Contents

Manufacturing Insight: Cnc Swiss Screw Machines

Precision Engineered Components Start Here: Honyo Prototype’s CNC Swiss Screw Machining Expertise

Honyo Prototype delivers mission-critical precision for complex, high-volume micro-components through advanced CNC Swiss screw machining. Our specialized Swiss-type lathes excel in producing intricate geometries—such as medical implants, aerospace fittings, and optical connectors—with exceptional repeatability at scales where sub-micron tolerances (±0.0002″) and flawless surface finishes are non-negotiable. Unlike conventional CNC turning, Swiss machining stabilizes the workpiece via a guide bushing during cutting, minimizing deflection to achieve superior accuracy on slender, delicate parts under 25mm diameter.

At Honyo, we integrate multi-axis live tooling, Y-axis milling, and secondary operations—including cross-drilling, threading, and milling—within a single setup. This eliminates handling errors, reduces lead times by up to 40%, and ensures stringent compliance with AS9100 and ISO 13485 standards. Our engineering team collaborates early in your design phase to optimize manufacturability, leveraging material science expertise across stainless steels, titanium, PEEK, and exotic alloys.

Accelerate your prototyping and production with Honyo’s Online Instant Quote platform. Upload your STEP or IGES file to receive a detailed technical assessment, DFM feedback, and a binding price within 2 hours—no sales calls or email delays. Experience how our Swiss machining capabilities transform design complexity into manufacturing certainty.

Typical Lead Time Comparison

| Service Tier | Industry Standard | Honyo Prototype |

|——————–|——————-|—————-|

| Prototype (10 pcs) | 15-20 business days | 7-10 business days |

| Production (1k pcs)| 25-30 business days | 12-18 business days |

Request your instant quote today and validate why global innovators trust Honyo for zero-defect Swiss-turned components.

