Introduction: Navigating the Global Market for cnc tap

Navigating the complexities of sourcing CNC taps can be a daunting challenge for international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. As industries increasingly rely on precision engineering and automation, understanding the nuances of CNC taps becomes crucial. This guide is designed to demystify the global market for CNC taps, providing insights into various types, applications, and the latest technological advancements.

In the following sections, we will explore the essential criteria for selecting the right CNC tap for your specific needs, including material considerations, precision levels, and compatibility with existing machinery. Additionally, we will cover supplier vetting processes to ensure you partner with reputable manufacturers, as well as cost analysis to help you budget effectively.

By the end of this guide, B2B buyers will be equipped with the knowledge to make informed purchasing decisions, ensuring that they not only acquire high-quality CNC taps but also foster long-term supplier relationships. Whether you’re in Germany, Saudi Arabia, or beyond, this comprehensive resource will empower you to navigate the global CNC tap market with confidence, leading to enhanced operational efficiency and product quality in your projects.

Understanding cnc tap Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Voron Tap V1 | Lightweight aluminum alloy construction, 5V only, optical microswitch | 3D printing setups, particularly Voron models | Pros: Easy installation, high sensitivity. Cons: Limited voltage range, may require specific compatibility checks. |

| CNC Voron Tap V2 | Supports 5-24V, enhanced stability with Hiwin rail, new optical sensor | Advanced 3D printing, industrial applications | Pros: Versatile voltage support, improved accuracy. Cons: Higher cost, may require additional setup for optimal performance. |

| Optical Sensor Tap | Utilizes optical sensors for triggering, reducing mechanical wear | Automated machinery, robotics | Pros: Reduced maintenance, high precision. Cons: May be sensitive to environmental factors, requiring careful placement. |

| Mechanical Tap | Traditional mechanical switch design, robust construction | General manufacturing, prototyping | Pros: Durable and reliable, low cost. Cons: Higher wear and tear, less sensitivity compared to optical types. |

| Magnetic Tap | Uses magnetic sensors for triggering, compact design | Compact machinery, space-constrained setups | Pros: Space-efficient, reliable in harsh environments. Cons: Potentially limited range of motion, requires careful installation. |

What Are the Characteristics of CNC Voron Tap V1 and Its Applications?

The CNC Voron Tap V1 is primarily designed for 3D printing applications, particularly with Voron printers. Its lightweight aluminum alloy construction makes it easy to install and minimizes impact on the printer’s movement. However, it operates on a 5V power supply only, which may limit its use in more versatile setups. B2B buyers should consider compatibility with existing systems before purchasing, as the V1 may require specific voltage configurations.

How Does CNC Voron Tap V2 Improve Upon Its Predecessor?

CNC Voron Tap V2 offers significant enhancements over the V1, including support for a wider voltage range (5-24V) and improved stability through the use of a Hiwin rail. This model is suitable for advanced 3D printing applications and industrial setups, where precision and flexibility are crucial. The introduction of a new optical sensor enhances its reliability and accuracy. Buyers should weigh the higher cost against the performance benefits, especially in high-demand environments.

What Advantages Do Optical Sensor Taps Provide for B2B Buyers?

Optical sensor taps are designed to utilize light-based triggering mechanisms, which significantly reduce mechanical wear compared to traditional taps. This makes them ideal for automated machinery and robotics where precision and longevity are essential. B2B buyers should consider the environmental conditions in which these sensors will operate, as they can be sensitive to dust and other obstructions that may affect performance.

Why Choose Mechanical Taps in Certain Manufacturing Scenarios?

Mechanical taps are known for their robust construction and reliability, making them a popular choice in general manufacturing and prototyping environments. They offer a cost-effective solution, but their traditional design may lead to higher wear rates and less sensitivity compared to newer technologies. B2B buyers looking for durability and lower upfront costs may find mechanical taps to be a suitable option, particularly in less demanding applications.

What Are the Benefits of Using Magnetic Taps in Compact Machinery?

Magnetic taps leverage magnetic sensors to trigger actions, allowing for a compact design that is beneficial in space-constrained setups. They are particularly useful in environments where reliability is crucial, such as in harsh industrial settings. However, B2B buyers should consider the potential limitations in the range of motion and ensure proper installation to maximize effectiveness.

Key Industrial Applications of cnc tap

| Industry/Sector | Specific Application of cnc tap | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Precision machining of components | Enhanced accuracy and reduced waste in production | Supplier reliability, certifications, and material quality |

| Aerospace | Manufacturing of critical structural parts | High durability and compliance with safety standards | Quality assurance processes and international shipping options |

| Electronics | Assembly of circuit boards and enclosures | Improved efficiency and reduced assembly time | Compatibility with existing systems and after-sales support |

| Medical Devices | Production of intricate medical instruments | Strict adherence to hygiene and precision requirements | Regulatory compliance and sourcing from certified suppliers |

| Consumer Goods | Customization of product designs | Increased customer satisfaction through tailored solutions | Flexibility in production and rapid prototyping capabilities |

How is CNC Tap Used in the Automotive Industry?

In the automotive sector, CNC taps are essential for precision machining of components such as engine blocks, transmission cases, and chassis parts. These components require high accuracy to ensure optimal performance and safety. By utilizing CNC taps, manufacturers can significantly reduce waste through efficient material use and minimize the likelihood of defects. International buyers should prioritize suppliers with proven track records in automotive standards, such as ISO/TS 16949 certification, to ensure quality and compliance.

