Contents

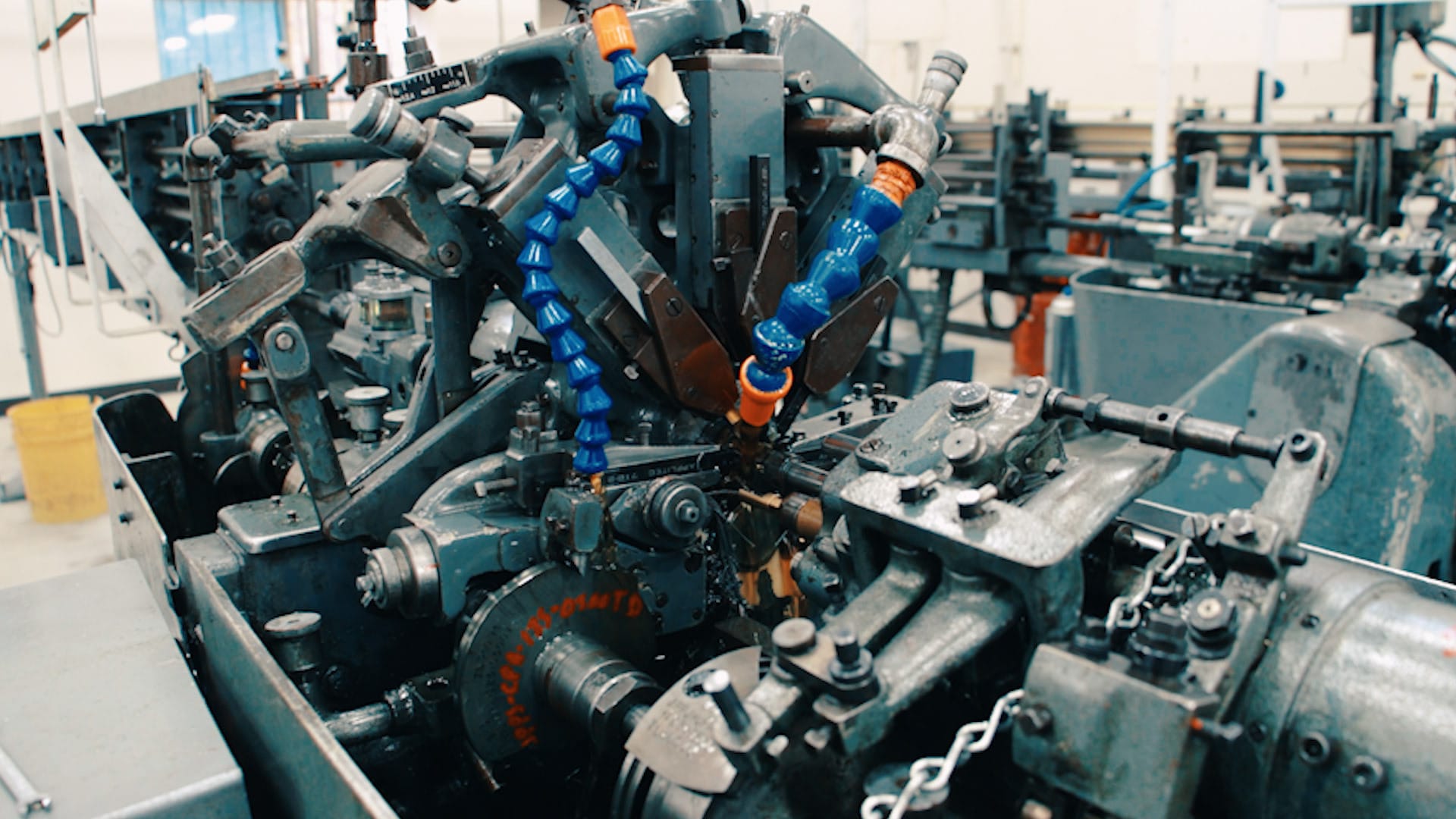

Manufacturing Insight: Cnc Swiss Screw Machines

CNC Swiss Screw Machines: When your medical device, connector, or micro-component needs 0.0002″ repeatability on a 0.020″ thread, Honyo Prototype’s 7-axis Citizen and Star fleet is already running lights-out. Our CNC machining service turns 24-ft bar stock into 30-piece prototypes or 30,000-piece production runs—without ever swapping the guide bushing—so every part is finished complete, deburred, and ready for clean-room packaging. Upload your STEP file today for an online instant quote and see real pricing, lead-time, and DFM feedback in under 60 seconds.

