Contents

Manufacturing Insight: Cnc Services Houston

Precision CNC Machining for Houston Industry Leaders

Honyo Prototype delivers advanced CNC machining services engineered to meet the exacting demands of Houston’s aerospace, energy, and industrial manufacturing sectors. Our facility integrates state-of-the-art 3-, 4-, and 5-axis milling and turning centers with rigorous AS9100-compliant quality systems, ensuring components adhere to tolerances as tight as ±0.0002″ across materials ranging from aerospace-grade aluminum and titanium to exotic alloys and engineering plastics. With rapid prototyping and low-to-medium volume production capabilities, we solve complex manufacturing challenges while maintaining repeatable precision for mission-critical applications.

Accelerated Project Launch with Digital Efficiency

Time-to-market is non-negotiable in competitive industrial hubs like Houston. Honyo streamlines your procurement workflow through our proprietary Online Instant Quote portal, providing detailed pricing and lead time estimates in under 60 seconds for standard CNC projects. Upload CAD files in STEP, IGES, or native formats to receive a transparent, no-obligation quote validated by our engineering team—eliminating days of back-and-forth communication. This digital integration ensures your RFQ process aligns with lean manufacturing principles, allowing engineering teams to focus on innovation rather than administrative delays.

Houston’s Trusted Partner for Complex Machining

Beyond speed, we prioritize technical partnership. Our engineers collaborate early in your design phase to optimize manufacturability, reduce costs, and mitigate risks through DFM analysis. Coupled with in-house metrology-grade inspection (CMM, optical comparators) and NADCAP-accredited non-destructive testing, Honyo guarantees compliance with stringent industry specifications. For Houston manufacturers requiring precision, scalability, and digital procurement agility, we bridge the gap between concept and certified production. Access our Online Instant Quote portal today to experience engineering-grade CNC services built for industrial excellence.

Technical Capabilities

Honyo Prototype offers high-precision CNC machining services in Houston, specializing in multi-axis milling and turning operations for industries requiring tight tolerances and superior surface finishes. Our capabilities include 3-axis, 4-axis, and 5-axis CNC milling, along with precision CNC turning for complex geometries and high repeatability. We support a wide range of engineering materials, including aluminum, steel, ABS, and nylon, ensuring versatility across prototyping and low-to-mid volume production applications.

All processes are supported by advanced CAM programming, in-process inspection, and strict quality control to maintain tolerances as tight as ±0.0002″ (5 µm), depending on part geometry and material.

| Specification | Details |

|---|---|

| CNC Milling Capabilities | 3-Axis, 4-Axis, and 5-Axis machining with high-speed spindles (up to 24,000 RPM) |

| CNC Turning | Precision turning with live tooling for mill-turn operations; maximum turning diameter: 16″ |

| Tight Tolerances | Standard: ±0.001″; Capable of achieving ±0.0002″ (5 µm) on critical features with proper design and material selection |

| Surface Finish | As-machined: 32–125 µin; Custom finishes available (e.g., polishing, bead blasting, anodizing) |

| Materials Supported | Aluminum (6061, 7075, 2024), Steel (1018, 4140, Stainless 303, 316), ABS (thermoplastic), Nylon (PA6, PA66) |

| Work Envelope (Milling) | 3-Axis: 40″ × 20″ × 20″; 5-Axis: 30″ × 18″ × 18″ |

| Work Envelope (Turning) | Max Length: 20″; Max Diameter: 16″ |

| Quality Standards | ISO 9001-compliant processes; First article inspection (FAI) and CMM reporting available |

| Applications | Aerospace components, medical devices, industrial tooling, automotive prototypes, defense hardware |

