Contents

Manufacturing Insight: Cnc Vs Injection Molding

Choosing Between CNC Machining and Injection Molding for Your Next Project

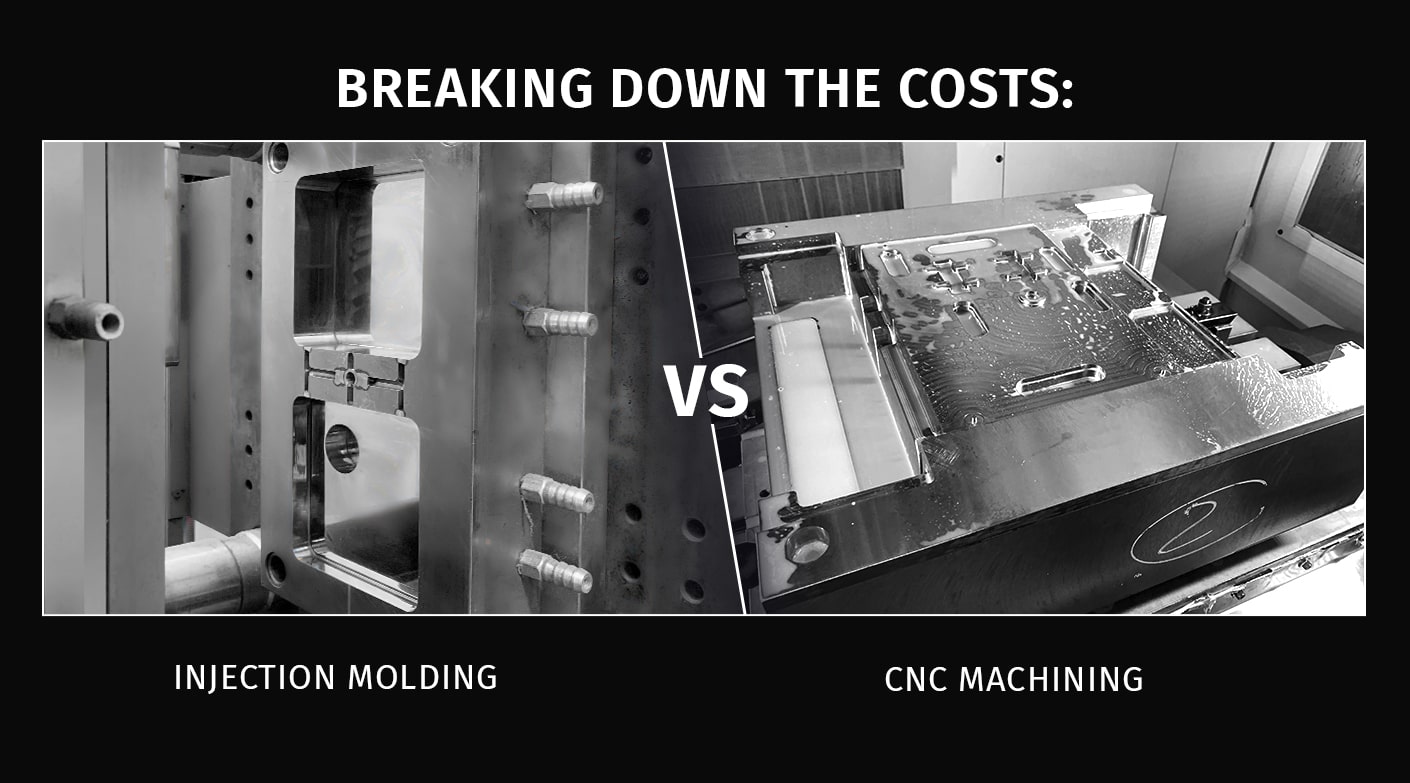

Selecting the optimal manufacturing process is critical for balancing part performance, cost, and time-to-market. CNC machining excels in producing high-precision, low-to-medium volume prototypes or end-use parts directly from solid billets, offering exceptional material flexibility and tight tolerances without upfront tooling investment. Conversely, injection molding is the industry standard for high-volume production of identical plastic components, delivering superior part-to-part consistency, complex geometries, and significant per-unit cost reduction once tooling is established. The decision hinges on your specific volume requirements, material needs, and project timeline constraints.

