Introduction: Navigating the Global Market for cnc swiss screw machine

In the fast-paced world of precision manufacturing, sourcing the right CNC Swiss screw machine can be a daunting challenge for international B2B buyers. With a myriad of options available, businesses must navigate complexities related to machine specifications, supplier reliability, and cost-effectiveness. This guide aims to simplify that journey by providing a comprehensive overview of CNC Swiss screw machines, covering essential aspects such as types, applications, and the nuances of supplier vetting.

Whether you are looking to enhance production capabilities in the automotive sector, streamline electronic component manufacturing, or explore innovative solutions for your unique machining needs, understanding the functionalities and advantages of CNC Swiss screw machines is crucial. This guide not only elucidates how these machines operate but also highlights their benefits, such as precision, versatility, and efficiency in producing high-volume, intricate parts.

For B2B buyers from regions like Africa, South America, the Middle East, and Europe—including key markets like Brazil and Vietnam—this guide serves as a critical resource. It empowers you to make informed purchasing decisions by equipping you with the knowledge necessary to assess suppliers, evaluate costs, and ultimately select the right CNC Swiss screw machine that aligns with your operational goals. By leveraging the insights presented here, you can confidently navigate the global market and enhance your manufacturing processes.

Understanding cnc swiss screw machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fixed Headstock Swiss | Features a fixed headstock with a sliding bushing for support. | Automotive, Aerospace, Electronics | Pros: High precision, ideal for small parts. Cons: Limited to shorter workpieces. |

| Sliding Headstock Swiss | Offers a sliding headstock that allows for longer workpieces. | Medical Devices, Precision Instruments | Pros: Versatile for various lengths, high speed. Cons: More complex setup. |

| Multi-Spindle Swiss | Incorporates multiple spindles to increase production capacity. | High-volume manufacturing, Mass production | Pros: Maximizes efficiency, reduces cycle time. Cons: Higher initial investment. |

| CNC Swiss | Fully automated with computer numerical control for precision. | Electronics, Telecommunications | Pros: Exceptional accuracy, programmable flexibility. Cons: Requires skilled operators for programming. |

| Hybrid Swiss Machines | Combines traditional machining with additive manufacturing. | Aerospace, Custom Components | Pros: Enhanced capabilities, suitable for complex geometries. Cons: Higher operational costs. |

What are the Characteristics of Fixed Headstock Swiss Machines?

Fixed headstock Swiss machines are designed for precision machining of small parts, typically featuring a stationary headstock with a sliding bushing. This design allows for high stability and accuracy, making them ideal for industries such as automotive and electronics where small, intricate components are essential. Buyers should consider the machine’s length capacity, as fixed headstock models are generally limited to shorter workpieces, which may not meet all production needs.

How Do Sliding Headstock Swiss Machines Enhance Versatility?

Sliding headstock Swiss machines are characterized by their ability to accommodate longer workpieces, thanks to the sliding headstock design. This feature allows for greater flexibility in machining various lengths, making them particularly suitable for medical devices and precision instruments. When purchasing, buyers should evaluate the machine’s speed and setup complexity, as these machines can offer significant throughput but may require more intricate configurations.

What Are the Advantages of Multi-Spindle Swiss Machines for High-Volume Production?

Multi-spindle Swiss machines are engineered to maximize production efficiency by incorporating multiple spindles, enabling simultaneous machining of several parts. This design is particularly advantageous for high-volume manufacturing environments, such as mass production in automotive and electronics sectors. Buyers should weigh the benefits of increased output against the higher initial investment and maintenance costs associated with these complex machines.

Why Choose CNC Swiss Machines for Precision and Flexibility?

CNC Swiss machines utilize computer numerical control, allowing for exceptional precision and flexibility in programming. This technology is particularly beneficial in industries like telecommunications and electronics, where intricate parts with tight tolerances are required. When considering a CNC Swiss machine, buyers should focus on the machine’s programming capabilities and the skill level of operators needed to maximize its potential.

How Do Hybrid Swiss Machines Integrate Traditional and Additive Manufacturing?

Hybrid Swiss machines combine traditional subtractive machining techniques with additive manufacturing capabilities, allowing for the creation of complex geometries that would be challenging to achieve with conventional methods. These machines are particularly suited for industries such as aerospace and custom components where design intricacy is paramount. Buyers should consider the higher operational costs associated with hybrid systems but may find the investment worthwhile for specialized production needs.

Key Industrial Applications of cnc swiss screw machine

| Industry/Sector | Specific Application of cnc swiss screw machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of precision fasteners and components | High-volume production with minimal waste | Supplier reliability, machine precision, and lead times |

| Electronics | Manufacturing of intricate connectors and housings | Ability to handle complex geometries and materials | Material compatibility, customization options, and quality control |

| Medical Devices | Creation of surgical instruments and implants | Strict adherence to precision and regulatory standards | Certifications, quality assurance processes, and traceability |

| Aerospace | Fabrication of lightweight, high-strength components | Enhanced performance and fuel efficiency | Material certifications, delivery schedules, and technical support |

| Telecommunications | Production of small parts for devices and infrastructure | Scalability and adaptability to design changes | Cost-effectiveness, production capacity, and after-sales support |

How is CNC Swiss Screw Machining Applied in the Automotive Industry?

In the automotive sector, CNC Swiss screw machines are essential for producing precision fasteners and components such as bolts, screws, and brackets. These machines can handle high-volume production runs while maintaining tight tolerances, which is crucial for ensuring the safety and reliability of vehicles. For international buyers, particularly from regions like Africa and South America, sourcing from manufacturers with proven reliability and quick turnaround times is vital to meet production schedules and minimize downtime.

What Role Does CNC Swiss Screw Machining Play in Electronics Manufacturing?