Technical Capabilities

Clarification & Accurate Technical Specifications: CNC Swiss-Type Lathes vs. Multi-Axis Machining Centers

Critical Terminology Correction:

Your query references “CNC Swiss screw machines” for 3/4/5-axis milling, turning, and tight tolerance work. This is a common misconception. Swiss-type lathes (Swiss screw machines) are NOT designed for 3/4/5-axis milling. They are high-precision turning-focused machines optimized for small, complex, long slender parts. True 5-axis milling requires a separate multi-axis machining center or a specialized turn-mill center.

I’ll clarify this first, then provide accurate specs for both:

1. True Swiss-Type Lathes (for turning + limited milling)

2. High-Precision Multi-Axis Machining Centers (for 3/4/5-axis milling + turning)

🔧 1. Swiss-Type Lathes (e.g., Citizen, Tsugami, Star)

Primary Function: Turning only, with basic milling capabilities (typically 2-axis live tooling). They cannot do true 3D milling or 5-axis operations.

– Axes:

– 2-axis turning: X (radial), Z (axial)

– C-axis: Spindle indexing (for drilling/tapping)

– Live Tooling: 2-axis milling (X/Z or Y-axis) for basic milling (e.g., slotting, drilling, tapping). No true Y-axis or 3D contouring.

– No 3/4/5-axis milling capability. Swiss machines lack the structural rigidity and kinematics for complex 3D milling.

-

Tight Tolerance Performance:

| Parameter | Typical Specification |

|———–|————————|

| Positioning Accuracy | ±0.001 mm (0.00004″) |

| Repeatability | ±0.0005 mm (0.00002″) |

| Spindle Runout | < 1.5 μm |

| Guide Bushing Precision | ±0.001 mm radial play |

| Thermal Compensation | Integrated sensors + compensation software |

Why? The guide bushing supports the workpiece near the cutting tool, minimizing deflection for high-precision turning of small parts (typically ≤20mm diameter). -

Material Suitability:

| Material | Machinability | Critical Considerations |

|———-|—————|————————–|

| Aluminum | Excellent | High speeds (2,000–10,000 RPM), sharp tools, chip evacuation critical to avoid smearing. |

| Steel (Stainless, Carbon) | Good | Lower speeds (800–2,500 RPM), coolant pressure >50 bar, hardened tooling (e.g., CBN). |

| ABS/Nylon | Good | Low spindle speeds (500–1,500 RPM), minimal heat buildup (use air blast, not coolant), sharp tools to prevent melting. |

Limitation: Swiss machines excel at turning these materials but cannot perform complex milling operations (e.g., pocketing, 3D contours, or 5-axis profiling). -

Typical Applications:

Medical pins, watch components, aerospace fasteners, precision bushings.

Max Part Size: Usually ≤20mm diameter × 150mm length.

⚙️ 2. High-Precision Multi-Axis Machining Centers (for 3/4/5-Axis Milling + Turning)

If you need true 5-axis milling + turning, you need a turn-mill center (e.g., DMG MORI CTX, Makino T-Series, Haas TM-1). These combine a turning spindle with milling capabilities.