What Role Does CNC Tap Play in Aerospace Manufacturing?

The aerospace industry relies on CNC taps for the production of critical structural components, including wing frames and fuselage sections. Given the stringent safety regulations, the precision and durability offered by CNC taps are invaluable. These tools help ensure that parts can withstand extreme conditions while maintaining structural integrity. Buyers in this sector must consider suppliers that demonstrate compliance with aerospace standards, such as AS9100, and can provide detailed documentation of their quality assurance processes.

How is CNC Tap Beneficial for Electronics Assembly?

CNC taps are widely used in the electronics industry for assembling circuit boards and enclosures. Their ability to produce intricate designs with high precision enhances efficiency and reduces assembly time. This is particularly important as electronic devices become more compact and complex. When sourcing CNC taps, international buyers should look for manufacturers that offer compatibility with various electronic components and provide robust after-sales support to address any technical issues.

Why is CNC Tap Important in Medical Device Production?

In the medical device sector, CNC taps are crucial for the production of intricate instruments such as surgical tools and diagnostic equipment. The need for high precision and adherence to hygiene standards makes CNC taps an ideal choice for this industry. Suppliers must be able to demonstrate compliance with medical regulations, such as ISO 13485, and ensure that all materials are biocompatible. Buyers should prioritize sourcing from certified suppliers to mitigate risks associated with product recalls or compliance issues.

How Does CNC Tap Support Customization in Consumer Goods?

CNC taps facilitate the customization of product designs in the consumer goods sector, allowing manufacturers to respond quickly to market demands. This capability enhances customer satisfaction by providing tailored solutions. The flexibility in production afforded by CNC taps enables rapid prototyping, which is crucial for testing new designs. International buyers should seek suppliers that can accommodate quick turnaround times and possess the technological capabilities to produce diverse product variations.

3 Common User Pain Points for ‘cnc tap’ & Their Solutions

Scenario 1: Navigating Installation Complexities of CNC Taps

The Problem: One of the most common challenges B2B buyers face with CNC taps is the complexity involved in installation. Many buyers, particularly in regions like Africa and South America, encounter difficulties due to a lack of clear installation guides and support. This can lead to significant downtime, as incorrect installation may require additional troubleshooting or even product replacement. Furthermore, the disparity in technical expertise among teams can exacerbate these issues, resulting in frustration and wasted resources.

The Solution: To mitigate installation challenges, buyers should prioritize sourcing CNC taps that come with comprehensive installation manuals and video guides. Companies like ChaoticLab provide detailed build manuals that outline the installation process step-by-step. Additionally, engaging with online communities, such as those on GitHub or dedicated forums, can provide real-time support and troubleshooting tips from experienced users. For businesses operating in areas with limited technical support, investing in training sessions or workshops can also empower employees with the necessary skills to install and maintain CNC taps effectively.

Scenario 2: Ensuring Compatibility with Existing Systems

The Problem: Another prevalent issue is ensuring that the CNC tap is compatible with existing machinery and systems. Buyers often face compatibility challenges due to the diverse range of CNC machines available in the market, which can lead to operational inefficiencies. For instance, a buyer in the Middle East might purchase a CNC tap that is not compatible with their specific printer model, resulting in wasted time and financial resources.

The Solution: To avoid compatibility pitfalls, it is crucial for buyers to conduct thorough research before making a purchase. This includes reviewing the specifications of the CNC tap and comparing them against the requirements of existing machinery. Buyers should also consult with manufacturers about compatibility with specific printer models, such as VORON V2.4 or Trident, which are known to work well with certain CNC taps. Additionally, utilizing a checklist that includes dimensions, voltage requirements, and mounting options can help ensure that the selected CNC tap will integrate seamlessly into existing systems.

Scenario 3: Addressing Performance and Maintenance Concerns

The Problem: Performance consistency and maintenance are vital concerns for B2B buyers using CNC taps. Many users report issues with precision, noise levels, and wear over time, which can lead to decreased productivity and increased costs. For example, a buyer in Europe may find that their CNC tap is not delivering the expected accuracy, resulting in quality control issues in their production line.

The Solution: To enhance performance and longevity, buyers should invest in high-quality CNC taps that are designed for durability and precision, such as those made from Al6061 T6 aluminum with advanced optical sensors. Regular maintenance is also crucial; creating a maintenance schedule that includes routine cleaning and lubrication can significantly extend the lifespan of the equipment. Buyers should look for taps that allow for easy maintenance, such as those with pre-installed linear guide rails, which can simplify the upkeep process. Moreover, staying connected with supplier support for guidance on best practices can help address performance-related concerns proactively, ensuring that operations run smoothly.

Strategic Material Selection Guide for cnc tap

When selecting materials for CNC taps, several factors must be considered to ensure optimal performance and longevity in various applications. The following analysis covers four common materials used in CNC tap manufacturing, focusing on their properties, advantages and disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Aluminum Alloys for CNC Taps?

Aluminum alloys, particularly Al6061 T6, are widely used in CNC taps due to their excellent mechanical properties. They offer a good balance of strength, weight, and corrosion resistance. Aluminum’s lightweight nature (approximately 2.7 g/cm³) reduces the overall weight of the CNC tap, which is crucial for maintaining the printer’s performance. Additionally, aluminum has a high thermal conductivity, which is beneficial for heat dissipation during operation.

Pros: Aluminum alloys are durable, lightweight, and resistant to rust and corrosion. They are also relatively easy to machine, which simplifies the manufacturing process and can lead to lower production costs.