In the electronics industry, CNC Swiss screw machines are utilized to manufacture intricate connectors, housings, and other components that require high precision. The versatility of these machines allows them to work with a variety of materials, including both common and exotic metals. Buyers in the Middle East and Europe should consider suppliers that offer customization options and robust quality control measures to ensure that the components meet stringent industry standards.

How Does CNC Swiss Screw Machining Benefit the Medical Device Sector?

The medical device industry relies heavily on CNC Swiss screw machining for the creation of surgical instruments and implants. Given the critical nature of these applications, the machines must operate with extreme precision and comply with rigorous regulatory standards. International buyers must prioritize sourcing from manufacturers who possess relevant certifications and demonstrate a commitment to quality assurance processes, as traceability is paramount in this sector.

In What Ways is CNC Swiss Screw Machining Used in Aerospace Manufacturing?

CNC Swiss screw machines are pivotal in the aerospace industry for fabricating lightweight, high-strength components that enhance aircraft performance and fuel efficiency. The ability to produce complex geometries with precision is essential in this field, where even minor deviations can have significant implications. When sourcing from suppliers, buyers should focus on material certifications, as well as the ability to meet strict delivery schedules and provide technical support.

How Does CNC Swiss Screw Machining Contribute to Telecommunications?

In the telecommunications sector, CNC Swiss screw machines are employed to manufacture small parts for devices and infrastructure, such as connectors and housings. The scalability of these machines allows for quick adaptations to design changes, which is crucial in a rapidly evolving industry. B2B buyers should seek suppliers that offer cost-effective solutions, high production capacity, and reliable after-sales support to maintain a competitive edge in the market.

3 Common User Pain Points for ‘cnc swiss screw machine’ & Their Solutions

Scenario 1: Challenges in Achieving Precision in Small Parts Production

The Problem: Many B2B buyers in industries such as electronics and automotive face difficulties when it comes to producing small, intricate components with high precision. The challenge lies in the tolerance levels, which can often be as tight as 0.0002 inches. When using standard machining tools, achieving such precision can result in increased scrap rates, production delays, and ultimately higher costs. Buyers may find themselves struggling with inconsistent part quality, leading to potential rework and supply chain disruptions.

The Solution: To overcome this challenge, buyers should invest in high-quality CNC Swiss screw machines that are specifically designed for precision machining. It’s crucial to evaluate machines based on their capability to maintain tight tolerances throughout the production run. Buyers should also consider integrating advanced software solutions that allow for real-time monitoring of production metrics, which can help in identifying deviations from quality standards promptly. Engaging with suppliers who offer comprehensive training on machine setup and operation can further enhance the precision of output. Regular maintenance schedules and the use of high-quality raw materials will ensure that machines perform optimally, minimizing errors and maximizing production efficiency.

Scenario 2: Difficulty in Handling Material Versatility

The Problem: B2B buyers often require the ability to work with a range of materials, from common metals like aluminum and brass to exotic materials such as titanium and specialized alloys. This versatility is vital for industries like aerospace and medical devices, where different applications demand specific material properties. However, many CNC Swiss screw machines are not equipped to handle such diversity, leading to limitations in production capabilities and the potential need to invest in multiple machines.

The Solution: Buyers should select CNC Swiss screw machines that are engineered for material versatility. Look for machines that feature adjustable tooling and programming capabilities to accommodate various materials without compromising quality. Additionally, sourcing machines from manufacturers that provide extensive material compatibility documentation can guide the selection process. Collaborating with machine suppliers who offer flexible tooling options and customization can also enhance the machine’s adaptability. Regularly updating tooling and machine parameters based on material properties will ensure efficient operations and prevent costly downtimes associated with material changes.

Scenario 3: High Setup Times Leading to Increased Costs

The Problem: In fast-paced manufacturing environments, long setup times for CNC Swiss screw machines can be a significant barrier. B2B buyers may find that the time taken to changeover between different parts can lead to inefficient use of machine hours, resulting in higher operational costs and reduced competitiveness in the market. This issue is particularly pertinent for companies that produce low-volume, high-mix components, where frequent adjustments are necessary.

The Solution: To mitigate high setup times, buyers should consider investing in CNC Swiss screw machines that feature quick-change tooling systems and efficient setup protocols. Utilizing machines that can be pre-programmed for different parts can significantly reduce changeover times. Additionally, investing in comprehensive training for operators on efficient setup procedures can enhance productivity. Implementing a lean manufacturing approach, where setup processes are continuously analyzed and improved, will also help in minimizing downtime. By optimizing setup times, companies can increase their production capacity and improve their overall profitability.

Strategic Material Selection Guide for cnc swiss screw machine

What Are the Key Materials for CNC Swiss Screw Machining?

When selecting materials for CNC Swiss screw machining, it is critical to consider their properties, advantages, disadvantages, and specific applications. Here, we analyze four common materials used in this process: Stainless Steel, Aluminum, Brass, and Plastic.

How Does Stainless Steel Perform in CNC Swiss Screw Machining?

Stainless steel is renowned for its corrosion resistance and strength, making it a popular choice for a variety of applications. Key properties include a high-temperature rating and excellent mechanical strength, which are essential for parts exposed to harsh environments. The primary advantages of stainless steel are its durability and resistance to rust, which is crucial in industries such as automotive and aerospace. However, it can be challenging to machine due to its toughness, leading to increased tool wear and production costs.

For international buyers, compliance with standards such as ASTM A276 or DIN 17440 is vital, especially in regions like Europe and the Middle East. Additionally, the availability of stainless steel grades may vary by region, impacting lead times and costs.

What Are the Benefits of Using Aluminum in CNC Swiss Screw Machining?

