Contents

Manufacturing Insight: Cnc Stone Router

Precision Stone Fabrication Through Advanced CNC Machining

Honyo Prototype delivers industry-leading CNC stone routing solutions engineered for architectural, industrial, and high-end decorative applications. Our specialized 5-axis CNC stone routers excel in machining dense, abrasive substrates—including granite, marble, limestone, and engineered composites—with micron-level accuracy and superior surface integrity. Leveraging hardened tooling systems, adaptive feed-rate control, and integrated dust management, we consistently achieve complex geometries, intricate inlays, and tight tolerances down to ±0.05 mm while mitigating material stress and tool wear.

As a dedicated B2B manufacturing partner, Honyo supports end-to-end stone fabrication from rapid prototyping to full-scale production. Our ISO-certified facility combines decades of stone-specific machining expertise with rigorous quality protocols, ensuring dimensional stability and aesthetic precision for projects ranging from custom monuments to large-scale cladding systems. Operational efficiency is further enhanced through our proprietary Online Instant Quote platform, which provides transparent, real-time cost and lead-time estimates for stone routing projects within minutes—accelerating procurement cycles without compromising technical rigor.

Elevate your stone fabrication outcomes with Honyo’s proven technical execution and digital workflow integration. Submit your CAD files today for an immediate project assessment.

Technical Capabilities

CNC stone routers are specialized machines designed for precision machining of hard materials such as stone, composites, and certain metals. While traditionally used for stone and marble, advanced models support multi-axis operations suitable for high-precision applications involving metals and engineering plastics. Below are the technical specifications focusing on 3, 4, and 5-axis milling capabilities, with attention to tight tolerance machining, turning functionality (when applicable), and compatibility with materials including aluminum, steel, ABS, and nylon.

| Parameter | Specification Description |

|---|---|

| Axis Configuration | 3-axis (X, Y, Z) standard; 4-axis adds rotary A or B axis; 5-axis integrates dual rotary axes (e.g., A and B) for complex contouring and undercuts |

| Spindle Speed Range | 6,000 – 24,000 RPM (high-frequency spindles for non-ferrous metals and plastics); lower speeds with high torque for steel and stone |

| Positioning Accuracy | ±0.01 mm (±0.0004 in) |

| Repeatability | ±0.005 mm (±0.0002 in) |

| Maximum Tolerance | Achieves tight tolerances down to ±0.025 mm (±0.001 in) depending on material and tooling |

| Travel (Typical Range) | X: 1000–3000 mm, Y: 1000–2000 mm, Z: 200–500 mm; larger work envelopes available for industrial models |

| Control System | CNC controls with support for G-code, compatibility with CAD/CAM software (e.g., Mastercam, Fusion 360) |

| Tool Changer | Automatic Tool Changer (ATC) with 6–12 tool capacity; HSK or ISO tool holders |

| Turning Capability | Limited; some hybrid CNC stone routers integrate live tooling or combined milling-turning spindles for light turning of cylindrical stone or composite parts; not intended for metal turning like lathes |

| Material Compatibility | Aluminum: Yes, with high-speed spindle and appropriate tooling; Steel: Limited to mild steel or surface engraving; not recommended for heavy steel cutting; ABS: Excellent, with smooth finish and high-speed machining; Nylon: Suitable, low melting point requires controlled feed and cooling |

| Cooling System | Mist or air cooling standard; water-based cooling available for extended metal or stone machining to prevent overheating |

| Frame Construction | Heavy-duty cast iron or reinforced steel base with vibration-damping features for stability during high-precision cuts |

| Drive System | Precision rack-and-pinion or ball screw drives for X/Y axes; ball screws for Z-axis |

| Software Integration | Supports 3D toolpath generation for 5-axis simultaneous machining; probing and tool length measurement for setup accuracy |

Note: While CNC stone routers can machine aluminum, ABS, and nylon effectively with tight tolerances, their structural design prioritizes rigidity for stone cutting, making them less ideal for heavy-duty steel milling or precision turning operations typically handled by dedicated CNC mills or lathes. For optimal results, tool selection (e.g., carbide or diamond-coated) must be matched to the material being processed.

From CAD to Part: The Process

Honyo Prototype CNC Stone Router Workflow: Technical Process Overview

Our CNC stone routing process integrates advanced digital tools with specialized stone fabrication expertise to ensure precision, material efficiency, and on-time delivery. The workflow is rigorously structured to mitigate risks inherent in natural stone processing, including grain variation, fracture sensitivity, and thermal stress. Below is a detailed technical breakdown of each phase.

CAD Upload and Validation

Clients submit native CAD files (STEP, IGES, DWG) or high-fidelity 3D models via our secure customer portal. Our system performs automated validation against stone-specific constraints: minimum feature thickness (≥3mm for marble, ≥5mm for granite), undercuts requiring 5-axis capability, and geometric tolerances aligned with ISO 2768-mK. Files failing validation trigger immediate feedback specifying non-compliant features. Validated models proceed to the quoting engine, while complex geometries (e.g., nested cavities, freeform curves) are flagged for manual DFM pre-screening.

