Contents

Manufacturing Insight: Cnc Wood Turning Lathe

Precision Wood Turning for Demanding Applications

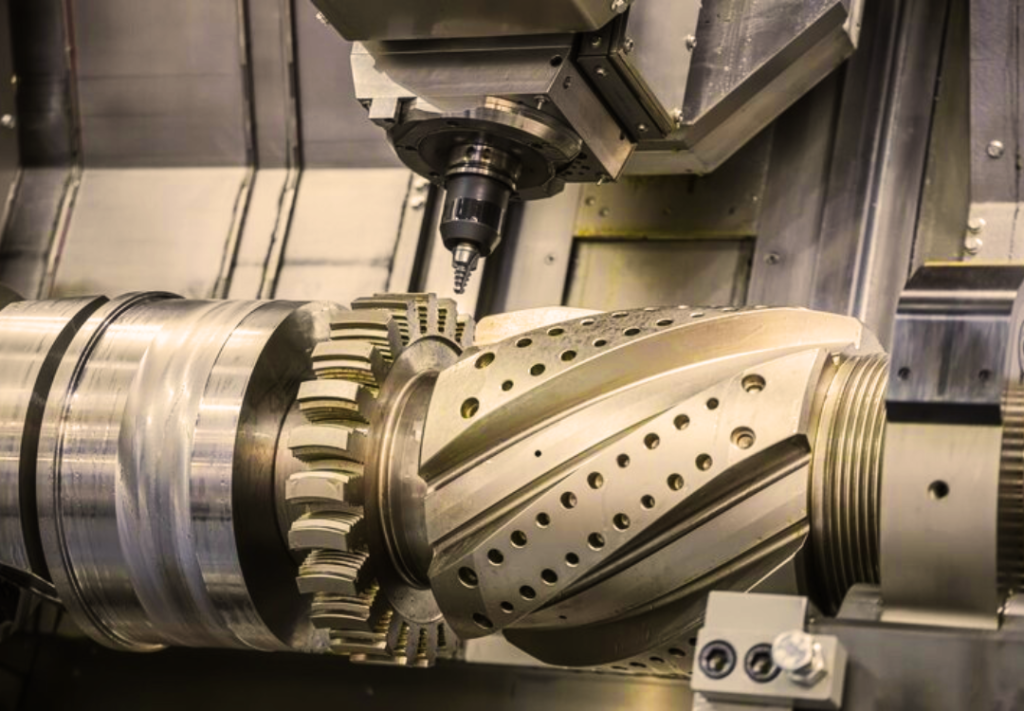

Honyo Prototype delivers advanced CNC wood turning lathe capabilities engineered to meet stringent industrial requirements for prototyping and low-to-mid volume production. Our specialized machining processes transform hardwoods, softwoods, and engineered composites into precision-turned components with exceptional surface finish and geometric accuracy. Unlike conventional woodworking methods, our CNC-controlled lathes maintain micron-level tolerances while optimizing material utilization and repeatability—critical for sectors including aerospace interiors, luxury furniture hardware, and medical device components where dimensional stability is non-negotiable.

Engineered for Material Integrity and Efficiency

Our mastery extends beyond machine operation to deep material science expertise. We account for wood’s anisotropic behavior, moisture content variability, and grain orientation during program development to prevent warping, tear-out, or dimensional drift. Utilizing high-speed spindles (5,000–15,000 RPM), diamond-tipped tooling, and adaptive feed-rate algorithms, we achieve finishes as fine as 32 μin Ra while minimizing cycle times. This technical rigor ensures your complex geometries—from intricate spindles to seamless tapered profiles—consistently meet ISO 2768-mK or custom tolerance specifications without secondary finishing.

Accelerate Your Project Timeline with Digital Workflow Integration

Honyo Prototype eliminates procurement bottlenecks through our Online Instant Quote platform. Upload CAD files (STEP, IGES, DWG) to receive a detailed manufacturability analysis and competitive pricing within minutes—not days. This transparent, engineer-validated system provides immediate clarity on lead times, material options, and cost drivers, enabling rapid project initiation. For time-sensitive wood-turned components requiring zero compromise on precision, our integrated digital-to-physical workflow ensures seamless transition from concept to certified production-ready parts.

Material Performance Comparison for CNC Wood Turning

| Material Type | Max Tolerance (±mm) | Surface Finish (μin Ra) | Typical Applications |

|---|---|---|---|

| Hard Maple | 0.025 | 32 | Precision fixtures, handles |

| Walnut | 0.05 | 40 | Decorative hardware, knobs |

| MDF (High-Density) | 0.08 | 50 | Prototyping, non-structural forms |

| Bamboo Composite | 0.03 | 36 | Sustainable consumer goods |

Initiate your next precision wood turning project with confidence: Access our Online Instant Quote system 24/7 at honyoprototype.com to validate feasibility and secure engineering support from day one.

Technical Capabilities

CNC wood turning lathes are primarily designed for rotational machining of wooden components using computer numerical control (CNC) systems. However, the request references multi-axis milling, tight tolerances, and non-wood materials such as aluminum, steel, ABS, and nylon—capabilities that extend beyond traditional wood-turning lathes and align more closely with CNC turning centers or multi-axis CNC machining centers. Below is a technical specification table for a high-precision CNC turning and milling machine capable of 3/4/5-axis operations, suitable for both wood and the mentioned engineering materials, with tight tolerance performance.

