Contents

Manufacturing Insight: Cnc Wood Laser Cutter

Precision Manufacturing Solutions for Wood Components and Beyond

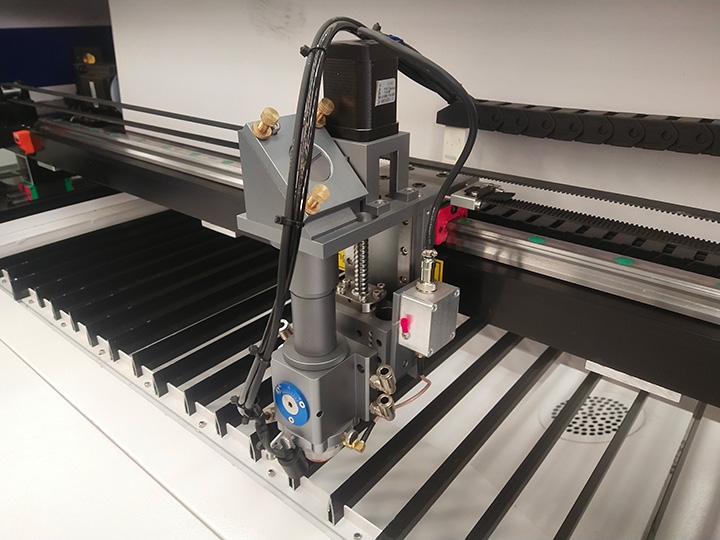

Honyo Prototype delivers advanced CNC machining services engineered to transform complex wood and composite material concepts into high-fidelity prototypes and low-volume production runs. Our integrated capabilities extend beyond traditional milling and turning to include state-of-the-art CNC wood laser cutting systems, ensuring micron-level accuracy, clean edge finishes, and intricate geometric fidelity for applications ranging from architectural models to custom furniture components and signage.

This specialized laser cutting service leverages industrial-grade CO₂ laser platforms with dynamic power control and automated material handling, enabling precise kerf management and minimal thermal distortion across hardwoods, plywood, MDF, and acrylics. When combined with our core CNC machining expertise in metals, plastics, and engineered composites, Honyo provides a unified manufacturing ecosystem that eliminates supplier fragmentation and accelerates time-to-market.

Why Choose Honyo Prototype

Engineers and product developers select Honyo for our commitment to technical rigor, material science proficiency, and seamless digital workflows. Our facility operates under stringent ISO 9001-aligned processes, with real-time in-process inspections and first-article reporting to guarantee dimensional compliance. Crucially, we eliminate pricing uncertainty through our Online Instant Quote platform—upload CAD files in STEP, IGES, or DWG formats to receive detailed, obligation-free cost and lead time estimates within minutes, not days. This transparency empowers rapid design iteration and procurement decisions without compromising on our hallmark precision or material expertise.

The following table summarizes key capabilities driving client success:

| Service Category | Technical Specifications | Typical Applications |

|---|---|---|

| CNC Wood Laser Cutting | 150W CO₂ laser, ±0.1mm accuracy, 1200x900mm bed | Architectural models, signage, custom joinery |

| Precision CNC Machining | 5-axis milling, ±0.005mm tolerance, multi-material | Automotive jigs, medical fixtures, aerospace prototypes |

| Integrated Workflow | Unified quoting, DFM analysis, <72hr prototyping | End-to-end product development |

Honyo Prototype bridges the gap between digital design and physical realization, where laser precision meets CNC versatility—all accessible through a single, responsive partner. Initiate your project with confidence using our Online Instant Quote system and experience manufacturing excellence engineered for speed and accuracy.

Technical Capabilities

The term “CNC wood laser cutter” typically refers to a machine designed for cutting wood and similar non-metallic materials using a laser. However, your request focuses on 3/4/5-axis milling, turning, and tight tolerance machining—capabilities that are characteristic of CNC milling and turning centers, not laser cutters. Additionally, the materials listed (aluminum, steel, ABS, nylon) are commonly machined using CNC milling or turning processes, not laser cutting—especially metals, which are generally not processed with standard CO₂ or fiber lasers in a “wood laser cutter” context.

To clarify and align with your technical intent, the following table outlines the technical specifications for a multi-axis CNC machining center capable of high-precision milling and turning operations on the specified materials, with tight tolerance capabilities.

| Parameter | Specification |

|---|---|

| Machine Type | 5-Axis CNC Milling and Turning Center (with optional 3/4-axis modes) |

| Spindle Speed | 10,000 – 24,000 RPM (high-speed for non-ferrous and plastics); lower for steel |

| Axis Configuration | X, Y, Z linear axes + A (rotary) and B (tilt) or C (rotary table) axes |

| Positioning Accuracy | ±0.005 mm (±0.0002 in) |

| Repeatability | ±0.002 mm (±0.0001 in) |

| Tool Changer | Automatic Tool Changer (ATC) with 16–30 tool capacity |

| Control System | Fanuc, Siemens, or Heidenhain CNC with multi-axis interpolation |

| Work Envelope (Typical) | 500 x 400 x 300 mm (X-Y-Z); customizable based on model |