Aluminum is celebrated for its lightweight nature and excellent machinability, making it suitable for high-speed applications. Its key properties include good thermal and electrical conductivity, as well as a low density. The advantages of aluminum include reduced manufacturing complexity and lower costs compared to metals like stainless steel. However, it may not be suitable for high-stress applications due to its lower tensile strength.

International buyers should consider the common standards for aluminum, such as ASTM B221 and JIS H4000, which ensure quality and compatibility. In regions like Africa and South America, the cost-effectiveness of aluminum can be a significant factor in material selection.

Why Choose Brass for CNC Swiss Screw Machining?

Brass is a copper-zinc alloy known for its excellent machinability and corrosion resistance. Key properties include good thermal conductivity and low friction, making it ideal for applications like fittings and connectors. The primary advantages of brass are its ease of machining and aesthetic appeal, often used in decorative applications. However, brass can be more expensive than aluminum and may not be suitable for high-temperature applications.

For buyers in Europe and the Middle East, adherence to standards like ASTM B16 and EN 12164 is essential for ensuring material quality. Additionally, the sourcing of brass may be affected by regional availability, impacting pricing and lead times.

How Do Plastics Fit into CNC Swiss Screw Machining?

Plastics, such as polycarbonate and nylon, offer versatility and lightweight properties. Key properties include chemical resistance and low thermal conductivity, making them suitable for various applications, especially in the electronics industry. The advantages of using plastics include lower costs and ease of machining, but they may not withstand high temperatures or mechanical stresses as well as metals.

International buyers should be aware of standards like ASTM D638 for plastics, which can vary significantly across regions. In markets such as Africa and South America, the growing demand for lightweight components makes plastics an appealing option, although sourcing may be limited.

Summary Table of Material Selection for CNC Swiss Screw Machining

| Material | Typical Use Case for cnc swiss screw machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Automotive and aerospace components | High corrosion resistance | Increased tool wear and cost | High |

| Aluminum | Lightweight structural parts | Excellent machinability | Lower tensile strength | Medium |

| Brass | Fittings and decorative items | Easy to machine | Higher cost than aluminum | Medium to High |

| Plastic | Electronics and lightweight components | Cost-effective and versatile | Limited high-temperature resistance | Low |

This strategic material selection guide provides B2B buyers with essential insights into the properties and applications of various materials used in CNC Swiss screw machining. Understanding these factors will help in making informed decisions that align with specific project requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc swiss screw machine

What Are the Key Stages in the Manufacturing Process of CNC Swiss Screw Machines?

The manufacturing process of CNC Swiss screw machines is intricate and involves several critical stages to ensure precision and efficiency. Understanding these stages can help international B2B buyers assess the capabilities of potential suppliers.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in manufacturing involves selecting high-quality raw materials, typically bars made from metals like stainless steel, aluminum, or brass. These materials must meet specific mechanical properties to withstand the machining processes. Once selected, the materials undergo preparation, which includes cutting to length and surface finishing to remove any imperfections. This ensures that the material is ready for the next stage of processing, ultimately contributing to the precision of the final product.

