Contents

Manufacturing Insight: Cnc Steel Parts

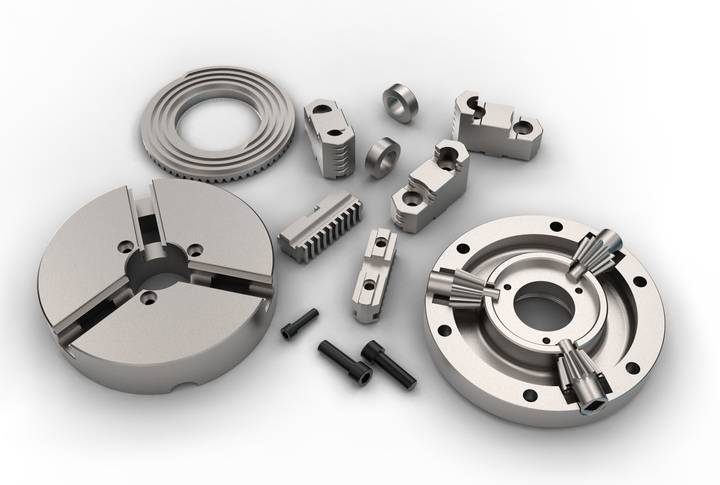

Precision CNC Steel Components Engineered for Demanding Applications

Honyo Prototype delivers mission-critical CNC machined steel parts meeting the exacting standards of aerospace, defense, medical, and industrial sectors. Our advanced 3-, 4-, and 5-axis milling and turning centers consistently produce complex geometries in a wide range of steel alloys including 4140, 1018, 17-4PH, 303, 304, and 316 stainless, hardened tool steels, and exotic alloys. We achieve tight tolerances down to ±0.0002 inches with superior surface finishes, supported by rigorous in-process and final inspection using calibrated CMMs and optical comparators to ensure dimensional accuracy and material integrity per AS9100 and ISO 9001 protocols.

Leverage our engineering expertise for prototypes through low-volume production runs where material performance, repeatability, and on-time delivery are non-negotiable. Accelerate your development cycle significantly by utilizing Honyo’s Online Instant Quote system. Upload your STEP or IGES file directly to our platform and receive a detailed, factory-validated quotation with manufacturability feedback within hours—not days—enabling faster iteration and project initiation.

Technical Capabilities

CNC Steel Parts – Technical Specifications Overview

Honyo Prototype delivers high-precision CNC machined components utilizing advanced 3-axis, 4-axis, and 5-axis milling technologies, as well as multi-axis turning centers. Our capabilities support tight tolerance requirements and complex geometries across a range of engineering materials including aluminum, steel, ABS, and nylon. Below is a summary of key technical specifications.

| Specification Category | Detail Description |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including live tooling for mill-turn operations) |

| Typical Tolerances | ±0.005 mm (±0.0002″) for critical features; standard tolerances per ISO 2768-mK unless otherwise specified |

| Surface Finish (Milled) | Ra 0.8 µm (32 µin) standard; down to Ra 0.4 µm (16 µin) with fine finishing passes |

| Surface Finish (Turned) | Ra 0.8–1.6 µm (32–63 µin), depending on material and geometry |

| Maximum Work Envelope | Milling: 1200 x 600 x 500 mm (47″ x 23.6″ x 19.7″); Turning: Ø300 mm x 500 mm length |

| Minimum Feature Size | Drilled holes: Ø0.5 mm (0.020″); internal radii: ≥0.5 mm (0.020″) |

| Materials – Metals | Aluminum (6061-T6, 7075-T6, 2024-T3), Steel (1018, 1045, 4140, 4340, Stainless 303, 304, 316) |

| Materials – Plastics | ABS (impact grade), Nylon 6/66 (reinforced and non-reinforced), POM (Delrin), PC, PEEK (on request) |

| Tooling & Fixturing | High-speed steel and carbide end mills; custom fixtures for 4th/5th axis setups; tombstone fixturing for batch production |

| Inspection & QA | In-house CMM, optical comparators, micrometers, and calipers; full first-article inspection reports (FAIR) available |

| Secondary Operations | Deburring, anodizing (Type II & III), passivation, powder coating, laser marking, tapping, inserts (heat-set or press-fit) |

All CNC steel parts are manufactured under strict process controls to meet demanding requirements in aerospace, medical, automotive, and industrial automation sectors. Design for manufacturability (DFM) feedback is provided to optimize cost, lead time, and performance.

