Introduction: Navigating the Global Market for cnc wood turning

Navigating the complex landscape of CNC wood turning can be a daunting challenge for international B2B buyers, particularly those seeking to source high-quality machinery and materials that meet their specific needs. As demand for precision-crafted wooden products rises globally, understanding the nuances of CNC wood turning technology becomes essential for businesses in regions such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Nigeria. This guide serves as a comprehensive resource, covering various types of CNC wood lathes, their applications, supplier vetting processes, and cost considerations.

By delving into the intricacies of CNC wood turning, this guide empowers buyers to make informed purchasing decisions that align with their operational goals and budgetary constraints. From distinguishing between hobbyist and industrial-grade machines to evaluating the latest technological advancements, readers will gain critical insights into optimizing their sourcing strategies. Additionally, understanding the global market dynamics will enable businesses to identify reliable suppliers and negotiate favorable terms, ultimately enhancing their competitive edge in the woodworking industry. Whether you are looking to automate your production line or explore new design possibilities, this guide will equip you with the knowledge necessary to navigate the global market effectively.

Understanding cnc wood turning Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automatic CNC Wood Lathe | Computer-controlled, high precision, various tooling options | Furniture manufacturing, custom wood products | Pros: High efficiency, consistent quality. Cons: Higher initial investment. |

| Multi-Spindle CNC Lathe | Capable of performing multiple operations simultaneously | Mass production of identical items | Pros: Increased productivity, reduced labor costs. Cons: Complexity in setup and maintenance. |

| 4-Axis CNC Wood Lathe | Allows for more complex shapes and designs, including 3D turning | Artistic woodturning, custom designs | Pros: Versatile applications, enhanced creativity. Cons: Requires skilled operators. |

| Mini Benchtop CNC Lathe | Compact size, ideal for small projects and hobbyists | Craftsmanship, small-scale production | Pros: Affordable, user-friendly. Cons: Limited capacity and features. |

| Self-Feeding CNC Lathe | Automatic loading and centering of wood pieces | Batch production of uniform designs | Pros: Reduced manual labor, efficient for high volume. Cons: Potentially higher maintenance needs. |

What Are the Key Characteristics of Automatic CNC Wood Lathes?

Automatic CNC wood lathes are designed for high precision and efficiency, utilizing computer numerical control to automate the turning process. These machines can handle various tooling options, making them suitable for diverse applications, from furniture manufacturing to custom wood products. When considering an automatic CNC lathe, buyers should evaluate factors such as spindle speed, bed length, and tooling compatibility to ensure it meets their production needs.

How Do Multi-Spindle CNC Lathes Enhance Production Efficiency?

Multi-spindle CNC lathes are engineered to perform multiple operations at once, significantly boosting productivity. This type is particularly advantageous for mass production, where identical items are required, such as furniture legs or spindles. Buyers should assess the machine’s setup complexity and maintenance requirements, as these can affect long-term operational costs and efficiency.

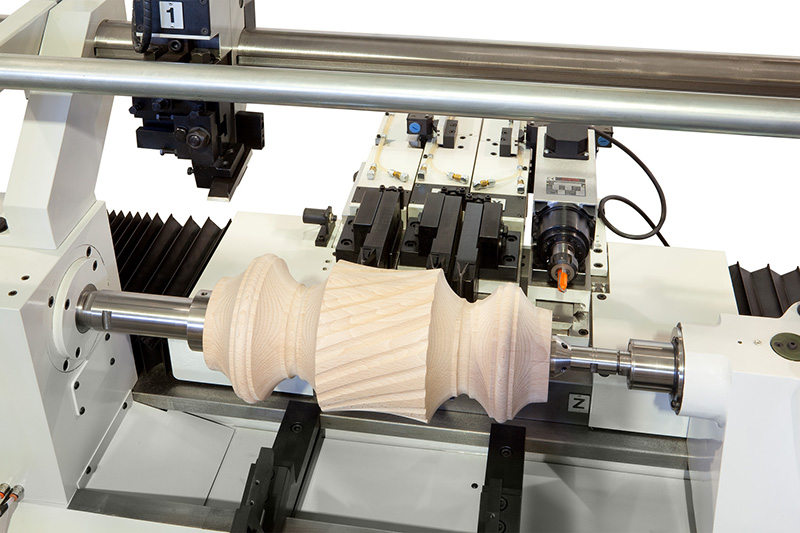

What Makes 4-Axis CNC Wood Lathes Suitable for Artistic Applications?

4-axis CNC wood lathes provide the capability to create intricate designs and shapes, making them ideal for artistic woodturning and custom projects. These machines can perform 3D turning, which allows for more creative freedom in design. When purchasing, businesses should consider the level of operator skill required and the types of projects they intend to undertake, as this will influence the machine’s effectiveness.

Why Choose Mini Benchtop CNC Lathes for Small-Scale Production?

Mini benchtop CNC lathes are compact and user-friendly, making them perfect for hobbyists and small-scale production. These machines are typically more affordable and suitable for crafting smaller items, such as decorative pieces and crafts. However, buyers should be aware of their limited capacity and features, which may not meet the demands of larger production runs.

What Are the Advantages of Self-Feeding CNC Lathes in Batch Production?

Self-feeding CNC lathes automate the loading and centering of wood pieces, making them highly efficient for batch production of uniform designs. This feature reduces manual labor and enhances production speed, making it a valuable investment for businesses focused on high-volume outputs. Buyers should also consider the potential for increased maintenance needs due to the automated systems involved.

