Contents

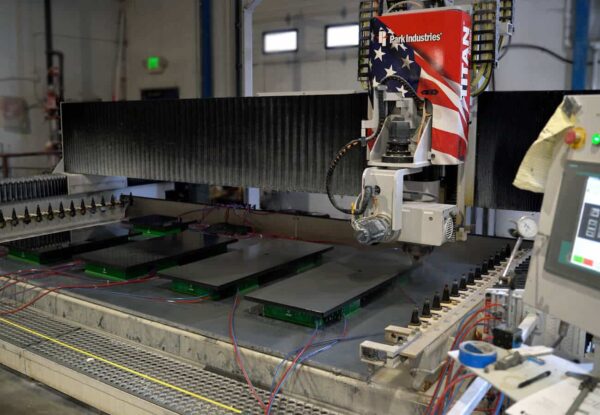

Manufacturing Insight: Cnc Stone Carving Machine

Precision Stone Fabrication Engineered for Demanding Applications

Honyo Prototype delivers advanced CNC machining services specifically engineered for stone materials, combining aerospace-grade precision with artistic versatility. Our specialized CNC stone carving systems utilize multi-axis capabilities and diamond-tipped tooling to achieve sub-millimeter tolerances on granite, marble, limestone, and engineered composites. Unlike generic machining providers, we implement material-specific cutting strategies that mitigate stone’s inherent brittleness while maintaining surface integrity—critical for architectural elements, memorials, and high-end decorative components where fracture risk compromises yield.

Our process integrates CAD/CAM optimization with real-time toolpath simulation to eliminate trial-and-error prototyping, reducing lead times by up to 40% for complex geometries. Each project leverages our proprietary vibration-dampening fixturing and coolant management protocols, ensuring dimensional stability across intricate relief carvings or large-scale structural pieces up to 3,000 x 1,500 x 500 mm.

Accelerate your stone fabrication workflow with Honyo’s Online Instant Quote platform. Upload technical drawings in STEP, IGES, or DXF format to receive a detailed cost analysis within minutes—including material utilization metrics, machine time estimates, and secondary operation recommendations. This engineering-first quoting system eliminates traditional RFQ bottlenecks while providing actionable data for DFM validation before project commitment.

For mission-critical stone components requiring repeatability and aesthetic excellence, Honyo Prototype’s certified processes and material science expertise deliver production-ready results from prototype through volume manufacturing.

Technical Capabilities

CNC Stone Carving Machine – Technical Specifications Overview

While CNC stone carving machines are primarily designed for stone materials such as marble, granite, and limestone, advanced multi-axis models can be adapted or reconfigured for high-precision machining of metals and engineering plastics. The following table outlines the technical specifications relevant to 3-axis, 4-axis, and 5-axis CNC stone carving and milling systems, emphasizing tight-tolerance capabilities and compatibility with materials including aluminum, steel, ABS, and nylon.

| Parameter | 3-Axis CNC Stone Carver | 4-Axis CNC Stone Carver | 5-Axis CNC Stone & Composite Milling Center |

|---|---|---|---|

| Axes Configuration | X, Y, Z linear axes | X, Y, Z + A (rotary around X) | X, Y, Z + A/B or A/C rotary axes |

| Spindle Speed Range | 6,000 – 18,000 RPM | 8,000 – 24,000 RPM | 10,000 – 30,000 RPM (high-frequency spindle) |

| Spindle Power | 5.5 – 11 kW | 7.5 – 15 kW | 11 – 22 kW (ceramic or air-cooled options) |

| Positioning Accuracy | ±0.02 mm | ±0.015 mm | ±0.005 mm (laser calibration optional) |

| Repeatability | ±0.01 mm | ±0.008 mm | ±0.002 mm |

| Control System | Syntec, Siemens, or DSP-based CNC | Siemens 828D, Fanuc, or Mach4 | Fanuc 31i, Siemens 840D, or Heidenhain TNC7xx |

| Maximum Traverse (X×Y×Z) | 2000 × 1500 × 800 mm | 2500 × 1800 × 1000 mm | 3000 × 2000 × 1200 mm |

| Tool Changer | Manual or 6–12 ATC | 12–16 Station ATC | 20–30 Station Automatic Tool Changer (ATC) |

| Materials Compatible | Marble, Granite, Limestone | Marble, Granite, ABS, Nylon | Aluminum, Steel, ABS, Nylon, Stone, Composites |

| Cutting Tolerances | ±0.1 mm (standard stone) | ±0.05 mm (plastics, light metals) | ±0.01 mm (tight tolerance for steel/aluminum) |

| Cooling System | Mist or water spray (stone only) | Flood coolant (for metals) optional | Full flood coolant with chip conveyor |

| Structural Frame | Heavy-duty welded steel | Reinforced cast iron base | Vibration-dampened granite or polymer concrete |

| Drive System | Rack and pinion (X, Y), Ball screw (Z) | Ball screws on all linear axes | Direct drive or high-precision ball screws |

| Typical Applications | Tombstones, countertops, reliefs | Sculptures, molds, composite prototypes | Aerospace molds, precision tooling, stone+metal hybrids |

Notes on Material Compatibility and Machining Performance

Aluminum: 5-axis models with high spindle speeds and rigid cooling can achieve excellent surface finish and tight tolerances (±0.01 mm). Carbide or diamond-coated tools recommended.