Cons: While aluminum is strong, it is not as hard as some other materials, which may lead to wear over time. It also has a lower temperature resistance compared to materials like steel.

Impact on Application: Aluminum taps are suitable for a variety of media and applications, but they may not perform well in high-temperature environments.

Considerations for International Buyers: Compliance with standards such as ASTM or DIN is critical. Buyers in Europe, for example, may prefer materials that meet specific EU regulations regarding manufacturing and environmental impact.

How Do Steel Alloys Compare for CNC Tap Applications?

Steel alloys, particularly stainless steel, are known for their high strength and durability. They can withstand higher temperatures and pressures, making them suitable for more demanding applications. Stainless steel also offers excellent corrosion resistance, which is advantageous in environments where moisture or chemicals are present.

Pros: Steel taps are incredibly robust and have a longer lifespan due to their hardness and resistance to wear. They are suitable for high-temperature applications and can handle a wider range of media.

Cons: The primary downside is the weight; steel taps are heavier than their aluminum counterparts, which can affect the overall dynamics of the CNC machine. Additionally, they are more expensive to manufacture due to the complexity of machining steel.

Impact on Application: Steel taps are ideal for applications involving abrasive media or high-temperature environments, ensuring consistent performance over time.

Considerations for International Buyers: Buyers should ensure that the steel used complies with international standards such as JIS or ASTM. Countries like Germany and Saudi Arabia may have specific regulations regarding the import of steel products.

What Role Does Plastic Play in CNC Taps?

Plastics, particularly engineering plastics like PEEK or nylon, are sometimes used in CNC taps for specific applications. These materials are lightweight and can be engineered to have excellent chemical resistance.

Pros: Plastic taps are resistant to corrosion and are less likely to damage sensitive components. They are also lightweight, which can reduce the overall load on the CNC machine.

Cons: The primary limitation is their lower strength and temperature resistance compared to metals, making them unsuitable for high-stress applications.

Impact on Application: Plastic taps are best suited for applications involving non-abrasive media at lower temperatures, such as certain types of liquids or gases.

Considerations for International Buyers: Compliance with environmental standards is crucial, especially in regions with strict regulations on plastic use. Buyers should also consider the recyclability of the materials.

How Do Composite Materials Enhance CNC Tap Performance?

Composite materials, such as carbon fiber reinforced plastics, offer an interesting alternative for CNC taps. These materials combine the advantages of plastics and fibers to provide enhanced strength and reduced weight.

Pros: Composites are lightweight and can be engineered for high strength and stiffness. They also offer excellent corrosion resistance and can be tailored for specific applications.

Cons: The manufacturing process for composites can be complex and costly. They may also have limitations in terms of temperature resistance compared to metals.

Impact on Application: Composite taps are suitable for specialized applications where weight reduction and strength are critical, such as in aerospace or automotive industries.

Considerations for International Buyers: Buyers should verify that composite materials meet relevant international standards and certifications, particularly in regions with stringent safety regulations.

Summary Table of Material Selection for CNC Taps

| Material | Typical Use Case for cnc tap | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloy | General CNC applications | Lightweight and corrosion-resistant | Lower temperature resistance | Medium |

| Steel Alloy | High-stress environments | High strength and durability | Heavier and more expensive | High |

| Plastic | Low-stress applications | Corrosion-resistant and lightweight | Lower strength and temperature limits | Low |

| Composite | Specialized applications | High strength-to-weight ratio | Complex manufacturing process | High |

This analysis provides a comprehensive overview of the materials suitable for CNC taps, enabling international B2B buyers to make informed decisions based on performance, cost, and regulatory compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc tap

What Are the Key Stages in the Manufacturing Process of CNC Taps?

The manufacturing of CNC taps involves several critical stages, each designed to ensure high precision and quality in the final product. Understanding these processes helps B2B buyers appreciate the craftsmanship involved and the importance of selecting suppliers with robust manufacturing capabilities.

Material Preparation: How Is the Right Material Chosen?

The first stage involves selecting suitable materials, predominantly high-grade aluminum alloys, such as Al6061 T6. This material is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. Suppliers typically conduct a thorough material inspection to ensure compliance with specifications, including chemical composition and mechanical properties. This step is crucial as the material directly impacts the tap’s performance and durability.

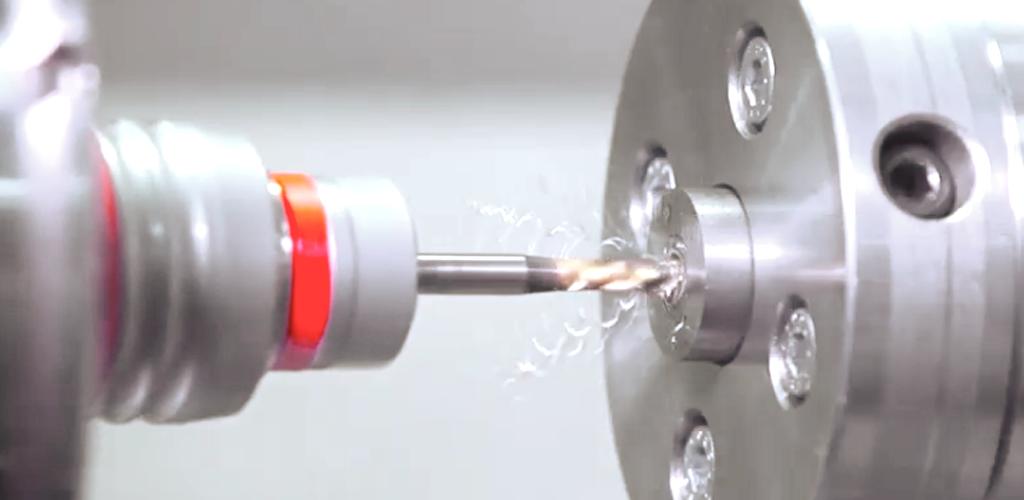

Forming: What Techniques Are Used to Shape CNC Taps?