Key Industrial Applications of cnc wood turning

| Industry/Sector | Specific Application of CNC Wood Turning | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Production of Table Legs and Furniture Components | Ensures consistent quality and precision, reducing material waste. | Machine capacity, speed, and compatibility with various wood types. |

| Musical Instruments | Crafting Wooden Instrument Bodies | Enables high-quality, intricate designs that enhance sound quality. | Precision requirements, tooling options, and customization capabilities. |

| Automotive Accessories | Manufacturing Wooden Steering Wheels | Provides unique aesthetics and ergonomic design for comfort. | Material sourcing, durability testing, and design flexibility. |

| Home Décor and Crafts | Creating Decorative Bowls and Vases | Allows for unique, custom designs that attract premium pricing. | Variety of lathe features, ease of use, and support for small batches. |

| Construction and Carpentry | Producing Architectural Millwork | Facilitates rapid production of custom architectural features. | Tolerance levels, machine size, and integration with CAD software. |

How Is CNC Wood Turning Used in Furniture Manufacturing?

In the furniture manufacturing sector, CNC wood turning is widely employed for producing components such as table legs and intricate furniture parts. By utilizing CNC technology, manufacturers can ensure uniformity and precision in each piece, significantly reducing material waste and production costs. International buyers, especially from regions like Africa and South America, should consider sourcing machines that can handle various wood types and offer sufficient capacity to meet their production needs.

What Role Does CNC Wood Turning Play in Musical Instrument Crafting?

CNC wood turning is crucial in the musical instrument industry, particularly for crafting wooden bodies of instruments like guitars and violins. This technology allows for the creation of complex shapes and designs that enhance the aesthetic and acoustic properties of the instruments. Buyers must focus on precision requirements and tooling options to ensure that the final products meet high-quality standards while also considering the unique characteristics of different wood species.

How Is CNC Wood Turning Beneficial for Automotive Accessories?

In the automotive accessories sector, CNC wood turning is utilized to manufacture unique wooden steering wheels and other interior features. This application not only adds a distinct aesthetic appeal but also improves ergonomic comfort for drivers. Businesses should evaluate the durability of materials used and the flexibility of design options when sourcing CNC machines for these applications, particularly in the Middle Eastern and European markets where customization is highly valued.

Why Is CNC Wood Turning Important for Home Décor and Crafts?

CNC wood turning is increasingly popular in the home décor and crafts industry, where artisans create decorative bowls, vases, and other unique items. The precision and efficiency of CNC technology allow for intricate designs that can command higher prices in the market. Buyers should look for machines that offer a variety of lathe features and are user-friendly, as many artisans may be small businesses or hobbyists seeking to scale their production.

How Does CNC Wood Turning Enhance Construction and Carpentry?

In construction and carpentry, CNC wood turning is used for producing architectural millwork, such as custom moldings and decorative features. This technology enables rapid production while maintaining high precision, which is essential for fitting elements in construction projects. Buyers should prioritize machines with high tolerance levels and the ability to integrate seamlessly with CAD software to streamline their design and production processes.

3 Common User Pain Points for ‘cnc wood turning’ & Their Solutions

Scenario 1: Navigating High Initial Investment Costs in CNC Wood Turning

The Problem: One of the most significant hurdles for B2B buyers in the CNC wood turning sector is the high initial investment required for purchasing advanced machines. Many businesses, particularly small to medium-sized enterprises in regions like Africa and South America, struggle to allocate sufficient capital for quality CNC wood lathes that can meet their production needs. This often leads to hesitation in upgrading from manual to automated systems, limiting their ability to scale operations and improve efficiency.

The Solution: To address the financial constraints associated with acquiring CNC wood turning machines, buyers should explore various financing options available in the market. Leasing CNC equipment can be a viable alternative, allowing businesses to utilize advanced technology without the burden of full upfront costs. Additionally, buyers should consider collaborating with manufacturers that offer flexible payment plans or financing partnerships. By carefully assessing different models, opting for machines that align with their specific production needs, and utilizing cost-effective CNC solutions, businesses can achieve a balance between affordability and efficiency. Researching and participating in industry trade shows can also provide insights into budget-friendly options and potential discounts.

Scenario 2: Overcoming Skills Gaps in CNC Wood Turning Operations

The Problem: Another prevalent challenge for B2B buyers in CNC wood turning is the skills gap within their workforce. Many companies find it difficult to hire or retain skilled operators who can effectively manage CNC machines. This issue is exacerbated in regions with limited access to technical training programs or educational resources, making it challenging to harness the full potential of CNC technology.

The Solution: To bridge this skills gap, companies should invest in comprehensive training programs for their existing workforce. Collaborating with local vocational schools or technical colleges to create tailored training modules on CNC wood turning can enhance the skill set of employees. Additionally, manufacturers often provide training sessions as part of the machine purchase; businesses should take advantage of these resources to ensure operators are proficient in using the equipment. Implementing a mentorship program where experienced operators guide novices can also foster knowledge transfer and improve overall operational efficiency. Furthermore, creating an engaging workplace culture that values continuous learning and skill development can help retain talent.

Scenario 3: Ensuring Precision and Consistency in CNC Wood Turning Production

The Problem: Achieving precision and consistency in CNC wood turning is crucial for maintaining product quality. B2B buyers often encounter challenges related to machine calibration, tool wear, and material variability, which can lead to defects and increased waste. Inconsistent output not only affects customer satisfaction but also increases production costs, posing a significant challenge for businesses aiming for competitiveness in the market.

