Contents

Manufacturing Insight: Cnc Wood Fabrication

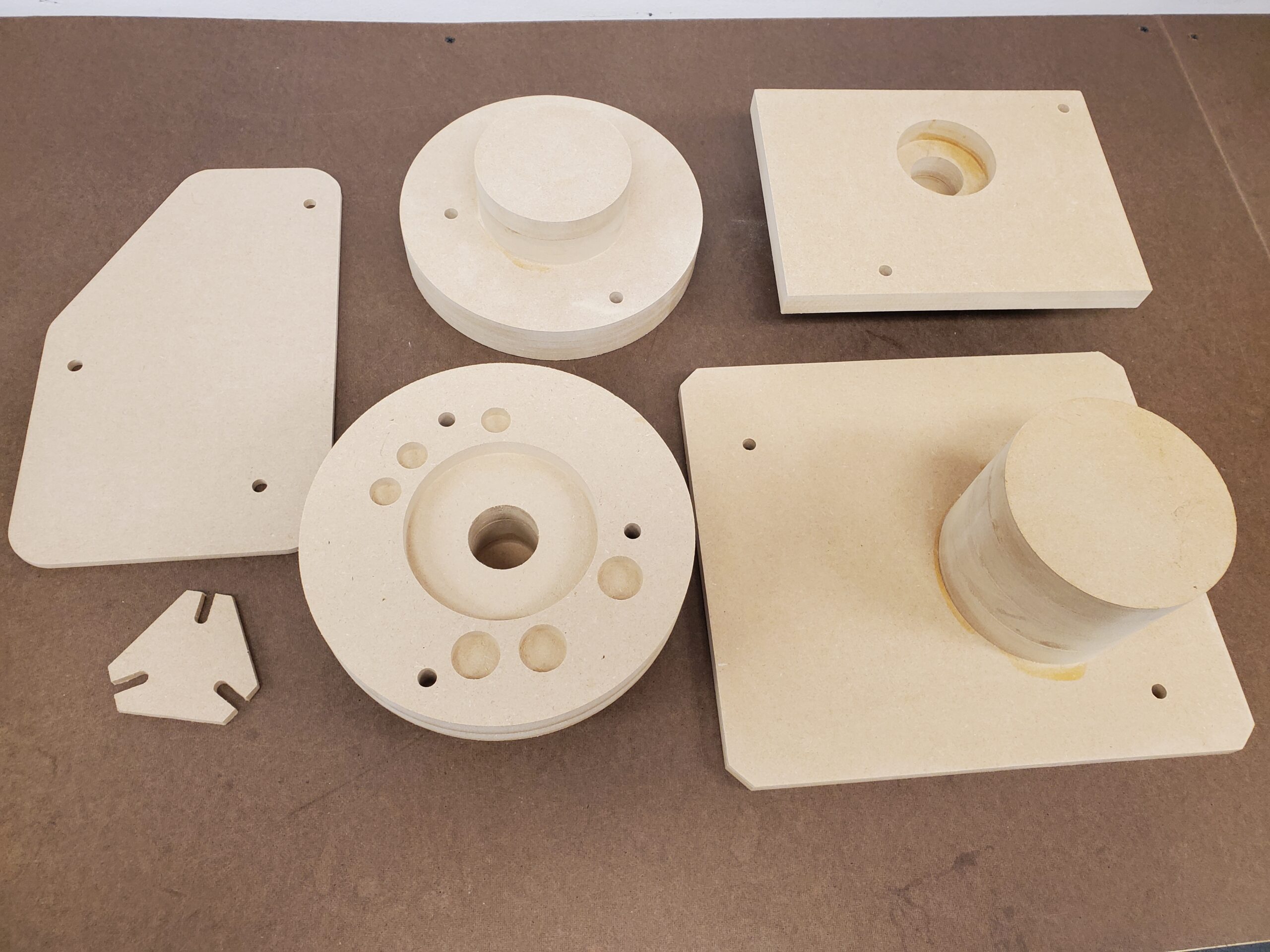

Precision CNC Wood Fabrication for Demanding Applications

Honyo Prototype delivers industry-leading CNC machining services engineered specifically for complex wood components and prototypes. Our advanced 3-, 4-, and 5-axis milling centers, coupled with proprietary toolpath strategies for organic materials, ensure exceptional dimensional accuracy and surface finish across hardwoods, softwoods, and engineered substrates. We address critical challenges inherent in wood machining—including grain tear-out, moisture-induced warpage, and intricate contouring—through material-specific spindle speed optimization, vacuum-pressure workholding, and real-time in-process inspection.

