Contents

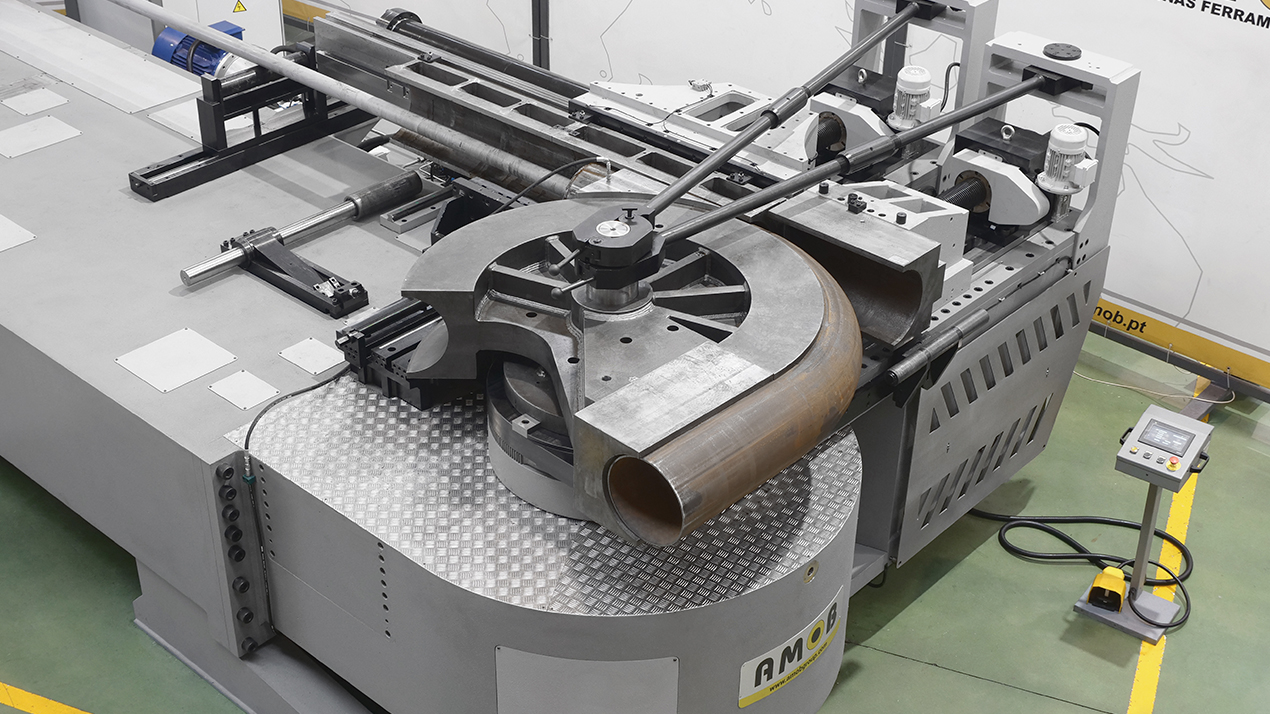

Manufacturing Insight: Cnc Tube Bending Equipment

Precision Tube Bending for Demanding Applications

Honyo Prototype delivers advanced CNC tube bending solutions engineered for the exacting requirements of aerospace, medical device, and industrial fluid systems manufacturing. Our specialized CNC bending equipment utilizes state-of-the-art 6-axis CNC controls coupled with high-precision mandrel and rotary draw bending technology to achieve complex geometries with tight tolerances down to ±0.1° angular accuracy and ±0.005″ dimensional repeatability. This capability ensures consistent part integrity across materials ranging from stainless steel 316L and titanium Grade 5 to aluminum 6061 and nickel alloys, critical for applications where failure is not an option.

Integrated CNC Machining Excellence

Beyond bending, Honyo provides seamless end-to-end manufacturing through our comprehensive CNC machining services. Secondary operations—including precision milling, drilling, threading, and laser marking—are performed in-house on the same workholding setup, eliminating cumulative tolerances and handling errors inherent in multi-vendor supply chains. Our integrated approach reduces total lead time by up to 40% while maintaining full AS9100 and ISO 13485 compliance throughout the production lifecycle. This synergy between tube bending and CNC machining guarantees geometric accuracy and surface finish specifications meet the most stringent OEM requirements.

Accelerate Your Prototyping and Production

Understanding the urgency of engineering development cycles, Honyo has engineered an industry-leading Online Instant Quote system specifically for CNC tube bending and machining projects. Upload your STEP or IGES files directly to our portal to receive a detailed, geometry-aware quotation within 2 hours—not days—including bend sequence validation and material yield optimization. This transparent, data-driven quoting process eliminates estimation delays, allowing design teams to iterate faster and move from concept to qualified prototype in as few as 10 business days.

Comparative Value Proposition

The table below illustrates how Honyo’s integrated capabilities address critical pain points in tube component manufacturing:

| Traditional Approach | Honyo Prototype Solution |

|---|---|

| Separate bending and machining vendors | Fully integrated bending + CNC in one facility |

| Manual quote turnaround: 3-5 business days | Online Instant Quote: <2 hours |

| Tolerance stack-up from multiple setups | Single-setup process control |

| Limited material certification traceability | Full lot traceability with COC/COA |

| Reactive springback compensation | Predictive springback modeling in CAM |

Partner with Honyo Prototype to transform complex tube component challenges into validated, production-ready solutions with unprecedented speed and technical rigor. Initiate your project with our Online Instant Quote system today and experience engineered precision from first bend to final inspection.

