Guide Contents

Project Insight: Cnc Swiss Screw Machine

Manufacturing Insight: CNC Swiss Screw Machines

Why Speed and Precision Are Non-Negotiable in Product Development

In today’s hyper-competitive hardware landscape, product development cycles are measured in weeks, not months. Every day saved in prototyping accelerates time-to-market, while micron-level precision ensures parts function flawlessly—critical for medical devices, aerospace components, or IoT hardware.

Design iterations that once took weeks now happen in days, but only when you can trust machining accuracy within ±0.01mm. Compromises on precision lead to costly rework, failed field tests, or safety risks.

Startups and engineers can’t afford to gamble with manual processes or DIY solutions—they need a partner who delivers industrial-grade precision at startup speed.

The Hidden Costs of In-House Swiss Machining

Upfront capital investment ($400k+) and financing costs ($8,500+/month) tie up critical funds that could fuel R&D or scaling—while locking you into fixed overheads even during low-volume phases.

Skilled labor shortages and maintenance downtime disrupt production schedules, delaying time-to-market. A single machine breakdown can halt entire projects for weeks.

DIY or low-cost solutions (e.g., $800–$1,500 DIY mills) lack the repeatability for functional parts—often failing to meet ±0.01mm tolerances required for real-world applications.

Example: A $15–20k monthly spend on external Swiss machining still carries hidden inefficiencies—manual quoting, communication delays, and scalability challenges that stifle innovation.

How Honyo Prototype Accelerates Your Innovation Cycle

Online Instant Quote: Our AI-powered platform analyzes your CAD in seconds, delivering real-time pricing, material recommendations, and manufacturability feedback—eliminating 3–5 day quote delays and guesswork.

Fast Turnaround: Prototype parts in 3–5 days, high-volume production in weeks—not months. Our Shenzhen hub leverages automated workflows and predictive scheduling to cut lead times by 40% vs. traditional shops.

Precision at Scale: 3/4/5-axis Swiss machining with ±0.01mm tolerances ensures your parts function as designed—from micro-threads on 0.4″ automotive components to complex aerospace assemblies.

Precision Engineering Without the Overhead

Zero upfront investment: Access industrial-grade Swiss machining with no capital expenditure—scale from single prototypes to 200k+ automotive-grade parts without equipment or facility costs.

Risk-free scalability: Our cloud-connected production network adapts seamlessly to your volume needs, whether you’re validating a new design or launching mass production.

Engineer-to-engineer collaboration: Partner with our team to optimize designs for manufacturability—reducing costs by 15–30% while accelerating time-to-market from concept to certified parts.

At Honyo Prototype, we don’t just machine parts—we accelerate your innovation. From your first prototype to global-scale production, our digital manufacturing platform turns complexity into confidence.