The Solution: To mitigate these issues, it is essential for businesses to implement a robust quality control system that includes regular machine maintenance and calibration checks. Establishing a routine schedule for inspecting tools and replacing them when necessary can prevent inconsistencies caused by tool wear. Additionally, investing in advanced CNC wood lathes equipped with real-time monitoring systems can provide immediate feedback on production processes, allowing for quick adjustments. Companies should also standardize their material specifications to minimize variability, ensuring that all inputs meet the required quality standards. Training staff on best practices for operating CNC machines and understanding the importance of precision can further enhance output consistency, leading to improved product quality and customer satisfaction.

Strategic Material Selection Guide for cnc wood turning

What Are the Key Materials Used in CNC Wood Turning?

CNC wood turning relies on a variety of materials, each with unique properties that affect the performance, cost, and suitability of the final products. Understanding these materials is crucial for international B2B buyers looking to optimize their production processes and meet market demands.

Which Wood Types Are Commonly Used in CNC Wood Turning?

-

Hardwoods (e.g., Oak, Maple, Cherry)

– Key Properties: Hardwoods are known for their density and durability, providing excellent resistance to wear and tear. They can withstand high temperatures and pressures during machining.

– Pros & Cons: Hardwoods offer superior aesthetics and finish quality, making them ideal for high-end furniture and decorative items. However, they are generally more expensive and can be more challenging to machine due to their density.

– Impact on Application: Hardwoods are compatible with a variety of finishes, enhancing their appeal in luxury markets. Their durability makes them suitable for products requiring longevity.

– Considerations for International Buyers: Compliance with international standards (e.g., ASTM D198, DIN 68800) is essential, especially regarding sourcing sustainably harvested wood. Buyers should also consider regional preferences for specific wood species. -

Softwoods (e.g., Pine, Cedar, Fir)

– Key Properties: Softwoods are lighter and easier to work with compared to hardwoods. They typically have a lower density, which can lead to faster machining speeds.

– Pros & Cons: Softwoods are usually more cost-effective and suitable for mass production. However, they may not provide the same level of durability and aesthetic appeal as hardwoods, making them less desirable for high-end applications.

– Impact on Application: Softwoods are commonly used in applications where weight is a concern, such as in the production of lightweight furniture or decorative items.

– Considerations for International Buyers: Buyers should be aware of local regulations regarding the sourcing of softwoods, particularly in regions where pests and diseases can affect timber quality. -

Plywood and Laminated Wood

– Key Properties: Plywood is made from thin layers of wood veneer glued together, providing enhanced strength and stability. It resists warping and cracking better than solid wood.

– Pros & Cons: Plywood is versatile and can be produced in large sheets, making it suitable for various applications. However, the quality can vary based on the adhesive used and the manufacturing process.

– Impact on Application: Plywood is ideal for applications requiring large, flat surfaces, such as cabinetry and furniture. Its layered structure allows for intricate designs in CNC wood turning.

– Considerations for International Buyers: Compliance with adhesive standards (e.g., JIS A 5908) is crucial to ensure product safety and durability. Buyers should also consider the environmental impact of the adhesives used in plywood manufacturing. -

Composite Materials (e.g., MDF, HDF)

– Key Properties: Medium Density Fiberboard (MDF) and High-Density Fiberboard (HDF) are engineered wood products made from wood fibers, wax, and resin. They offer uniform density and smooth surfaces for machining.

– Pros & Cons: Composites are cost-effective and can be easily machined into complex shapes. However, they may not be as durable as solid wood and can be susceptible to moisture damage.

– Impact on Application: Composites are often used in applications where a smooth finish is required, such as in cabinetry and decorative moldings.

– Considerations for International Buyers: Buyers should check for compliance with international standards regarding formaldehyde emissions (e.g., CARB Phase 2, EPA TSCA Title VI) to ensure safety and environmental responsibility.

Summary Table of Material Selection for CNC Wood Turning

| Material | Typical Use Case for CNC Wood Turning | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Hardwoods | High-end furniture, decorative items | Superior aesthetics and durability | Higher cost and machining complexity | High |

| Softwoods | Lightweight furniture, decorative items | Cost-effective and easy to machine | Less durable than hardwoods | Low |

| Plywood and Laminated Wood | Cabinetry, furniture | Enhanced strength and stability | Quality can vary based on adhesives | Medium |

| Composite Materials | Cabinetry, decorative moldings | Uniform density and smooth finish | Susceptible to moisture damage | Low |

This comprehensive analysis of materials for CNC wood turning equips international B2B buyers with the insights necessary to make informed decisions, ensuring that their product offerings meet both market demands and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc wood turning

What Are the Main Stages in the Manufacturing Process of CNC Wood Turning?

The manufacturing process for CNC wood turning typically encompasses several key stages: material preparation, forming, assembly, and finishing. Each of these stages plays a crucial role in ensuring that the final product meets the desired specifications and quality standards.

Material Preparation: How Is Raw Material Selected and Processed?

Material selection is the first step in CNC wood turning. Common materials include hardwoods, softwoods, and engineered woods, each offering unique properties suited for different applications. Buyers should consider factors such as wood grain, density, and moisture content when selecting materials.

Once selected, the raw materials undergo preparation, which involves cutting them to the required dimensions and moisture conditioning to prevent warping during processing. This stage may also include quality checks to ensure that the wood is free from defects, such as knots or cracks, which could affect the integrity of the final product.