From CAD to Part: The Process

Honyo Prototype CNC Steel Parts Manufacturing Process

Honyo Prototype executes CNC steel parts production through a rigorously defined workflow designed for precision, efficiency, and quality assurance. The process begins when a client uploads a CAD model via our secure online portal. Accepted formats include STEP, IGES, Parasolid, and native formats from SolidWorks, Creo, and Fusion 360. Our system validates geometry integrity and units to prevent downstream errors, ensuring the model meets minimum feature size requirements for CNC machining.

Following CAD upload, our proprietary AI quoting engine generates an instant preliminary quote. This system analyzes part complexity, material utilization, machine time estimates, and geometric tolerances against real-time shop floor data. Crucially, the AI cross-references current steel billet inventory (including grades like AISI 1018, 304SS, 4140, and 17-4PH) and prevailing material costs. The quote includes explicit lead time projections based on machine availability and material sourcing timelines, with options for expedited processing where feasible.

The Design for Manufacturability (DFM) phase is a critical value-add step conducted by our engineering team. Unlike automated-only competitors, Honyo combines AI-driven analysis with human expert review. Engineers assess tool accessibility, optimal fixturing strategies, potential vibration risks in thin-walled sections, and secondary operation sequencing. We provide actionable feedback within 24 hours, suggesting modifications such as adjusted radii, relieved corners, or tolerance rationalization to reduce cycle time without compromising function. Client approval of the DFM report is mandatory before production release.

