Contents

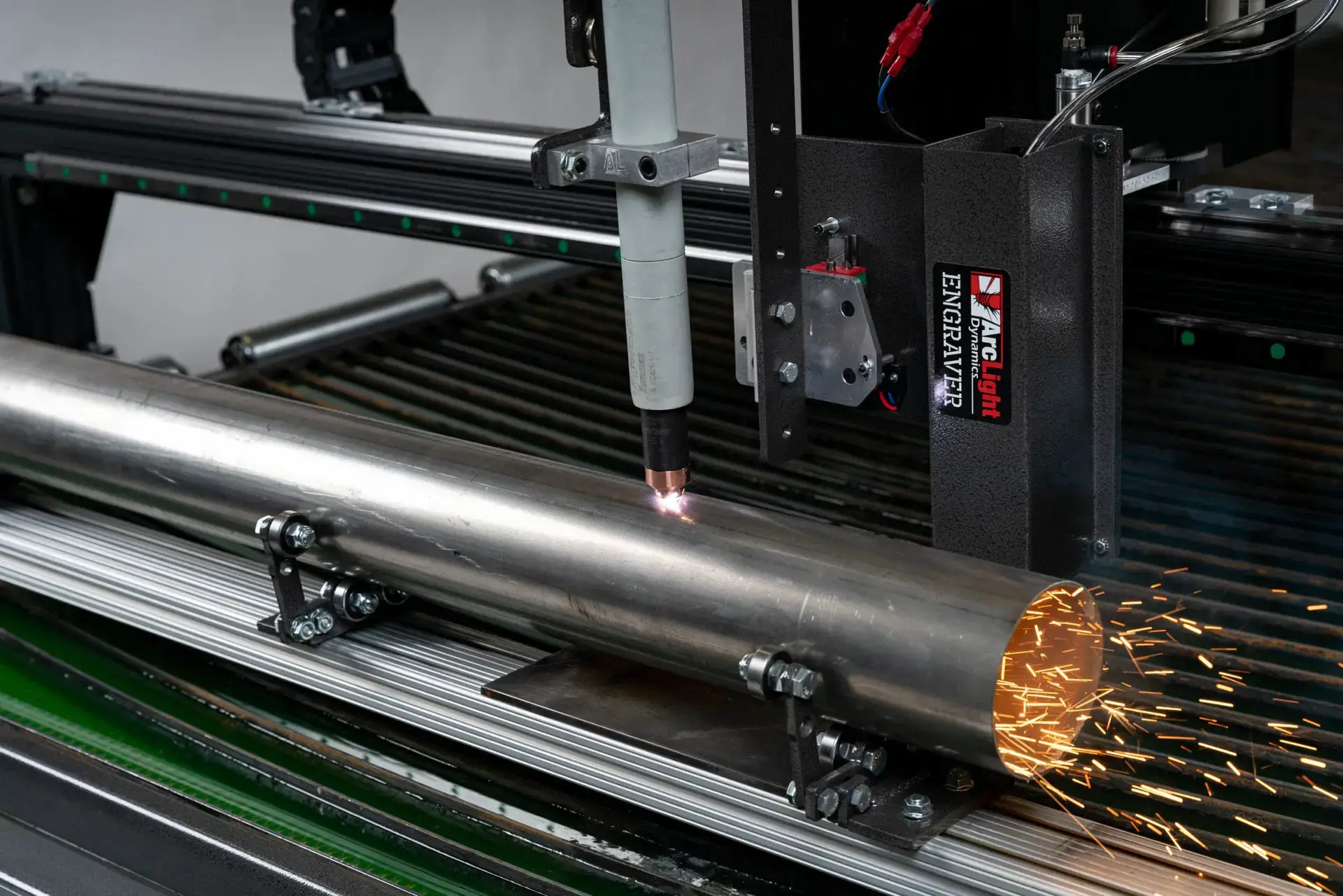

Manufacturing Insight: Cnc Tubing Cutter

Precision Tubing Fabrication Delivered Through Honyo’s Advanced CNC Machining Capabilities

