Contents

Manufacturing Insight: Cnc Threading

Precision CNC Threading Solutions from Honyo Prototype

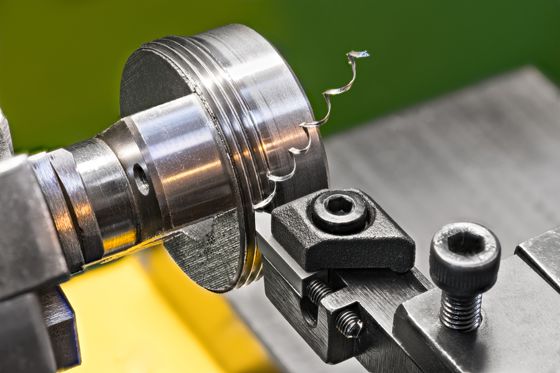

CNC threading represents a critical capability in precision manufacturing, demanding exacting control over thread forms, pitch, and tolerances to ensure functional integrity in assemblies. At Honyo Prototype, our advanced CNC machining services deliver exceptional accuracy for both internal and external threads across complex geometries and demanding materials, including aerospace alloys, medical-grade stainless steels, and engineering plastics. Our multi-axis milling and turning centers achieve tight tolerances down to ±0.005mm, adhering to ISO 2768 and customer-specific thread standards while maintaining surface finishes critical for sealing and fatigue resistance.

We integrate threading seamlessly within comprehensive part production, supporting secondary operations such as heat treatment, anodizing, and precision metrology to eliminate supply chain fragmentation. For engineering teams requiring rapid validation, Honyo’s Online Instant Quote system provides transparent, geometry-driven pricing within minutes—enabling immediate project scoping without traditional quoting delays. This accelerates prototyping and low-volume production cycles while maintaining the repeatability essential for mission-critical applications. Partner with Honyo Prototype to transform threading challenges into reliable, high-performance components with streamlined procurement.

Technical Capabilities

CNC threading is a precision machining process used to create internal or external threads on a workpiece using computer-controlled milling or turning equipment. When performed on 3-, 4-, or 5-axis CNC machines, threading operations benefit from enhanced toolpath control, improved access to complex geometries, and tighter tolerances. This capability is especially critical in aerospace, medical, and automotive industries where thread accuracy and surface integrity are paramount.

The following table outlines key technical specifications for CNC threading across multi-axis milling and turning platforms, with emphasis on tight tolerance capabilities and material compatibility:

| Parameter | Specification Details |

|---|---|

| Machining Platform | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning (including mill-turn centers) |

| Thread Types Supported | External and internal threads (UNF, UNC, NPT, metric, custom profiles) |

| Tolerance Range | ±0.0002″ (±0.005 mm) for critical threads; typical thread class 2A/2B or 3A/3B |

| Positional Accuracy | ±0.0001″ (±0.0025 mm) on 5-axis systems with thermal compensation and encoders |

| Surface Finish (Ra) | 16–32 μin (0.4–0.8 μm) typical; down to 8 μin (0.2 μm) with fine finishing passes |

| Spindle Speed Range | Up to 20,000 RPM (milling); up to 6,000 RPM (turning), depending on material and tooling |

| Feed Rate Control | Precise synchronization for thread pitch (C-axis control in turning) |

| Tooling | Solid carbide taps, thread mills, indexable thread inserts, high-speed steel (HSS) taps |

| Thread Milling Capabilities | Full thread depth in single or helical interpolation; left- and right-hand threads |

| Materials Compatible | Aluminum (6061, 7075), Steel (4140, 1018, stainless), ABS, Nylon (6, 66), and other engineering plastics |

| Aluminum Threading | High-speed threading with coolant-through tools; minimal burring; tolerance ±0.0002″ |

| Steel Threading | Requires rigid setup; peck tapping or thread milling for deep holes; tolerance ±0.0003″ |

| ABS & Nylon Threading | Low cutting forces; sharp tooling required; oversized tap drills to prevent stripping |

| In-Process Inspection | Probing systems for thread pitch, pitch diameter, and depth verification |

| Software Support | CAM software (e.g., Mastercam, Siemens NX) with thread milling and rigid tapping cycles |

| Coolant & Lubrication | Through-spindle coolant (high-pressure) for chip evacuation; air blast for plastics |

5-axis CNC systems enable off-center and angled threading operations without manual re-fixturing, greatly improving geometric accuracy and repeatability. For tight tolerance applications, thermal stability, machine calibration, and tool wear monitoring are maintained through regular preventive maintenance and quality control protocols.