After material selection, the shaping process begins. CNC machining is the primary technique used, employing computer-controlled tools to achieve high precision. This process allows for the creation of complex geometries and fine tolerances, often reaching precision levels of up to 0.4μm (0.0004mm). Machining centers may include milling, turning, and drilling operations, depending on the design requirements. Advanced techniques such as laser cutting may also be utilized for intricate designs.

Assembly: How Are CNC Taps Assembled for Optimal Performance?

Once individual components are machined, they move to the assembly stage. This process typically involves the integration of various parts, including sensors, guide rails, and electronic components. For instance, CNC taps often feature optical microswitches that enhance accuracy and reduce noise. During assembly, meticulous attention is paid to alignment and fitting to ensure that the final product operates smoothly and effectively. Quality checks at this stage may include verifying the functionality of electronic components and mechanical fittings.

Finishing: What Role Does Surface Treatment Play in Quality Assurance?

The finishing stage is vital for enhancing the durability and aesthetic appeal of CNC taps. Common finishing techniques include anodizing and polishing, which improve corrosion resistance and surface smoothness. These treatments are particularly important for applications in harsh environments, as they extend the lifespan of the product. A thorough inspection is conducted post-finishing to ensure that all surface treatments meet the required standards.

What Quality Assurance Practices Are Critical in CNC Tap Manufacturing?

Quality assurance is an integral part of the manufacturing process, ensuring that products meet specified standards and customer expectations. For B2B buyers, understanding these practices is essential for evaluating potential suppliers.

What International Standards Should Buyers Consider?

International standards such as ISO 9001 play a crucial role in quality assurance. ISO 9001 outlines the requirements for a quality management system (QMS), focusing on meeting customer needs and enhancing satisfaction. Compliance with this standard indicates that the manufacturer has established processes for consistent quality control.

In addition to ISO certifications, industry-specific standards such as CE marking for products sold in Europe and API standards for oil and gas applications may apply. These certifications demonstrate adherence to safety and performance requirements, which can be particularly relevant for B2B buyers in various sectors.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints throughout the manufacturing process include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials for compliance with specifications before they enter the production process. This step prevents defects from propagating through the manufacturing stages.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to monitor critical dimensions and tolerances. This ensures that any deviations are caught early, reducing waste and rework.

-

Final Quality Control (FQC): The final inspection occurs after assembly and finishing. This stage typically includes functional testing of the CNC tap to ensure it meets operational specifications. Any product not meeting quality standards is either reworked or discarded.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to ensure their suppliers adhere to high-quality standards. Here are several strategies:

-

Conduct Supplier Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control practices. This allows buyers to evaluate compliance with international standards and assess overall operational efficiency.

-

Request Quality Reports: Suppliers should be able to provide documentation demonstrating their adherence to quality standards. This may include inspection reports, test results, and certifications.

-

Utilize Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased assessment of a supplier’s quality control processes and product quality. This is particularly beneficial for international buyers who may not have direct access to suppliers.

What Are the Nuances of Quality Control for International B2B Buyers?

For B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Regional regulations and standards may vary significantly, affecting product acceptance and market entry.

-

Compliance with Local Regulations: Buyers should ensure that their suppliers comply with local regulations and standards. For example, products exported to the EU must meet CE marking requirements, while those intended for markets in the Middle East may need to comply with local certifications.

-

Cultural Considerations: Different regions may have varying expectations regarding quality and service. Understanding cultural nuances can enhance communication and collaboration with suppliers, ultimately leading to better quality outcomes.

-

Logistics and Supply Chain Considerations: International shipping can introduce variables that affect product quality, such as temperature and humidity control. Buyers should work with suppliers to ensure appropriate packaging and handling during transit to mitigate these risks.

By comprehensively understanding the manufacturing processes and quality assurance practices associated with CNC taps, B2B buyers can make informed decisions, fostering strong supplier relationships and ensuring the delivery of high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc tap’

To successfully procure a CNC tap, especially in the context of international B2B transactions, it’s essential to follow a structured approach. This guide provides a clear checklist to help you navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the technical specifications required for your CNC tap. This includes parameters like size, weight, material (such as aluminum alloys), and compatibility with specific printer models. Understanding these details will streamline your communication with suppliers and ensure you select a product that meets your operational needs.

Step 2: Research Potential Suppliers

Invest time in researching various suppliers that specialize in CNC taps. Look for manufacturers with a solid reputation in the industry, particularly those who have experience with the specific models you are interested in, such as the Voron V2.4 or Trident. Evaluate their online presence, customer reviews, and feedback from other buyers to gauge their reliability and product quality.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers possess the necessary certifications and quality assurances. Certifications may include ISO standards or specific industry-related accreditations that indicate adherence to quality management systems. This step is crucial as it helps mitigate risks associated with product performance and compliance with international standards.

Step 4: Request Samples

Once you have narrowed down your options, request samples of the CNC taps you are considering. Testing samples allows you to assess the quality, precision, and functionality of the products firsthand. Look for indicators such as the weight, ease of installation, and operational noise levels, especially if the tap is designed for high precision applications.