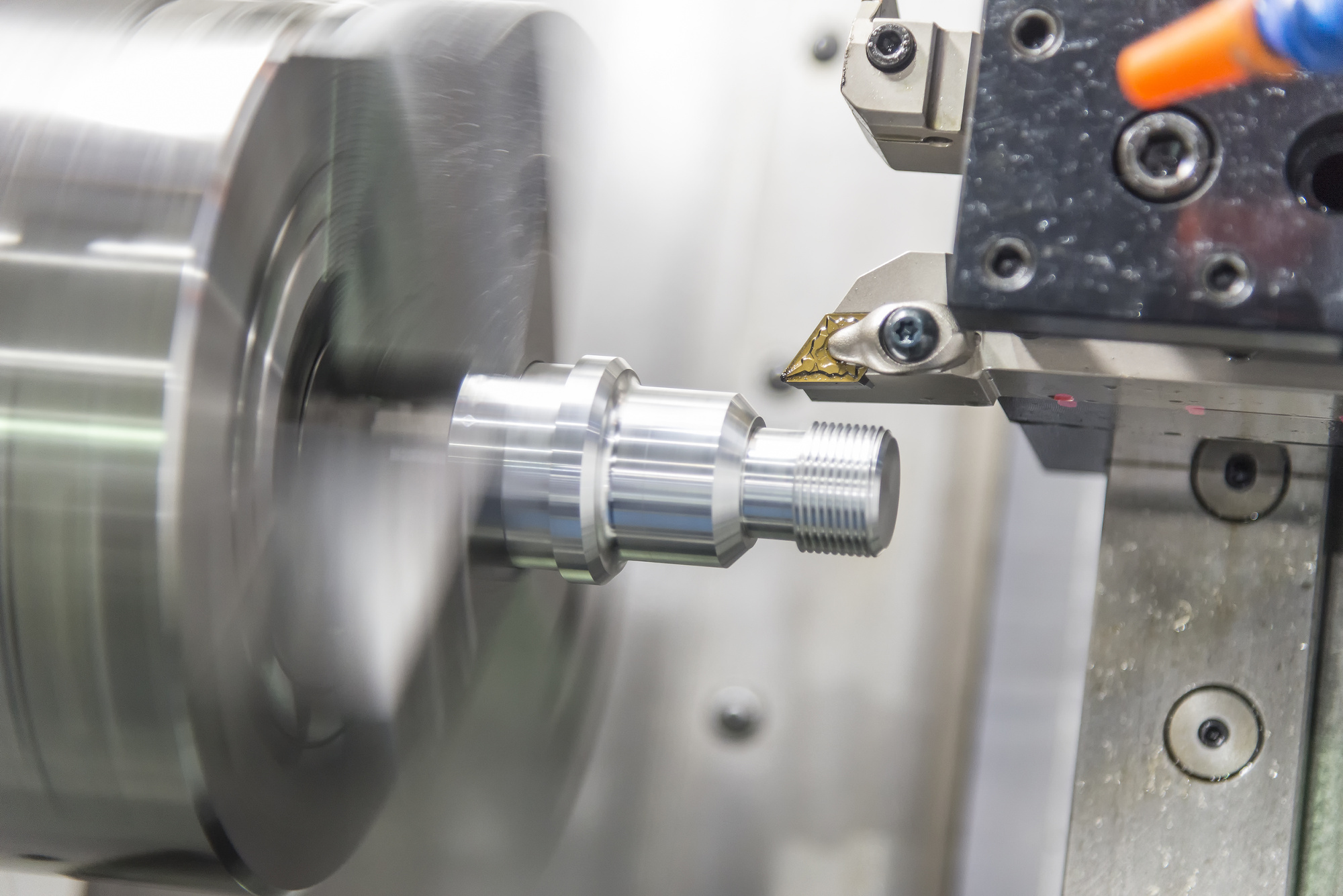

Forming: What Techniques Are Used for Precision Machining?

The forming stage is where the real machining takes place. CNC Swiss screw machines utilize a unique mechanism where the workpiece is held in place while the tools move in a synchronized manner to perform various operations such as turning, milling, and drilling. The sliding headstock design allows for longer workpieces to be machined with high precision, especially in producing small, intricate parts.

Key techniques in this stage include:

- Turning Operations: The primary function of Swiss screw machines, where rotating tools shape the workpiece.

- Multi-Operation Capabilities: These machines can perform several operations simultaneously, reducing cycle times and increasing productivity.

- Live Tooling: This technique enables the use of additional tooling while the workpiece is rotating, allowing for complex geometries to be achieved in a single setup.

Assembly: How Are Components Brought Together for Final Products?

Once individual components are machined, the assembly stage commences. This involves the meticulous joining of parts to create the final product. Depending on the complexity of the component, assembly may require various techniques, including threading, fastening, or welding.

At this stage, manufacturers often employ automated systems to ensure precision and reduce human error. For B2B buyers, understanding the assembly capabilities of a supplier can provide insights into their ability to meet complex specifications.

Finishing: What Processes Are Used to Achieve the Desired Surface Quality?

The finishing stage is crucial for ensuring that the final product meets aesthetic and functional requirements. Common finishing processes for CNC Swiss screw machine products include:

- Deburring: Removing sharp edges and burrs from machined parts to enhance safety and functionality.

- Polishing and Coating: Applying surface treatments that improve corrosion resistance and aesthetic appeal.

- Quality Inspection: Final inspection processes are often integrated into this stage to ensure that each component meets the required specifications.

What Quality Control Measures Are Essential for CNC Swiss Screw Machines?

Quality assurance is paramount in the manufacturing process of CNC Swiss screw machines. It ensures that products meet international standards and customer expectations.

Which International Standards Are Relevant for Quality Assurance?

International standards such as ISO 9001 set the framework for quality management systems, ensuring that manufacturers maintain high standards throughout the production process. For specific industries, additional certifications may be required:

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- API Certification: Relevant for manufacturers supplying to the oil and gas industry, ensuring adherence to specific quality and safety standards.

B2B buyers should inquire about these certifications when evaluating potential suppliers.

What Are the Common Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are integral to the manufacturing process and can be categorized as follows:

- Incoming Quality Control (IQC): Ensures that raw materials meet specified standards before production begins.

- In-Process Quality Control (IPQC): Involves continuous monitoring during the manufacturing process to catch any deviations from quality standards.

- Final Quality Control (FQC): Conducted after production to verify that the finished products meet all specifications and quality standards before shipping.

These checkpoints help maintain a consistent quality level and can significantly reduce the risk of defects in the final product.

Which Testing Methods Are Commonly Used for Quality Assurance?

Several testing methods are employed to ensure that CNC Swiss screw machine products meet quality standards:

- Dimensional Inspection: Using precision tools such as calipers and micrometers to verify that parts are within specified tolerances.

- Functional Testing: Assessing whether the components perform as intended under operational conditions.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing or X-ray inspection help detect internal flaws without damaging the product.

Understanding these testing methods can give B2B buyers confidence in the quality of the products they are purchasing.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is crucial to ensuring a reliable supply chain. Here are some effective methods:

What Role Do Audits Play in Supplier Verification?

Conducting regular audits is a fundamental practice for assessing a supplier’s adherence to quality standards. Buyers can request:

- On-Site Audits: Visiting the supplier’s facility to evaluate their manufacturing processes and quality control measures firsthand.

- Third-Party Audits: Engaging independent organizations to conduct audits can provide an unbiased assessment of the supplier’s quality management systems.

How Important Are Quality Control Reports and Documentation?

Suppliers should provide comprehensive quality control reports that detail testing results, inspection outcomes, and any corrective actions taken. Buyers should look for:

- Documentation of Standards Compliance: Clear records demonstrating adherence to relevant international and industry-specific standards.

- Traceability: Ability to trace materials and components back to their source, ensuring accountability and transparency.

What Are the Nuances of Quality Control Certification for International Buyers?

When dealing with suppliers from different regions, particularly in Africa, South America, the Middle East, and Europe, buyers should be aware of the following:

- Regional Compliance Requirements: Different regions may have specific regulations that affect product quality and safety. Understanding these can help buyers make informed decisions.

- Language Barriers: Ensure that documentation is available in a language that is easily understandable to facilitate effective communication.

- Cultural Differences: Be aware of cultural nuances that may impact supplier interactions and quality expectations.