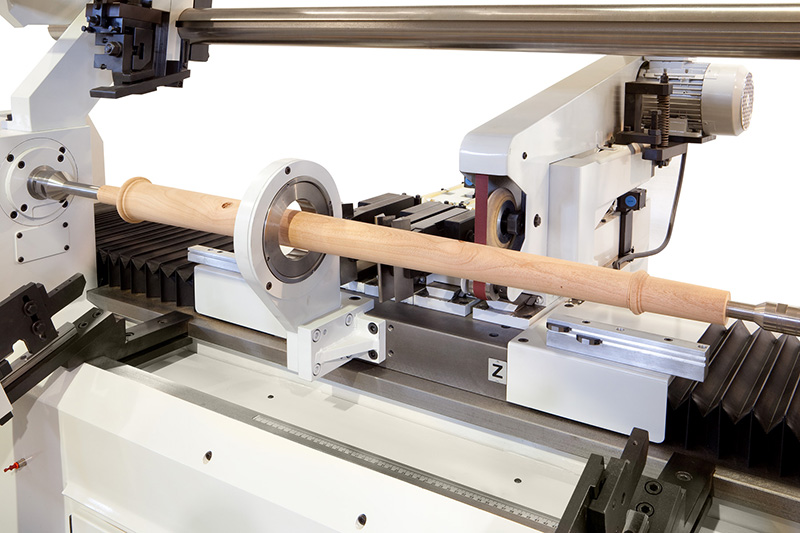

What Techniques Are Used in the Forming Stage?

The forming stage is where CNC wood turning truly comes into play. Using computer numerical control (CNC) technology, a programmed lathe precisely shapes the wood. The key techniques include:

- Turning: The workpiece is rotated against a stationary cutting tool, allowing for the creation of symmetrical shapes.

- Facing: This technique flattens the ends of the wood to create a smooth surface.

- Boring and Drilling: These processes create holes of various diameters and depths, essential for components requiring fasteners or fittings.

CNC technology ensures consistency and accuracy, which are critical for mass production. The use of CAD/CAM software allows for complex designs to be easily replicated, reducing lead times and minimizing human error.

How Is Assembly Handled in CNC Wood Turning?

In many cases, CNC wood turning products are part of a larger assembly. The assembly stage involves the integration of various components, such as fittings or hardware, to create a finished product. This can include:

- Joining: Techniques such as doweling, gluing, or using screws to assemble multiple parts.

- Alignment: Ensuring that all components fit together properly to maintain the structural integrity of the product.

Efficient assembly processes can significantly impact production timelines and costs, making it essential for manufacturers to optimize this stage.

What Finishing Techniques Are Applied Post-Manufacturing?

The finishing stage includes treatments that enhance the aesthetic appeal and durability of the wood product. Common techniques involve:

- Sanding: This process smoothens the surface, preparing it for further treatment.

- Staining and Sealing: These treatments add color and protect the wood from moisture and damage.

- Coating: Applying varnishes or lacquers can provide a glossy finish and enhance the product’s lifespan.

Quality assurance during the finishing stage is crucial, as it directly affects customer satisfaction and the product’s marketability.

What Quality Assurance Measures Are Essential in CNC Wood Turning?

Quality assurance (QA) is integral to the CNC wood turning process, ensuring that products meet international and industry-specific standards. Buyers should be aware of the various QA measures that manufacturers implement.

Which International Standards Should Be Considered for CNC Wood Turning?

Manufacturers often adhere to international standards such as ISO 9001, which outlines quality management systems. Compliance with these standards indicates a commitment to quality and customer satisfaction. Other relevant certifications may include:

- CE Marking: Signifies that products meet EU safety, health, and environmental protection standards.

- API Certification: Relevant for products used in the oil and gas industry, ensuring they meet specific quality and safety criteria.

Understanding these certifications can help B2B buyers assess the reliability and credibility of potential suppliers.

What Are the Key Quality Control Checkpoints in CNC Wood Turning?

Quality control checkpoints are crucial for maintaining product integrity throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials before production to ensure they meet specifications.

- In-Process Quality Control (IPQC): Conducted during manufacturing, this phase includes monitoring processes and conducting tests to catch defects early.

- Final Quality Control (FQC): This final inspection stage ensures that the finished product meets all specifications and standards before shipment.

Implementing these checkpoints can significantly reduce the risk of defects and enhance overall product quality.

What Common Testing Methods Are Used in CNC Wood Turning Quality Assurance?

Common testing methods employed during quality assurance include:

- Dimensional Testing: Ensures that the product meets specified measurements and tolerances.

- Visual Inspection: A thorough examination for surface defects, color consistency, and overall appearance.

- Performance Testing: Evaluates the product’s functionality and durability under various conditions.

These testing methods provide critical insights into the quality of the final product and help in making necessary adjustments before delivery.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential to ensure reliable partnerships. Here are several strategies:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturer’s quality management systems and processes firsthand.

- Quality Reports: Requesting detailed quality assurance reports can provide insights into the supplier’s QC practices and product history.

- Third-Party Inspections: Engaging independent inspection agencies can offer unbiased assessments of product quality and compliance with standards.

Buyers should not only focus on the initial product quality but also evaluate the supplier’s ongoing commitment to maintaining high standards.

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers should be aware of specific nuances related to quality control that may vary by region. For example, certifications recognized in Europe may differ from those in Africa or South America. Understanding these regional differences can help buyers make informed decisions when selecting suppliers.