Step 5: Assess Pricing and Payment Terms

Analyze the pricing structures provided by different suppliers while ensuring they align with your budget. Pay attention to the total cost of ownership, including shipping, taxes, and potential import duties. Additionally, clarify payment terms—look for flexible options that could include credit terms or discounts for bulk orders.

Step 6: Review Warranty and After-Sales Support

Investigate the warranty terms offered by the suppliers, as well as the level of after-sales support available. A robust warranty can safeguard your investment against defects and performance issues. Ensure the supplier provides accessible customer service for troubleshooting and maintenance advice, which is vital for minimizing downtime in production.

Step 7: Finalize Your Order and Logistics

Once you have selected a supplier, finalize your order details, including quantities, shipping methods, and delivery timelines. Discuss logistics thoroughly to prevent any delays in receiving your CNC taps. Consider factors such as shipping costs and customs clearance procedures, especially when sourcing from international suppliers.

By following this checklist, B2B buyers can navigate the complexities of sourcing CNC taps more effectively, ensuring they make informed decisions that align with their operational requirements and business goals.

Comprehensive Cost and Pricing Analysis for cnc tap Sourcing

What Are the Key Cost Components for CNC Tap Production?

When sourcing CNC taps, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials, such as aluminum alloys (e.g., Al6061 T6), significantly impacts the cost. Higher quality materials enhance durability and performance but come at a premium.

-

Labor: Labor costs vary based on geographic location and the complexity of the manufacturing process. Skilled labor is essential for precision machining, which is critical for achieving the ultra-high precision levels of 0.4μm associated with CNC taps.

-

Manufacturing Overhead: This encompasses expenses related to facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize overhead, ultimately affecting pricing.

-

Tooling: Tooling costs include the expense of specialized equipment and dies required for producing CNC taps. These costs can be amortized over larger production runs, making it essential to consider order volume.

-

Quality Control (QC): Rigorous quality control measures are necessary to ensure product reliability and adherence to specifications. The costs associated with QC can vary based on the complexity of the product and the certifications required.

-

Logistics: Shipping and handling costs, including customs duties and insurance, play a significant role in overall expenses, especially for international buyers. Understanding Incoterms is vital for clarifying responsibilities and costs.

-

Margin: Suppliers will typically include a profit margin in their pricing, which can vary significantly based on market demand, competition, and the perceived value of the product.

How Do Price Influencers Affect CNC Tap Sourcing?

Several factors influence the pricing of CNC taps, which can vary significantly across regions:

-

Volume/MOQ: Minimum order quantities (MOQs) often lead to discounts. Higher volumes generally reduce the per-unit cost, making it beneficial for buyers to consolidate orders.

-

Specifications and Customization: Custom designs or specific technical requirements can increase costs. Buyers should clearly define their specifications to avoid unexpected price hikes.

-

Material Quality and Certifications: Higher quality materials and relevant certifications (e.g., ISO standards) can command higher prices. Buyers should assess whether the certifications are necessary for their intended application.

-

Supplier Factors: Supplier reputation, reliability, and customer service can influence pricing. Established suppliers may offer higher prices due to their proven track record but may provide better quality assurance.

-

Incoterms: Understanding shipping terms can significantly affect pricing. Different Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and duties, which can impact total costs.

What Are Effective Buyer Tips for Negotiating CNC Tap Prices?

When negotiating prices for CNC taps, especially in international markets, buyers can leverage several strategies:

-

Research and Benchmarking: Conduct thorough research to understand market prices and competitor offerings. This information can strengthen your negotiation position.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better pricing and terms. Long-term partnerships often yield discounts and improved service.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the TCO, which includes maintenance, operational costs, and potential downtime. A lower initial price may lead to higher long-term expenses.

-

Negotiate Based on Volume: If feasible, commit to larger orders to negotiate lower prices. Suppliers are often more willing to provide discounts for bulk purchases.

-

Stay Informed on Market Trends: Fluctuations in material costs and global supply chain issues can affect pricing. Staying informed helps you time your purchases effectively.

Conclusion: What Should International Buyers Keep in Mind?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing CNC taps is critical. Currency fluctuations, shipping logistics, and local regulations can all influence costs. Always seek multiple quotes and consider engaging with local representatives who understand the regional market dynamics. Keep in mind that the prices discussed are indicative and can vary based on specific circumstances and market conditions.

Alternatives Analysis: Comparing cnc tap With Other Solutions

Exploring Alternatives to CNC Tap: A Comparative Analysis

In the realm of automated tapping solutions, businesses often seek alternatives to the CNC Tap due to varying operational needs, budget constraints, or specific application requirements. Understanding the strengths and weaknesses of different technologies can empower B2B buyers to make informed decisions that align with their production goals.

| Comparison Aspect | Cnc Tap | Alternative 1: Auto Z Klicky | Alternative 2: Manual Tapping System |

|---|---|---|---|

| Performance | Ultra-high precision (0.4μm) | Moderate precision; slower response | Variable precision; dependent on operator skill |

| Cost | $46.99 (V2 model) | $20 – $30 | $10 – $50 |

| Ease of Implementation | Easy installation; minimal setup | Requires calibration; moderate setup | Requires training; labor-intensive |

| Maintenance | Low; occasional cleaning needed | Moderate; needs regular checks | High; frequent maintenance and setup |

| Best Use Case | High-volume, precision tasks | Prototyping and light-duty tasks | Low-budget projects and manual applications |

What are the Advantages and Disadvantages of Auto Z Klicky?

