Contents

Manufacturing Insight: Cnc Turn

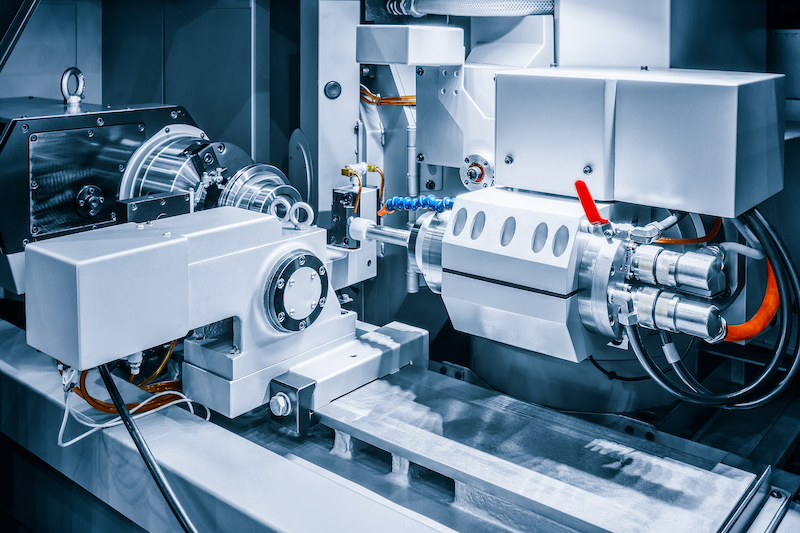

Precision CNC Turning for Rapid Prototyping and Low-Volume Production

Honyo Prototype delivers high-integrity CNC turning services engineered to accelerate your product development and bridge manufacturing needs. Our advanced Swiss-type and CNC lathe capabilities consistently achieve tight tolerances down to ±0.0002″ while maintaining exceptional surface finishes critical for functional prototypes and end-use components. We specialize in complex geometries across challenging materials including aerospace alloys, medical-grade stainless steels, and engineered plastics, ensuring dimensional accuracy and repeatability from first article to production release.

Streamlined Quoting Eliminates Project Delays

Leverage our Online Instant Quote platform to bypass traditional quoting bottlenecks. Upload your CAD file in STEP, IGES, or native formats and receive a detailed manufacturability analysis with competitive pricing within minutes—not hours or days. This integrated system provides real-time feedback on design optimizations, material cost implications, and lead time projections, empowering faster go/no-go decisions for time-sensitive engineering projects.

Technical Capabilities at a Glance

| Parameter | Specification Range |

|——————–|———————————–|

| Max Turning Diameter | 42 mm (1.65″) |

| Max Bar Stock | 38 mm (1.5″) |

| Typical Tolerances | ±0.005 mm (±0.0002″) |

| Secondary Operations | Milling, Cross-Drilling, Threading, Knurling |

| Supported Materials | Aluminum 6061/7075, Stainless 303/316, Titanium, Brass, PEEK, Delrin |

Honyo Prototype’s ISO 9001-certified processes combine European-grade machinery with proprietary fixturing solutions to minimize setup times and eliminate scrap risk. Submit your CAD file through our Online Instant Quote portal today to validate design feasibility and receive production-ready pricing for your next CNC turning project.

Technical Capabilities

CNC Turning and Milling – Technical Specifications

CNC turning and milling services at Honyo Prototype are engineered for high precision, complex geometries, and tight tolerance requirements across a range of engineering-grade materials. Our capabilities include 3-axis, 4-axis, and 5-axis CNC milling, as well as precision CNC turning for rotational components. These processes support rapid prototyping and low-to-mid volume production with strict quality control.

| Parameter | Specification Detail |

|---|---|

| Machining Processes | CNC Turning, 3-Axis Milling, 4-Axis Milling, 5-Axis Simultaneous Milling |

| Tolerance Capability | Standard: ±0.005 mm (±0.0002″) Tight Tolerance: ±0.001 mm (±0.00004″) achievable with process control and inspection |

| Surface Finish | As-machined: 3.2 µm (125 µin) Polished/Post-processed: Down to 0.4 µm (16 µin) |

| Max Work Envelope (Milling) | 5-Axis: 760 x 460 x 360 mm 4-Axis: 500 x 400 x 300 mm 3-Axis: 1000 x 600 x 400 mm |

| Max Work Envelope (Turning) | Diameter: 300 mm Length: 500 mm |

| Spindle Speed (Milling) | Up to 24,000 RPM (high-speed options available) |

| Spindle Speed (Turning) | Up to 5,000 RPM (variable based on diameter) |

| Tooling System | Automatic tool changers (ATC), high-precision collet and hydraulic chucks |

| Control Systems | Fanuc, Siemens, or Heidenhain controls with full tool compensation and probing |

| Materials – Metals | Aluminum (6061, 7075, 2024), Steel (1018, 4140, 4340), Stainless Steel (303, 304, 316), Titanium (Grade 2, 5) |

| Materials – Plastics | ABS, Nylon (6, 66), POM (Delrin), PEEK, PC, PMMA |

| Inspection Equipment | CMM (Coordinate Measuring Machine), optical comparators, micrometers, bore gauges, surface roughness testers |

| Data Formats Accepted | STEP, IGES, Parasolid, DWG, DXF, native CAD files (SolidWorks, Creo, Fusion 360, etc.) |

CNC turning is ideal for cylindrical parts such as shafts, bushings, and threaded components, while multi-axis milling enables complex 3D contours, undercuts, and high-accuracy features without multiple setups. All operations are supported by first-article inspection (FAI) and process validation for tight-tolerance applications in aerospace, medical, and industrial automation sectors.