By thoroughly understanding the manufacturing processes and quality assurance measures associated with CNC Swiss screw machines, B2B buyers can make informed decisions, ensuring they partner with suppliers who meet their rigorous standards for quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc swiss screw machine’

Introduction

This practical sourcing guide is designed for B2B buyers looking to procure CNC Swiss screw machines. These machines are essential for producing high-precision parts in various industries, including automotive and electronics. By following this step-by-step checklist, you will streamline the procurement process and ensure you select the right machine and supplier for your operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Determine the dimensions, materials, tolerances, and production volume required for your applications. Consider factors such as:

– Diameter Range: Specify the maximum and minimum diameters you need the machine to handle.

– Material Compatibility: Ensure the machine can work with the materials you intend to use, whether they are common metals or exotic materials.

Step 2: Conduct Market Research

Investigate the market to identify potential suppliers of CNC Swiss screw machines. Look for manufacturers known for their quality and reliability. Key aspects to focus on include:

– Industry Reputation: Research online reviews, testimonials, and case studies to gauge supplier reliability.

– Product Range: Ensure the suppliers offer a variety of models that can meet your specifications.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Key considerations include:

– Certifications: Verify that the supplier holds relevant industry certifications, ensuring adherence to quality standards.

– Experience: Look for suppliers with a proven track record in producing CNC Swiss screw machines.

Step 4: Request Quotes and Compare Costs

Once you have identified potential suppliers, request detailed quotes that outline costs, delivery timelines, and warranty terms. When comparing costs, consider:

– Total Cost of Ownership: Factor in installation, training, maintenance, and operational costs over the machine’s lifespan.

– Payment Terms: Review payment options and terms to ensure they align with your budget and cash flow.

Step 5: Assess After-Sales Support and Service

After-sales support can significantly impact your operations. Ensure that the supplier offers comprehensive support services, which may include:

– Training Programs: Check if they provide training for your staff on machine operation and maintenance.

– Technical Support: Confirm the availability of technical support and spare parts, especially if your operations rely heavily on the machine.

Step 6: Negotiate Terms and Finalize the Contract

Once you have selected a supplier, engage in negotiations to finalize the terms of the contract. Focus on:

– Delivery Schedule: Agree on a realistic delivery timeline that meets your operational needs.

– Warranty Clauses: Ensure the contract includes clear warranty terms that cover potential defects or failures.

Step 7: Plan for Installation and Training

After securing your CNC Swiss screw machine, develop a plan for installation and training. This step is vital to maximize your investment and ensure smooth integration into your production line. Consider:

– Site Preparation: Ensure that your facility is ready for the new machine, including necessary utilities and workspace.

– Comprehensive Training: Schedule training sessions for your operators to familiarize them with the machine’s features and maintenance requirements.

By following this checklist, you can effectively navigate the procurement process for CNC Swiss screw machines, ensuring a successful investment for your business.

Comprehensive Cost and Pricing Analysis for cnc swiss screw machine Sourcing

What Are the Key Cost Components for CNC Swiss Screw Machines?

When sourcing CNC Swiss screw machines, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of raw materials significantly influences the overall cost. High-quality metals, such as stainless steel or exotic alloys, will command higher prices. Buyers should consider the specific requirements of their applications when selecting materials.

-

Labor: Labor costs encompass both direct and indirect expenses. Skilled machinists who operate and maintain CNC Swiss screw machines typically demand higher wages due to their specialized training and expertise. Additionally, training costs should be factored in if new employees are brought on board.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and equipment depreciation. A well-maintained facility with advanced technology will have higher overhead costs but may lead to better output quality and efficiency.

-

Tooling: Tooling costs can vary widely based on the complexity of the parts being produced. Custom tooling may be necessary for specific applications, which can increase upfront costs. Regular maintenance and replacement of tooling should also be considered in the budget.

-

Quality Control (QC): Effective quality control systems are vital in ensuring precision and consistency in production. Investing in quality assurance technologies and processes can lead to higher upfront costs but ultimately reduce the risk of defects and rework.

-

Logistics: The costs associated with shipping, handling, and storage of the machines and parts should not be overlooked. International buyers, especially those from Africa, South America, and the Middle East, may face additional challenges related to customs and import duties.

-

Margin: Supplier margins can vary based on competition, market demand, and the supplier’s reputation. Understanding the market landscape will help buyers negotiate better pricing.

What Factors Influence the Pricing of CNC Swiss Screw Machines?

Several factors play a critical role in determining the pricing of CNC Swiss screw machines:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer discounts for bulk purchases. Understanding the MOQ requirements can help buyers gauge their purchasing strategy effectively.

-

Specifications and Customization: Custom features or specifications can lead to higher costs. Buyers should clearly define their needs to avoid unnecessary expenses.

-

Materials Used: The choice of materials affects both the initial purchase price and long-term operational costs. Exotic materials may be cost-prohibitive but could offer better performance and longevity.

-

Quality and Certifications: Machines that come with industry certifications or have undergone rigorous testing generally carry a premium price. Investing in certified equipment can reduce operational risks.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding the chosen Incoterms (International Commercial Terms) is vital, as they determine the responsibilities of buyers and sellers in shipping and logistics, which can affect overall costs.

What Tips Can Buyers Utilize to Optimize Costs?

To optimize costs when sourcing CNC Swiss screw machines, consider the following strategies:

-

Negotiation: Engage in discussions with suppliers to explore potential discounts or alternative pricing structures, especially for larger orders. Building a strong relationship can lead to more favorable terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the upfront costs. Consider maintenance, operational efficiency, and potential downtime when selecting a machine.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, and the Middle East should be aware of currency fluctuations, import tariffs, and shipping costs that can impact the final price. Collaborating with local experts can mitigate risks associated with international sourcing.