The Auto Z Klicky is a popular alternative that offers a mechanical approach to bed leveling and probing. While it provides moderate precision, it operates at a slower response rate compared to the CNC Tap. The cost is relatively lower, making it attractive for businesses with budget constraints. However, it requires more calibration and setup time, which can reduce overall efficiency. Maintenance is moderate, as it necessitates regular checks to ensure consistent performance. This solution is ideal for prototyping and light-duty tasks but may fall short in high-volume production environments.

How Does a Manual Tapping System Compare?

Manual tapping systems are a traditional approach that can be highly effective in low-budget scenarios. They are cost-effective, with prices ranging from $10 to $50, depending on the quality and complexity of the tool. However, the precision is variable, heavily relying on the operator’s skill and experience. Implementing a manual system requires significant training, making it labor-intensive. Maintenance demands are high, as frequent checks and adjustments are necessary to maintain performance. While this solution can be suitable for small-scale projects or DIY applications, it may not meet the rigorous demands of professional manufacturing.

Conclusion: How to Choose the Right Tapping Solution for Your Business?

When selecting a tapping solution, B2B buyers must consider various factors, including performance requirements, budget constraints, and the scale of operations. The CNC Tap stands out for its precision and low maintenance, making it an excellent choice for high-volume production settings. In contrast, alternatives like the Auto Z Klicky and manual systems offer different advantages that may better suit smaller projects or budget-sensitive operations. Ultimately, the right choice will depend on the specific needs of the business, including production volume, desired accuracy, and available resources for implementation and maintenance. By evaluating these aspects, buyers can make informed decisions that enhance their operational efficiency and product quality.

Essential Technical Properties and Trade Terminology for cnc tap

What Are the Key Technical Properties of CNC Taps?

Understanding the essential technical properties of CNC taps is crucial for B2B buyers to make informed purchasing decisions. Below are critical specifications that define the performance and suitability of CNC taps.

1. Material Grade: Why Is It Important?

Most CNC taps are constructed from high-grade materials such as Al6061 T6 aluminum or stainless steel. The material grade significantly affects durability, wear resistance, and heat tolerance. For instance, Al6061 T6 is known for its excellent strength-to-weight ratio and corrosion resistance, making it ideal for high-performance applications. Buyers must consider the material grade to ensure the CNC tap meets their specific operational conditions and longevity expectations.

2. Tolerance: How Does Precision Affect Performance?

Tolerance refers to the allowable deviation in the dimensions of the CNC tap components. For high-precision applications, tolerances as tight as 0.4μm (0.0004mm) are often specified. This level of precision is critical for applications where accuracy is paramount, such as in 3D printing or CNC machining. A CNC tap that meets strict tolerance standards ensures consistent performance and reduces the risk of errors during operation.

3. Weight: Why Is It a Critical Factor?

The weight of a CNC tap, often measured in grams, influences its impact on the overall system. For example, a lightweight design (around 59.8g) minimizes the strain on the printer’s moving parts, enhancing operational efficiency. When selecting a CNC tap, buyers should evaluate the weight to ensure it aligns with their machinery’s capabilities and does not impede performance.

4. Voltage Compatibility: How Does It Affect Usability?

CNC taps may have specific voltage requirements, such as 5V or a wider range of 5-24V. This compatibility is vital for ensuring seamless integration with existing systems. Buyers should verify the voltage specifications to avoid potential operational issues and ensure compatibility with their power supply setups.

5. Probing Life Span: What Should Buyers Expect?

The life span of a CNC tap’s probing mechanism is another key property. Many taps are rated for over 70 million probing cycles, indicating their durability and reliability over time. Understanding the expected life span helps buyers assess long-term value and maintenance needs, making it an essential consideration in the purchasing process.

What Common Trade Terms Should B2B Buyers Know?

In addition to technical properties, being familiar with industry terminology is crucial for effective communication and decision-making in B2B transactions.

1. OEM (Original Equipment Manufacturer): What Does It Mean?

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of CNC taps, understanding OEM relationships can help buyers identify quality standards and compatibility with their existing systems.

2. MOQ (Minimum Order Quantity): Why Is It Relevant?

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to plan their inventory and budget effectively. It can also indicate the supplier’s commitment to quality and production efficiency.

3. RFQ (Request for Quotation): How Should It Be Used?

An RFQ is a document that a buyer sends to suppliers to request pricing and other details for specific products. Crafting a detailed RFQ for CNC taps can help buyers receive accurate quotes and make better purchasing decisions based on cost, specifications, and lead times.

4. Incoterms: Why Are They Important for International Trade?

Incoterms (International Commercial Terms) are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand their obligations regarding shipping, insurance, and delivery, which is particularly important for international B2B transactions involving CNC taps.

5. Lead Time: What Should You Expect?

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is crucial for inventory management and project planning, allowing buyers to align their production schedules accordingly.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and long-term success in their projects involving CNC taps.

Navigating Market Dynamics and Sourcing Trends in the cnc tap Sector

What Are the Current Market Dynamics and Key Trends in the CNC Tap Sector?

The CNC tap sector is witnessing a transformative period characterized by increased automation, precision engineering, and the integration of advanced materials. Key drivers of this evolution include the growing demand for high-quality manufacturing solutions across various industries, including automotive, aerospace, and consumer electronics. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers that offer innovative, reliable, and cost-effective solutions. The rise of Industry 4.0 has propelled the adoption of smart manufacturing technologies, enhancing operational efficiency and reducing lead times.