Additionally, buyers should consider language barriers, cultural differences in business practices, and the potential for varying levels of regulatory compliance. Establishing clear communication and expectations can mitigate misunderstandings and foster successful partnerships.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures in CNC wood turning is essential for B2B buyers. By focusing on these aspects, businesses can ensure they partner with reliable suppliers capable of delivering high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc wood turning’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers interested in procuring CNC wood turning solutions. Whether you are an established manufacturer or a startup, this guide will help you navigate the complexities of sourcing CNC wood lathes, ensuring you make informed decisions that align with your business needs.

1. Define Your Technical Specifications

Before engaging with suppliers, clearly outline your technical requirements. Consider the types of wood products you intend to manufacture and the specific features you need in a CNC wood lathe, such as spindle speed, axis capabilities (2-axis, 4-axis, etc.), and automation levels. This step is crucial as it will guide your supplier selection and ensure the machinery meets your production goals.

2. Research Potential Suppliers

Conduct thorough research to identify potential suppliers of CNC wood turning machines. Look for companies with a solid reputation in the industry, especially those that cater to international markets, as they are more likely to understand your specific needs. Use platforms like industry trade shows, online directories, and trade associations to compile a list of credible suppliers.

3. ✅ Verify Supplier Certifications

Ensure that the suppliers you consider possess relevant certifications and compliance with international standards. Certifications such as ISO 9001 for quality management or CE marking for safety can indicate a supplier’s commitment to quality and reliability. This verification process helps mitigate risks associated with equipment performance and safety.

4. Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations that include pricing, lead times, and warranty conditions. Pay close attention to the specifications outlined in the quote to ensure they align with your requirements. A comprehensive quotation will allow you to make accurate comparisons and assess the value offered by each supplier.

5. Evaluate After-Sales Support and Training

Inquire about the after-sales services provided by the suppliers, such as installation, maintenance, and operator training. A supplier that offers robust support can significantly reduce downtime and enhance the efficiency of your operations. Ensure that the training provided is tailored to your team’s skill level, enabling them to maximize the use of the CNC wood lathe.

6. Check Customer References and Case Studies

Request references from previous customers who have procured similar CNC wood turning machines. Speaking directly with these clients can provide invaluable insights into the supplier’s reliability, service quality, and machine performance. Additionally, ask for case studies that demonstrate how the supplier has successfully addressed challenges similar to yours.

7. Negotiate Terms and Finalize the Agreement

Once you have selected a supplier, negotiate terms that suit your business needs, including payment schedules, delivery timelines, and service agreements. Ensure all agreements are documented clearly to avoid any misunderstandings later. A well-negotiated contract will protect your interests and establish a solid foundation for a long-term business relationship.

By following these steps, you can confidently navigate the sourcing process for CNC wood turning solutions, ensuring that you select the best equipment to enhance your production capabilities.

Comprehensive Cost and Pricing Analysis for cnc wood turning Sourcing

What Are the Key Cost Components in CNC Wood Turning?

Understanding the cost structure of CNC wood turning is crucial for international B2B buyers. The main cost components include:

-

Materials: The choice of wood species significantly impacts costs. Common materials like pine are more affordable than exotic woods like mahogany or teak. Additionally, the quality of the wood (e.g., sustainably sourced or certified) can also elevate costs.

-

Labor: While CNC machines automate much of the wood turning process, skilled labor is still necessary for setup, programming, and maintenance. Labor costs can vary widely by region; for instance, labor in Europe may be more expensive than in parts of Africa or South America.

-

Manufacturing Overhead: This includes expenses related to the operation of machinery, utilities, rent, and administrative costs. Efficient production processes can help minimize overhead, leading to more competitive pricing.

-

Tooling: Cutting tools and fixtures are essential for CNC operations. The quality and type of tooling can affect both the initial investment and ongoing costs. High-quality tools may have a higher upfront cost but can lead to better production efficiency and lower long-term expenses.

-

Quality Control (QC): Ensuring that finished products meet specifications requires a dedicated QC process. This can involve additional labor costs and equipment, but it is crucial for maintaining product quality and customer satisfaction.

-

Logistics: Shipping costs, customs duties, and insurance are vital factors, especially for international buyers. These costs can fluctuate based on the origin and destination of the materials or finished products.

-

Margin: Suppliers typically add a profit margin to cover their costs and generate profit. Understanding this margin can help buyers negotiate better deals.

How Do Price Influencers Affect CNC Wood Turning Costs?

Several factors can influence the pricing of CNC wood turning services:

-

Volume and Minimum Order Quantity (MOQ): Larger orders generally attract lower per-unit costs due to economies of scale. Buyers should consider negotiating MOQs that align with their production needs to optimize costs.

-

Specifications and Customization: Customized designs or intricate specifications can lead to higher costs. Buyers should clearly outline their requirements to avoid unexpected charges.

-

Materials: The choice of materials not only affects the initial price but also influences production time and tooling wear. Understanding the material’s properties can help in making cost-effective choices.

-

Quality and Certifications: Products that require specific certifications (e.g., FSC certification for sustainable wood) may incur additional costs. Buyers should assess the need for certifications based on market demands.

-

Supplier Factors: The reputation, location, and reliability of suppliers can impact pricing. Established suppliers may charge more but often offer better quality assurance and reliability.

-

Incoterms: Familiarity with Incoterms is crucial for international transactions. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect total costs.

What Are the Best Tips for Negotiating CNC Wood Turning Prices?

International buyers should adopt strategic approaches to ensure cost-efficiency in sourcing CNC wood turning services:

-

Negotiate Wisely: Leverage volume commitments and long-term partnerships to negotiate better pricing. Suppliers may offer discounts for bulk purchases or repeat business.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also ongoing costs such as maintenance, logistics, and potential downtime. A slightly higher initial price might lead to lower overall costs.

