies, B2B buyers can navigate the complexities of CO2 laser metal cutting, leading to more effective purchasing decisions and improved operational outcomes.

Navigating Market Dynamics and Sourcing Trends in the co2 laser metal cutting Sector

What Are the Current Market Dynamics and Key Trends in CO2 Laser Metal Cutting?

The CO2 laser cutting market is experiencing significant transformation driven by technological advancements and changing buyer preferences. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe increasingly seek efficiency and precision in manufacturing, the demand for CO2 laser cutting systems is on the rise. Key trends include the integration of automation and smart technology, which enhance operational efficiency, reduce lead times, and minimize human error. Buyers are also focusing on systems that offer versatility in cutting a wide range of materials, including metals and non-metals, which is one of the CO2 laser’s strengths.

Furthermore, the competitive landscape is evolving, with manufacturers introducing hybrid systems that blend CO2 and fiber laser technologies, providing buyers with flexible options tailored to specific applications. In regions like Germany and Vietnam, where precision engineering is paramount, these hybrid systems are gaining traction. Additionally, the rising adoption of Industry 4.0 practices is influencing sourcing decisions, prompting buyers to seek suppliers that offer IoT-enabled machines for better monitoring and maintenance.

How Does Sustainability Impact Sourcing in the CO2 Laser Metal Cutting Sector?

Sustainability has become a cornerstone of sourcing strategies for international B2B buyers in the CO2 laser metal cutting sector. Companies are increasingly recognizing the environmental impact of their operations and the importance of ethical supply chains. This shift is driving demand for manufacturers that prioritize sustainable practices, such as energy-efficient technologies and responsible sourcing of materials.

Moreover, the use of eco-friendly assist gases and materials is gaining attention. Buyers are looking for suppliers that provide ‘green’ certifications, ensuring that their products meet stringent environmental standards. For instance, using nitrogen as an assist gas in CO2 laser cutting not only improves cutting quality but also minimizes harmful emissions. Additionally, many manufacturers are adopting circular economy principles, aiming to reduce waste and promote recycling of materials.

Buyers should evaluate potential suppliers based on their sustainability initiatives and certifications. This not only aligns with corporate social responsibility goals but also enhances brand reputation in increasingly eco-conscious markets.

What Is the Evolution of CO2 Laser Metal Cutting Technology?

CO2 laser cutting technology has a rich history dating back to its introduction in the 1960s. Initially designed for industrial applications, it quickly became a preferred method for cutting various materials due to its precision and versatility. Over the decades, CO2 lasers have evolved significantly, with advancements in power output and efficiency leading to improved cutting speeds and quality.

In the 1990s, the introduction of more sophisticated optics and control systems revolutionized the technology, allowing for finer cuts and the ability to work with thicker materials. As the market matured, manufacturers began developing hybrid systems that incorporate fiber laser technology, offering enhanced capabilities for specific applications. This evolution is critical for B2B buyers who are now faced with an array of options that cater to diverse operational needs, from cutting thin sheets to thicker metal components.

Understanding this evolution helps buyers make informed decisions about investing in CO2 laser cutting systems that not only meet current needs but also adapt to future technological advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of co2 laser metal cutting

-

How do I choose the right CO2 laser cutter for my business needs?

Selecting the appropriate CO2 laser cutter involves assessing your specific production requirements. Consider factors such as the thickness and type of materials you’ll be cutting, the desired cutting speed, and the precision needed for your applications. Additionally, evaluate the operational costs, including power consumption and maintenance requirements. Engaging with manufacturers to discuss your needs and seeking demonstrations can provide valuable insights into which model aligns best with your operational goals. -

What types of materials can CO2 laser cutters effectively cut?

CO2 laser cutters are versatile and can effectively cut various materials, including mild steel, stainless steel, aluminum, plastic, wood, tile, and even stone. Their ability to handle thicker materials (over 5mm) makes them suitable for diverse applications in industries like manufacturing, automotive, and construction. Understanding the material composition and thickness is crucial in determining the most effective laser settings for optimal cutting quality. -

What are the advantages of using CO2 laser cutting technology over fiber lasers?

CO2 lasers offer distinct advantages, particularly in cutting thicker materials and a wider range of substances, including non-metals. They typically provide superior edge quality and smoother surface finishes on thicker materials. However, they may incur higher operational and maintenance costs compared to fiber lasers. Evaluating your specific applications and material types will help you determine if CO2 technology is the right fit for your production needs. -

What is the minimum order quantity (MOQ) for CO2 laser cutting services?

MOQs can vary widely among suppliers, often influenced by the type of service and the complexity of the project. Many manufacturers may require a minimum order to justify production costs, especially for custom cuts or specialized projects. It’s advisable to communicate directly with potential suppliers to understand their MOQ policies and explore options for smaller runs if necessary. -

What payment terms are typically offered by CO2 laser cutting suppliers?

Payment terms can differ significantly based on the supplier’s policies and your business relationship. Common options include upfront payment, partial payment upon order confirmation, or payment upon delivery. For international transactions, consider using secure payment methods such as letters of credit or escrow services to mitigate risk. Always clarify payment terms before finalizing agreements to avoid misunderstandings. -

How can I ensure quality assurance (QA) when sourcing CO2 laser cutting services?

To ensure quality assurance, establish clear specifications for your cutting requirements, including tolerances and material standards. Request samples or prototypes to evaluate the supplier’s capabilities. Additionally, inquire about the supplier’s QA processes, certifications, and experience in the industry. Regular communication and establishing a feedback loop can further enhance product quality and alignment with your expectations. -

What logistics considerations should I keep in mind when importing CO2 laser-cut products?