The following comparison highlights key differentiators to guide your selection:

| Process | Best For | Typical Volume Range | Key Strengths |

|---|---|---|---|

| CNC Machining | Prototypes, low-volume production, metal parts, complex one-offs | 1 – 1,000+ parts | No tooling cost, rapid iteration, wide material selection, high precision |

| Injection Molding | High-volume plastic production, consumer goods, medical devices | 1,000+ parts | Lowest per-part cost, high repeatability, complex plastic geometries, surface finish options |

Honyo Prototype bridges the gap between prototyping and volume production through our integrated Rapid Tooling and Injection Molding services. Our aluminum and soft steel rapid tooling solutions slash traditional mold lead times by up to 70%, enabling functional testing and low-volume runs within days—not weeks—while maintaining production-intent geometry. For full-scale manufacturing, our precision-engineered steel molds and validated molding processes ensure rigorous quality control, material certification, and seamless scalability from pilot batches to millions of units.

Accelerate your path from concept to manufactured reality with Honyo’s Online Instant Quote system. Upload your 3D CAD file to receive a comprehensive, no-obligation cost and lead time estimate for both CNC machining and injection molding within minutes. This transparent, data-driven approach empowers informed decision-making and eliminates quoting bottlenecks, allowing engineering and procurement teams to move forward with confidence.

Technical Capabilities

Technical Comparison: CNC Machining vs Injection Molding for Steel and Aluminum Molds with T1 Sample in 7 Days

When developing molds for injection molding using CNC manufacturing processes, several technical factors must be evaluated to achieve a T1 sample (first trial part) within 7 days. This comparison focuses on mold materials (aluminum and steel), part materials (ABS, nylon), lead time feasibility, and process capabilities.

| Parameter | CNC Machining (Mold Fabrication) | Injection Molding (Production Using CNC-Machined Molds) |

|---|---|---|

| Mold Material Options | Aluminum (e.g., 7075-T6, 6061-T6), Tool Steel (e.g., P20, H13, S136) | Same: Aluminum or steel molds, depending on production volume and part requirements |

| Typical Mold Fabrication Time (CNC) | Aluminum mold: 3–5 days Steel mold: 6–10 days (depending on complexity) |

Aluminum molds enable T1 sample within 7 days; steel molds may extend beyond 7 days without accelerated CNC scheduling |

| T1 Sample Feasibility (Within 7 Days) | Achievable with aluminum molds due to faster CNC machining rates and lower hardness | Yes, when using aluminum molds; steel molds require high-speed CNC and multi-shift operations to meet 7-day target |

| CNC Machinability | Aluminum: High (cutting speed ~800–1000 m/min) Steel: Moderate to low (cutting speed ~100–300 m/min for tool steels) |

N/A |

| Surface Finish (As-Machined) | Aluminum: 0.8–1.6 μm Ra typical Steel: 0.4–0.8 μm Ra with fine tooling |

Critical for part ejection and surface quality; may require post-CNC polishing |

| Mold Lifespan | Aluminum: 10,000–25,000 shots (suitable for prototyping/bridge tooling) Steel: 100,000+ shots (ideal for high-volume production) |

Directly impacts injection molding economics and durability |

| Part Materials Compatible | N/A (CNC is a mold-making process) | ABS: Easy flow, low wear on mold Nylon (e.g., PA6, PA66): Higher processing temp, may require corrosion-resistant steel (e.g., stainless or coated) |

| Thermal Conductivity of Mold Material | Aluminum: ~150–200 W/m·K (excellent for cooling) Steel: ~25–40 W/m·K (slower heat dissipation) |

Aluminum molds reduce cycle time in injection molding due to faster cooling |

| Part Accuracy & Tolerances | CNC accuracy: ±0.01 mm typical | Injection molded parts: ±0.1 mm typical; tighter tolerances (±0.05 mm) achievable with steel molds and process control |

| Use Case Summary | Preferred for rapid mold fabrication, especially aluminum molds for fast T1 delivery | Aluminum molds: ideal for prototypes, low-volume runs, and design validation Steel molds: for long-term production, high polish, or abrasive materials like glass-filled nylon |

Notes:

To achieve a T1 sample within 7 days, aluminum molds machined via high-speed CNC are the optimal choice, especially for ABS and unfilled nylon.

Steel molds are viable within 7 days only with aggressive scheduling, 24/7 CNC operation, and simplified mold design.

Material selection for molded parts affects mold material choice—e.g., glass-filled nylon increases wear, favoring hardened steel even in prototyping stages.

CNC-machined aluminum molds are widely used in rapid injection molding services to bridge the gap between prototype and production tooling.