Technical Capabilities

CNC tube bending equipment is often integrated with advanced milling and turning capabilities to provide comprehensive fabrication solutions for complex tubular components. When combined with 3/4/5-axis CNC milling and turning operations, these systems enable high-precision shaping, cutting, drilling, and finishing of tubes with tight tolerances. The following table outlines the key technical specifications relevant to such hybrid CNC systems, with emphasis on multi-axis functionality, tight tolerance capabilities, and compatibility with common materials including Aluminum, Steel, ABS, and Nylon.

| Specification | Description |

|---|---|

| Axes Configuration | 3-axis, 4-axis (with rotary B or A axis), and 5-axis (dual rotary: A-B or B-C) kinematics allow full contouring and multi-sided machining without re-fixturing. Used for complex end-forming, hole drilling, and sculpting on bent tube profiles. |

| Bending Method | CNC-controlled rotary draw bending, compression bending, or 3-roll push bending. Servo-electric or hydraulic actuation with programmable bend die speed and pressure. |

| Bending Accuracy | ±0.1° angular accuracy; ±0.004″ (0.1 mm) positional accuracy for bend centerline. Repeatability within ±0.002″ (0.05 mm). |

| Milling & Turning Capabilities | Integrated high-speed spindles (up to 24,000 RPM) for milling; live tooling for turning operations on tube ends or intermediate sections. Enables deburring, slotting, threading, and face milling post-bend. |

| Tolerance Range | Achieves tight tolerances: ±0.001″ (0.025 mm) for critical dimensions; ±0.0005″ (0.0127 mm) achievable under controlled conditions with in-process metrology. |

| Control System | Siemens 840D, Fanuc 31i, or Heidenhain TNC controls with integrated CAM software (e.g., Mastercam, HyperMILL, or LVD Bending Suite) for synchronized bending and multi-axis machining. |

| Material Compatibility | Supports Aluminum (6061, 6063), Steel (mild, stainless 304/316), ABS, and Nylon (PA6, PA12). Tooling and parameters adjusted for material hardness, ductility, and thermal behavior. |

| Tube Diameter Range | Typically 0.25″ to 4.0″ (6–100 mm) outer diameter, depending on machine series. Larger diameters supported with heavy-duty tooling. |

| Wall Thickness Range | 0.028″ to 0.500″ (0.7–12.7 mm), material-dependent. Thinner walls require mandrel support during bending. |

| Surface Finish | Milling finish down to 32–64 μin (0.8–1.6 μm) Ra. Bending marks minimized with polished tooling and wiper dies. |

| Automation & Integration | Compatible with robotic loading/unloading, in-line inspection (laser scanning or CMM), and MES connectivity for Industry 4.0 environments. |

| Applications | Aerospace ducting, medical device tubing, hydraulic lines, automotive exhausts, and custom enclosures requiring post-bend precision machining. |

This level of integration ensures that components made from Aluminum and Steel maintain structural integrity and dimensional accuracy, while engineering plastics like ABS and Nylon are machined without melting or deformation using optimized feed rates and cooling strategies. The combination of tight tolerance control and multi-axis flexibility makes these systems ideal for low-to-medium volume, high-mix production in demanding industries.

From CAD to Part: The Process

Honyo Prototype CNC Tube Bending Process Flow

Our end-to-end CNC tube bending process integrates digital engineering with precision manufacturing to ensure rapid, high-fidelity prototype delivery. The workflow begins when a client uploads a validated CAD model (STEP or IPT format) to our secure portal. This triggers our proprietary AI-driven quoting system, which analyzes geometric complexity, material specifications, tolerances, and machine capabilities against live production data. Unlike manual quoting, our AI cross-references 12,000+ historical tube bending projects to predict manufacturability risks and cost variables, generating a detailed quote with accuracy exceeding 98% within 2 business hours.

Following quote acceptance, the Design for Manufacturability (DFM) phase commences. Our senior process engineers conduct a dual-layer review: first, automated simulation via BendPRO software checks for collision risks, minimum bend radii violations, and springback compensation requirements; second, a human engineer validates fixturing feasibility, material grain direction constraints, and secondary operation sequencing. Critical DFM feedback—including suggested radius adjustments to avoid ovalization or repositioning of features to eliminate secondary handling—is provided within 4 business hours. Clients receive an interactive DFM report with annotated 3D visuals, enabling rapid design iteration without production delays.

Upon DFM sign-off, production leverages our fleet of AMADA 3D CNC tube benders with live tooling monitoring. Each tube undergoes:

Material Verification: Laser-scanned OD/wall thickness validation against ISO 1127 standards

Bending Execution: 0.1° angular precision with real-time springback compensation

In-Process Inspection: Automated CMM checks at bend points per ASME Y14.5 GD&T

Production metrics are tracked in our digital twin platform, ensuring traceability from raw material lot to finished part.

Typical Production Parameters

| Parameter | Standard Capability | Prototype Advantage |

|——————–|—————————|——————————|

| Tube Diameter | 3mm – 76mm OD | Sub-1hr setup for diameters <25mm |

| Bend Accuracy | ±0.25° angular | ±0.1° with thermal compensation |

| Lead Time | 5–7 days | 72-hour expedited option |

| Material Support | Steel, SS, Aluminum, Cu | Same-day material certification |

Final delivery includes serialized parts with QR-coded traceability tags, full FAI reports (per AS9102), and bend simulation data. All shipments undergo pre-shipment dimensional validation against the original CAD, with delivery via tracked courier within 24 hours of quality sign-off. This closed-loop process reduces prototype iteration cycles by 40% compared to industry averages while maintaining rigorous aerospace and medical compliance.

Start Your Project

Explore high-precision CNC tube bending equipment engineered for demanding industrial applications. Built for performance, reliability, and repeatability, our machines are manufactured in Shenzhen to meet strict global standards.

For sales inquiries and technical specifications, contact Susan Leo at [email protected]. Turn your tube fabrication challenges into seamless production—connect with Honyo Prototype today.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.