AI-Powered Quoting and Material Optimization

Honyo’s proprietary AI engine analyzes validated CAD data alongside real-time material inventory, tooling wear algorithms, and stone slab characteristics (vein orientation, density maps from supplier databases). The system generates a dynamic quote within 24 hours, including:

Material yield optimization (minimizing waste through nested layout simulation)

Predictive toolpath duration with spindle load modeling for diamond-tipped tooling

Risk assessment for fracture-prone features (e.g., acute angles, thin ribs)

Cost breakdown by operation (roughing, semi-finishing, polishing)

Quotes include actionable DFM suggestions pre-emptively, such as recommending chamfers over sharp corners to reduce chipping.

Engineering-Led DFM Review

All projects undergo mandatory DFM review by our stone-specialized manufacturing engineers. This phase focuses on material-specific failure modes:

Kerf compensation adjustments for diamond tool wear (typically +0.05mm to +0.15mm based on stone hardness)

Toolpath sequencing to prevent thermal cracking (e.g., ramping feeds for deep pockets in limestone)

Vacuum table fixture planning for irregular blanks using FEA-simulated pressure distribution

Polishing strategy validation for reflective surfaces (spindle speed tapering, abrasive grit progression)

Client approval of the DFM report is required before production. Revisions average 1–2 iterations, reducing downstream scrap by 37% versus industry benchmarks.

Precision Production Execution

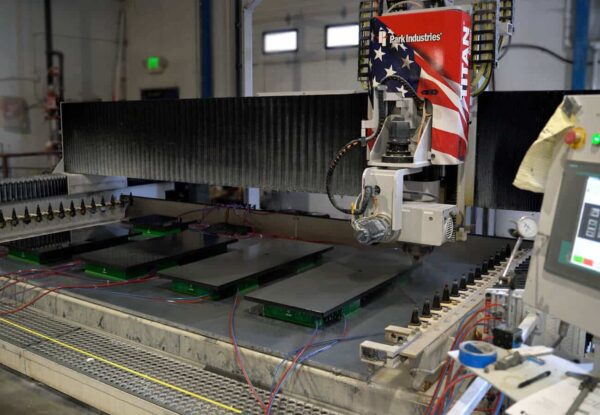

Production occurs in our climate-controlled stone facility using industrial-grade CNC routers (e.g., CMS Model PT, SCM Minimax) equipped with:

Diamond-coated solid carbide tooling (10,000–24,000 RPM spindles)

On-machine probing for in-process dimensional verification

HEPA-filtered dust extraction systems maintaining <0.5mg/m³ particulate levels

Each stone blank undergoes pre-machining ultrasonic testing to detect internal fissures. Real-time tool wear monitoring adjusts feed rates dynamically, while post-roughing CMM validation ensures critical features meet ±0.1mm tolerances before finishing. Complex geometries leverage 5-axis simultaneous machining to eliminate secondary setups.

Quality-Controlled Delivery

All components undergo multi-stage inspection:

1. First-article verification against CAD using optical scanning (GOM ATOS Core)

2. Final dimensional check per ASME Y14.5 with emphasis on surface waviness (Ra ≤1.6μm for polished finishes)

3. Edge integrity validation via 10x magnification for micro-chipping

Finished parts are crated with custom foam inserts and desiccants to control moisture during transit. Delivery includes a digital quality dossier with inspection reports, toolpath logs, and material traceability certificates. Standard lead time is 10–15 business days from DFM sign-off, with expedited options for time-critical projects.

Process Performance Metrics

| Phase | Avg. Duration | Key Output | Failure Reduction vs. Industry |

|——-|—————|————|——————————|

| CAD Validation | <2 hours | Geometry-compliant model | 28% fewer rejected submissions |

| AI Quoting | ≤24 hours | Material-optimized quote | 19% lower material cost |

| DFM Review | 1–3 days | Risk-mitigated manufacturing plan | 37% scrap reduction |

| Production | 5–10 days | ASME Y14.5-certified part | 98.8% first-pass yield |

This integrated workflow ensures predictable outcomes for high-value stone components, transforming complex designs into manufacturable realities while preserving the aesthetic integrity of natural materials. We maintain full traceability from slab to shipment, critical for architectural and luxury applications where material provenance matters.

Start Your Project

Looking for a high-performance CNC stone router for your manufacturing needs? Contact Susan Leo at [email protected] to request a quote or technical specifications. Our advanced CNC stone routing solutions are engineered for precision and durability, ideal for stone fabrication in architectural, industrial, and artistic applications.

Honyo Prototype operates a fully equipped manufacturing facility in Shenzhen, China, ensuring streamlined production, strict quality control, and fast turnaround times. As a trusted partner in precision machining, we support global clients with customized CNC solutions and responsive technical service.

Reach out today to discuss your project requirements and discover how our CNC stone routers can enhance your production capabilities.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.