Contents

Manufacturing Insight: Cnc Turn-Mill

Precision Turn-Mill Capabilities Accelerate Complex Part Production at Honyo Prototype

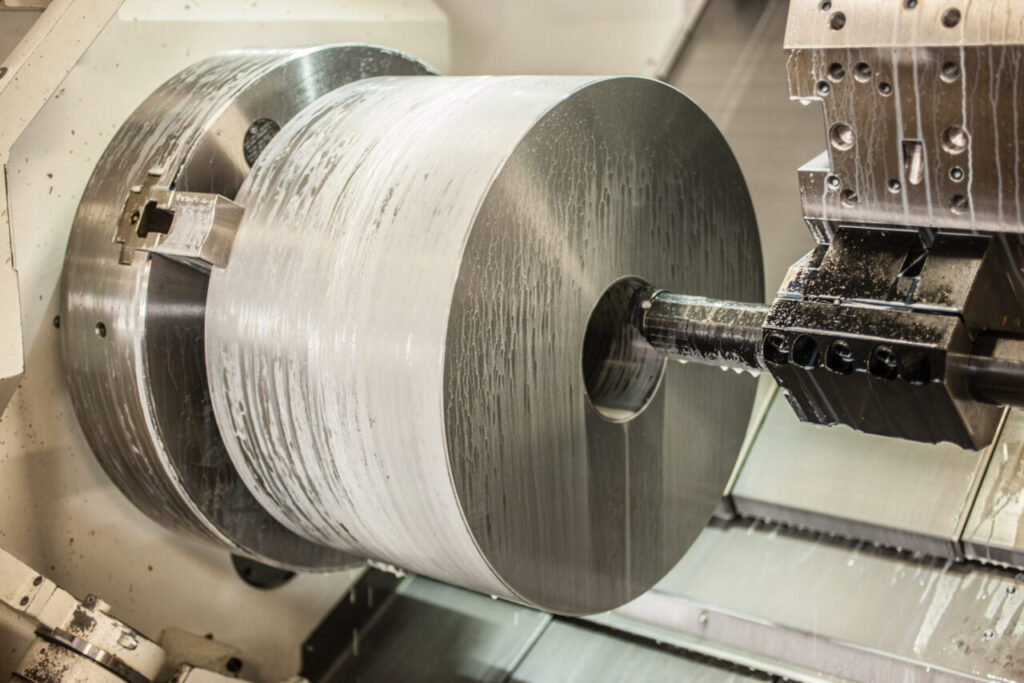

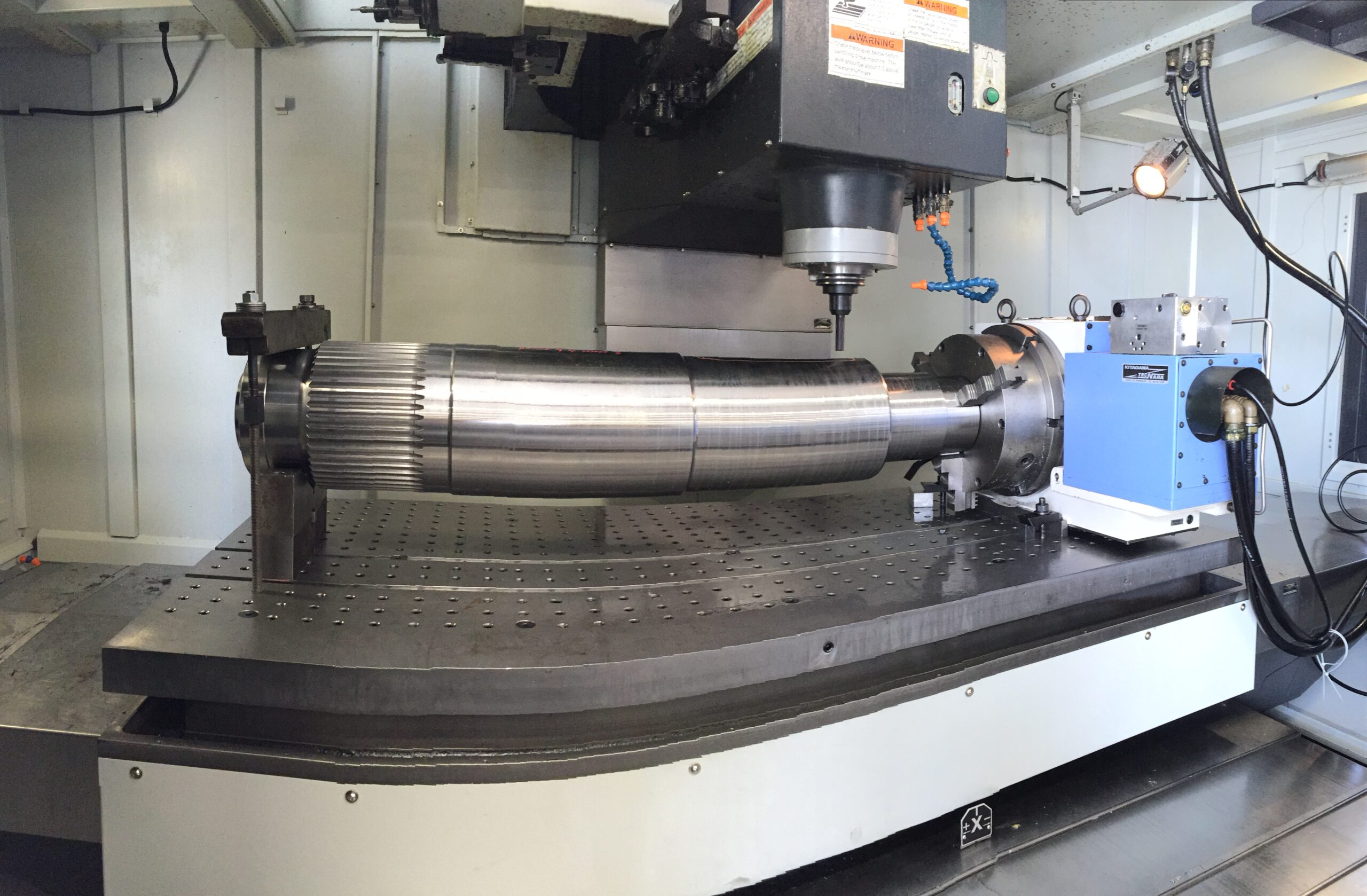

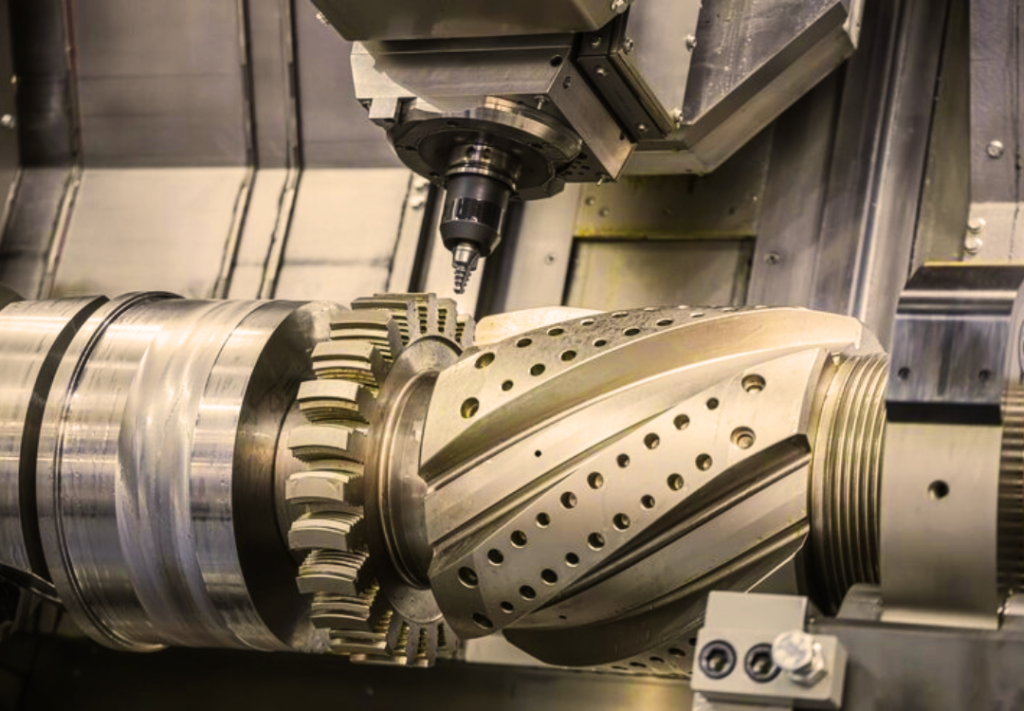

Honyo Prototype delivers advanced CNC turn-mill machining services designed to streamline the production of highly complex, tight-tolerance components requiring both rotational and milling operations. Our state-of-the-art multi-axis turn-mill centers integrate live tooling, Y-axis capabilities, and sub-spindles to execute intricate geometries in a single setup, eliminating secondary operations and significantly reducing lead times. This integrated approach ensures exceptional part accuracy, superior surface finishes, and minimized handling risks for mission-critical applications across aerospace, medical, and industrial automation sectors.

Leveraging our extensive expertise in multi-tasking machining strategies, Honyo optimizes material utilization and throughput while maintaining strict adherence to ISO 9001 quality standards. We specialize in transforming challenging designs—from Swiss-type turned components with complex milled features to fully contoured organic shapes—into high-integrity production-ready parts. To accelerate your project timeline, Honyo provides an Online Instant Quote system that delivers accurate, detailed pricing and manufacturability feedback within minutes, empowering rapid prototyping and low-to-mid volume production decisions without compromising engineering rigor. Request your quote today to experience seamless turn-mill manufacturing excellence.