-

Understand Pricing Nuances: Prices may vary based on regional economic conditions, currency fluctuations, and shipping costs. Being informed about these factors can enhance negotiation leverage.

-

Research Market Trends: Keeping abreast of industry trends and competitor pricing can provide insights that strengthen negotiation positions.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing, service, and flexibility in future transactions.

In conclusion, understanding the comprehensive cost structure, price influencers, and negotiation strategies is essential for international B2B buyers seeking CNC wood turning services. By making informed decisions, businesses can optimize their sourcing strategies and achieve better financial outcomes.

Alternatives Analysis: Comparing cnc wood turning With Other Solutions

Exploring Alternatives to CNC Wood Turning: A Comprehensive Comparison

In the woodworking industry, CNC wood turning is a popular method for creating precise and symmetrical wooden products. However, there are alternative technologies and methods that also serve similar purposes. Understanding the strengths and weaknesses of these alternatives can help B2B buyers make informed decisions based on their specific operational needs and budget constraints.

Comparison Table

| Comparison Aspect | CNC Wood Turning | Traditional Wood Turning | CNC Milling |

|---|---|---|---|

| Performance | High precision and repeatability | Skilled craftsmanship, variable results | Excellent for complex geometries |

| Cost | Moderate to high initial investment | Low initial investment, high labor cost | High initial investment, cost-effective for large batches |

| Ease of Implementation | Requires CAD/CAM training | Requires skilled labor and manual tools | Requires CNC programming knowledge |

| Maintenance | Moderate maintenance needs | Low maintenance but high skill dependency | High maintenance, especially for complex machines |

| Best Use Case | Mass production of uniform items | Unique, artisanal pieces | Complex parts with intricate details |

Detailed Breakdown of Alternatives

Traditional Wood Turning

Traditional wood turning involves using manual lathes operated by skilled artisans. This method is characterized by the craftsmanship involved, allowing for unique, one-of-a-kind pieces that can reflect the artisan’s style. However, the performance can vary widely based on the skill level of the operator, leading to inconsistencies in product quality. While the initial investment is lower compared to CNC options, labor costs can be significant, particularly for larger production runs. Traditional wood turning is best suited for custom, artisanal pieces where individuality and craftsmanship are valued over uniformity.

CNC Milling

CNC milling is another alternative that utilizes computer-controlled machines to remove material from a workpiece. This method excels in producing complex geometries and intricate designs, making it a great choice for projects requiring detailed specifications. However, CNC milling typically comes with a higher initial investment compared to traditional wood turning and may require more extensive training for operators. While it can be cost-effective for mass production, the maintenance demands can also be significant, especially for advanced milling machines. CNC milling is ideal for manufacturers looking to produce intricate parts at scale while maintaining high precision.

Conclusion: How to Choose the Right Solution for Your Needs

When considering alternatives to CNC wood turning, B2B buyers should evaluate their specific production requirements, budget constraints, and desired product outcomes. If the goal is to create uniform, high-precision items at scale, CNC wood turning remains an excellent choice. However, for businesses focusing on unique, custom pieces, traditional wood turning may be more appropriate despite its labor costs. On the other hand, if complex designs are essential, CNC milling could provide the best solution, albeit at a higher initial investment. Ultimately, the choice will depend on balancing precision, cost, and the desired level of craftsmanship in the final products.

Essential Technical Properties and Trade Terminology for cnc wood turning

What Are the Key Technical Properties in CNC Wood Turning?

When evaluating CNC wood turning machines, understanding critical specifications is essential for making informed purchasing decisions. Here are some of the key technical properties to consider:

1. Material Grade

Material grade indicates the quality and type of materials used in the construction of CNC wood lathes. Common materials include high-speed steel (HSS) or carbide for cutting tools. Higher-grade materials ensure longevity and resistance to wear, reducing the need for frequent replacements. For B2B buyers, investing in machines with superior material grades translates to lower operational costs and increased productivity over time.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension of a part. In CNC wood turning, tight tolerances (e.g., ±0.1 mm) are crucial for ensuring that the finished product meets design specifications. This is particularly important for industries requiring high precision, such as furniture manufacturing or intricate craft projects. A machine’s ability to maintain tight tolerances can significantly affect product quality and customer satisfaction.

3. Maximum Workpiece Size

The maximum workpiece size defines the largest dimensions of the material that can be processed by the CNC lathe. This specification includes maximum diameter and length capabilities. Understanding these limits is vital for businesses, as they dictate the scope of projects the lathe can handle. Buyers should assess their production needs to ensure that the machine can accommodate the sizes of the wood products they intend to manufacture.

4. Power Rating

Power rating, typically measured in horsepower (HP), indicates the motor’s capability to perform tasks efficiently. A higher power rating enables the lathe to handle tougher materials and larger workpieces without sacrificing performance. For B2B operations, selecting a machine with adequate power can lead to faster cycle times and improved overall productivity, which is essential for meeting market demands.

5. Axis Configuration

The axis configuration of a CNC lathe—such as 3-axis or 4-axis—determines the complexity of the shapes it can produce. A 3-axis machine is suitable for simpler designs, while a 4-axis machine can perform more intricate tasks, including complex carvings and designs. Understanding the required axis configuration is essential for businesses looking to expand their product offerings or improve design capabilities.

What Are Common Trade Terms in CNC Wood Turning?