Honyo Capabilities & Technology

Honyo’s Swiss CNC Machining Capabilities

Precision Engineering Engineered for Critical Applications

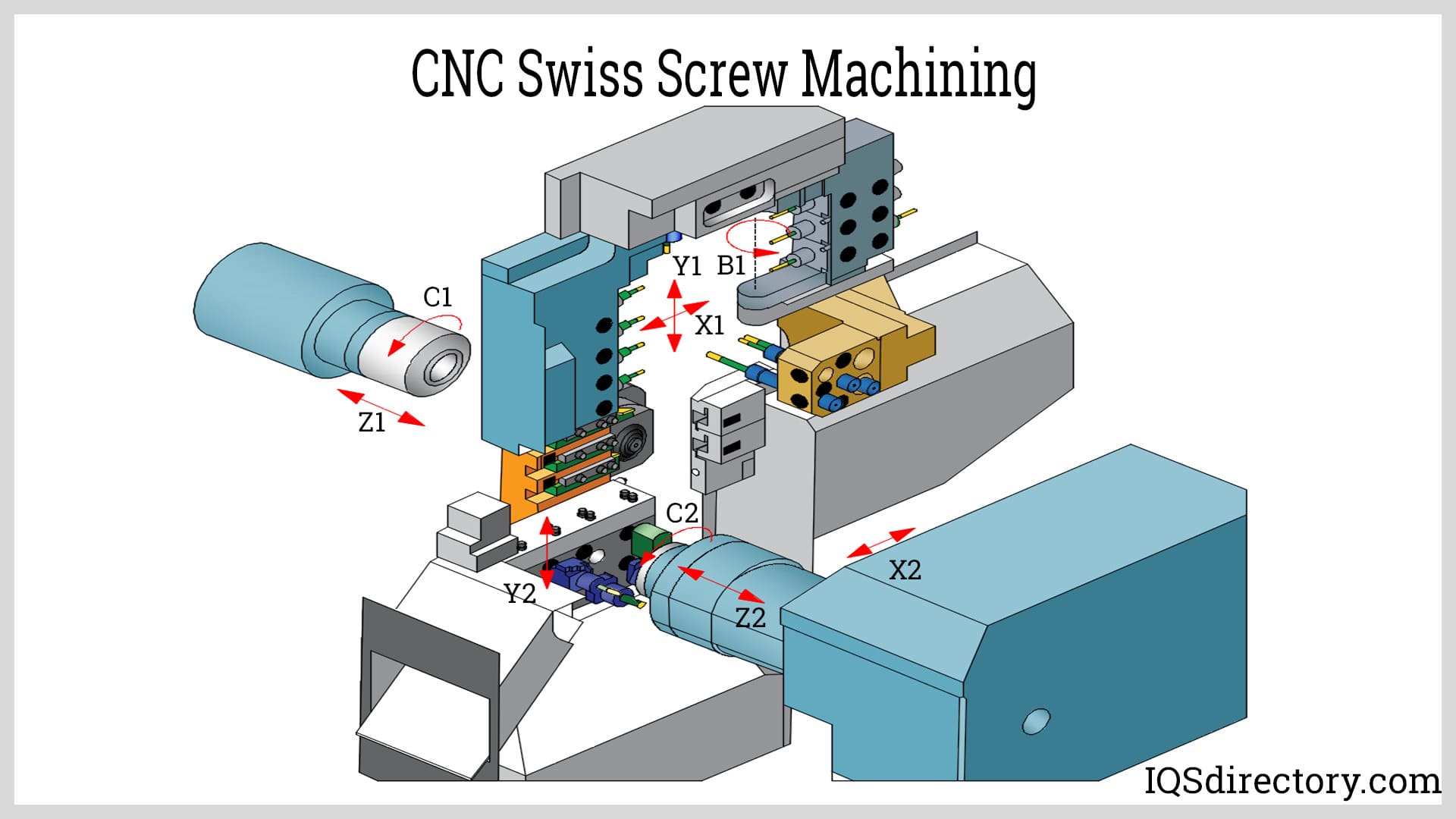

3/4/5-axis Swiss CNC machining for complex geometries with micron-level precision

Consistent ±0.01mm tolerances for medical, aerospace, and automotive components

Multi-spindle and twin-slide capabilities for intricate threading and high-volume production

Scalable Production from Prototype to Mass Production

Zero minimum order quantities—perfect for startups and small batches

Seamless transition from 1 prototype to 10,000+ production parts without retooling

Flexible scheduling to accommodate urgent needs and large-scale orders

ISO 9001:2015 Certified Quality Assurance

Rigorous in-process inspections with GD&T compliance and real-time dimensional tracking

Full material traceability and certified test reports for regulatory adherence

End-to-end quality control from raw material to final delivery

Smart Manufacturing Services for Faster Results

Online Instant Quote: Real-time pricing and lead times within seconds—no more manual quotes or guesswork

AI-Powered DFM Optimization: Automated design feedback to reduce costs, eliminate bottlenecks, and accelerate time-to-market

Lightning-Fast Turnaround: Prototype delivery in 3-5 days; production in 1-2 weeks with expedited options for critical projects

Honyo Prototype: Where innovation meets precision. Let’s build the future—faster, smarter, and with unmatched accuracy.

Materials & Surface Finishes

Material Options & Finishes for Precision Swiss Screw Machining

Swiss screw machining demands meticulous material selection to achieve micron-level precision and functional reliability. At Honyo Prototype, we optimize material and finish choices to maximize part performance while minimizing cost and lead time—so you get production-ready parts without the capital burden of in-house machinery.

Key Materials for Swiss Screw Applications

Aluminum 6061: Ideal for lightweight, corrosion-resistant components. Excellent machinability for complex geometries with ±0.01mm tolerances. Common in aerospace brackets, medical devices, and automotive sensors.

Aluminum 7075: High-strength alternative for structural applications. Used in high-load scenarios like drone frames or racing components where weight savings are critical.

Stainless Steel 304: Versatile corrosion resistance for food-grade and general industrial use. Perfect for threaded fasteners, medical instruments, and chemical-handling parts.

Stainless Steel 316: Enhanced marine/chemical resistance. Ideal for surgical implants, offshore equipment, and pharmaceutical machinery exposed to chlorides.

Brass C110: Superior electrical conductivity and machinability. Best for electrical contacts, valve bodies, and decorative hardware requiring precise threading.

PEEK: High-performance thermoplastic for extreme temperatures (-200°C to +250°C) and chemical exposure. Used in aerospace seals, surgical tools, and semiconductor components.

Surface Finish Options

Anodizing (Type II/III): Enhances aluminum corrosion resistance and wear properties. Available in clear or colored finishes for aesthetic and functional needs (e.g., consumer electronics housings).