Technical Capabilities

CNC Turn-Mill Technical Specifications

CNC turn-mill machining combines turning and milling operations in a single setup using multi-axis machines, enabling complex geometries with high precision. These machines are ideal for producing intricate components requiring tight tolerances, reduced handling, and improved accuracy. Below are the key technical specifications for 3/4/5-axis CNC turn-mill systems focused on precision manufacturing.

| Parameter | Specification Description |

|---|---|

| Axis Configuration | 3-axis (X, Y, Z) standard milling with turning on C-axis; 4-axis adds rotary indexing (B or A); 5-axis enables simultaneous multi-directional tool movement (A-B or A-C rotary axes) for complex contours |

| Turning Capabilities | Live tooling allows milling while part is rotated; capable of facing, grooving, threading, drilling, and contour turning during rotation |

| Spindle Speed (Milling) | Up to 12,000 RPM (standard), up to 24,000 RPM on high-speed spindles |

| Spindle Speed (Turning) | Up to 5,000 RPM (steel), up to 8,000 RPM (aluminum and plastics) |

| Tool Capacity | 12–30 station tool turrets with optional live tooling; automatic tool changers (ATC) available on 4/5-axis models |

| Positioning Accuracy | ±0.005 mm (±0.0002 in) |

| Repeatability | ±0.002 mm (±0.0001 in) |