Technical Capabilities

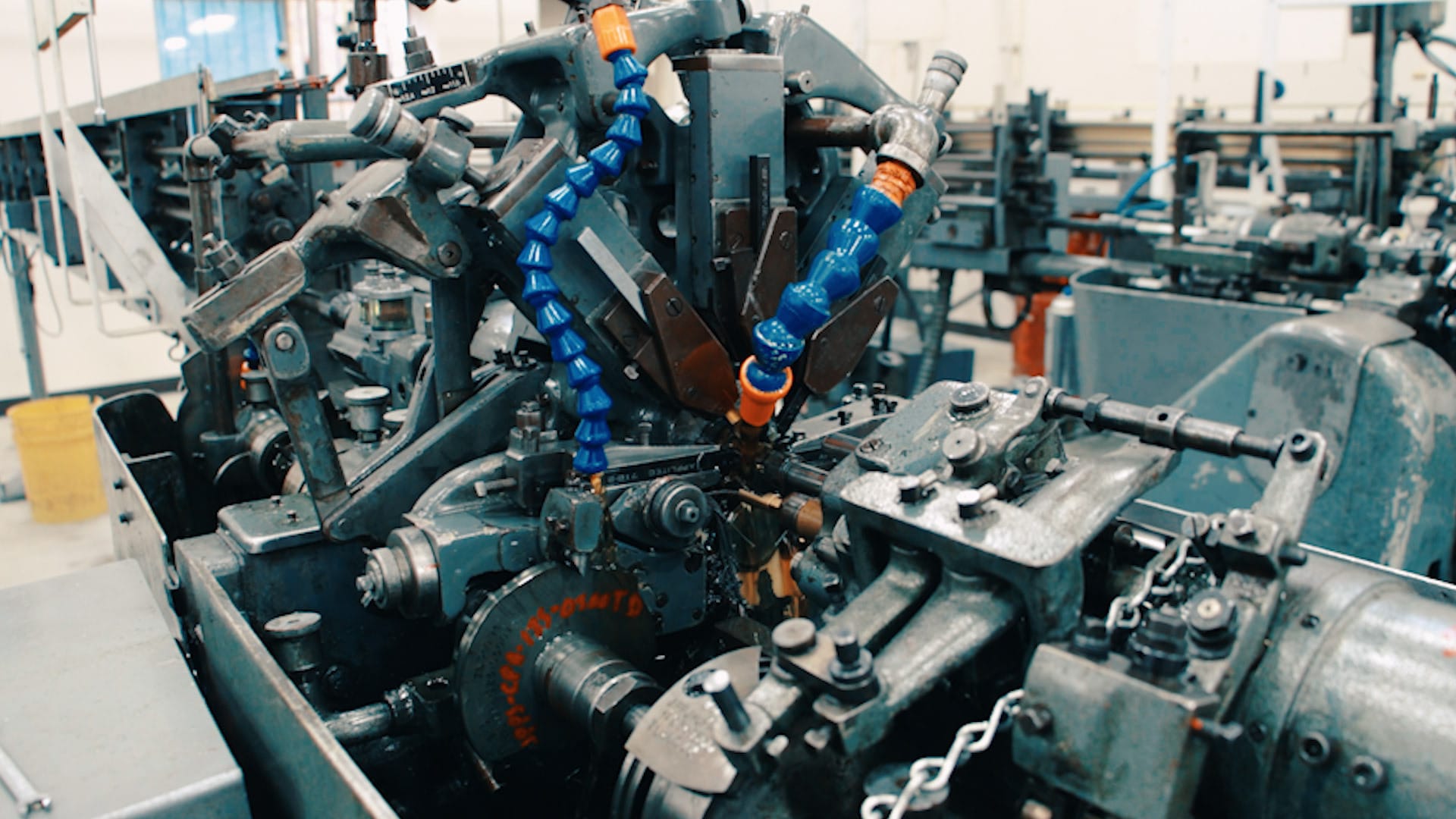

CNC Swiss screw machines are precision machining centers designed for high-accuracy production of small, complex turned components. These machines utilize a sliding headstock and guide bushing to support the workpiece close to the cutting tool, minimizing deflection and enabling tight tolerances typically within ±0.0002″ (±0.005 mm). Equipped with live tooling, modern Swiss machines offer multi-axis milling and turning capabilities in a single setup, supporting 3, 4, or 5-axis operations for enhanced part complexity.

These machines are ideal for high-volume, precision parts in industries such as medical, aerospace, and electronics. They can process a wide range of materials including aluminum, steel, plastics like ABS and nylon, and other specialty alloys. The integration of milling axes allows for cross-drilling, contouring, flat surfaces, and off-center features without secondary operations.

Below is a summary of technical specifications relevant to CNC Swiss screw machines with multi-axis capabilities:

| Feature | Specification / Detail |

|---|---|

| Machine Type | CNC Swiss-Type Automatic Lathe with Live Tooling |

| Axis Configuration | 3-Axis (X, Z, C), 4-Axis (+Y), 5-Axis (+B or secondary spindle with Y/B) |

| Bar Stock Capacity | Typically 1/8″ to 1.25″ (3–32 mm); some models up to 2″ (51 mm) |

| Spindle Speed | 5,000 – 12,000 RPM (dependent on material and tooling) |

| Sub-Spindle | Integrated for backworking, enabling complete part-off in one setup |

| Guide Bushing | Standard; ensures rigidity and precision for slender parts |

| Tooling Stations | 8–24 stations, including turning, drilling, and live milling tools |

| Live Tooling RPM | Up to 10,000 RPM for milling, drilling, tapping, and contouring |

| Positioning Accuracy | ±0.0001″ (±0.0025 mm) |

| Repeatability | ±0.00008″ (±0.002 mm) |

| Typical Tolerance Range | ±0.0002″ to ±0.0005″ (±0.005–0.013 mm) |

| Common Materials | Aluminum (6061, 7075), Steel (12L14, 416 SS, 17-4 PH), ABS, Nylon (6/66), Brass, Titanium |

| Material Suitability | Ductile metals and engineering plastics; optimized for excellent surface finish |

| Coolant System | High-pressure through-tool cooling for chip evacuation and tool life |

| Control System | Fanuc, Siemens, Mitsubishi, or proprietary CNC with conversational programming options |

| Automation Compatibility | Bar feeders, gantry loaders, and robotic systems for lights-out manufacturing |

Swiss screw machines excel in maintaining tight tolerances across diverse materials. Aluminum and steel are commonly machined for structural and mechanical components, while ABS and nylon are used for lightweight, non-conductive, or wear-resistant parts. The multi-axis milling capability allows integration of complex 3D features—such as milled flats, hex shapes, cross-holes, and slots—without requiring secondary operations, reducing lead time and improving geometric consistency.