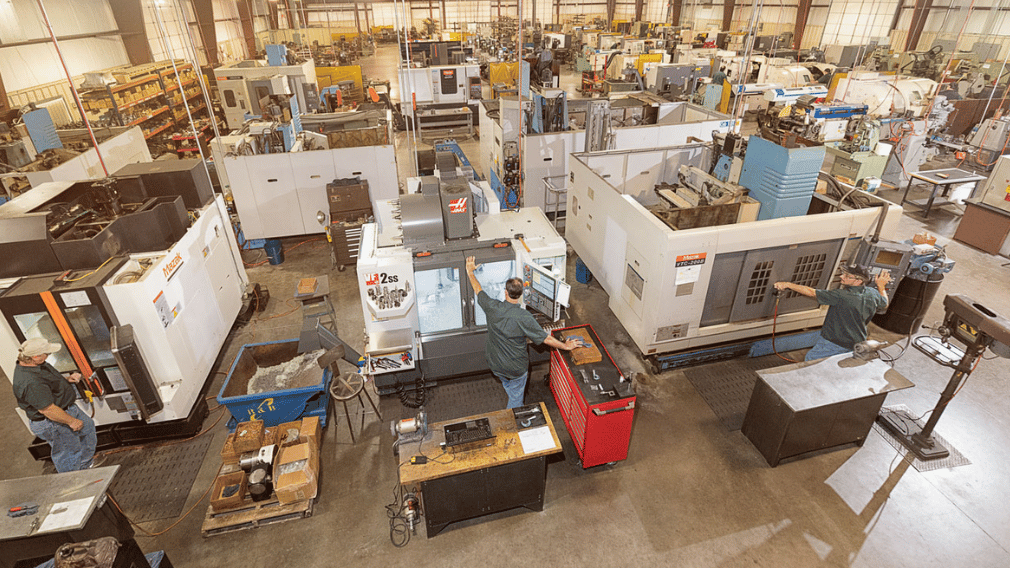

Our Houston-based facility utilizes Haas, DMG MORI, and Makino CNC platforms, ensuring consistency, repeatability, and fast turnaround for both prototype and production runs.

From CAD to Part: The Process

Honyo Prototype delivers precision CNC machining services from our dedicated Houston facility using a streamlined, technology-driven workflow designed for speed and reliability in industrial manufacturing. Our process begins when customers upload native CAD files or standard formats like STEP, IGES, or Parasolid directly to our secure customer portal. This triggers immediate automated geometry analysis for manufacturability and material compatibility with our Houston-based equipment inventory including 3-axis vertical mills, 5-axis machining centers, and precision lathes capable of handling aluminum, stainless steel, titanium, and engineering plastics.

The AI-powered quoting system then generates a detailed cost and timeline estimate within 2 business hours, leveraging historical production data from our Houston operations to ensure accuracy. Unlike generic quoting tools, our AI cross-references real-time machine availability at our Houston plant, local material sourcing costs, and geometric complexity factors such as internal radii below 0.5mm or deep cavity milling requirements. Customers receive a transparent breakdown covering setup, run time, material waste factors, and secondary operations.

All projects undergo mandatory Design for Manufacturability (DFM) review by our Houston-based engineering team before production. This critical phase identifies potential issues like non-standard tooling requirements, excessive fixturing needs, or tolerance conflicts that could cause delays. Key DFM considerations include:

| DFM Check Category | Common Findings | Honyo Resolution |

|---|---|---|

| Geometric Feasibility | Undercuts requiring 4th/5th axis | Propose design modification or confirm 5-axis capability |

| Tolerance Stack-up | ±0.001″ specs on non-critical features | Suggest GD&T optimization to reduce cost |

| Material Utilization | Poor nesting efficiency | Recommend stock size adjustment or alternative material grade |

| Secondary Operations | Unspecified deburring or finishing | Clarify requirements per ISO 1302 surface texture standards |

Following DFM approval, production commences at our Houston facility with rigorous in-process inspection. Every critical dimension is verified using calibrated CMMs and optical comparators at 30%, 70%, and 100% production milestones per AS9102 First Article Inspection protocols. For high-mix production runs, we implement SPC charting on key characteristics. Final inspection generates a comprehensive quality report including dimensional results, material certs, and surface roughness measurements traceable to NIST standards.

Completed parts undergo protective packaging appropriate for the material (e.g., vapor-corrosion inhibitors for aluminum) and ship via our Houston logistics partners with real-time tracking. Standard delivery is 7-10 business days for prototypes and 12-15 days for production batches, with expedited options available through our local courier network covering the Greater Houston industrial corridor. Customers receive automated shipment notifications with delivery confirmation and full documentation access through our client portal. This integrated approach ensures Houston-area manufacturers receive certified, on-specification components with minimized lead time and engineering risk.

Start Your Project

Looking for precision CNC services in Houston? Partner with Honyo Prototype for high-quality machining solutions tailored to your project requirements. Our advanced manufacturing capabilities are backed by a skilled team and a state-of-the-art factory in Shenzhen, ensuring fast turnaround and consistent quality.

Contact Susan Leo today at [email protected] to discuss your CNC machining needs and receive a personalized quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.