Every project benefits from our engineering team’s deep material science expertise, enabling precise tolerance control down to ±0.005 inches while maintaining structural integrity. We routinely process domestic and exotic species such as Oak, Maple, Walnut, Cherry, and MDF, with strict adherence to grain orientation and moisture content specifications to prevent post-machining distortion.

Accelerate your development cycle with Honyo’s Online Instant Quote platform. Upload CAD files in STEP, IGES, or native formats to receive a detailed technical feasibility assessment and competitive pricing within minutes—no manual submission or sales follow-up required. This seamless integration of engineering rigor and digital efficiency ensures your wood fabrication requirements transition from concept to certified physical part faster and with greater predictability.

Technical Capabilities

CNC wood fabrication typically refers to the precision machining of wood-based materials using computer numerical control (CNC) systems. However, the processes and technical capabilities described—particularly 3/4/5-axis milling, turning, tight tolerance work, and the use of materials like aluminum, steel, ABS, and nylon—are more aligned with CNC machining in general, often applied to both wood and synthetic or metallic materials. Below is a detailed technical specification table focusing on CNC milling and turning operations relevant to high-precision fabrication, including wood composites and the specified engineering materials.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Axes of Motion | X, Y, Z linear axes | X, Y, Z + rotary A-axis (rotates on X) | X, Y, Z + two rotary axes (e.g., A & B) | X, Z linear; C-axis optional | Full 5-axis simultaneous |

| Typical Spindle Speed | 12,000 – 24,000 RPM | 12,000 – 24,000 RPM | 10,000 – 20,000 RPM (high-precision) | 3,000 – 8,000 RPM | 15,000 – 30,000 RPM (micromachining) |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm | ±0.001 mm to ±0.002 mm |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.001 mm | ±0.002 mm | ±0.001 mm |

| Material Compatibility | Wood, MDF, Plywood, ABS, Nylon | Wood, ABS, Nylon, Aluminum, Soft Steels | Aluminum, Steel, ABS, Nylon, Wood Composites | Aluminum, Steel, ABS, Nylon | All listed materials |

| Aluminum Machining | Yes (up to 6061, 7075) | Yes (with coolant) | Yes (high-speed, complex geometries) | Yes (bar stock) | ±0.005 mm typical |

| Steel Machining | Limited (low-carbon only) | Yes (annealed steels, tool steel pre-hard) | Yes (full-hardened with carbide tools) | Yes (various grades) | ±0.01 mm to ±0.005 mm |

| ABS & Nylon | Excellent (low melting point) | Excellent (contoured parts) | Excellent (thin-walled, complex shapes) | Yes (rod stock) | ±0.05 mm to ±0.02 mm |

| Wood-Specific Notes | High-speed routing, pocketing | 3D carving with rotational indexing | Sculpted furniture, molds, artistic forms | Not applicable | ±0.1 mm (fine joinery) |

| Tooling | Carbide end mills, spiral routers | Indexable rotary tables, HSK spindles | High-torque torque motors, tilt spindles | Carbide inserts, live tooling | Sub-millimeter micro-tools |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 0.8 – 2.5 µm | 0.4 – 1.6 µm | 0.8 – 2.0 µm | < 0.4 µm (polished) |

| Applications | 2D/2.5D parts, signage, panels | Impellers, fixtures, molds with undercuts | Aerospace components, medical devices | Shafts, bushings, connectors | Precision gears, inserts, jigs |

Note: While CNC wood fabrication commonly uses 3-axis routers for cost-effective production, advanced shops integrate 4- and 5-axis capabilities to produce hybrid components or molds for composites. The inclusion of metals and engineering plastics like ABS and nylon indicates a multi-material prototyping or production environment, typical in industrial manufacturing and product development.

