Contents

Manufacturing Insight: Cnc Telescope

Precision CNC Machining for Demanding Telescope Component Fabrication

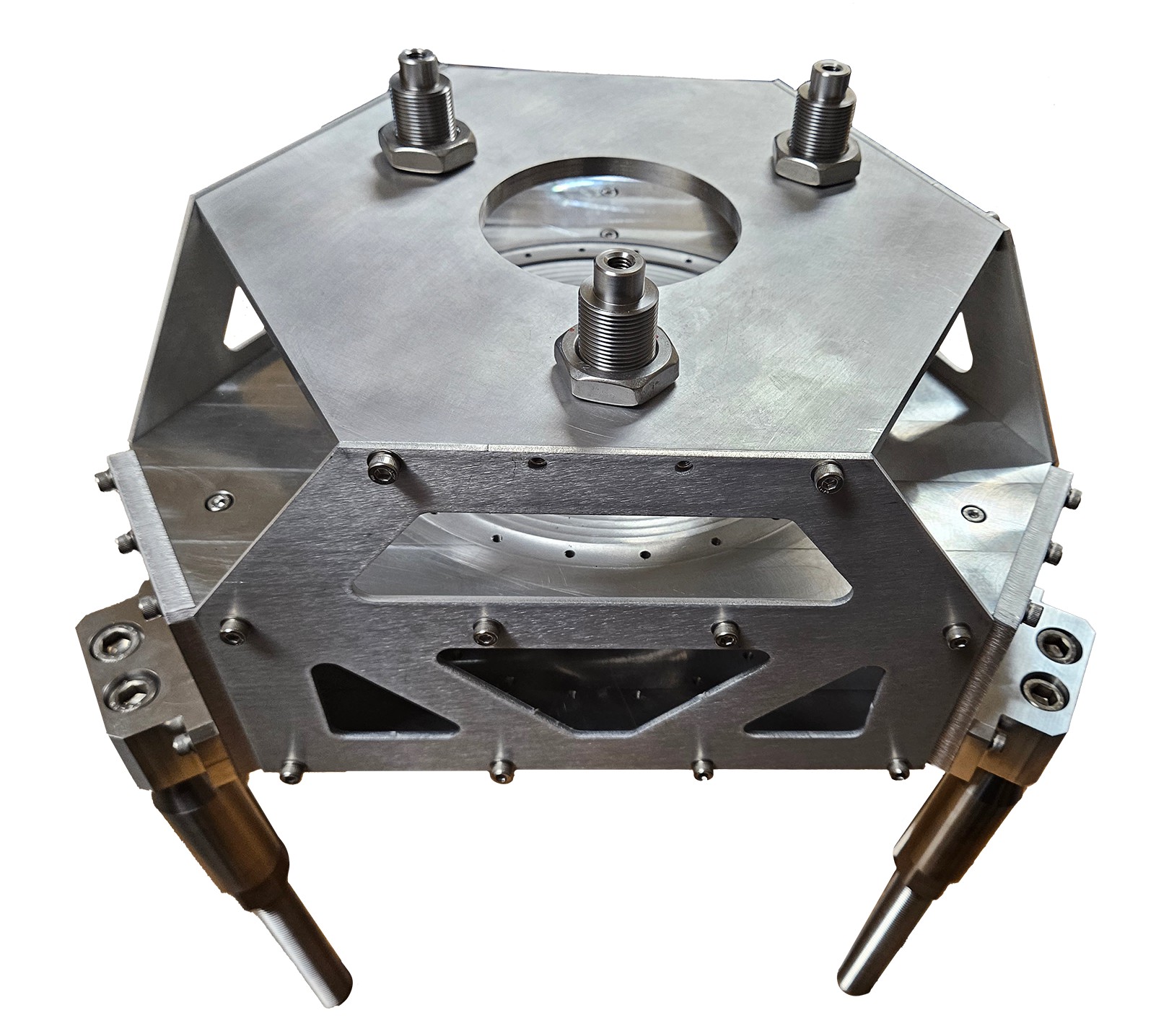

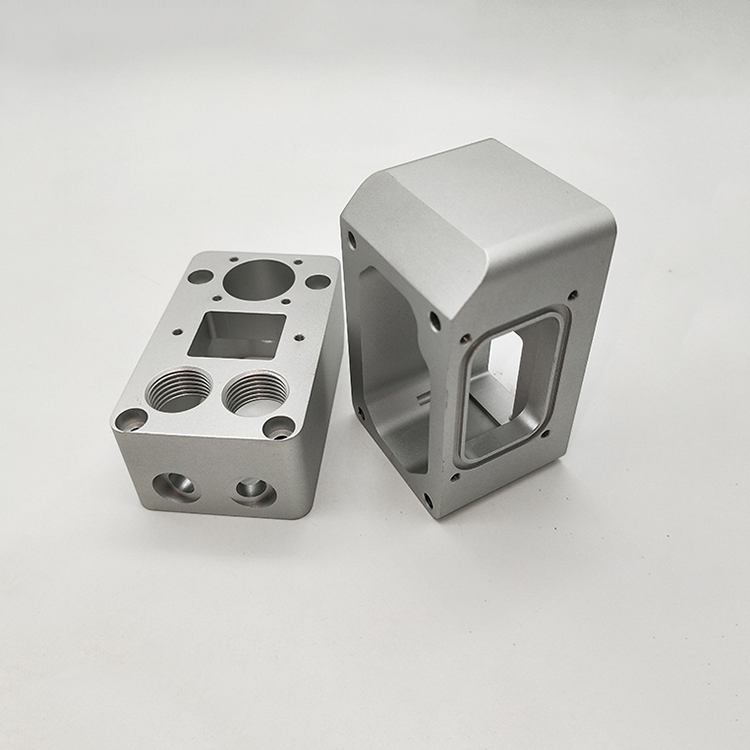

At Honyo Prototype, we engineer mission-critical telescope components where micron-level accuracy directly impacts optical performance and structural integrity. Our advanced CNC machining capabilities deliver complex, high-tolerance parts in aerospace-grade aluminum, titanium, Invar, and specialty composites—ensuring thermal stability, dimensional repeatability, and surface finishes critical for astronomical instrumentation. From primary mirror mounts to precision encoder housings, we solve the unique challenges of low-volume, high-complexity fabrication inherent in telescope development.

Our multi-axis milling and turning centers achieve sub-micron tolerances while maintaining strict material property control, validated through in-process CMM verification and first-article inspection reports. This technical rigor minimizes assembly drift and thermal distortion in sensitive optical systems, directly supporting your project’s performance targets. Honyo specializes in transitioning R&D designs into manufacturable realities without compromising on the geometric complexity required for next-generation telescope architectures.

Accelerate your prototyping timeline with Honyo’s Online Instant Quote platform. Upload your STEP or IGES files to receive a detailed manufacturability analysis and competitive pricing within hours—not days. This real-time transparency empowers engineering teams to iterate designs rapidly while maintaining budgetary control throughout the development cycle. For telescope projects demanding zero-compromise precision, Honyo Prototype delivers the technical execution and responsive partnership essential for success.

