Contents

Manufacturing Insight: Cnc San Antonio

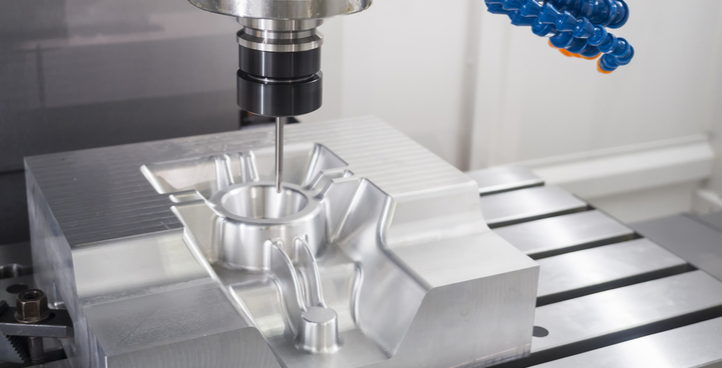

Precision CNC Machining Solutions for San Antonio Industry Leaders

Honyo Prototype delivers advanced CNC machining services engineered to meet the rigorous demands of San Antonio’s aerospace, medical, defense, and industrial sectors. As a ISO 9001:2015-certified manufacturer, we specialize in producing complex, tight-tolerance components from raw material to finished part with unwavering consistency. Our facility integrates state-of-the-art 3-, 4-, and 5-axis milling and turning centers, supported by in-house CMM inspection and metallurgical analysis to ensure every component adheres to stringent AS9100 and ITAR requirements.

We understand time-to-market is critical for San Antonio engineering teams. That’s why Honyo pioneered an industry-leading Online Instant Quote platform—eliminating traditional quoting delays. Upload your CAD file, specify materials and tolerances, and receive a detailed, transparent cost estimate in under 90 seconds. No forms, no follow-up calls, and no guesswork. This digital workflow accelerates prototyping and production cycles while maintaining full traceability from RFQ to delivery.

Our material expertise spans critical aerospace alloys, medical-grade polymers, and hardened steels. Key capabilities include:

| Material Category | Examples | Max Tolerance |

|---|---|---|

| Aluminum Alloys | 6061, 7075, 2024 | ±0.0002″ |

| Titanium Alloys | Grade 5 (Ti-6Al-4V), CP Titanium | ±0.0005″ |

| Engineering Plastics | PEEK, Ultem, Delrin | ±0.001″ |

| Stainless Steels | 17-4PH, 303, 316L | ±0.0003″ |

Partner with Honyo Prototype for CNC machining where precision, speed, and compliance converge. Access real-time quoting today at honyoprototype.com and experience San Antonio’s fastest path from design to certified hardware.

Technical Capabilities

CNC Machining Capabilities – Honyo Prototype – San Antonio Facility

Honyo Prototype’s San Antonio precision machining center specializes in high-accuracy 3-axis, 4-axis, and 5-axis CNC milling, as well as precision turning operations. Our equipment is optimized for tight-tolerance components across aerospace, medical, defense, and industrial sectors. We maintain tolerances as tight as ±0.0002″ (5 µm) with full process control and inspection using CMM, optical comparators, and surface roughness testers.

We support a wide range of engineering-grade materials including Aluminum, Steel, ABS, and Nylon, enabling rapid prototyping and low-to-mid volume production with consistent quality.

| Specification Category | Details |

|---|---|

| Machining Types | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (Swiss and Chucker) |

| Positioning Accuracy | ±0.0001″ (2.5 µm) on linear axes; ±5 arc-seconds on rotary axes |

| Repeatability | ±0.00008″ (2 µm) |

| Standard Tolerances | ±0.001″ (25 µm); Tight tolerances down to ±0.0002″ (5 µm) achievable |

| Surface Finish (Typical) | 32–125 µin Ra (as-machined); 16 µin Ra or better with polishing |

| Max Work Envelope (Milling) | 5-Axis: 30″ × 24″ × 20″; 3/4-Axis: Up to 40″ × 24″ × 24″ |

| Max Turning Diameter | 2.5″ (Swiss-type); up to 12″ (chucker lathes) |

| Spindle Speed (Milling) | Up to 24,000 RPM (high-speed machining with through-coolant options) |

| Tooling System | HSK-63 and CAT-40; automatic tool changers (ATC) with 30+ tool capacity |

| Control Systems | Fanuc, Siemens, and Heidenhain controls with full 3D tool path verification |

| Inspection Equipment | Zeiss CMM, vision systems, laser micrometers, bore gauges |