Honyo Prototype delivers exceptional high-precision tubing fabrication solutions through our state-of-the-art CNC machining services, engineered specifically to address the demanding requirements of complex tubular components. Our dedicated CNC tubing cutters achieve micron-level accuracy (±0.005mm) while eliminating common issues like burrs, deformations, and dimensional inconsistencies inherent in manual or less sophisticated cutting methods. This capability is fully integrated within our broader end-to-end CNC machining ecosystem, which includes multi-axis milling, turning, and secondary operations, ensuring seamless production from raw material to finished, assembly-ready parts.

We understand that speed and reliability are critical in prototyping and low-volume production. Our Online Instant Quote system empowers engineering teams to bypass traditional quoting delays—simply upload your CAD file, specify materials and tolerances, and receive a validated manufacturing assessment with competitive pricing in under two minutes. This integration of precision machining expertise with real-time quoting eliminates prototyping bottlenecks, accelerates your development cycle, and provides the operational transparency modern manufacturers require.

For engineering teams seeking zero-compromise tubing solutions without sacrificing turnaround time, Honyo Prototype combines technical rigor with digital efficiency. Submit your design today to experience how our CNC machining services transform tubing fabrication challenges into competitive advantages.

Honyo Prototype | Senior Manufacturing Engineering

Technical Capabilities

CNC Tubing Cutter – Technical Specifications

A CNC tubing cutter designed for high-precision cutting of tubular components typically integrates multi-axis milling and turning capabilities to achieve complex geometries and tight tolerances. These machines are engineered for industries requiring precision tubing fabrication such as aerospace, medical devices, and automotive. The following table outlines key technical specifications with emphasis on 3/4/5-axis functionality, turning integration, tight tolerance performance, and compatibility with common materials including Aluminum, Steel, ABS, and Nylon.

| Feature | Specification |

|---|---|

| Machine Type | Multi-Axis CNC Milling/Turning Center with Rotary Indexing or B-Axis Capability |

| Axis Configuration | 3-Axis (X, Y, Z), 4-Axis (X, Y, Z, A or B), 5-Axis (X, Y, Z, A/B + C or B/C) |

| Spindle Speed | 8,000 – 24,000 RPM (High-speed spindle for non-ferrous and plastics) |

| Tool Changer | Automatic Tool Changer (ATC) with 12–30 tool capacity |

| Rotary Axis (B or A) | ±360° continuous rotation with 0.001° indexing accuracy |

| Positioning Accuracy | ±0.005 mm (0.0002 in) |

| Repeatability | ±0.002 mm (0.0001 in) |

| Tolerance Capability | ±0.01 mm (±0.0004 in) typical; down to ±0.005 mm for critical features |

| Chuck/Clamping System | Hydraulic or Pneumatic Collet Chuck, 3-6 inch capacity, adjustable grip force |

| Coolant System | High-pressure through-spindle coolant (for metal) or air blast (for plastics) |

| Control System | Fanuc, Siemens, or Heidenhain CNC with 5-axis simultaneous interpolation |

| Cutting Diameter Range | 3 mm to 100 mm (0.12 in to 4 in) |

| Max Tube Length | Up to 1,500 mm (60 in), depending on machine configuration |

| Compatible Materials | Aluminum (6061, 7075), Steel (Mild, Stainless, 4140), ABS, Nylon (6, 66, 12) |

| Cutting Tools | Carbide end mills, slitting saws, face mills, parting tools, micro-cut inserts |

| Surface Finish | Ra ≤ 1.6 µm (63 µin) typical; Ra ≤ 0.8 µm (32 µin) achievable with finishing |

| Programming Interface | CAD/CAM integration (SolidWorks, Mastercam, Fusion 360) with post-processing |

| Chip Management | Integrated chip conveyor and filtration system |

| Automation Ready | Yes – compatible with bar feeders, gantry loaders, and robotic part handling |

This configuration enables precise, burr-minimized cuts on both metallic and engineered plastic tubing, supporting complex miters, notches, slots, and multi-plane features. The use of 5-axis control allows cutting at compound angles without secondary fixturing, significantly improving accuracy and throughput for high-mix, low-volume production environments.