-

Supplier Diversity: Diversifying suppliers can create competitive pressure, potentially leading to better pricing and service levels. It also reduces the risk of supply chain disruptions.

Conclusion

Sourcing CNC Swiss screw machines requires a comprehensive understanding of the cost structure and pricing influencers. By considering materials, labor, manufacturing overhead, tooling, quality control, logistics, and supplier margins, buyers can make more informed decisions. Additionally, leveraging negotiation strategies and understanding the nuances of international trade can further enhance cost-effectiveness in sourcing these critical machines. Always remember that indicative prices may vary based on market conditions and specific buyer requirements.

Alternatives Analysis: Comparing cnc swiss screw machine With Other Solutions

In the landscape of precision manufacturing, the CNC Swiss screw machine stands out for its unique capabilities in producing small, intricate parts at high volumes. However, various alternative solutions exist, each with its own strengths and weaknesses. This section will compare CNC Swiss screw machines against two viable alternatives: traditional CNC lathes and multi-spindle screw machines. Understanding these options can help B2B buyers make informed decisions based on their specific manufacturing needs.

Comparison Table

| Comparison Aspect | Cnc Swiss Screw Machine | Traditional CNC Lathe | Multi-Spindle Screw Machine |

|---|---|---|---|

| Performance | High precision (tolerance of 0.0002 inches), fast cycle times (up to 10,000 RPM) | Moderate precision, suitable for larger parts | High production rates, less precision |

| Cost | Higher initial investment, lower operating costs due to efficiency | Lower initial investment, variable operating costs | Moderate initial cost, but higher operational costs due to complexity |

| Ease of Implementation | Requires skilled setup and programming | Easier to set up for various part sizes | Complex setup, needing specialized knowledge |

| Maintenance | Low maintenance with regular checks | Moderate maintenance requirements | High maintenance due to multiple spindles |

| Best Use Case | Ideal for high-volume, small, intricate parts in industries like automotive and electronics | Suitable for a wide range of part sizes, including larger components | Best for mass production of simpler parts, such as fasteners and bolts |

Detailed Breakdown of Alternatives

Traditional CNC Lathe

Traditional CNC lathes are versatile machines capable of handling a variety of part sizes and shapes. They are easier to operate and set up compared to Swiss screw machines, making them a good choice for manufacturers who require flexibility in their production processes. However, they typically offer lower precision than Swiss screw machines, especially when machining very small parts. For industries requiring high precision and rapid production of tiny components, such as medical devices or intricate automotive parts, traditional CNC lathes may fall short.

Multi-Spindle Screw Machine

Multi-spindle screw machines excel in high-volume production and can significantly reduce cycle times for simpler parts. They are particularly useful for producing items like screws, bolts, and other fasteners in large quantities. However, these machines often lack the precision of CNC Swiss screw machines, which can be a limitation when intricate designs or tight tolerances are required. Additionally, the complexity of multi-spindle machines can lead to higher maintenance costs and a steeper learning curve for operators, making them less appealing for businesses focused on precision machining.

Conclusion

When choosing the right manufacturing solution, B2B buyers should carefully evaluate their specific needs, including the type of parts being produced, volume requirements, and budget constraints. CNC Swiss screw machines are unmatched in precision and efficiency for small, complex parts, making them ideal for high-tech industries. Traditional CNC lathes offer flexibility and ease of use for a broader range of applications but may not meet the precision demands of certain projects. Meanwhile, multi-spindle screw machines provide high-speed production capabilities for simpler components but come with higher maintenance requirements and lower precision. By assessing these factors, buyers can select the most appropriate solution to enhance their manufacturing operations.

Essential Technical Properties and Trade Terminology for cnc swiss screw machine

What Are the Key Technical Properties of CNC Swiss Screw Machines?

Understanding the technical specifications of CNC Swiss screw machines is crucial for international B2B buyers to ensure they select the right equipment for their manufacturing needs. Here are some essential properties to consider:

1. Tolerance

Tolerance refers to the allowable deviation from a specified dimension. CNC Swiss screw machines can achieve tolerances as tight as ±0.0002 inches. This level of precision is critical in industries such as electronics and aerospace, where even minor deviations can affect performance and safety. Buyers must ensure that the machine’s tolerance capabilities align with the requirements of their specific applications.

2. Material Grade

The material grade denotes the type of metal or alloy that the machine can efficiently process. Common materials include stainless steel, aluminum, brass, and plastics. Different materials require specific tooling and settings to achieve optimal results. Buyers should assess the range of materials they intend to work with and verify that the Swiss screw machine can handle them effectively.

3. Bar Diameter Capacity

Swiss screw machines typically accommodate bar stock diameters ranging from 1mm to 32mm (0.04 to 1.25 inches). This specification is vital for determining the size of components that can be manufactured. Buyers need to consider the dimensions of the parts they require and ensure that the machine can support the necessary bar diameter.

4. Cycle Time

Cycle time refers to the duration it takes to produce one part, which can be as short as 10 seconds for simple components. Short cycle times enhance production efficiency, making CNC Swiss screw machines suitable for high-volume manufacturing. Understanding the cycle time helps buyers estimate production capacity and aligns with their operational timelines.

5. Spindle Speed

Spindle speed, measured in RPM (revolutions per minute), indicates how fast the machine can rotate the workpiece. CNC Swiss screw machines can operate at speeds up to 10,000 RPM, enabling rapid material removal and efficient processing. Higher spindle speeds contribute to faster production rates, which is essential for industries that require quick turnaround times.

What Are Common Trade Terms Related to CNC Swiss Screw Machines?

