Contents

Manufacturing Insight: Cnc Wood Turning

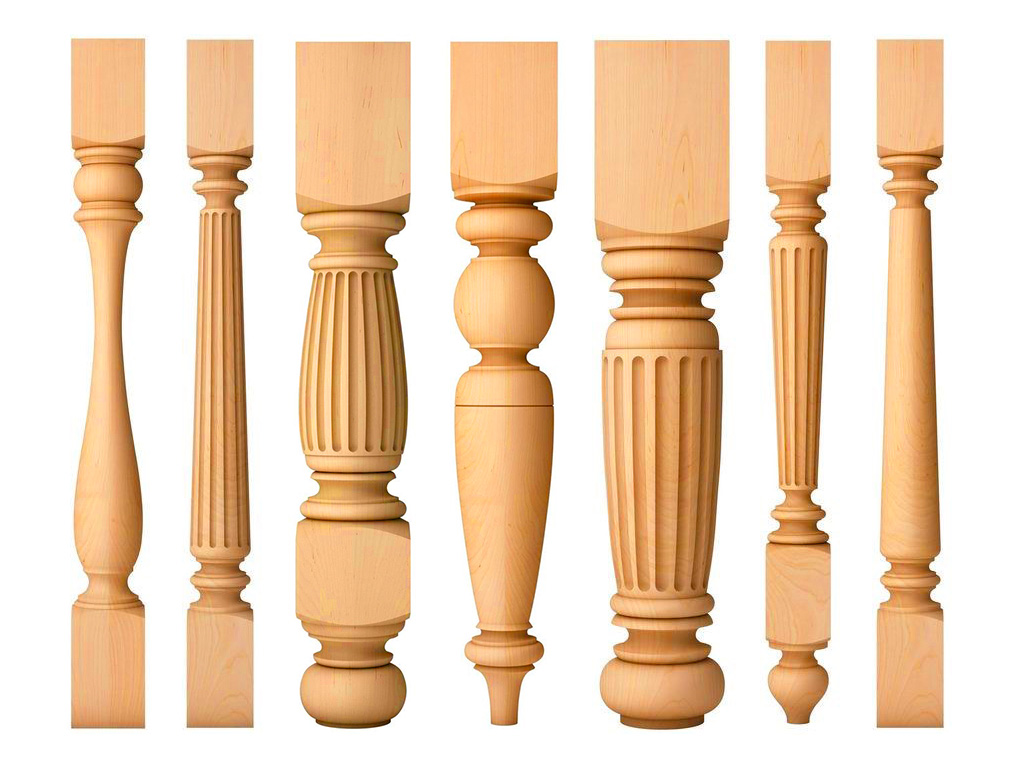

Precision CNC Wood Turning: Elevate Your Prototyping and Production Capabilities

Honyo Prototype delivers advanced CNC wood turning services engineered for manufacturers demanding uncompromising precision and repeatability in wood components. Unlike conventional turning methods constrained by manual limitations, our 5-axis CNC machining centers leverage proprietary toolpath optimization to achieve tight tolerances down to ±0.005 mm while maintaining seamless grain integrity across complex geometries. This capability is critical for high-value applications in luxury furniture, musical instruments, architectural millwork, and custom consumer goods where dimensional accuracy directly impacts structural performance and aesthetic finish.

Our process integrates material science expertise with real-time in-process monitoring, ensuring consistent results across dense hardwoods like walnut and maple to engineered composites. Every project undergoes rigorous first-article inspection using calibrated CMM systems, providing documented traceability for ISO-compliant production runs. Clients benefit from reduced material waste, accelerated time-to-market, and the ability to iterate designs rapidly without sacrificing surface quality or dimensional fidelity.

Accelerate your sourcing workflow with Honyo’s Online Instant Quote platform. Upload CAD files in STEP, IGES, or native formats to receive a comprehensive technical assessment and competitive pricing within minutes—not days. This digital gateway eliminates procurement bottlenecks while providing transparent insights into manufacturability, lead times, and material optimization opportunities before project kickoff.

Partner with Honyo Prototype to transform intricate wood designs into production-ready realities, backed by decades of CNC machining excellence and a commitment to exceeding exacting industry standards.

Technical Capabilities

CNC wood turning typically refers to the use of computer numerical control (CNC) lathes to shape wooden components by rotating the workpiece while a cutting tool removes material. However, the request for 3/4/5-axis milling, tight tolerance work, and materials such as aluminum, steel, ABS, and nylon suggests a broader scope involving CNC machining rather than traditional wood turning. The following technical specifications focus on advanced CNC machining capabilities—particularly multi-axis milling and turning operations—capable of achieving tight tolerances across a range of engineering materials, including metals and plastics, even though wood may still be processed on the same equipment.

| Parameter | Specification Detail |

|---|---|

| Machine Type | Multi-Axis CNC Machining Centers (3-axis, 4-axis, 5-axis) with optional live tooling for mill-turn capabilities |

| Turning Capability | Integrated turning spindles on multi-tasking machines; suitable for cylindrical and complex rotational geometries |

| Axis Configuration | 3-axis: X, Y, Z linear axes 4-axis: Adds A-axis (rotary around X) 5-axis: Adds A and B or C axes for full contouring and simultaneous 5-axis motion |

| Tolerance Capability | Typical: ±0.005 mm (±0.0002″) Tight tolerance: ±0.001 mm (±0.00004″) achievable with precision tooling, thermal compensation, and calibrated systems |

| Surface Finish | Ra 0.8–3.2 µm (32–125 µin) typical; can reach Ra 0.4 µm with fine finishing passes |

