Contents

Manufacturing Insight: Cnc Turning Products

Honyo Prototype CNC Turning Capabilities

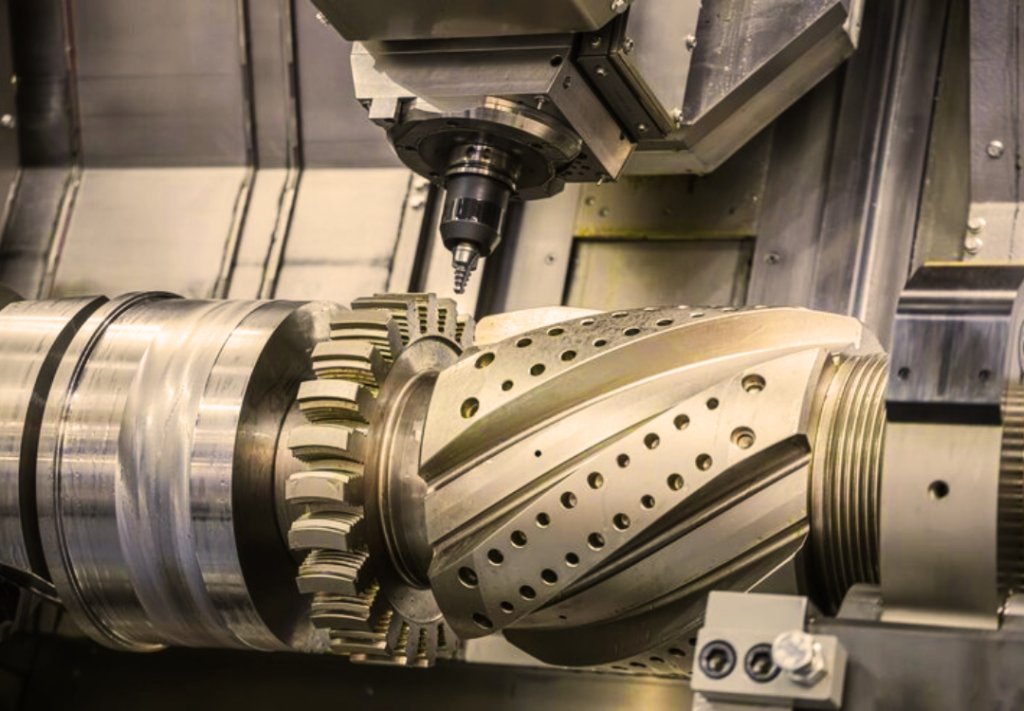

Honyo Prototype delivers precision CNC turning services engineered for demanding industrial applications, transforming raw materials into high-integrity cylindrical components with exceptional accuracy and repeatability. Our advanced Swiss-type and multi-axis turning centers consistently achieve tight tolerances down to ±0.0002 inches while accommodating complex geometries, intricate threading, and critical surface finishes required in aerospace, medical, and automation sectors. We machine a comprehensive range of materials—including stainless steel, titanium, aluminum, brass, and engineering plastics—to produce prototypes, bridge production runs, and full-volume turned parts meeting ISO 9001 quality standards.

Accelerate your sourcing process with our Online Instant Quote platform, which provides validated pricing and lead times in under 60 seconds. Simply upload your STEP or IGES file to receive a manufacturability assessment alongside a formal quotation, eliminating traditional RFQ delays without compromising on technical rigor. This seamless integration of digital efficiency and precision manufacturing ensures your CNC turning projects transition rapidly from design intent to certified, production-ready components. Partner with Honyo to leverage agile, high-fidelity turning solutions backed by engineering expertise and transparent project execution.

Technical Capabilities

CNC Turning Products – Technical Specifications

CNC turning products at Honyo Prototype are manufactured using advanced multi-axis machining centers to achieve high precision, complex geometries, and tight tolerances. Our capabilities span 3, 4, and 5-axis milling combined with CNC turning operations, enabling the production of intricate rotational and prismatic components. We specialize in high-accuracy parts for aerospace, medical, automotive, and industrial applications.

The following table outlines key technical specifications for our CNC turning and milling services:

| Specification Category | Details |

|---|---|

| Machining Capabilities | 3-Axis, 4-Axis, and 5-Axis CNC Milling combined with CNC Turning (Mill-Turn) |

| Maximum Work Envelope | Turning: Ø400 mm x 500 mm length; Milling: 800 mm x 500 mm x 400 mm (X-Y-Z) |

| Spindle Speed (Turning) | Up to 6,000 RPM (higher speeds available for specific materials) |

| Spindle Speed (Milling) | Up to 24,000 RPM with through-coolant options |

| Tolerance Capability | Standard: ±0.025 mm; Tight Tolerance: ±0.005 mm (achievable with process control and metrology) |

| Surface Finish | Typical: Ra 1.6 µm; Fine Finish: Ra 0.4 µm (with polishing or grinding post-process) |

| Primary Materials | Aluminum (6061, 7075, 2024), Steel (1018, 4140, Stainless 303, 316), ABS, Nylon (PA6, PA66) |

| Material Form | Bar stock (round, hex, square), billet, or custom preforms |

| Coolant Systems | Flood coolant, mist coolant, and dry machining options |

| In-Process Inspection | On-machine probing and laser tool measurement for dimensional control |

| Post-Processing Options | Deburring, anodizing (Type II & III for aluminum), passivation (stainless steel), bead blasting, custom coating |

| Certifications & Standards | ISO 9001:2015 compliant, GD&T expertise, first article inspection (FAI) reporting (AS9102), PPAP support |