| Tight Tolerance Capability | ±0.0125 mm (±0.0005 in) typical; down to ±0.005 mm (±0.0002 in) with process control and metrology |

| Work Envelope (Max) | Diameter: up to 300 mm; Length: up to 600 mm (varies by machine model) |

| Materials Supported | Aluminum (6061, 7075), Steel (4140, 1018, Stainless 303/316), ABS, Nylon (6, 66), and other engineering plastics |

| Surface Finish (Typical) | 0.8–3.2 µm Ra (milled); 0.4–1.6 µm Ra (turned); achievable down to 0.2 µm Ra with fine finishing |

| Coolant System | High-pressure through-spindle cooling; optional mist or air cooling for plastics |

| Control System | Fanuc, Siemens, or Heidenhain CNC with 5-axis simultaneous interpolation and collision avoidance |

| Fixturing | Collet chucks, hydraulic/electric chucks, custom fixtures; CMM inspection compatible design |

Material Notes

Aluminum alloys are commonly machined on turn-mill centers due to their excellent machinability, low cutting forces, and high thermal conductivity. Steel components require higher torque and rigid setups, especially for hard turning operations. ABS and Nylon are processed at reduced speeds with sharp tooling to prevent melting or burring, using air blow or minimal coolant. All materials benefit from the reduced setup count and enhanced geometric control offered by multi-axis turn-mill technology.

This integrated approach ensures high repeatability, minimized part handling, and suitability for complex, high-tolerance components used in aerospace, medical, and automation industries.