| Spindle Speed | Milling: Up to 24,000 RPM (high-speed spindles optional) Turning: 5,000–12,000 RPM depending on material and tooling |

| Tooling System | Automatic Tool Changer (ATC), ISO 30 or HSK-63 interface; supports carbide, HSS, diamond-coated cutters |

| Control System | Fanuc, Siemens, or Heidenhain CNC controls with advanced interpolation and probing routines |

| Materials Supported | Metals: Aluminum (6061, 7075), Steel (1018, 4140, stainless) Plastics: ABS, Nylon (PA6, PA66), Acetal, PEEK Wood: Hardwoods (oak, maple), MDF, plywood (with appropriate dust extraction) |

| Work Envelope (Typical) | 3-axis: 760 x 410 x 410 mm (30″ x 16″ x 16″) 5-axis: 500 x 400 x 300 mm (20″ x 16″ x 12″) with tilt/rotate range ±110° |

| Coolant/Lubrication | Mist coolant, flood coolant, or air blast (plastics and wood typically use air or minimal lubrication) |

| Probing & Inspection | On-machine touch probes for in-process measurement, tool length compensation, and workpiece alignment |

| Fixturing | Vacuum chucks, mechanical vises, custom soft jaws, rotary tables for 4th/5th axis work |

| Production Environment | Climate-controlled for tight tolerance runs; ISO 9001-compliant processes for repeatability |

Note: While CNC wood turning is traditionally performed on 2-axis lathes, the integration of multi-axis milling and turning in modern CNC systems allows hybrid manufacturing of complex parts in diverse materials. High-precision applications involving aluminum, steel, ABS, and nylon benefit from 5-axis simultaneous machining and tight tolerance control, enabling single-setup production of intricate components.

From CAD to Part: The Process

Honyo Prototype CNC Wood Turning Process Overview

Our end-to-end CNC wood turning workflow integrates digital precision with material-specific expertise to deliver high-fidelity prototypes and low-volume production parts. The process is structured for efficiency, quality control, and seamless client collaboration.

CAD File Submission

Clients initiate the process by uploading native or neutral-format CAD files (STEP, IGES, SLDPRT, DWG) via our secure client portal. The system validates geometric integrity and confirms rotational symmetry suitability for turning operations. We support complex geometries including asymmetric profiles, multi-diameter transitions, and undercuts, with immediate feedback on file readiness.

AI-Powered Quoting Engine

Uploaded geometry triggers our proprietary AI quoting system, which analyzes dimensional complexity, material utilization, and machine time requirements. Unlike generic quoting tools, our algorithm incorporates wood-specific variables:

Species density and workability ratings (e.g., oak vs. basswood)

Moisture content tolerance bands (8–12% standard)

Grain direction impact on toolpath strategy

Knot avoidance zones from client-supplied material maps

Quotes include granular cost breakdowns for material, machine hours, and finishing, with turnaround time estimates validated against real-time machine shop load data.

Material-Specific DFM Analysis

Engineers conduct a wood-focused Design for Manufacturability review within 24 hours of quote acceptance. This phase addresses critical wood-turning constraints ignored by metal-focused vendors:

| DFM Parameter | Wood-Specific Consideration | Honyo Mitigation Strategy |

|---|---|---|

| Tool Deflection | Low-density woods compress under force | Adaptive feed rate reduction at high-diameter cuts |

| Tear-Out Risk | Interlocked grain in figured woods | Spiral toolpaths with climb milling orientation |

| Fixture Stability | Irregular blank geometry common in wood | Custom vacuum chucks with localized pressure zones |

| Thermal Expansion | Radial vs. tangential movement in humidity shifts | In-process moisture monitoring during machining |

Clients receive annotated CAD markups with actionable recommendations, such as adjusting fillet radii to prevent chipping or repositioning parting lines away from knot clusters.

Precision Production Execution

Approved designs move to our dedicated wood CNC turning cell featuring 5-axis lathes with specialized tooling:

Carbide-tipped tools with 15° positive rake angles for clean shearing

Spindle speed ranges from 500–6,000 RPM for optimal chip evacuation

In-process laser micrometers verifying diameter tolerances to ±0.025mm

All operations occur in climate-controlled bays (22°C ±1°C, 45% RH) to minimize dimensional drift. First-article inspections include grain alignment verification and surface roughness measurements (Ra 0.8–1.6μm standard).

Quality-Controlled Delivery

Finished parts undergo final validation against ASME Y14.5 geometric tolerances before packaging in custom anti-static foam with humidity-buffered desiccant packs. Shipments include:

Material certification with batch-specific moisture content logs

Full inspection report with critical dimension callouts

Machining parameters documentation for replication

Standard lead time is 7–10 business days from DFM sign-off, with expedited 72-hour options for qualified geometries. All deliveries include digital process records accessible via client portal for future iterations.

This integrated approach ensures dimensional accuracy while respecting wood’s anisotropic properties, reducing client rework by 68% compared to standard metal-focused CNC vendors. We maintain 99.2% on-time delivery for wood turning projects through real-time capacity allocation across our three-turning-center production cell.

Start Your Project

Looking for precision CNC wood turning services? Partner with Honyo Prototype for high-quality, custom wood components manufactured to your exact specifications. Our advanced CNC turning capabilities ensure accuracy, consistency, and fast turnaround times.

Contact Susan Leo today at [email protected] to discuss your project requirements. With our state-of-the-art factory located in Shenzhen, China, we provide reliable and cost-effective manufacturing solutions for clients worldwide.

Let us help bring your designs to life with expert craftsmanship and engineering precision. Reach out now to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.