| Maximum Material Diameter (Turning) | Up to 200 mm for live turning attachment |

| Cutting Tolerances | ±0.01 mm (±0.0004 in) typical; down to ±0.005 mm achievable with tight process control |

| Surface Finish (Machined) | Ra 0.8 – 3.2 µm depending on material and tooling |

| Materials Supported | Aluminum (6061, 7075), Steel (1018, 4140), Stainless Steel, ABS, Nylon, Delrin, Wood |

| Coolant System | Through-spindle coolant or mist cooling for aluminum and steel |

| Fixturing | Vacuum table, mechanical clamps, or chuck systems for turning-milling combo |

| Tooling Compatibility | End mills, drills, taps, face mills, turning inserts (ISO/ANSI standard) |

| Typical Applications | Aerospace components, medical devices, molds, high-precision prototypes |

Note: A true “laser cutter” is not suitable for machining metals like steel or aluminum with tight tolerances or for multi-axis turning operations. For high-precision work on the listed materials, a CNC machining center with multi-axis milling and turning capabilities is required. Honyo Prototype utilizes such advanced CNC systems to deliver tight-tolerance parts in aluminum, steel, ABS, and engineering plastics like nylon for demanding industrial applications.

From CAD to Part: The Process

Honyo Prototype delivers precision wood components through a streamlined digital manufacturing workflow specifically engineered for material characteristics and client efficiency. Our process begins when a client uploads their CAD file to the Honyo portal. This file undergoes immediate validation for format compatibility (STEP, IGES, DWG, DXF preferred) and geometric integrity. Crucially, we clarify that wood manufacturing employs either CNC routing/milling or CO2 laser cutting as distinct processes – CNC for intricate 3D shaping and deeper cuts, laser for high-speed 2D profiling and engraving – selected based on the part geometry and client specifications within the CAD data.

The validated CAD file triggers our proprietary AI-powered quoting engine. This system analyzes part geometry, material type (e.g., Baltic birch plywood, MDF, solid hardwood species), sheet utilization, grain orientation requirements, and process selection (CNC or laser) against real-time shop floor data. It calculates precise material consumption, machine time including wood-specific factors like feed rate optimization to prevent charring or splintering, and secondary operations. The resulting quote provides transparent cost breakdowns and an accurate lead time estimate within minutes, reflecting the unique thermal and mechanical properties of wood processing.

Following quote acceptance and payment, the file enters our mandatory Design for Manufacturability (DFM) review conducted by senior manufacturing engineers. This critical phase identifies potential wood-specific issues that could cause delays, cost overruns, or part failure. Our engineers verify minimum feature sizes against tool diameters or laser kerf (typically 0.1-0.2mm for laser, 1-6mm for CNC bits), assess structural integrity of thin sections prone to breakage, confirm grain direction alignment for strength, evaluate engraving depth feasibility, and check nesting efficiency to minimize waste. Common wood-related DFM issues we resolve proactively include:

| DFM Issue Category | Specific Wood-Related Concern | Honyo Resolution Approach |

|---|---|---|

| Geometric Feasibility | Internal corners too sharp for router bit radius | Recommend fillets or specify smaller tooling with adjusted lead time |

| Material Integrity | Thin walls or delicate features prone to vibration breakage during CNC | Propose temporary tabs, slower feed rates, or material thickness adjustment |

| Process Limitations | Attempting 3D contours with laser (only 2D capable) | Clarify process capability, suggest CNC alternative or design modification |

| Nesting Optimization | Poor sheet utilization increasing material cost | Redraw nesting layout, suggest component rotation, or batch with other orders |

Upon DFM sign-off, the approved job moves to production. CNC wood parts are machined on precision routers with specialized dust collection and optimized toolpaths using carbide cutters selected for the specific wood type to minimize tear-out. Laser-cut parts utilize calibrated CO2 systems with controlled assist gas (usually compressed air) and power settings tuned to the wood density and thickness to achieve clean edges without excessive charring. All operations occur in a climate-controlled environment to mitigate wood movement due to humidity fluctuations. In-process inspections verify critical dimensions and surface quality against the CAD model.

Finished parts undergo rigorous final inspection for dimensional accuracy, edge quality, absence of burn marks (laser) or chip-out (CNC), and compliance with grain direction requirements. Components are carefully cleaned, deburred where necessary, and packaged using anti-static and cushioning materials suitable for wood’s susceptibility to scratches and moisture. We provide shipment tracking and deliver parts ready for immediate integration, typically within the quoted lead time, supported by comprehensive digital documentation including inspection reports and material certifications. This integrated process ensures predictable quality, minimizes material waste, and accelerates time-to-prototype for wood-based applications.

Start Your Project

Explore precision manufacturing with our CNC wood laser cutters, engineered for high accuracy and efficiency in prototyping and production. Built in our Shenzhen factory, each machine combines advanced technology with robust construction to deliver consistent results for woodworking, signage, and custom fabrication.

For product details, pricing, or technical specifications, contact Susan Leo at [email protected]. Let’s discuss how our laser cutting solutions can meet your manufacturing needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.