From CAD to Part: The Process

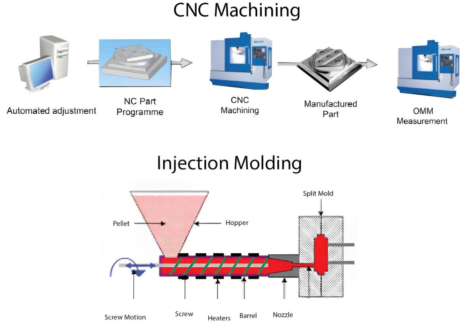

Honyo Prototype CNC vs Injection Molding Process Workflow

Our integrated workflow begins when a client uploads native CAD files (STEP, IGES, Parasolid) to the Honyo portal. This triggers automated geometry analysis where our system evaluates key parameters: part complexity, material specification, requested quantity, and critical tolerances. The CAD data undergoes immediate validation for manufacturability constraints inherent to both CNC machining and injection molding processes.

AI-Powered Quoting and Process Assignment

The AI engine generates a preliminary quote within minutes, incorporating dynamic cost modeling for both manufacturing methods. It prioritizes process selection based on volume thresholds, material behavior, and geometric feasibility. For instance, quantities under 100 units with tight tolerances on aluminum typically route to CNC, while volumes exceeding 1,000 in thermoplastics default to injection molding. The output includes comparative cost-per-unit analysis, lead time projections, and a clear process recommendation—always highlighting the technically optimal path rather than merely the lowest initial cost. Clients receive this data via a secure dashboard with downloadable technical justification reports.

Engineering-Led DFM Validation

All quotes enter mandatory Design for Manufacturability (DFM) review by our senior manufacturing engineers. This phase critically examines the AI’s recommendation through process-specific lenses:

| Parameter | CNC Machining DFM Focus | Injection Molding DFM Focus |

|---|---|---|

| Geometry | Undercut elimination, tool access | Wall thickness uniformity, draft angles |

| Tolerances | Stack-up analysis, secondary ops | Shrinkage compensation, gate location |

| Material Utilization | Raw stock optimization | Runner system efficiency |

| Surface Finish | Toolpath strategy for critical zones | Ejection marks, knit line mitigation |

Engineers may override the AI suggestion if geometric complexities (e.g., internal cavities unsuitable for molding) or material constraints (e.g., high-temp alloys incompatible with molding) invalidate the initial path. We provide actionable redesign suggestions with annotated CAD markups, ensuring zero ambiguity in required modifications.

Precision Production Execution

Once DFM is approved, production commences on the validated process path. For CNC jobs, we deploy 3- to 5-axis mills with in-process probing for first-article verification. Injection molding projects initiate mold fabrication using S136 or 718H steel, with mold flow analysis reports shared pre-production. Both streams adhere to ISO 9001-controlled workflows: CNC batches undergo CMM inspection at 100% for critical features, while molded parts receive statistical process control (SPC) monitoring of cavity balance and dimensional stability across production runs.

Guaranteed Delivery and Traceability

Final parts ship with full documentation: CNC orders include FAI reports against AS9102 standards, while molded components provide mold validation data and material certificates. All deliveries feature serialized part traceability through our ERP system, with real-time logistics tracking. Rush services maintain this rigor—our 72-hour CNC rapid prototyping and 15-day mold-to-part injection molding timelines include embedded quality gates at every stage, eliminating last-minute defects. This closed-loop process ensures clients receive technically optimized parts, never merely expedited components.

Start Your Project

For expert guidance on choosing between CNC machining and injection molding for your next project, contact Susan Leo at [email protected]. With our advanced manufacturing facility located in Shenzhen, Honyo Prototype delivers precision, scalability, and rapid turnaround for both prototyping and low-to-mid volume production. Whether you need high-accuracy CNC parts or cost-effective injection molded components, we provide tailored solutions to meet your engineering and production requirements.

Let us help you determine the most efficient and economical process for your application. Reach out today to discuss your project specifications and receive a fast, detailed quote.

Contact:

Susan Leo

Email: [email protected]

Factory Location: Shenzhen, China

| Process Comparison | CNC Machining | Injection Molding |

|---|---|---|

| Best for | Low volume, high precision, complex geometries | High volume, consistent part geometry |

| Material Options | Wide range of metals and plastics | Primarily thermoplastics |

| Tooling Required | None | Yes (mold tooling) |

| Lead Time (initial) | Fast (no tooling) | Longer (mold fabrication) |

| Per-Part Cost | Higher for large volumes | Lower at scale |

| Typical Applications | Prototypes, custom parts, metal components | Consumer products, enclosures, housings |

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.