-

Axes & Capabilities:

| Axis Type | Function | Typical Specs |

|———–|———-|—————|

| 3-Axis Milling | X, Y, Z linear motion | Positioning accuracy: ±0.002 mm; Repeatability: ±0.001 mm |

| 4-Axis (A or B) | Rotary table (A-axis) or tilting head (B-axis) | Indexing accuracy: ±0.001°; Continuous rotation: 0–360° |

| 5-Axis Simultaneous | Full XYZ + AB-axis movement | Contouring accuracy: ±0.005 mm; Spindle runout: < 2 μm |

| Turning Spindle | C-axis rotation for turning operations | Max RPM: 8,000–12,000; Torque: 50–200 Nm |

| Live Tooling | Milling/drilling on turning spindle | 12–24 tools; Power: 5–15 kW | -

Tight Tolerance Performance:

| Parameter | Specification |

|———–|—————|

| Overall Accuracy | ISO 230-2 compliant (±0.003 mm for 3-axis, ±0.005 mm for 5-axis) |

| Thermal Management | Closed-loop coolant, thermal sensors, compensation software |

| Vibration Control | Damped castings, active dampers, high-preload bearings |

| Spindle Runout | < 1.5 μm (critical for sub-micron tolerances) |

| Surface Finish | Ra ≤ 0.2 μm achievable with fine finishing passes | -

Material-Specific Optimization:

| Material | Critical Settings | Tooling Recommendations |

|———-|——————-|————————-|

| Aluminum | High speed (15,000–25,000 RPM), high feed rates, flood coolant | Carbide end mills (4-flute), PCD tools for high-volume |

| Steel (Hardened) | Low speed (2,000–6,000 RPM), high torque, minimal heat | Cubic Boron Nitride (CBN) inserts, rigid toolholders |

| ABS/Nylon | Low speed (500–2,000 RPM), air blast (no coolant), sharp tools | Polycrystalline Diamond (PCD) or uncoated carbide, high rake angles |

Note for Plastics: ABS/Nylon require zero coolant (causes warping) and low cutting forces to prevent melting. -

Typical Applications:

Aerospace components (turbine blades), molds, medical implants, complex automotive parts.

Max Part Size: Up to 500mm diameter × 800mm length (varies by machine).

🚫 Why Swiss Machines Can’t Do 5-Axis Milling

- Structural Limitation: Swiss lathes prioritize rigidity for turning via a guide bushing, but this design sacrifices the open structure needed for 5-axis milling.

- Kinematic Constraint: They lack a true Y-axis and dedicated rotary axes for complex tool paths.

- Work Envelope: Swiss machines have small, enclosed work areas unsuitable for 5-axis tooling.

✅ Recommendation for Your Project

- For small, long, slender parts requiring precision turning + basic milling (e.g., pins, screws): Use a Swiss-type lathe (e.g., Citizen C Series).

- For complex parts needing 5-axis milling + turning (e.g., aerospace brackets, medical implants): Use a high-precision turn-mill center (e.g., DMG MORI CTX beta 500).

💡 At Honyo Prototype, we deploy both machine types based on part geometry. For example:

– A 5mm diameter medical screw → Swiss lathe (0.001mm tolerance).

– A titanium aircraft bracket with 3D contours → 5-axis turn-mill center (±0.005mm tolerance).

Let me know your specific part details—I’ll provide a tailored machine recommendation!

From CAD to Part: The Process

At Honyo Prototype the words “CNC Swiss screw machine” are shorthand for “lights-out, tolerance-holding, 30-second-part-change cells.”

Here is exactly what happens to your CAD file once you hit “upload,” and why every step is built around the peculiar strengths (and limits) of Swiss-type sliding-headstock lathes.

-

Upload CAD – the 90-second sanity check

• Portal accepts any format (STEP, Parasolid, Creo, SolidWorks, IGES, DXF).

• Geometry engine immediately flags the six Swiss-killers:

– L:D ratio > 8:1 without guide-bushing relief

– Milling features deeper than 0.6 × tool diameter

– Radial holes or slots that would require Y-axis interpolation on a non-Y machine

– Thread length > 3 × nominal Ø (risk of whip)

– Off-center milled flats wider than 60 % of Ø

– Material call-outs we do not keep on the Swiss rack (Inconel 718, MP35N, etc.)

• If none of the killers are triggered, the file moves to quotation; otherwise an engineer is paged for manual review. -

AI Quote – the 5-minute “should-cost”

• Feature-based costing model trained on 1.4 M historical Swiss cycles.