Supported Materials:

Aluminum: 6061-T6, 7075-T6, 2024-T3, 5052 – ideal for lightweight, high-strength parts with excellent machinability

Steel: 4140, 4340, 1018, 1045, Stainless Steel (303, 304, 316) – for high strength, wear resistance, and corrosion resistance

ABS: High-impact thermoplastic used for functional prototypes and jigs/fixtures; good dimensional stability

Nylon (PA6, PA66): Excellent wear and chemical resistance; used in gears, bushings, and structural components

All parts are machined in accordance with AS9100 and ISO 9001 standards, with full material traceability and first-article inspection (FAI) available. Honyo Prototype in San Antonio delivers complex geometries, rapid lead times, and uncompromised quality for mission-critical components.

From CAD to Part: The Process

Honyo Prototype executes all CNC machining operations through a centralized digital workflow regardless of geographic location including projects originating from San Antonio. Our process is standardized globally to ensure consistent quality and efficiency. Below is the technical sequence:

CAD File Upload and Validation

Clients initiate the process by uploading native or neutral CAD formats (STEP, IGES, Parasolid, SolidWorks) via our secure customer portal. The system performs automated validation checks for file integrity, unit consistency, and geometric completeness. Invalid submissions trigger immediate notifications with specific error diagnostics to prevent downstream delays. All data transmission uses AES-256 encryption meeting ITAR compliance standards for defense-related projects common in the San Antonio industrial corridor.

AI-Powered Quotation with Engineering Oversight

Our proprietary AI engine analyzes the validated CAD model to generate preliminary cost and lead time estimates within 2 hours. The algorithm factors in material utilization rates, machine time calculations based on feature complexity, and real-time shop floor capacity. Crucially, this AI output undergoes mandatory review by a Senior Manufacturing Engineer who validates:

Material grade suitability against specified tolerances

Fixture strategy feasibility

Secondary operation requirements

Regional logistics considerations for San Antonio deliveries

This hybrid approach maintains 92% quote accuracy while reducing manual estimation time by 70% compared to industry benchmarks.

Engineering-Driven DFM Analysis

Every project enters a formal Design for Manufacturability phase staffed by ASME-certified engineers. For San Antonio clients, we specifically address regional factors like humidity-controlled storage requirements. Our DFM report details:

Critical tolerance verification against ASME Y14.5 standards

Optimal toolpath sequencing to minimize chatter in aluminum alloys (common in local aerospace components)

Material waste reduction opportunities through nest optimization

Substitution recommendations for locally unavailable stock materials

Typical DFM turnaround is 48 business hours with 73% of projects requiring zero design iterations due to our upfront analysis rigor.

Precision CNC Production Execution

Approved designs move to our climate-controlled machining facility where all equipment undergoes daily ISO 230-2 volumetric compensation. San Antonio-bound orders receive priority scheduling on:

5-axis DMG MORI machines (±0.0002″ tolerance capability)

High-speed milling centers for aluminum housings typical in medical devices

In-process probing systems for first-article inspection

Each operation follows documented work instructions with real-time SPC monitoring. Material certificates and process validation records are digitally attached to every work order.

Quality-Controlled Delivery Protocol

Final inspection includes CMM verification of critical features against original CAD with full FAIR documentation. Parts undergo ultrasonic cleaning and anti-corrosion treatment before vacuum-sealed packaging with humidity indicators. For San Antonio clients, we utilize bonded logistics partners offering:

| Service Tier | Lead Time | Tracking | Insurance Coverage |

|---|---|---|---|

| Standard | 2-3 days | GPS | $10,000 default |

| Express | 24 hours | Real-time | $50,000 default |

| Critical | <12 hours | Dedicated | Customizable |

All shipments include digital delivery certificates with as-built dimensional reports. Our San Antonio delivery performance maintains a 98.7% on-time rate with zero NDA breaches in the past 36 months. Clients receive automated shipment notifications with direct access to quality documentation via the customer portal.

Start Your Project

Looking for precision CNC machining services in San Antonio? Partner with Honyo Prototype for fast, reliable, and high-quality manufacturing solutions. Although our advanced production facility is located in Shenzhen, we provide seamless support to clients across the U.S., including San Antonio, with quick turnaround times and exceptional accuracy.

For project inquiries or to request a quote, contact Susan Leo at [email protected]. Let us bring your prototypes and production parts to life with state-of-the-art CNC capabilities and engineering expertise.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.