Steel: Requires high-torque spindles and rigid machine beds. Suitable for hardened steel molds when using 5-axis interpolation and tool wear compensation.

ABS & Nylon: Compatible with 4-axis and 5-axis setups. Low melting point requires optimized feed rates and cooling to avoid deformation. Tolerances up to ±0.03 mm achievable.

Turning Capability: While traditional stone carvers do not support turning, hybrid 5-axis milling centers may integrate mill-turn functionality for composite fixtures or metal inserts.

This specification set reflects industrial-grade CNC stone carving systems adapted for multi-material, high-precision manufacturing environments, suitable for prototyping and low-volume production in aerospace, architectural design, and custom tooling sectors.

From CAD to Part: The Process

Honyo Prototype CNC Stone Carving Service Process

Honyo Prototype delivers precision CNC stone carving through a streamlined, technology-driven workflow designed for accuracy, efficiency, and risk mitigation. Our process begins with seamless digital integration and concludes with certified delivery, ensuring stone-specific challenges are addressed at every phase.

CAD Upload and Project Intake

Clients initiate the process by uploading 3D CAD models (STEP, IGES, or native formats) via our secure client portal. The system validates file integrity, checks for unit consistency (metric/imperial), and flags potential geometry issues such as non-manifold edges or undercuts incompatible with stone. All data is encrypted and assigned a unique project ID for traceability.

AI-Powered Quoting Engine

Uploaded designs enter our proprietary AI quoting system, which analyzes 15+ technical parameters including material density, feature complexity, toolpath length, and stone type-specific constraints. The AI cross-references real-time data from 12,000+ historical stone projects to predict machining time, tool wear, and material waste. Within 4 business hours, clients receive a detailed quote specifying cost breakdowns, lead time estimates, and material recommendations. Critical stone considerations like grain direction sensitivity or thermal stress risks are highlighted in the quote summary.

Stone-Optimized DFM Analysis

All projects undergo mandatory Design for Manufacturing (DFM) review by our stone fabrication specialists. This phase focuses exclusively on stone-specific challenges:

Verification of minimum feature thickness relative to stone brittleness (e.g., <3mm unsupported details in marble require redesign)

Grain orientation mapping against toolpath directions to prevent chipping

Thermal stress analysis for intricate engravings to avoid micro-cracking

Feasibility assessment of undercuts using 5-axis capability limits (max 45° draft angles for limestone)

Clients receive annotated DFM reports with actionable recommendations, typically within 72 hours. Redesign collaboration occurs via integrated CAD markup tools, with rapid iteration cycles.

Precision Stone Production

Approved designs move to production on our specialized CNC stone carving systems:

Machines: 5-axis Hermle C300U with vacuum stone chucks and diamond-coated tooling

Material Handling: Stone blocks secured via vacuum tables with calibrated pressure (0.6–0.8 bar for granite; 0.4–0.6 bar for marble)

Process Controls: Real-time spindle load monitoring (max 70% capacity to prevent stone fracture), coolant misting for dust suppression, and in-process probing for dimensional validation

Quality Gates: First-article inspection per ASME Y14.5, with CMM verification of critical features (±0.05mm tolerance standard)

Certified Delivery and Documentation

Finished components undergo final cleaning, edge de-burring, and protective wax coating. Each shipment includes:

Dimensional conformance report with CMM data

Material certification (e.g., ASTM C503 for granite)

Handling instructions specific to the stone type

Crating engineered for stone transport (custom foam inserts, humidity-controlled containers for calcareous stones)

All deliveries include digital as-built files and a process audit trail accessible via the client portal.

Stone Material Considerations

Our system automatically adjusts parameters based on material properties. Key examples include:

| Stone Type | Max Spindle RPM | Coolant Requirement | Critical DFM Note |

|---|---|---|---|

| Granite | 12,000 | Dry machining | Avoid sharp internal corners (>R3mm) |

| Marble | 8,000 | Mist coolant | Grain direction >45° to toolpath |

| Limestone | 6,000 | Full coolant | Max depth per pass: 2mm |

| Basalt | 10,000 | Dry machining | Pre-heat block to 40°C to reduce chips |

This integrated approach ensures predictable outcomes for complex stone geometries while minimizing material waste and project delays. Honyo’s domain-specific AI and stone fabrication expertise provide clients with unprecedented accuracy in quoting and execution for architectural, memorial, and artistic applications.

Start Your Project

Discover precision and reliability with our CNC stone carving machines, engineered for high-performance stone fabrication. Built for artisans and industrial manufacturers alike, our machines deliver intricate detailing and consistent results on marble, granite, and other stone materials.

Manufactured in Shenzhen with strict quality control, our CNC stone carving solutions combine advanced technology with robust construction to meet the demands of modern stone processing.

For inquiries or to request a machine specification sheet, contact Susan Leo at [email protected]. Let’s shape your next project with precision.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.