Emerging trends include the shift towards customization and rapid prototyping, enabling businesses to respond swiftly to market changes. The demand for CNC taps that support diverse voltage options, such as the new 5-24V models, reflects the need for greater flexibility in production environments. Additionally, advancements in sensor technology, like the use of optical microswitches, are enhancing the accuracy and durability of CNC taps, meeting the rigorous standards of modern manufacturing.

International buyers are also becoming more discerning, favoring suppliers that provide detailed product specifications and robust customer support. This shift necessitates a thorough understanding of the global supply chain landscape, including potential disruptions and sourcing challenges. Buyers should prioritize partnerships with manufacturers that demonstrate a commitment to quality control, innovation, and customer service to navigate this dynamic market effectively.

How Is Sustainability Influencing the Sourcing of CNC Taps in B2B Markets?

Sustainability has become a critical consideration in the sourcing of CNC taps, as businesses increasingly recognize their environmental impact. The manufacturing processes associated with CNC taps often involve significant energy consumption and waste generation. Therefore, international B2B buyers are now more inclined to seek out suppliers who prioritize eco-friendly practices and materials.

Ethical sourcing has emerged as a cornerstone of modern supply chains, emphasizing the importance of responsible procurement. Buyers are encouraged to assess suppliers based on their adherence to sustainability standards and certifications, such as ISO 14001, which focuses on effective environmental management systems. Additionally, the use of recycled materials and sustainable manufacturing practices can significantly mitigate the carbon footprint associated with CNC tap production.

Investing in ‘green’ certifications not only enhances brand reputation but also aligns with the increasing regulatory demands for sustainability in various regions. By choosing suppliers committed to sustainable practices, businesses can ensure they are contributing positively to the environment while also meeting the expectations of eco-conscious consumers and stakeholders.

What Is the Evolution of CNC Taps and Its Relevance to B2B Buyers?

The evolution of CNC taps dates back to the early developments in automation and precision machining. Initially designed for basic applications, these tools have undergone significant advancements, driven by technological innovations and the increasing demands of various industries. The introduction of CNC technology revolutionized the manufacturing landscape, allowing for higher accuracy, repeatability, and efficiency in production processes.

Over the years, CNC taps have evolved to incorporate advanced materials such as aluminum alloys, which enhance durability and reduce weight. The latest models, including those designed for specific 3D printer configurations like the Voron series, highlight the trend towards specialization and customization in the CNC tap market.

This evolution is particularly relevant for B2B buyers seeking reliable and innovative solutions that can adapt to their unique production needs. Understanding the historical context of CNC taps aids buyers in making informed decisions, ensuring they invest in tools that not only meet current performance standards but also align with future industry developments.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc tap

-

How do I choose the right CNC tap for my application?

Selecting the appropriate CNC tap involves considering factors such as precision, material compatibility, and application requirements. Look for taps with high precision ratings (e.g., 0.4μm) and robust materials like Al6061 T6 aluminum for durability. Assess the compatibility with your specific CNC machine model, such as the Voron series, and consider the effective travel impact. Reviewing user feedback and performance comparisons can also guide your choice, ensuring that you select a tap that meets your operational needs while minimizing potential issues. -

What is the best way to evaluate suppliers of CNC taps?

Evaluating suppliers requires a multi-faceted approach. Start by checking their industry reputation through reviews and testimonials from previous clients. Request samples to assess product quality firsthand. Verify certifications related to quality management, such as ISO standards, and inquire about their manufacturing processes. Additionally, assess their customer service responsiveness and support for international shipping, as reliable logistics are crucial for smooth operations across borders, particularly for buyers in Africa, South America, the Middle East, and Europe. -

What customization options are available for CNC taps?

Many suppliers offer customization options for CNC taps to meet specific operational requirements. This may include adjustments in size, voltage compatibility (e.g., 5V vs. 5-24V), or additional features like enhanced optical sensors. When discussing customization, clearly outline your needs, including technical specifications and intended applications. Be sure to inquire about any associated costs, lead times, and the supplier’s ability to accommodate such requests without compromising quality or performance. -

What are the minimum order quantities (MOQs) for CNC taps?

Minimum order quantities for CNC taps can vary significantly between suppliers. Some may offer flexible MOQs for smaller businesses, while others might require larger bulk orders to ensure cost-effectiveness. When negotiating, consider discussing your volume needs and potential for future orders. It’s essential to understand how MOQs impact pricing and shipping costs, particularly for international transactions, as these factors can affect your overall budgeting and planning. -

What payment terms should I expect when sourcing CNC taps internationally?

Payment terms in international trade can differ by supplier and region. Common options include upfront payments, deposits, or payment upon delivery. Discuss terms such as net 30 or net 60 days, which can help manage cash flow. Additionally, consider secure payment methods like letters of credit or escrow services to mitigate risks. Always clarify any currency exchange implications, especially when dealing with suppliers from diverse regions like Africa, South America, and Europe. -

How can I ensure quality assurance when purchasing CNC taps?

Quality assurance is critical when sourcing CNC taps. Request detailed specifications and documentation, including material certifications and manufacturing processes. Ask suppliers about their quality control measures, such as inspections and testing protocols during production. If possible, conduct on-site visits or audits to evaluate their facilities. Establishing clear quality benchmarks and expectations in advance can help mitigate risks and ensure that the final product meets your operational standards. -

What logistics considerations should I keep in mind when importing CNC taps?