| Parameter | Specification |

|---|---|

| Machine Type | 5-Axis CNC Turning and Milling Center (Mill-Turn) |

| Axis Configuration | X, Y, Z, C (rotary), B (tilting spindle or table); capable of simultaneous 5-axis machining |

| Spindle Speed (Turning) | 3,000 – 12,000 RPM (high-speed option up to 18,000 RPM) |

| Spindle Power (Turning) | 7.5 – 15 kW (adjustable based on material) |

| Live Tooling (Milling) | Integrated motorized tooling with up to 12,000 RPM for cross-drilling, tapping, and milling |

| Chuck Size | 6″ – 10″ (150 – 250 mm) hydraulic or pneumatic |

| Bar Capacity | Up to 51 mm (2″) diameter through spindle (optional) |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Tolerance Capability | Achieves ±0.01 mm (tight tolerance for precision components) |

| Control System | Fanuc 31i, Siemens 840D, or Heidenhain TNC7 |

| Coolant System | High-pressure coolant with mist collection (essential for metal and thermoplastics) |

| Tool Magazine Capacity | 12 – 30 stations (depending on configuration) |

| Work Envelope (Turning) | Max turning diameter: 500 mm; max turning length: 1,000 mm |

| Materials Compatible | Aluminum (6061, 7075), Steel (1018, 4140), ABS, Nylon (PA6, PA66), Wood (hardwood, MDF, plywood) |

| Surface Finish (Typical) | Ra 0.8 – 1.6 µm (metals); Ra 3.2 µm (wood/plastics) with finishing passes |

| Automation Ready | Yes – compatible with robotic loading/unloading and pallet systems |

| Software Compatibility | CAD/CAM integration (Mastercam, SolidCAM, Fusion 360) |

Notes:

While traditional CNC wood lathes focus on 2-axis turning (X and Z), modern mill-turn centers combine turning with multi-axis milling to produce complex hybrid parts.

Tight tolerances (±0.01 mm) are achievable in metals and engineering plastics when proper fixturing, tooling, and thermal stability are maintained.

ABS and nylon require lower cutting speeds and optimized tool geometry to prevent melting or deformation.

Steel and aluminum demand rigid machine construction, high torque spindles, and effective chip management.

The inclusion of Y-axis and B-axis enables off-center milling and angled features, critical for 5-axis part consolidation.

This specification reflects a high-end CNC mill-turn machine suitable for precision prototyping and low-volume production across multiple materials, including wood, metals, and thermoplastics.

From CAD to Part: The Process

Honyo Prototype CNC Wood Turning Lathe Process Flow

Honyo Prototype executes a streamlined, technology-driven workflow for CNC wood turning lathe projects, ensuring precision, efficiency, and client transparency from initial design to final delivery. The process begins with CAD Upload, where clients submit detailed 3D models in industry-standard formats (STEP, IGES, or native CAD files). Our secure portal validates geometry integrity and confirms compatibility with wood-specific machining constraints, such as grain orientation and material anisotropy.

Following upload, the AI-Powered Quoting Engine analyzes the CAD data in real time. This system leverages Honyo’s proprietary database of 15,000+ historical wood machining projects to generate instant cost and lead time estimates. The AI factors in wood species density, required tolerances, surface finish specifications, and feature complexity (e.g., undercuts, thin walls) while accounting for moisture content stability protocols unique to wood substrates. Clients receive a detailed quote breakdown within 2 business hours, including material cost variables based on sustainable sourcing options.

The Design for Manufacturability (DFM) Review phase involves dual validation: automated analysis via Honyo’s wood-specific DFM algorithms and manual assessment by senior manufacturing engineers. This stage identifies critical wood machining considerations such as minimum wall thickness for structural integrity, optimal spindle speed/feed rate recommendations based on wood hardness, and grain-direction alignment to prevent tear-out. Clients receive a formal DFM report with actionable feedback, typically within 24 hours, highlighting potential cost or timeline optimizations.

Production commences only after client approval of the DFM report. Honyo utilizes 5-axis CNC wood lathes with adaptive toolpathing to accommodate wood’s natural variability. Each job undergoes rigorous in-process verification:

Material moisture content verification (target 6–8% for stability)

First-article inspection against ASME Y14.5 geometric tolerances

Real-time vibration monitoring to prevent chatter on delicate features

All wood components are machined in a climate-controlled facility (22°C ±1, 45% RH) to minimize dimensional drift during production.

Delivery encompasses final quality validation and logistics. Each shipment includes:

Certificate of Conformance with measured critical dimensions

Material溯源 documentation (FSC/PEFC-certified sources)

Humidity-stable packaging with desiccant for transit protection

Standard lead time from DFM approval to shipment is 7–10 business days for prototypes and 12–15 days for low-volume production runs. Honyo provides real-time shipment tracking and post-delivery technical support for assembly integration.

Material Compatibility Summary

| Wood Type | Max. Diameter (mm) | Min. Wall Thickness (mm) | Key Machining Notes |

|——————–|——————–|————————–|—————————————–|

| Hard Maple | 300 | 2.5 | Requires sharp carbide tools; prone to burning at high RPM |

| Walnut | 350 | 3.0 | Optimal finish at 8,000–10,000 RPM; avoid end-grain machining |

| Cherry | 250 | 2.0 | Low vibration settings recommended; sensitive to moisture shifts |

| Bamboo Composite | 400 | 4.0 | Requires diamond-coated tools; pre-drying essential |

| Plywood (Birch) | 500 | 5.0 | Limited to face-grain turning; avoid core voids |

This integrated process eliminates traditional wood machining uncertainties through data-driven decision-making, ensuring repeatable quality for prototyping and bridge production applications. Honyo maintains ISO 9001:2015 certification with wood-specific process controls documented in our AS9100-aligned quality management system.

Start Your Project

Looking for precision CNC wood turning lathe solutions? Contact Susan Leo at [email protected] to discuss your project requirements. Our advanced manufacturing facility in Shenzhen delivers high-accuracy components with fast turnaround times. Let Honyo Prototype be your trusted partner for quality and efficiency in CNC wood turning. Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.