When importing CO2 laser-cut products, consider shipping methods, customs regulations, and potential tariffs. Evaluate shipping times and costs, and ensure that the supplier can accommodate your desired delivery schedule. It’s also essential to verify the packaging standards to prevent damage during transit. Engaging a logistics partner familiar with international shipping can streamline the process and mitigate potential delays. -

How can I vet potential suppliers for CO2 laser cutting services?

Vetting suppliers involves several steps. Start by researching their reputation through online reviews and testimonials. Request references from previous clients to gauge their reliability and quality of service. Assess their certifications and compliance with international standards. Additionally, consider visiting their facilities or arranging virtual tours to inspect their equipment and processes. Establishing a strong communication channel will also help ensure that they understand your needs and can meet your expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Co2 Laser Metal Cutting Manufacturers & Suppliers List

1. Reddit – CO2 Laser Cutting Solutions

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: CO2 laser cutting for 0.25mm sheet metal; suitable materials include stainless steel or any metal that doesn’t melt below 300C; precise cutting required within prosumer laser cutter limits; dimensions for cutting: 200mm x 200mm sheet into 40x40mm squares; alternative suppliers mentioned: Sendcutsend, Oshcut; concerns about CO2 laser’s capability to cut metal; discussion on fiber lasers and diode l…

2. OMTech – CO2 and Fiber Laser Cutters

Domain: omtechlaser.com

Registered: 2020 (5 years)

Introduction: CO2 Laser Cutters and Engravers, Fiber Lasers, and More – OMTech Laser. Products include: OMTech Polar Lite 55W, OMTech Polar+ 55W, OMTech Maker 60W, OMTech Maker 90W, OMTech Maker 100W, OMTech Maker 150W, OMTech Pronto 35 60W, OMTech Pronto 45 100W, OMTech Pronto 60 130W, OMTech Pronto 75 150W, OMTech Pro 2440, OMTech Pro 3655, OMTech Pro 3655 Hybrid, OMTech K40+, OMTech Galvo 30W, OMTech Galvo 5…

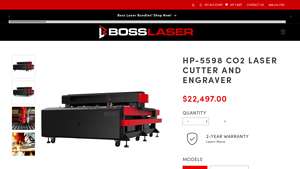

3. Boss Laser – HP-5598 CO2 Laser Cutter and Engraver

Domain: shop.bosslaser.com

Registered: 2012 (13 years)

Introduction: Product Name: HP-5598 Co2 Laser Cutter and Engraver

Price: $22,497.00

Power: Up to 250 watts

Cutting Capability: Can cut up to 16ga Stainless Steel & 18ga Mild Steel

Features:

– Dual control technology for vector cutting and raster engraving of both metal and non-metal materials

– New Flex™ LIVE reciprocating laser heads

Materials Supported:

– Non-Metals: Acrylic, Brick, Cardboard, Corian, Cork,…

4. Kern – CO2 Laser Systems

Domain: kernlasers.com

Registered: 1998 (27 years)

Introduction: Kern offers CO2 laser systems capable of cutting light gauge sheet metal, particularly effective with 150 to 650 watt CO2 lasers. Key features include: 1. Circular Polarized Beam: Reduces reflection off reflective metals, improving cut quality and consistency, especially on stainless steel and aluminum. 2. Automatic Capacitance Sensing Height Follower: Ensures optimal focus and distance from the m…

5. Esprit Automation – Fiber Laser Solutions

Domain: espritautomation.com

Registered: 2001 (24 years)

Introduction: Fiber Laser:

– Wavelength: 1.06 μm

– Best for cutting metals, especially highly reflective metals like copper and brass.

– Suitable for marking metal with high precision.

– Can cut stainless steel, mild steel, coated stainless steel, aluminium, copper, brass.

– Not suitable for cutting non-metals like textiles, wood, stone, etc.

– Cutting speed advantage (up to five times greater on thin mat…

6. LightBurn Software – Laser Engraving Solutions

Domain: forum.lightburnsoftware.com

Registered: 2017 (8 years)

Introduction: 1 mm mild steel plate, 60w CO2 laser, Cermark for engraving, anodized aluminum can be engraved without additional agents, MDF, Methacrylate, plywood can be cut and engraved, painted metal can be engraved, aluminum composite panel (ACP) is suitable for engraving, high-wattage machines required for metal cutting, fiber lasers can engrave metal.

Strategic Sourcing Conclusion and Outlook for co2 laser metal cutting

In conclusion, CO2 laser cutting technology continues to offer significant advantages for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Its versatility in cutting various materials, including metals and non-metals, positions it as a reliable choice for diverse manufacturing needs. While fiber laser systems are gaining traction due to their speed and efficiency, CO2 lasers still excel in specific applications, particularly when dealing with thicker materials and achieving superior edge quality.

Strategic sourcing remains crucial for companies looking to optimize their operations and cost structures. By carefully evaluating the total cost of ownership, operational capabilities, and specific project requirements, businesses can make informed decisions that enhance productivity and profitability.

As the laser cutting market evolves, international buyers are encouraged to stay informed about technological advancements and market trends. Engaging with reputable suppliers and participating in industry discussions can provide valuable insights that drive competitive advantage. Moving forward, investing in the right laser cutting technology will not only improve operational efficiency but also pave the way for innovation and growth in the global manufacturing landscape.