Technical Capabilities

The term “CNC telescope” does not refer to an optical or astronomical instrument in this context, but rather appears to describe a complex mechanical assembly or housing component typically manufactured using CNC machining processes. Such a component may be part of a motion system, inspection equipment, or adjustable support structure requiring high precision and repeatability. Below are the technical specifications related to the CNC machining of such a telescope-like assembly, focusing on multi-axis milling, turning, tight tolerances, and common engineering materials.

CNC Machining Specifications for Precision Telescope Assembly

| Parameter | Specification Details |

|---|---|

| Machining Type | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (for cylindrical components such as focus tubes or mounts) |

| Axis Capabilities | 3-Axis: XYZ linear motion for basic contouring and drilling. 4-Axis: Adds rotational A-axis (X-axis rotation), enabling indexing of cylindrical surfaces. 5-Axis: Full simultaneous motion with A and B or C axes, allowing complex angular features and undercuts without re-fixturing |

| Tolerance Levels | Standard: ±0.005 mm (±0.0002″) Tight Tolerance (Critical Interfaces): ±0.001 mm to ±0.0025 mm (±0.00004″ to ±0.0001″) Concentricity: ≤0.005 mm TIR (Total Indicated Runout) for rotating parts |

| Surface Finish | Typical: 0.8–3.2 µm Ra High-Precision Seals/Bearings: ≤0.4 µm Ra |