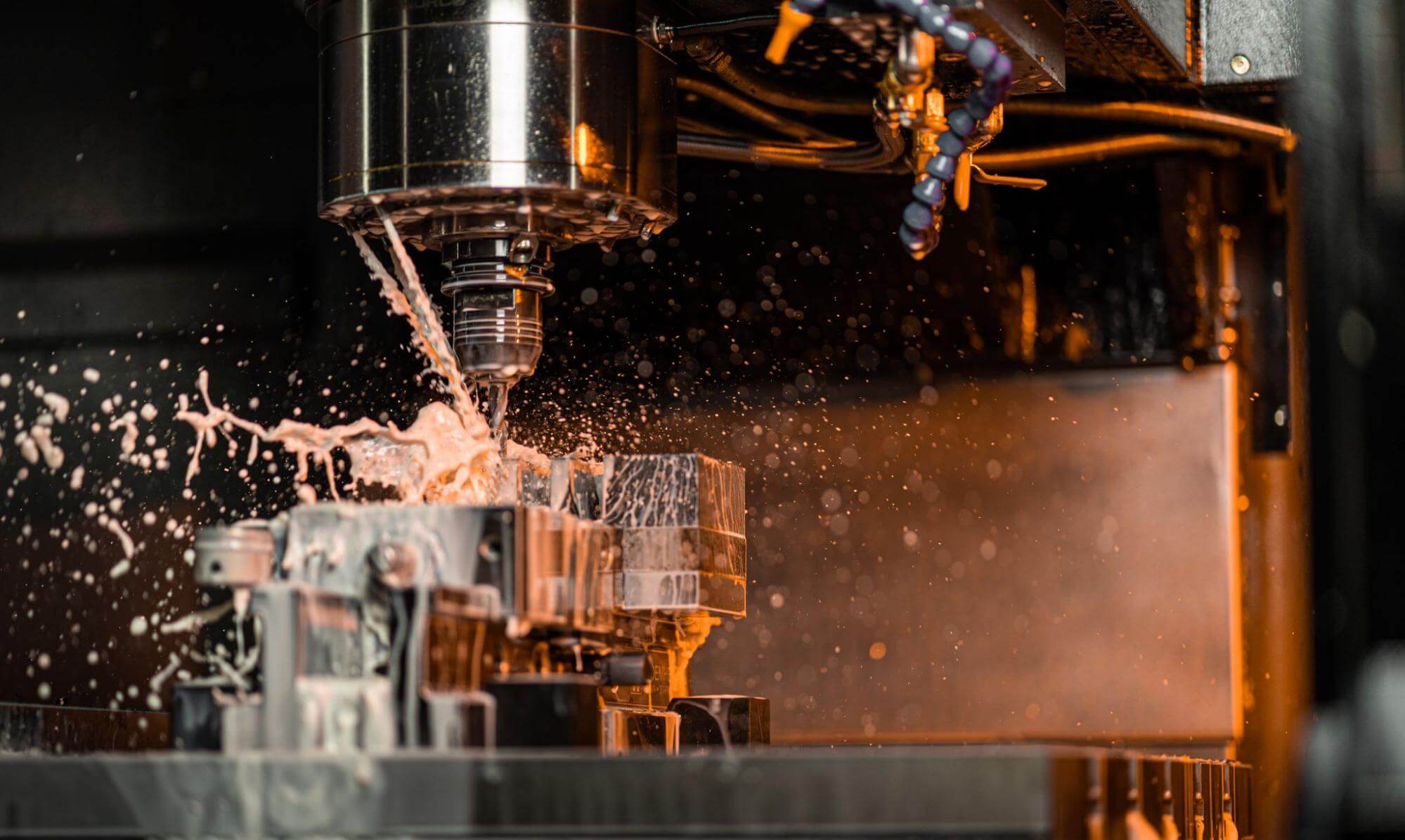

Production occurs in our climate-controlled facility using certified ISO 9001:2015 processes. Steel parts are machined on HAAS and DMG MORI 3- to 5-axis CNC centers with Renishaw probing for in-process verification. All steel stock undergoes material certification checks (mill test reports) prior to machining. Critical dimensions are inspected at 25%, 50%, and 100% production intervals using CMMs and optical comparators, with full first-article inspection reports provided. Heat-treated steels follow documented tempering and stress-relieving protocols per ASTM standards.

Final delivery includes comprehensive documentation: FAIR (First Article Inspection Report), material certs, and surface finish validation. Parts are packaged in anti-corrosion VCI paper with custom foam cradling for steel components prone to burring or scratching. Logistics leverage tracked freight with real-time shipment visibility, and all deliveries include a digital quality passport accessible via QR code on the packaging.

Common Steel Grades Processed at Honyo Prototype

| Material Grade | Typical Applications | Key Machining Considerations |

|---|---|---|

| AISI 1018 | Shafts, brackets, pins | Low carbon; minimal work hardening. Ideal for high-speed machining with coated carbide tools. |

| AISI 4140 | Gears, spindles, tooling | Pre-hardened variants require rigid setups. Use sharp inserts and controlled feeds to manage chip evacuation. |

| AISI 304/304L | Food processing, marine | Low thermal conductivity necessitates reduced SFM. Avoid dwell times to prevent galling. |

| 17-4 PH | Aerospace fittings, valves | H900 condition requires specialized toolpaths. Post-machining heat treatment may be needed for final properties. |

This integrated process minimizes iteration cycles by resolving manufacturability issues upfront, reduces scrap rates by 30% compared to industry averages, and ensures steel components meet stringent dimensional and metallurgical requirements for mission-critical applications.

Start Your Project

Looking for precision CNC steel parts manufactured to exact specifications? Honyo Prototype delivers high-quality, reliable components for demanding industrial applications. With our advanced CNC machining capabilities and strict quality control, we ensure durability, accuracy, and fast turnaround times.

Our manufacturing facility is located in Shenzhen, a global hub for precision engineering and rapid production. This strategic location enables efficient operations and seamless logistics for both domestic and international clients.

Contact Susan Leo today to discuss your CNC steel part requirements.

Email: [email protected]

Let Honyo Prototype be your trusted partner in precision manufacturing.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.