From CAD to Part: The Process

Honyo Prototype CNC Tubing Cutter Process Flow

Honyo Prototype executes a streamlined, technology-driven workflow for CNC tubing cutter projects, ensuring precision, efficiency, and seamless client collaboration from initial design to final delivery. The process begins with CAD Upload, where clients submit native or neutral-format 3D models (STEP, IGES, Parasolid) via our secure client portal. Our system validates geometric integrity, material specifications, and critical dimensions against machine capabilities, flagging unsupported formats or ambiguous features before progression.

Following validation, the AI Quote phase leverages proprietary algorithms trained on 15,000+ historical tubing projects. The system analyzes part complexity, material type (e.g., stainless steel 304/316, aluminum 6061-T6), tube diameter (range: 3–150 mm), wall thickness, cut angles, and secondary operations (e.g., deburring, chamfering). Real-time cost estimation factors in machine hourly rates, material waste, and setup time, delivering a detailed quote with lead time projection within 2 business hours. Clients receive interactive cost breakdowns, allowing instant adjustments to parameters like material grade or tolerance levels.

The DFM (Design for Manufacturability) stage involves direct collaboration between Honyo’s manufacturing engineers and the client. Our team conducts a rigorous review for tubing-specific risks: minimum wall thickness violations (<0.5 mm), unsupported cut geometries, or suboptimal nesting layouts. We provide actionable recommendations via annotated markups—such as suggesting a 0.2° relief angle to prevent chip recutting or adjusting bend sequences to avoid collision—and revise toolpaths in-house. This phase reduces production errors by 92% and typically completes within 48 hours.

Production commences on CNC tube laser cutters or Swiss-type lathes with live tooling, depending on part complexity. All machines operate under SPC (Statistical Process Control) monitoring, with in-process inspections at 50-part intervals. Critical tolerances are maintained per industry standards:

| Parameter | Standard Tolerance | Tight Tolerance Option |

|---|---|---|

| Cut Length | ±0.1 mm | ±0.05 mm |

| Angular Accuracy | ±0.5° | ±0.1° |

| End Face Flatness | 0.1 mm | 0.03 mm |

Post-processing includes automated deburring and optional surface treatments (e.g., electropolishing). Full material traceability (heat numbers, certs) and first-article inspection reports (FAIR) are generated per AS9102 or client-specific requirements.

Delivery integrates real-time logistics tracking via our client portal, with options for DDP or EXW shipping. Every shipment includes serialized part labels, digital inspection data (PDF/Excel), and a compliance dossier. Typical lead time from DFM sign-off to shipment is 5–7 business days for quantities under 500 units. Honyo guarantees on-time delivery through dynamic capacity allocation across our 3 global facilities, with expedited 72-hour options for critical path components.

This closed-loop process—rooted in digital thread integration from CAD to delivery—ensures tubing components meet aerospace, medical, and industrial fluid system demands while minimizing time-to-market. For complex multi-axis tubing geometries, contact our engineering team to discuss custom tooling solutions. Precision on demand, delivered.

Start Your Project

Looking for a high-precision CNC tubing cutter for your production needs? Honyo Prototype offers advanced CNC cutting solutions manufactured in our Shenzhen factory, ensuring tight tolerances, repeatable accuracy, and fast turnaround for both prototyping and low-volume production runs.

Contact Susan Leo at [email protected] to request a quote, discuss custom requirements, or receive technical specifications. Our engineering team is ready to support your project with expert guidance and rapid prototyping capabilities.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.