From CAD to Part: The Process

Honyo Prototype executes CNC turn-mill operations through a rigorously defined workflow designed for precision, efficiency, and technical transparency. This integrated process leverages multi-axis capabilities to produce complex geometries in a single setup, minimizing handling errors and secondary operations. Below is the technical sequence:

Upload CAD

Clients initiate the process by uploading native or neutral format CAD files (STEP, IGES, Parasolid) via our secure customer portal. Our system performs an initial validation check for file integrity, unit consistency, and geometric completeness. Critical parameters such as material specifications, tolerances (including GD&T callouts), surface finish requirements, and critical feature annotations are extracted for downstream processing. Incomplete submissions trigger an automated notification requesting clarification before progression.

AI Quote

The validated CAD geometry undergoes automated analysis using Honyo’s proprietary AI-driven quoting engine. This system decomposes the part into manufacturable features, identifying turn-mill specific elements such as off-axis milling pockets, cross-drilled holes, and complex contouring. Material utilization, machine time estimates (factoring in B-axis indexing and live tooling cycles), and fixture requirements are calculated. The AI generates a preliminary quote within 2 hours, including cost breakdowns for material, machine hours, and secondary processes. All quotes include a technical confidence score (0–100%) based on geometric complexity and tolerance density, with scores below 85% flagged for immediate engineering review.

DFM (Design for Manufacturability)

Every turn-mill project undergoes mandatory engineering-led DFM analysis. Our manufacturing engineers evaluate the design against machine capabilities (e.g., maximum bar stock diameter, live tooling reach, sub-spindle limitations) and process physics. Common turn-mill specific optimizations include:

Redesigning features to minimize turret indexing time

Adjusting wall thicknesses to prevent chatter during milling operations

Resolving potential tool interference in multi-axis movements

Recommending optimal stock allowances for critical diameters

The DFM report details actionable suggestions with annotated visuals, tolerance stack-up analysis, and alternative manufacturing approaches. Client approval of the DFM report is required before production release. Typical DFM turnaround is 24–48 hours for standard components.

Production

Approved jobs enter our production queue with strict adherence to documented procedures:

Material verification via certified mill test reports

CAM programming using Mastercam with machine-specific post-processors

First-article inspection (FAI) per AS9102 standards, including CMM verification of all critical features

In-process gauging at defined checkpoints (e.g., after main spindle operations, sub-spindle transfers)

Real-time machine monitoring for vibration, thermal drift, and tool wear

Turn-mill production occurs exclusively on multi-tasking lathes (e.g., Mazak Integrex i-200S, DMG MORI NTX 1000) with Y-axis and sub-spindle capabilities. All processes follow documented work instructions traceable to ISO 9001:2015 standards.

Delivery

Final inspection includes full dimensional reporting against the original CAD model and client specifications. Parts ship with:

Dimensional results report (PDF)

Material certification

Process validation records

Cleanliness certification (for medical/aerospace)

Standard lead time from DFM approval to shipment is 7–12 business days for quantities ≤50 pieces. Expedited options include 72-hour rush production (with DFM completion in 4 hours) for urgent requirements.

Process performance metrics are maintained for continuous improvement:

| Process Stage | Avg. Duration | Key Quality Metric | Target Threshold |

|---|---|---|---|

| CAD Upload to AI Quote | < 2 hours | File Validity Rate | ≥ 98% |

| DFM Analysis | 24–48 hours | First-Pass Yield | ≥ 92% |

| Production | 7–12 days | FAI Acceptance Rate | 100% |

| Delivery | On schedule | On-Time Delivery | ≥ 99% |

This closed-loop methodology ensures turn-mill components meet stringent functional requirements while providing clients with full technical visibility from design intent to certified delivery. All process deviations trigger root cause analysis per our corrective action protocol.

Start Your Project

Looking for high-precision CNC turn-mill services? Partner with Honyo Prototype for reliable, efficient, and scalable manufacturing solutions.

Our advanced turn-mill capabilities combine turning and milling operations in a single setup, ensuring tight tolerances, reduced cycle times, and superior part accuracy. Ideal for complex, high-volume, or prototype components across aerospace, medical, automotive, and industrial sectors.

All production is managed at our state-of-the-art factory in Shenzhen, leveraging cutting-edge equipment and rigorous quality control to meet international standards.

Contact Susan Leo today to discuss your project requirements or request a quote.

Email: [email protected]

Honyo Prototype – Precision. Performance. Partnership.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.