Logistics play a vital role in the successful importation of CNC taps. Confirm the supplier’s shipping capabilities and timelines to ensure they align with your project schedules. Understand the customs regulations for your region, including any tariffs or duties that may apply. Work with a reliable freight forwarder who can assist with documentation and clearance processes. Additionally, factor in potential delays due to international shipping challenges, especially in regions with varying infrastructure reliability. -

How can I handle potential issues with CNC tap performance after purchase?

Addressing performance issues with CNC taps requires a proactive approach. Start by reviewing the installation and operating guidelines provided by the supplier. If problems persist, contact the supplier for support, as they may offer troubleshooting assistance or warranty services. Document any issues comprehensively, including performance metrics and operational conditions, to facilitate discussions with the supplier. Building a good relationship with your supplier can enhance communication and lead to quicker resolutions for any concerns.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Cnc Tap Manufacturers & Suppliers List

1. Chaotic Lab – CNC Voron Tap

Domain: chaoticlab.com

Registered: 2015 (10 years)

Introduction: CNC Voron Tap V1.0 / V2.0

– Regular price: $44.99

– Variants:

– CNC Voron Tap V2.0 (red) – sold out

– CNC Voron Tap V2.0 (black) – sold out

– CNC Voron Tap V1.0 (black) – sold out

– CNC Voron Tap Sensor V2.1 – sold out

– 30-day money back guarantee

– Fast global shipping

– 1-year warranty

– Weight: 65g without screws

– Compatibility: Requires MGN12 X-Axis, not older MGN9

– Features:

– …

2. VORON – CNC Voron Tap Module

Domain: github.com

Registered: 2007 (18 years)

Introduction: Designed for VORON2.4 R2 and VORON Trident. CNC Voron Tap circuit module is 5V ONLY.

3. Vitalii – CNC TAP Kit

Domain: kb-3d.com

Registered: 2019 (6 years)

Introduction: Vitalii CNC TAP Kit for Voron; Free shipping on purchases over $150 (Contiguous US only); Same day shipping cut-off at 2PM EST.

4. Voron Design – CNC Tap Insights

Domain: forum.vorondesign.com

Registered: 2018 (7 years)

Introduction: CNC Tap experiences discussed in the Voron Design Forums highlight several key points: 1. Users recommend considering the rigidity of the aluminum tap and the importance of choosing the right model. 2. Concerns about the ChaoticLab CNC Tap include inadequate customer support and design flaws, such as the use of a single MGN7 rail without side stabilization, leading to wobble. 3. Users have reporte…

5. CHAOTICLAB – CNC Voron Tap Black V2

Domain: 3djake.com

Registered: 2015 (10 years)

Introduction: {“product_name”: “CHAOTICLAB CNC Voron Tap Black V2”, “price”: “53.54”, “weight”: “65g”, “material”: “Al6061 aluminium”, “model_type”: [“V2.4 R1/R2”, “Trident”], “features”: [“CNC milled”, “HIWIN MGN7H linear rails”, “OMRON EE-SX4320 optical microswitch”, “Easy installation”, “Lightweight design”], “compatibility”: [“LDO Motors Voron V2.4”, “LDO Motors Voron Trident”], “included_items”: [“1 x CNC …

6. Fabreeko – CHAOTICLAB CNC Voron Tap v2

Domain: fabreeko.com

Registered: 2020 (5 years)

Introduction: {“product_name”: “CHAOTICLAB CNC Voron Tap v2”, “price”: “$46.99”, “color_options”: [“Black”, “Red”], “stock_status”: “Only 0 left in stock”, “description”: “Smaller and lightweight, this full CNC version of tap features a Hiwin rail for excellent performance and durability. Experience higher accuracy and reliability with the OMRON EE-SX4320.”, “specifications”: {“precision”: “0.4μm (0.0004mm)”, “…

7. 3DP Blog – CNC Voron Tap v2

Domain: 3dpblog.com

Registered: 2017 (8 years)

Introduction: CNC Voron Tap v2 is a DIY ultra-precision optic sensor for auto bed leveling (ABL) designed for CoreXY 3D printers like Voron 2.4 and Voron Trident. It features a high precision of 0.4μm (0.0004mm) and consists of a fixed part (red), moving part (black), an optic sensor, small MGN09 rail, and magnets. The CNC version weighs 65g and integrates a Hiwin linear rail, offering better sturdiness and res…

Strategic Sourcing Conclusion and Outlook for cnc tap

In the rapidly evolving landscape of CNC technology, strategic sourcing of CNC taps has emerged as a pivotal factor for international B2B buyers. Key takeaways highlight the importance of selecting high-quality materials, such as Al6061 T6 aluminum, and ensuring compatibility with specific printer models like the VORON series. Buyers should prioritize precision engineering, as demonstrated by the ultra-high accuracy of 0.4μm, which significantly enhances operational efficiency and product quality.

Investing in reliable suppliers who offer robust customer support and clear installation guidelines can mitigate risks associated with sourcing. The transition from V1 to V2 models illustrates the continuous improvement in design and functionality, providing buyers with options that cater to diverse operational needs.

Looking ahead, businesses in Africa, South America, the Middle East, and Europe should leverage strategic sourcing to not only reduce costs but also to enhance their competitive edge in the market. By focusing on partnerships with reputable manufacturers and staying abreast of technological advancements, companies can position themselves for sustained growth. Now is the time to evaluate your CNC tap sourcing strategy and embrace innovations that drive performance and reliability.