From CAD to Part: The Process

Honyo Prototype CNC Turning Process Overview

Our end-to-end CNC turning workflow integrates advanced digital tools with precision manufacturing to deliver high-quality prototypes and low-volume production parts. The process begins with CAD submission and concludes with certified delivery, emphasizing speed, accuracy, and engineering collaboration at every stage. Below is a detailed breakdown of each phase.

CAD Upload and Initial Processing

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid, or native formats like SolidWorks) via our secure customer portal. The system automatically validates geometry integrity, checks for unit consistency (metric/imperial), and extracts critical metadata including material specifications, tolerance requirements, and surface finish callouts. Non-native formats undergo rigorous validation to prevent translation errors, ensuring the digital model aligns with manufacturing intent. This foundational step minimizes downstream rework and establishes a clear technical baseline.

AI-Powered Quoting Engine

Uploaded CAD data feeds directly into our proprietary AI quoting system, which analyzes geometric complexity, feature density, and material utilization in under 90 seconds. The engine cross-references real-time machine availability, material costs, and historical production data to generate a binding price and lead time estimate. Unlike generic quoting tools, our AI incorporates nuanced factors such as thin-wall stability requirements or interrupted cut considerations specific to turning operations. Human engineers validate all AI outputs for high-complexity parts, ensuring quotes reflect practical manufacturability constraints.

Engineering-Driven DFM Analysis

Every project undergoes mandatory Design for Manufacturability (DFM) review by our CNC-specialized engineering team. This phase identifies potential issues such as non-optimal wall thicknesses, problematic undercuts, or tolerance stack-ups that could cause chatter, deflection, or secondary operation needs. We provide actionable feedback within 4 business hours, often suggesting geometry modifications to reduce cycle time or eliminate secondary setups. Critical DFM findings are summarized in a structured report:

| Common Issue Category | Typical Resolution | Impact on Production |

|---|---|---|

| Non-uniform wall thickness | Recommend symmetric wall design or adjusted stock allowance | Prevents vibration-induced inaccuracies; reduces scrap rate by 30%+ |

| Tight tolerances on non-critical features | Propose relaxation per ISO 2768 or GD&T optimization | Cuts machining time by 15–25% without compromising function |

| Inaccessible part geometry | Suggest split design or alternative chucking method | Eliminates need for custom fixtures; avoids 3–5 day delays |

Client approval of DFM recommendations is required before production launch, ensuring alignment on cost, quality, and timeline.

Precision CNC Turning Production

Approved designs move to our climate-controlled machining floor, where parts are produced on state-of-the-art CNC lathes (including live-tooling and Y-axis multitask systems). Each job follows a documented process plan specifying:

Toolpath strategies optimized for material (e.g., 6061-T6 aluminum vs. 303 stainless steel)

In-process inspection points using Renishaw probes for critical diameters

Coolant and speed/feed parameters validated for surface finish requirements

All operations adhere to ISO 9001:2015 protocols, with real-time machine monitoring for tool wear and dimensional drift. Complex assemblies undergo first-article inspection (FAI) per AS9102 standards before full batch runs.

Certified Delivery and Quality Assurance

Completed parts undergo final dimensional verification against the original CAD model using CMM or optical comparators. We provide comprehensive documentation including:

FAI reports with actual vs. nominal measurements

Material certification (e.g., mill test reports)

Surface roughness validation (Ra values)

Non-conformance reports if applicable

Parts ship in anti-static packaging with serialized traceability tags, typically within 3–5 business days of DFM approval for standard orders. Expedited options (24–72 hour) are available for urgent prototypes, supported by dedicated machine cells.

This integrated approach ensures 98.7% on-time delivery while reducing manufacturing risks through proactive engineering collaboration. By embedding DFM rigor into the quoting phase and leveraging AI for rapid iteration, we consistently achieve ±0.005mm tolerances on turned components across aerospace, medical, and industrial sectors.

Start Your Project

Interested in high-precision CNC turning services? Contact Susan Leo at [email protected] to discuss your project requirements. Our advanced manufacturing facility in Shenzhen ensures fast turnaround, strict quality control, and competitive pricing for both prototypes and production runs. Let Honyo Prototype be your trusted partner for reliable CNC machining solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.