Familiarity with industry jargon is vital for effective communication in B2B transactions. Here are some common terms that buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of CNC Swiss screw machines, OEMs provide the machines or components that other businesses use to manufacture their products. Understanding OEM relationships can help buyers identify reputable suppliers and ensure product quality.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant in manufacturing, as it can affect production planning and inventory management. Buyers should clarify MOQs with suppliers to ensure they can meet order requirements without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests a detailed quote from suppliers for specific products or services. This process allows buyers to compare prices, terms, and capabilities. Understanding how to craft an effective RFQ can lead to better pricing and service agreements.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding the delivery of goods. These terms clarify who is responsible for shipping, insurance, and tariffs, which is particularly important in international transactions. Familiarity with Incoterms can help buyers avoid misunderstandings and facilitate smoother logistics.

5. Lead Time

Lead time is the time taken from placing an order to receiving the goods. In the context of CNC Swiss screw machines, understanding lead time is crucial for project planning and inventory management. Buyers should discuss lead times with suppliers to ensure they align with production schedules.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions about CNC Swiss screw machines, ensuring they choose the right equipment for their specific needs while navigating the complexities of global trade.

Navigating Market Dynamics and Sourcing Trends in the cnc swiss screw machine Sector

What Are the Current Market Trends Impacting CNC Swiss Screw Machines?

The CNC Swiss screw machine sector is witnessing robust growth driven by several global dynamics. The increasing demand for high-precision components across various industries, particularly automotive, aerospace, and electronics, is a significant factor. As manufacturers strive for efficiency and precision, CNC Swiss screw machines offer the capability to produce complex parts at high volumes with minimal human intervention. This automation trend is further amplified by advancements in technology, such as Industry 4.0, which integrates IoT and AI, leading to smarter manufacturing processes.

Emerging B2B sourcing trends highlight a shift towards supplier partnerships that prioritize innovation and reliability. International buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers who can not only meet quality standards but also adapt to changing market demands quickly. This adaptability is crucial in regions like Brazil and Vietnam, where local industries are rapidly evolving. Moreover, the rise of e-commerce platforms for industrial machinery is enabling buyers to explore a broader range of options, facilitating competitive pricing and improved negotiation power.

How Is Sustainability Shaping Sourcing Practices for CNC Swiss Screw Machines?

Sustainability has become a cornerstone of modern B2B sourcing strategies. The environmental impact of manufacturing processes is under scrutiny, prompting international buyers to consider the sustainability practices of their suppliers. In the CNC Swiss screw machine sector, this includes evaluating energy consumption, waste management, and the use of recyclable materials. Suppliers are increasingly adopting ‘green’ certifications, which assure buyers of their commitment to environmentally friendly practices.

Furthermore, ethical sourcing is gaining traction as companies prioritize transparency in their supply chains. This shift is particularly relevant for international buyers who are concerned about the socio-economic impacts of their purchasing decisions. By selecting suppliers that adhere to ethical standards, companies not only enhance their brand reputation but also contribute positively to local economies. As demand for sustainable practices grows, suppliers who incorporate eco-friendly materials and processes will likely gain a competitive edge in the market.

What Is the Historical Context of CNC Swiss Screw Machines?

The evolution of CNC Swiss screw machines dates back to the late 19th century in Switzerland, where precision engineering was paramount for industries like watchmaking. The design of these machines allowed for the mass production of small, intricate parts, setting a new standard for manufacturing efficiency. The introduction of CNC technology in the latter half of the 20th century revolutionized the sector, enabling programmable precision and higher production rates.

Today, CNC Swiss screw machines are not only integral to traditional industries but have also found applications in emerging sectors, reflecting the ongoing need for precision in a rapidly changing global marketplace. This historical backdrop underscores the importance of investing in reliable and advanced machinery to stay competitive in the ever-evolving B2B landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc swiss screw machine

-

How do I select the right CNC Swiss screw machine for my production needs?

Choosing the right CNC Swiss screw machine involves assessing your specific production requirements, including part complexity, material types, and volume. Consider the machine’s maximum diameter and length capabilities, as well as its precision level. Additionally, evaluate the machine’s automation features for efficiency and ease of use. It’s also beneficial to consult with suppliers about your needs to ensure the machine can accommodate future growth or diversification in product lines. -

What are the advantages of CNC Swiss screw machines over traditional lathes?

CNC Swiss screw machines offer unparalleled precision, especially for small, intricate parts, thanks to their sliding headstock design and guide bushing support. This setup allows for superior Z-axis motion, enabling the production of high volumes of complex components with tight tolerances. Moreover, they can perform multiple operations simultaneously, reducing cycle times and improving overall production efficiency compared to traditional lathes. -

What materials can be processed with CNC Swiss screw machines?

CNC Swiss screw machines are highly versatile and can process a wide range of materials, including metals like aluminum, brass, stainless steel, and exotic alloys. They can also handle various plastics. The machine’s high-speed cutting capabilities allow it to work with both common and specialized materials, making it ideal for industries like automotive and electronics that often require diverse material applications. -

What should I consider when vetting suppliers of CNC Swiss screw machines?

When vetting suppliers, prioritize their experience and reputation in the industry, as well as their track record with international clients. Request references and case studies to gauge their reliability. Additionally, assess their technical support capabilities, warranty offerings, and availability of spare parts. It’s also wise to inquire about their compliance with international quality standards and certifications to ensure you receive a machine that meets global benchmarks. -

What are the typical payment terms when purchasing CNC Swiss screw machines?

Payment terms can vary significantly between suppliers, but common arrangements include a deposit upon order confirmation, with the balance due prior to shipment or upon delivery. Some suppliers may offer financing options or installment plans, particularly for higher-value machines. Always clarify payment terms, including currency and method, and consider negotiating to ensure terms align with your financial strategy. -

What is the minimum order quantity (MOQ) for CNC Swiss screw machines?