Familiarity with industry jargon can enhance communication and negotiation with suppliers. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In CNC wood turning, partnering with an OEM can provide businesses access to specialized machinery or components tailored to specific needs. This collaboration can result in unique product offerings and competitive advantages.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQs is crucial for B2B buyers, especially when budgeting for initial investments in CNC machinery or components. Balancing MOQ with production needs can help manage inventory costs and ensure that capital is effectively utilized.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a detailed quote for specific products or services. For businesses in the CNC wood turning sector, sending RFQs can streamline the procurement process and ensure competitive pricing. This practice is essential for maintaining cost-efficiency in production.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers regarding shipping and delivery. Understanding these terms is vital for B2B transactions, as they clarify who bears the risk and costs at various stages of transport. Proper knowledge of Incoterms can prevent misunderstandings and ensure smoother international trade operations.

5. CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing)

CAD refers to software used for designing products, while CAM refers to software that controls manufacturing processes. In CNC wood turning, integrating CAD/CAM systems enhances design precision and automates production, significantly improving efficiency. For B2B buyers, investing in compatible CAD/CAM technology can lead to higher-quality outputs and reduced lead times.

By understanding these essential technical properties and trade terminology, international B2B buyers can make informed decisions, negotiate effectively, and ultimately enhance their woodworking operations.

Navigating Market Dynamics and Sourcing Trends in the cnc wood turning Sector

What Are the Key Market Dynamics and Trends Influencing CNC Wood Turning?

The CNC wood turning sector is experiencing significant transformation driven by globalization, technological advancements, and changing consumer preferences. Key trends include the increasing adoption of automated machinery, which enhances production efficiency and precision. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek to optimize their operations, the demand for versatile CNC wood lathes that can handle various applications—from crafting furniture to producing intricate art pieces—is on the rise.

Emerging technologies such as IoT integration and artificial intelligence are reshaping sourcing strategies, enabling manufacturers to streamline production processes and improve supply chain transparency. Moreover, the shift towards digital platforms for procurement is facilitating faster decision-making and enhancing access to a broader range of suppliers. Buyers are increasingly leveraging online configurators and real-time pricing tools, making it essential for suppliers to maintain competitive pricing and high-quality offerings.

In addition, sustainability is becoming a core concern for many businesses. As environmental regulations tighten globally, companies are prioritizing sourcing practices that minimize waste and utilize renewable materials. This trend not only helps in compliance but also enhances brand reputation, appealing to environmentally conscious consumers.

How Can Sustainability and Ethical Sourcing Impact CNC Wood Turning?

Sustainability is a critical factor in the CNC wood turning industry, influencing both purchasing decisions and manufacturing processes. The environmental impact of wood sourcing is significant, with deforestation and habitat destruction posing major concerns. As a result, B2B buyers are increasingly looking for suppliers who can demonstrate a commitment to sustainable practices. This includes sourcing wood from certified forests and employing eco-friendly machining processes that reduce waste and energy consumption.

Ethical supply chains are essential for ensuring that materials are sourced responsibly. Buyers should prioritize suppliers with certifications such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification), which guarantee that wood products come from sustainably managed forests. Additionally, the use of reclaimed or recycled wood is gaining traction as a viable alternative, offering both environmental benefits and unique aesthetic qualities.

Investing in ‘green’ technologies, such as energy-efficient CNC machines and biodegradable lubricants, can further enhance sustainability efforts. By aligning their sourcing strategies with environmental considerations, businesses can not only reduce their ecological footprint but also attract a growing segment of eco-conscious customers.

What Is the Evolution of CNC Wood Turning and Its Relevance Today?

CNC wood turning has evolved significantly since its inception in the late 20th century. Originally reliant on manual operations, the introduction of computer numerical control technology revolutionized the industry, enabling precision machining and automated processes. This shift allowed for greater consistency and efficiency, which are vital in meeting the demands of modern manufacturing.

Today, CNC wood turning machines are equipped with advanced features such as multi-axis capabilities and automatic tool changers, further enhancing their versatility. This evolution has made CNC wood turning accessible not only to large-scale manufacturers but also to small businesses and hobbyists, democratizing the market. As the technology continues to advance, the sector is poised for further growth, driven by innovations that cater to the diverse needs of international B2B buyers.

In conclusion, understanding the dynamics of the CNC wood turning market, alongside sustainability and ethical sourcing practices, is crucial for buyers seeking to navigate this complex landscape effectively. By aligning their strategies with current trends, businesses can ensure they remain competitive while contributing positively to the environment.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc wood turning

-

How do I choose the right CNC wood turning lathe for my business?

Choosing the right CNC wood turning lathe depends on your specific needs, including the types of products you plan to manufacture and your production volume. Consider factors such as the machine’s size, versatility (e.g., multi-axis capabilities), and the materials it can handle. Additionally, evaluate the machine’s automation features to ensure they align with your workflow. Look for suppliers who provide detailed specifications and support for installation and training, which can significantly ease the transition to CNC technology. -

What are the common applications of CNC wood turning machines?

CNC wood turning machines are widely used in various applications, including the production of furniture components, decorative items, and custom wood crafts. They excel in creating symmetrical objects such as table legs, bowls, vases, and spindles. Additionally, advanced CNC lathes can perform complex tasks like milling, grooving, and embossing, making them ideal for both hobbyists and industrial manufacturers looking to streamline production and improve precision. -

What should I consider when vetting CNC wood turning suppliers?