| Materials Processed | Aluminum (6061-T6, 7075-T6): Lightweight, high strength-to-density ratio, excellent machinability. Used for structural housings and optical mounts. Steel (4140, 17-4 PH Stainless): High strength and wear resistance. Used for load-bearing shafts, gears, and precision spindles. ABS (Acrylonitrile Butadiene Styrene): Moderate strength, good impact resistance. Used for non-structural covers, enclosures, or prototypes. Nylon (PA6, PA66): Low friction, high wear resistance. Used for bushings, insulating spacers, and non-metallic bearing surfaces |

| Feature Complexity | Deep pocketing, thin walls (as low as 0.5 mm), helical interpolation for thread milling, angled mounting surfaces, integrated cooling channels (in high-performance variants) |

| Tooling Requirements | Carbide end mills (2–10 mm diameter), micro-drills (down to 0.5 mm), high-precision collet systems (e.g., ER25, HSK), and through-coolant tooling for deep cavity machining |

| Inspection Methods | CMM (Coordinate Measuring Machine), optical comparators, laser micrometers, roundness testers for turned components |

| Secondary Operations | Deburring (manual and automated), passivation (stainless steel), anodizing (aluminum), heat treatment (steel), precision cleaning |

This machining approach ensures repeatable production of telescope assemblies with precise alignment features, thermal stability, and long-term durability under dynamic loading. Multi-axis CNC capabilities reduce setup time and improve geometric accuracy, especially for parts requiring compound angles or internal features not accessible via 3-axis methods.

From CAD to Part: The Process

Honyo Prototype executes CNC telescope component manufacturing through a rigorously defined workflow designed for optical precision and client transparency. The process begins when clients upload native or neutral format CAD files including STEP IGES or Parasolid via our secure customer portal. Our system validates file integrity and extracts critical geometries dimensional tolerances surface finish specifications and material requirements essential for astronomical applications.

Next our proprietary AI quoting engine processes the CAD data against dynamic parameters including real-time machine availability material costs labor rates and historical production metrics. This generates a detailed quote within 2 hours specifying exact pricing lead time machining strategies and any preliminary feasibility flags such as micron-level tolerances requiring specialized tooling or environmental controls during machining.

The Design for Manufacturability DFM phase follows immediately upon quote acceptance. Our senior optical manufacturing engineers conduct a comprehensive review focusing on telescope-specific challenges like mirror substrate stress points baffle light-trap geometries and thermal expansion compatibility between dissimilar materials. We provide actionable feedback through annotated CAD markups and a formal DFM report identifying potential assembly conflicts surface metrology risks or opportunities to optimize weight without compromising optical performance. Client approval of the DFM package is mandatory before proceeding.

Production initiates in our climate-controlled facility with strict particulate control. Telescope components undergo precision CNC machining using 5-axis milling centers with sub-micron repeatability and diamond turning for optical surfaces. Critical stages include stress-relieved aluminum or Zerodur substrate milling mirror figure generation via slow-servo turning and baffle tube threading with controlled surface roughness Ra < 0.8 μm. All processes adhere to ISO 9001 protocols with in-process metrology using coordinate measuring machines and laser trackers. Final optical surfaces are verified through interferometry to λ/10 accuracy.

Delivery encompasses rigorous packaging in custom foam-lined containers with desiccant for mirror assemblies and shock-monitoring labels. Each shipment includes full traceability documentation first-article inspection reports interferometer maps and a certificate of conformance. Standard delivery is 15-20 business days from DFM approval with expedited options available. We provide real-time shipment tracking and post-delivery support including assembly guidance for complex optical trains. This closed-loop process ensures your telescope components meet the exacting demands of observational astronomy with zero defects on arrival.

Start Your Project

For precision CNC telescope components manufactured to exact specifications, contact Susan Leo at [email protected]. Honyo Prototype offers advanced CNC machining services from our ISO-certified factory in Shenzhen, ensuring high accuracy, rapid turnaround, and consistent quality for optical and aerospace applications.

We specialize in complex, low-volume prototypes and scalable production runs, leveraging state-of-the-art 3-, 4-, and 5-axis CNC equipment. Our in-house capabilities include milling, turning, and finishing of aluminum, stainless steel, and specialty alloys commonly used in telescope assemblies.

Partner with a trusted manufacturer serving global clients in the photonics and instrumentation industries. Reach out today to request a quote or discuss your design requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.