The MOQ for CNC Swiss screw machines can vary by manufacturer and machine model. While some suppliers may have a minimum requirement, others might allow single-unit purchases, especially for standard models. For custom machines or configurations, higher MOQs are often expected. Discuss your needs directly with suppliers to understand their policies and explore potential flexibility. -

How can I ensure quality assurance (QA) in my CNC Swiss screw machine purchase?

To ensure quality assurance, request detailed documentation of the machine’s manufacturing process, including quality control measures and testing procedures. Inquire about the supplier’s certifications and adherence to international standards, such as ISO 9001. It may also be beneficial to arrange for on-site inspections or third-party evaluations before finalizing your purchase to ensure the machine meets your specifications. -

What are the logistics considerations for importing CNC Swiss screw machines?

When importing CNC Swiss screw machines, consider shipping methods, tariffs, and customs regulations relevant to your country. Work closely with your supplier to coordinate shipping schedules and obtain necessary documentation for customs clearance. Additionally, assess the costs associated with transportation and potential delays, and explore logistics providers that specialize in heavy machinery to ensure safe and timely delivery.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Cnc Swiss Screw Machine Manufacturers & Suppliers List

1. Swistek – Swiss Type Automatic Screw Machines

Domain: swistek.com

Registered: 2010 (15 years)

Introduction: New Swiss Type Automatic Screw Machines for sale at Swistek Machinery America. Brands include STAR, TSUGAMI, GANESH, HANWHA, SWISTEK, and CITIZEN. Contact information: 50 Seemans Lane, Milford, CT, 06460, Phone: 203-301-4848, Email: [email protected]. Active inventory includes various types of machinery and accessories.

2. Avant Engineering – Swiss CNC Machining

Domain: avantiengineering.com

Registered: 2000 (25 years)

Introduction: Swiss screw machining, also known as Swiss CNC machining, is a precise and efficient method for producing small, complex parts in high volumes. Key components include a sliding headstock, guide bushing, live tooling, and multi-axis control. Benefits include exceptional precision (tolerances as tight as ±0.0002 inches), faster production with shorter cycle times, and flexibility across materials su…

3. Star CNC – Swiss-type Automatic Lathes

Domain: starcnc.com

Registered: 1997 (28 years)

Introduction: Star CNC offers a range of Swiss-type Automatic Lathes designed for small, complex, and precise metal components machining. Key features include fast job processing, high process reliability, simple operation, energy efficiency, and low non-productive time. Current models include SB-12R Type G, SB-16R Type G, SB-20R Type G, SD-26 Type S, SK-51 Type A, SL-10, SP-20, SR-10J, SR-20JII Type A/B, SR-20…

4. Machinestation – Used CNC Swiss Lathes

Domain: machinestation.us

Registered: 2013 (12 years)

Introduction: Used CNC Swiss Lathes for Sale | Enhance Your Machining Accuracy | Brands: Daewoo, Doosan, DMG Mori, Haas, Hyundai, Matsuura, Mazak, Mighty Viper, Mori Seiki, Nakamura, Okuma, Sharp, SNK, Star, Takisawa, Toyoda, Tsugami, Yama Seiki, YCM | Contact: +1 909-919-9600 | Email: [email protected] | Machines Under $25k | Exclusive lineup of incoming machines available for reservation with a refundable dep…

5. CNC Turning Center – Swiss Screw Machines

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Swiss Screw Machine/CNC Turning Center Metalworking Lathes available on eBay. Categories include various types of lathes such as Swiss Screw Machines, CNC Turning Centers, and more. Brands featured include CINCINNATI, Clausing, Daewoo, DMG MORI, Doosan, Emco, FANUC, Haas, Hardinge, Hitachi, Kennametal, Kyocera, Mazak, Miyano, Okuma, Samsung, Schaublin, Star, and unbranded options. Machines vary in…

6. Citizen-Cincom – CNC Swiss Machining Centers

Domain: productivity.com

Registered: 1991 (34 years)

Introduction: CNC Swiss machining centers, represented by Citizen-Cincom, leader in Swiss turning and milling industry for over 25 years. High performance and accuracy for long length/diameter applications and complex, multi-axis milling. Fast, precise cutting performance suitable for medical, automotive, firearms, and general job shop applications. User-friendly controls with advanced programming for multi-pro…

7. Millennium Machine & Tool – Swiss Screw Machine Services

Domain: mmtinc.net

Registered: 2004 (21 years)

Introduction: Swiss Screw Machine Services offered by Millennium Machine & Tool include ultra-precise machining capabilities using eight Swiss turning lathes and five conventional CNC lathes within a 77,000 sq. ft facility. The services are designed for small, high-precision parts necessary for critical components in various industries such as aerospace, agriculture, automotive, recreation, and military. Key fe…

Strategic Sourcing Conclusion and Outlook for cnc swiss screw machine

In the rapidly evolving landscape of precision manufacturing, CNC Swiss screw machines stand out as indispensable tools for producing high-quality, intricate components. Their unique ability to operate at exceptional tolerances, combined with high-speed production capabilities, makes them ideal for industries ranging from automotive to electronics. Strategic sourcing of CNC Swiss screw machines not only enhances production efficiency but also reduces costs and improves product quality, crucial factors for businesses seeking competitive advantages in global markets.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, investing in these machines represents an opportunity to streamline operations and meet the rising demand for precision parts. Engaging with reliable suppliers who understand regional market dynamics can facilitate access to advanced technology and support.

Looking ahead, the integration of automation and digital solutions in CNC Swiss screw machining will further revolutionize manufacturing processes. Companies that prioritize strategic sourcing of these machines will be well-positioned to capitalize on emerging trends and innovations. We encourage international buyers to explore partnerships with reputable manufacturers and distributors, ensuring they remain at the forefront of precision engineering and production excellence.