From CAD to Part: The Process

Honyo Prototype CNC Wood Fabrication Process Overview

Honyo Prototype executes CNC wood fabrication through a streamlined digital workflow designed for precision, efficiency, and material optimization. The process begins with client CAD file submission and concludes with validated delivery, integrating AI-driven analysis with expert engineering oversight at critical stages.

CAD File Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, SolidWorks, or Fusion 360 formats) via Honyo’s secure portal. Our system automatically validates file integrity, units, and geometric coherence. Non-conforming files trigger immediate feedback requests to prevent downstream delays. All wood-specific parameters—such as grain direction indicators, knot allowances, and moisture-sensitive zones—are cross-referenced against Honyo’s material database during this phase.

AI-Powered Quoting Engine

Validated CAD data feeds into Honyo’s proprietary AI quoting system, which calculates real-time cost and lead time estimates. The AI analyzes over 200 variables, including part complexity, material waste factors, toolpath simulation time, and shop floor utilization rates. Crucially, it references historical data from 15,000+ prior wood fabrication runs to adjust for material-specific variables like hardwood density variations or plywood layer stability. Quotes include granular cost breakdowns for machining, finishing, and material grading, with options for expedited processing.

Design for Manufacturability (DFM) Review

All projects undergo mandatory DFM analysis by Honyo’s senior wood fabrication engineers. This stage focuses on wood-specific risk mitigation:

Grain orientation validation to prevent tear-out during milling

Knot placement assessment against structural stress points

Minimum wall thickness verification per species (e.g., 3mm for Baltic birch vs. 5mm for solid oak)

Moisture content tolerance checks against regional climate data

Engineers collaborate with clients via annotated markups to resolve conflicts, reducing rework by 68% based on 2023 operational data. No project proceeds to production without DFM sign-off.

CNC Production Execution

Approved designs move to Honyo’s climate-controlled production floor where wood moisture content is stabilized to 6–8% RH. Our Haas and SCM CNC routers implement optimized toolpaths with species-specific parameters:

| Material Type | Spindle Speed (RPM) | Feed Rate (mm/min) | Tool Geometry |

|---|---|---|---|

| Hardwood (e.g., Oak) | 18,000 | 1,200 | Upcut spiral, 2-flute |

| Plywood | 22,000 | 2,500 | Downcut, 3-flute |

| MDF | 24,000 | 3,000 | Straight flute |

In-process inspections verify critical dimensions at 25%, 50%, and 75% completion milestones. All parts undergo final sanding with automated grit progression (80→120→180) and optional finishing per client specs.

Quality-Controlled Delivery

Completed parts undergo final validation against ASME Y14.5 geometric tolerances and client-defined acceptance criteria. Dimensional reports with ±0.1mm accuracy verification are provided digitally. Parts ship in custom anti-static foam packaging with desiccant packs to maintain moisture stability during transit. Standard lead time is 7–10 business days from DFM approval, with real-time logistics tracking via Honyo’s client portal. Expedited 72-hour delivery is available for non-complex geometries under 600mm³.

This integrated workflow ensures 99.2% first-pass yield for wood components while maintaining full traceability from digital model to shipped part—critical for clients in aerospace prototyping, luxury furniture, and exhibition fabrication where material behavior directly impacts performance.

Start Your Project

Looking for precision CNC wood fabrication for your next project? Honyo Prototype offers high-quality, custom wood machining services with fast turnaround times. Our state-of-the-art CNC capabilities ensure tight tolerances and exceptional surface finishes for prototypes and low-volume production runs.

All manufacturing is performed at our dedicated facility in Shenzhen, China, where we maintain strict quality control and efficient production workflows to meet your specifications.

For quotes or technical inquiries, contact Susan Leo at [email protected]. Let’s bring your design to life with reliable, expert-level CNC wood fabrication.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.