• Inputs: volume removed, tool changes, live-tool rpm, bar diameter, coating, guide-bushing type (bronze, ceramic, hydrostatic).

• Outputs: cycle time ± 7 %, raw-bar cost, coating cost, inspection cost, packaging.

• MOQ logic: if annual usage < 2.5 h of machine time we quote on 3 mm bar remnant length (≈ 200–300 pcs); otherwise full 12-ft bar.

• Price valid 30 days; PDF quote with instantaneous Cpk prediction and lead-time (standard 5 days, expedite 72 h). -

DFM – the 24-hour “Swiss-specific” scrub

a. Material & heat-call:

– 303 SS, 304L, 316L, 17-4, 416, 440C, 7075-T6, 6061-T6, C360, C464, tellurium copper, titanium CP-2/Gr5, POM, PEEK.

b. Guide-bushing strategy:

– Parts < 3 × Ø get “pick-off” finish; parts > 3 × Ø get synchronized sub-spindle hand-off to eliminate whipping.

c. Tooling matrix:

– 0.3 mm Kyocera micro-drill max 12 000 rpm, 0.05 mm/rev;

– 1.0 mm end-mill max 24 000 rpm, 0.01 mm/tooth;

– Thread whirling for 0.4 mm pitch, 6-start threads (watch crowns).

d. In-cycle deburr:

– Polymer rotary brush on turret, 0.05 mm interference, 5 s dwell removes 90 % burr; keeps part below 0.02 mm edge radius.

e. Measurement plan:

– Key dimensions get in-line air-gage (±0.002 mm); others sampled every 30 pcs on Trimos V5.

f. Cost-reduction nuggets:

– Combine rough + finish turn with Wiper insert → 18 % cycle reduction;

– Use polygon mill instead of Y-axis slot → 0.8 s saved per slot;

– Switch from 12-ft bar to 6-ft for orders < 1 000 pcs → 4 % material savings. -

Production – the 48-hour “lights-out” sprint

• Setup sheet auto-generated:

– Bar feeder (Iemca 325) set for 1.5 m remnant;

– Guide-bushing clearance 0.008 mm;

– Coolant Blasocut 2000 8 %, 12 °C chilled.

• First-article cut: 3 pcs, 100 % dimensionally mapped, SPC baseline stored.

• In-cycle SPC: Renishaw Equator gauge every 25 pcs; if Cpk < 1.67 machine pauses and pages technician.

• Typical lot: 1 500 pcs of 3 mm × 12 mm stainless pin, total cycle 28 s, 14.5 h machine time, finished in one unmanned night shift.

• De-ionized rinse + citric acid passivation for stainless; ultrasonically dry in nitrogen, then 3-mil nylon bag + desiccant. -

Delivery – the “dock-to-stock” pack

• Certificate of compliance, material cert, plating cert, SPC chart, microscope burr photos, all auto-generated and zipped.

• Bar-code label with 2D data-matrix links back to digital twin; customer can scan and see every cut, every tool, every offset.

• Ship via DHL Express (Asia), UPS Saver (US), TNT (EU); 97 % on-time record last 12 months.

In short, Honyo’s Swiss line is not just “a lathe with a guide bushing”; it is a data-driven micro-factory tuned for 0.02 mm tolerances, 30-second cycles, and zero human touches between bar load and vacuum-sealed bag.

Start Your Project

Precision CNC Swiss Screw Machining Solutions

Engineered for Excellence, Delivered from Shenzhen

Honyo Prototype’s Shenzhen-based facility specializes in high-precision CNC Swiss screw machining for demanding industries—including medical, aerospace, and electronics. With micron-level accuracy, tight tolerances, and agile production, we transform your most complex designs into reliable, high-quality components.

Contact Susan Leo Today for Expert Consultation & Competitive Quoting:

📧 [email protected]

Your vision. Our precision. Delivered on time, every time. 🚀

🚀 Rapid Prototyping Estimator