When vetting suppliers for CNC wood turning machines, consider their reputation, experience, and customer reviews. Look for suppliers that provide comprehensive technical support, training, and after-sales services. Verify their certifications and compliance with international quality standards, which can ensure reliability and safety. Additionally, assess their ability to customize machines to meet your specific production needs and their responsiveness to inquiries and requests for information. -

What are the typical minimum order quantities (MOQs) for CNC wood turning machines?

Minimum order quantities can vary significantly among suppliers, with some offering single units while others may have higher MOQs. Generally, industrial suppliers may require higher MOQs due to the cost of production and shipping. However, many suppliers are willing to negotiate, especially for first-time buyers or long-term partnerships. It’s advisable to discuss your specific needs with potential suppliers to find a mutually beneficial arrangement. -

How can I ensure quality assurance (QA) in CNC wood turning products?

To ensure quality assurance in CNC wood turning products, establish clear specifications and tolerances with your supplier before production begins. Request samples or prototypes to evaluate the machining quality and accuracy. Implement regular quality checks throughout the production process, and consider third-party inspections if you’re sourcing from overseas. Establishing a solid communication channel with your supplier can also help address any quality concerns promptly. -

What payment terms are commonly offered by CNC wood turning suppliers?

Payment terms can vary widely among suppliers, but common practices include a deposit upfront, with the remaining balance due upon delivery or after inspection. Some suppliers may offer net payment terms (e.g., net 30 or net 60 days) based on your creditworthiness and relationship with them. Always clarify payment methods (e.g., wire transfer, letter of credit) and any potential additional fees to avoid misunderstandings. -

What logistics considerations should I be aware of when importing CNC wood turning machines?

Logistics considerations for importing CNC wood turning machines include shipping methods, customs regulations, and potential tariffs or duties. Ensure your supplier provides comprehensive shipping documentation, including invoices and packing lists. It’s advisable to work with experienced freight forwarders who can help navigate international shipping complexities. Additionally, factor in lead times for production and delivery to align with your operational schedules. -

How can I customize my CNC wood turning machine for specific projects?

Customization options for CNC wood turning machines often include selecting specific tools, software configurations, and machine sizes tailored to your projects. Engage with your supplier early in the purchasing process to discuss your requirements. Many suppliers offer modular designs that can accommodate various attachments and capabilities. Ensure you communicate your production goals and any unique specifications to achieve the best results from your customized machine.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Cnc Wood Turning Manufacturers & Suppliers List

1. STYLECNC – Automatic CNC Wood Lathe Machines

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: Automatic CNC Wood Lathe Machine for Beginners & Experts – STYLECNC offers a variety of CNC wood lathes suitable for hobby and industrial use. Key models include: STL0525 ($4,780 – $6,960) for hobbyists, STL2530-S4 ($8,880 – $10,180) for 4-axis 3D turning, STL1530-S ($7,180 – $7,680) for industrial use, STL1516-3S3 ($8,780 – $9,080) for multi-spindle turning, STL0410 ($2,800 – $3,100) as a mini be…

2. CutR – Custom Wood CNC Turning Services

Domain: cutr.com

Registered: 2001 (24 years)

Introduction: Custom Wood CNC Turning service with over 50 CNC turning machines. Tolerances up to ± 0.1 mm and speeds up to 3200 RPM. Maximum part diameter of 200 mm (7.8 in) and maximum part length of 1200 mm (47.2 in). Maximum swing over the carriage is 350 mm (13.7 in) and maximum spindle through-hole is 40 mm (1.5 in). CNC turning is efficient for producing parts with symmetry on the center axis, offering f…

3. EagleTec – CNC Woodworking Lathe EA-TL1230SF

Domain: eagletec-cnc.com

Registered: 2019 (6 years)

Introduction: Model: EA-TL1230SF

Category: CNC Woodworking Lathe

Brand: EagleTec

Condition: New

Reference Price: USD8580.00 / SET

Price Range: USD8580 to USD9998 / SET

Production Capacity: 100 Sets Monthly

Lead Time: 10 to 15 days

Payment Method: T/T, Western Union, Money Gram

H.S. Code: 84659200.00

Popularity: 4.9 based on 5.0

Product Description: Fully automatic wood lathe machine with auto feed system, one …

4. Budget-Friendly CNC Controller and Software Recommendations

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: CNC Wood Lathe with approximately 1 meter work width. User is on a low budget and seeking recommendations for budget controllers and easy-to-use software. Previous experience with ArtCam noted, but requires software that can output G-code for lathe operations.

Strategic Sourcing Conclusion and Outlook for cnc wood turning

As the demand for precision and efficiency in woodworking continues to rise, strategic sourcing for CNC wood turning equipment has become a pivotal consideration for businesses worldwide. Key takeaways from this guide highlight the importance of investing in high-quality CNC wood lathes that cater to a variety of applications, from hobbyist projects to industrial-scale production. By leveraging advanced CNC technology, companies can enhance their productivity, reduce material waste, and achieve superior craftsmanship.

Moreover, understanding the specific needs of your market—whether in Africa, South America, the Middle East, or Europe—will enable you to select machines that not only meet your operational requirements but also align with regional preferences and market trends. Engaging with reputable suppliers and manufacturers can provide significant advantages in terms of pricing, support, and customization options.

Looking ahead, the future of CNC wood turning is bright, with ongoing innovations poised to further transform the industry. International B2B buyers are encouraged to seize this opportunity to optimize their sourcing strategies. By investing in state-of-the-art CNC wood turning solutions, you can position your business for sustained growth and success in an increasingly competitive landscape.