From CAD to Part: The Process

Honyo Prototype CNC Threading Process Overview

Honyo Prototype executes CNC threading through a rigorously defined workflow designed for precision, speed, and engineering validation. This process ensures thread specifications align with functional requirements while minimizing lead times and non-conformance risks. Below is the end-to-end sequence:

CAD Upload and Initial Processing

Clients submit native CAD files (STEP, IGES, or native formats like SLDPRT, IPT) via Honyo’s secure cloud portal. The system performs automated geometry validation to confirm file integrity and identifies critical threading features such as major/minor diameters, pitch, thread class (e.g., 6G, 2B), and engagement length. Unsupported formats trigger immediate client notification for correction, preventing downstream delays.

AI-Powered Quoting Engine

Honyo’s proprietary AI engine analyzes the validated CAD model within 2 hours to generate a technical-commercial quote. For threading operations, the AI cross-references: material compatibility with thread standards (e.g., ISO metric, UN/UNF), toolpath complexity (internal vs. external, blind vs. through holes), and geometric constraints (e.g., thread runout, chamfer requirements). Cost and lead time calculations account for thread-specific factors like multi-pass sequencing for large pitches or vibration-sensitive materials. Clients receive a transparent breakdown of threading operation costs separate from base machining.

Engineering-Driven DFM Analysis

All threading features undergo mandatory Design for Manufacturability (DFM) review by Honyo’s manufacturing engineers. This phase focuses exclusively on thread feasibility and performance:

Verification of thread standard compliance (e.g., ASME B1.1, ISO 68-1)

Assessment of minimum wall thickness for internal threads to prevent stripping

Evaluation of tool access and rigidity for deep or small-diameter threads

Recommendations for optimized thread forms (e.g., replacing rolled threads with cut threads for hardened materials)

Tolerance stack-up analysis for mating components

Clients receive a formal DFM report with actionable suggestions; unresolved conflicts halt progression to production. Typical resolution time is under 24 business hours.

CNC Production Execution

Approved orders enter production with threading operations governed by validated machine programs:

High-precision CNC mills/lathes equipped with rigid tapping units or live tooling

In-process probing for thread pitch diameter verification at critical stages

Material-specific parameters: reduced feed rates for stainless steel, coolant-through tooling for aluminum to prevent chip jamming

Real-time monitoring of torque and spindle load to detect thread form deviations

Thread critical dimensions are measured per ANSI/ASME B1.2 using calibrated thread plug/ring gauges or optical comparators. Statistical process control (SPC) data is logged for traceability.

Delivery and Documentation

Completed parts undergo final thread inspection against the original CAD and client specifications. Honyo delivers:

Dimensional report with thread-specific measurements (pitch diameter, functional diameter, lead error)

Material certification and RoHS/REACH compliance documentation

AS9102 First Article Inspection (FAI) reports for aerospace clients

Traceable batch records including machine IDs and operator certifications

Standard delivery includes secure packaging with thread protectors for critical assemblies. Rush services achieve 5-day turnaround for simple threaded components.

Key Thread Specification Capabilities

Honyo maintains strict adherence to international standards across all threading operations. Critical parameters are controlled to the following tolerances:

| Parameter | Capability Range | Typical Tolerance (Metric) | Typical Tolerance (Imperial) |

|---|---|---|---|

| Thread Diameter | M1.6 to M64 | ±0.025 mm (6H) | ±0.001 in (2B) |

| Pitch | 0.25 mm to 6.0 mm | ±0.015 mm | ±0.0005 in |

| Thread Depth | 1.5xD to 4.0xD | ±0.1 mm | ±0.005 in |

| Thread Class | 4G/6G, 3B/2B, UNC/UNF | Per ISO 965/ASME B1.1 | Per ASME B1.1 |

This integrated process ensures Honyo delivers threads meeting functional assembly requirements while eliminating common failure modes like galling, incomplete engagement, or dimensional drift. All threading data remains accessible via the client portal for future production runs.

Start Your Project

For precision CNC threading solutions, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen ensures high accuracy, fast turnaround, and strict quality control for your custom threading requirements. Partner with Honyo Prototype for reliable, large-volume or prototype-level CNC threading services backed by engineering expertise.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.