We maintain strict process controls for tight-tolerance components, utilizing calibrated CMMs, optical comparators, and surface profilometers for quality assurance. Multi-axis integration allows for complex parts to be completed in a single setup, reducing lead time and improving geometric accuracy. Materials such as aluminum and steel are machined for structural and high-strength applications, while engineering plastics like ABS and nylon are used for lightweight, non-conductive, or wear-resistant components.

From CAD to Part: The Process

Honyo Prototype CNC Turning Process Overview

Honyo Prototype executes CNC turning projects through a rigorously defined workflow designed to ensure precision, efficiency, and client alignment. The process begins with CAD file submission and culminates in certified delivery, integrating automated intelligence with expert engineering oversight at critical stages.

CAD File Upload and Initial Processing

Clients upload native or neutral CAD formats (STEP, IGES, Parasolid, or native SOLIDWORKS/Inventor) via Honyo’s secure portal. Our system validates geometric integrity, units, and feature completeness. Non-native formats undergo automated topology checks to prevent data corruption. This phase typically completes within 2 hours of submission, with immediate feedback if files fail validation criteria.

AI-Powered Quoting with Engineering Verification

Uploaded geometry triggers our proprietary AI quoting engine, which analyzes part complexity, material requirements, tolerances, and secondary operations. The AI cross-references real-time machine availability, material costs, and historical production data to generate a preliminary quote. Crucially, all AI outputs undergo mandatory review by a Senior Manufacturing Engineer. This human-in-the-loop step ensures contextual accuracy—adjusting for factors like thin-wall stability, micro-feature machining, or material anisotropy—before the quote is released. Standard turnaround is 24–48 hours.

Collaborative DFM Analysis

Upon quote acceptance, Honyo’s DFM team conducts a bilateral manufacturability review. Unlike automated DFM tools, our engineers engage clients to discuss trade-offs between design intent and production reality. Key focus areas include:

| DFM Issue Category | Typical Impact | Honyo Resolution Approach |

|---|---|---|

| Wall Thickness Variance | Vibration-induced chatter, dimensional drift | Recommend ribbing or stock redistribution |

| Tight Tolerances (±0.0005″) | Extended cycle time, tool wear acceleration | Propose GD&T optimization or selective plating |

| Undercuts/Keyways | Multi-setup requirements, alignment errors | Suggest EDM alternatives or simplified profiles |

| Material Selection | Chip evacuation issues, surface finish loss | Substitute with equivalent ISO-grade alloys |

This phase concludes with a formal DFM report detailing actionable revisions, cost implications of “as-is” manufacturing, and lead time impacts. Client sign-off is required before proceeding.

Precision Production Execution

Approved designs move to production on Honyo’s monitored CNC turning centers (Swiss-type and 2-axis lathes with live tooling). Each run follows:

Material certification verification against AMS/ASTM standards

First-article inspection per AS9102 with CMM and optical comparator

In-process SPC checks at critical stages (e.g., post-roughing, pre-finishing)

Final inspection against all geometric tolerances and surface roughness specs

All machining parameters are logged in our MES for full traceability, with real-time alerts for out-of-tolerance conditions.

Certified Delivery and Post-Production Support

Completed parts undergo final packaging with anti-corrosion protection and serialized barcoding. Deliverables include:

FAI report with full dimensional data

Material test certificates

Process validation documentation

Digital twin comparison (actual vs. nominal geometry)

Shipments include IoT-enabled tracking with environmental monitoring (humidity, shock). Honyo maintains a 99.2% on-time delivery rate for CNC turning projects, with dedicated post-delivery engineering support for assembly integration or field performance analysis.

This integrated workflow—combining AI scalability with deep manufacturing expertise—ensures Honyo delivers complex turned components with reduced time-to-market while eliminating costly design-to-production disconnects.

Start Your Project

Looking for high-precision CNC turning products for your next project? Honyo Prototype delivers reliable, repeatable results with fast turnaround times. Our state-of-the-art machining capabilities are supported by a fully equipped factory in Shenzhen, ensuring strict quality control and competitive pricing for both prototypes and production runs.

Contact Susan Leo today to discuss your requirements and receive a personalized quote.

Email: [email protected]

Partner with a trusted manufacturing solution based in the heart of China’s innovation hub.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.