Passivation: Critical for stainless steel to remove surface contaminants and maximize corrosion resistance—essential for medical and food industry parts.

Mirror Polishing: Achieves <0.1μm Ra surface finish for optical components, watch parts, or high-precision sensor housings.

Powder Coating: Durable, abrasion-resistant finish for structural parts needing color consistency and environmental protection (e.g., outdoor equipment).

Electroplating (Nickel, Zinc): Adds conductivity, wear resistance, or corrosion protection for brass and steel components in harsh environments (e.g., automotive connectors).

How to Choose the Right Material for Your Swiss Screw Project

Performance Requirements: Match material properties to end-use conditions—e.g., PEEK for high-temp applications, 7075 aluminum for structural strength.

Machinability Considerations: Softer materials like brass and 6061 aluminum machine faster, reducing cycle times and costs. Harder alloys (e.g., 316 stainless) may require slower feeds but deliver higher strength.

Cost vs. Functionality: Balance material cost with part functionality. For example, 304 stainless offers good corrosion resistance at lower cost than 316 unless specific marine exposure is needed.

Tolerance Sensitivity: Materials with stable thermal properties (like 6061 aluminum) maintain tight tolerances during machining better than others—critical for ±0.01mm precision.

Why Partner with Honyo Prototype?

Online Instant Quote: Get real-time pricing in seconds via our AI-powered platform—no manual calculations or waiting days for quotes.

AI-Optimized Manufacturing: Our algorithms analyze your design to recommend optimal materials, finishes, and process parameters for cost and precision—eliminating the $400k+ capital expenditure of owning a Swiss machine.

Fast Turnaround: From quote to delivery in 3–5 days for prototypes, 7–10 days for production runs—saving you weeks compared to traditional suppliers.

💡 Pro Tip: Need to validate material suitability? Upload your CAD file to our platform for instant material/finish recommendations tailored to your application’s stress, environment, and budget. No engineering guesswork—just precision, delivered.

From Quote to Part: Our Process

How It Works: From CAD to Part

At Honyo Prototype, we’ve engineered a digital-first workflow that transforms your design into precision parts in record time—no capital investment, no guesswork. From upload to delivery, every step is optimized for speed, transparency, and unmatched accuracy.

Upload CAD File

Seamless integration: Upload standard CAD files (STEP, STL, IGES) in seconds—no technical expertise required.

Instant validation: Automated checks flag compatibility issues or design flaws before quoting, saving you time and rework.

Enterprise-grade security: Your designs stay encrypted and accessible 24/7 via our secure cloud platform.

AI-Powered Instant Quote

60-second pricing: Receive a real-time, itemized quote—no manual estimations or waiting days for a response.

Data-driven accuracy: Our AI analyzes geometry, materials, tolerances, and volume to generate precise costs with zero hidden fees.

Transparent breakdown: See exactly where your investment goes (materials, machining, setup) with clear, auditable cost breakdowns.

Proactive DFM Analysis

AI-driven optimization: Our engine identifies manufacturability risks and suggests design tweaks to reduce costs and improve part performance.

Swiss-specific insights: Tailored feedback on thread accuracy, material selection, and feature complexity for Swiss screw machining.

Collaborative refinement: Work directly with our engineers to finalize designs in hours, not weeks—before production even starts.

Precision Production & Delivery

±0.01mm tolerances: Leverage our Swiss screw machines for high-precision functional prototypes and end-use parts—no compromise on quality.

72-hour prototype turnaround: Automated scheduling and real-time production tracking ensure on-time delivery for even urgent orders.

Zero-defect guarantee: Rigorous QC at every stage, from raw material inspection to final dimensional verification.

Ready to skip the $400k machine investment and operational headaches? Start your project in minutes—no commitment, just precision.

Start Your Project with Honyo

Start Your Project with Honyo

Precision Swiss Machining, Zero Capital Risk

Skip $400K+ machine investments: Pay per part, no financing, maintenance, or labor overhead

Achieve ±0.01mm tolerances with 3/4/5-axis CNC capabilities for mission-critical components

Scale seamlessly from prototypes (1 unit) to 100,000+ parts – no compromises on quality or lead time

AI-Driven Efficiency for Faster Time-to-Market

Instant online quotes: Upload CAD files → get real-time pricing in <5 minutes

Proprietary AI optimizes material selection, toolpaths, and cycle times for maximum cost savings

Prototypes in 3–5 days; high-volume production with consistent precision and <10-day lead times

Your Trusted Partner in Innovation

Founder Susan Leo and Shenzhen/Dongguan engineering team deliver end-to-end solutions

Visit our facilities for hands-on collaboration on design-for-manufacturability (DFM)

Ready to start? [email protected] | +86 139 2843 8620

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.