From CAD to Part: The Process

Honyo Prototype CNC Swiss Screw Machine Process Overview

Honyo Prototype utilizes advanced CNC Swiss-type lathes for high-precision, high-volume production of complex turned components, typically small-diameter parts requiring tight tolerances and secondary operations. Our streamlined workflow ensures rapid turnaround while maintaining rigorous quality standards. Below is the detailed process flow.

CAD Upload and Initial Processing

Clients submit 3D CAD models (STEP, IGES, or native formats) via our secure online portal. Our system immediately validates file integrity, checks for unit consistency, and identifies critical features such as diameters, lengths, and geometric dimensioning. This stage confirms the model aligns with Swiss machining capabilities, including guide bushing constraints and maximum bar stock dimensions.

AI-Assisted Quoting Engine

Uploaded CAD data feeds into our proprietary AI quoting platform, which analyzes geometry, material specifications, and tolerances to generate a preliminary cost estimate within 2–4 hours. The AI evaluates factors including cycle time projections, material utilization rates, toolpath complexity, and secondary operation requirements. Human engineers review all AI outputs to validate feasibility, adjusting for nuances like micro-feature machining or non-standard alloys. Clients receive a formal quote with lead time, unit cost, and material options.

Engineering-Driven DFM Analysis

Upon quote acceptance, our manufacturing engineering team conducts a comprehensive Design for Manufacturability (DFM) review. This phase focuses on optimizing part geometry for Swiss machining efficiency, addressing potential issues such as:

Minimum wall thicknesses relative to bar stock diameter

Tolerance stack-ups affecting concentricity

Feasibility of cross-drilling or off-axis features

Surface finish requirements versus achievable Ra values

We provide actionable feedback within 24 hours, suggesting modifications to reduce costs or accelerate production without compromising function. Client approval of the DFM report is mandatory before proceeding.

Precision Production Execution

Approved designs move to our Swiss machining cell, featuring Tsugami and Citizen machines with live tooling, sub-spindles, and Y-axis capabilities. Key production steps include:

Material preparation (bar stock loading, deburring)

First-article inspection against CAD using CMM and optical comparators

Batch production with real-time SPC monitoring of critical dimensions

In-process metrology for features like thread pitch, groove depths, and positional tolerances

All runs adhere to ISO 9001 protocols, with documentation of machine parameters, tool wear logs, and environmental controls.

Quality-Controlled Delivery

Final inspection occurs per AS9102 standards, including full FAIR documentation for aerospace clients. Parts undergo:

Dimensional verification against all blueprint callouts

Surface roughness testing (Ra 0.4–1.6 µm typical)

Material certification cross-checking

Visual inspection for burrs or machining marks

Completed orders ship with traceability reports, material certs, and inspection data via tracked logistics. Standard lead time is 7–10 days from DFM approval, with expedited options available.

Process Performance Metrics

| Stage | Typical Duration | Key Output | Quality Gate |

|——-|——————|————|————-|

| CAD Upload | <1 hour | Validated geometry file | File compatibility check |

| AI Quote | 2–4 hours | Cost/lead time estimate | Engineering validation |

| DFM | ≤24 hours | Optimized design package | Client signoff |

| Production | 3–7 days | FAI-approved batch | Full dimensional report |

| Delivery | 1–2 days | Shipped parts + documentation | Final inspection clearance |

This integrated process minimizes risk through AI-driven efficiency and human engineering oversight, delivering precision Swiss-turned components with consistent micron-level accuracy for medical, aerospace, and industrial applications.

Start Your Project

Looking for precision CNC Swiss screw machining services? Contact Susan Leo at [email protected] to discuss your project requirements.

Honyo Prototype operates a state-of-the-art manufacturing facility in Shenzhen, China, specializing in high-precision, high-efficiency production of small, complex turned components. Our CNC Swiss machines deliver tight tolerances and superior surface finishes for industries including medical, aerospace, electronics, and automation.

Partner with us for fast turnaround, rigorous quality control, and expert engineering support from prototyping through volume production.

Contact Susan Leo today at [email protected] to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.