Introduction: Navigating the Global Market for cnc routing table

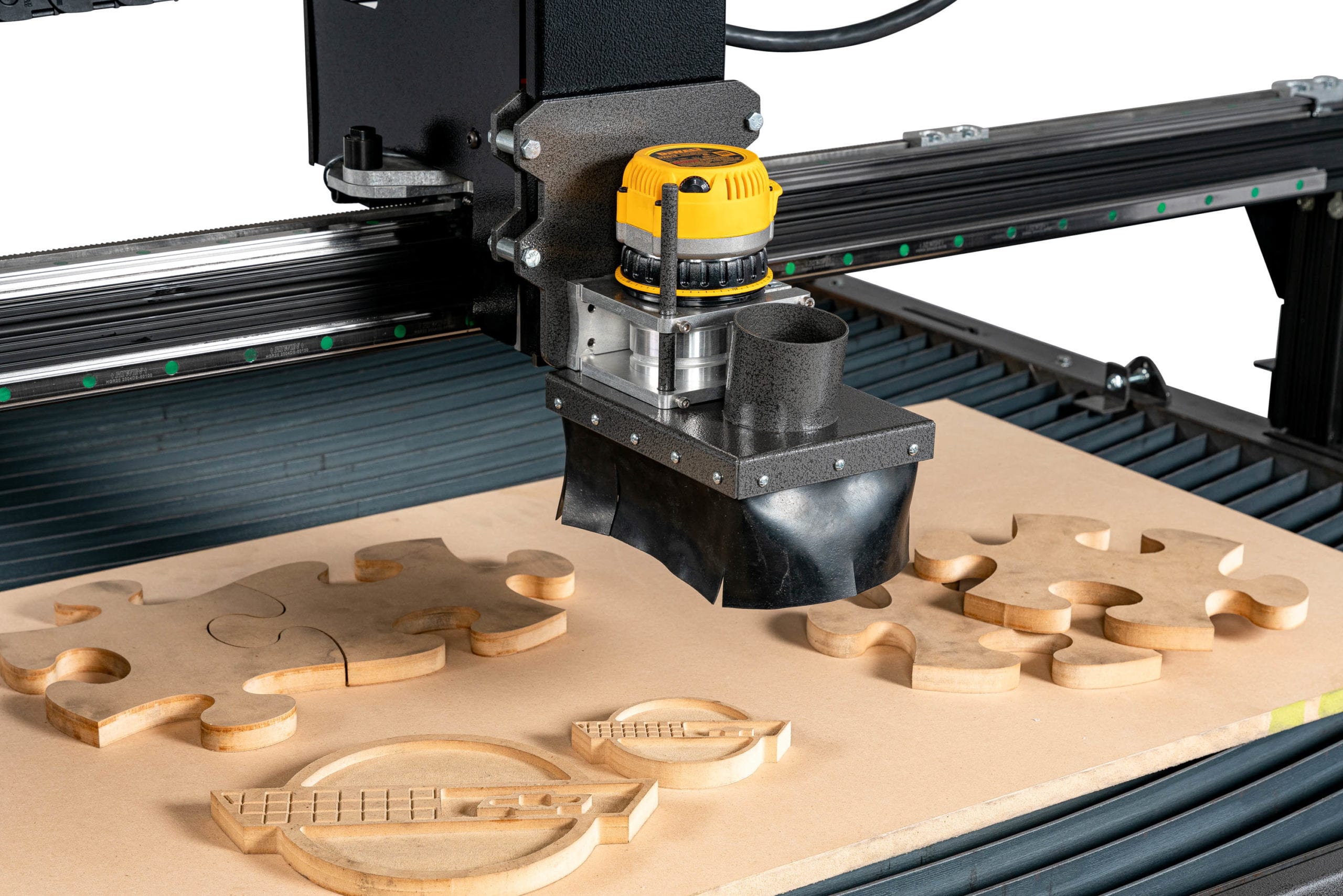

Navigating the global market for CNC routing tables can present significant challenges for international B2B buyers, particularly when it comes to sourcing reliable and high-quality equipment. With diverse applications ranging from woodworking to metal fabrication, selecting the right CNC router is essential for enhancing operational efficiency and product quality. This comprehensive guide will explore various types of CNC routing tables, their applications across different industries, supplier vetting processes, and a detailed analysis of costs involved.

By equipping buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Brazil—with actionable insights, this resource aims to empower informed purchasing decisions. Understanding the nuances of the CNC routing table market will enable businesses to make strategic investments that align with their production needs and budget constraints.

Additionally, we will delve into critical factors such as maintenance, warranty options, and technical support, ensuring that you are not only purchasing a product but also investing in a solution that supports your long-term operational goals. Whether you are a small business seeking to expand your capabilities or a large enterprise aiming for efficiency, this guide will serve as your roadmap to successfully navigating the complexities of the CNC routing table market.

Understanding cnc routing table Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard CNC Router | Versatile, often includes a large working area (e.g., 4’x8′) | Woodworking, furniture making, signage | Pros: High versatility, suitable for various materials. Cons: Can be expensive, requires training. |

| Compact CNC Router | Smaller footprint, ideal for limited space | Small workshops, hobbyists, educational use | Pros: Space-efficient, lower initial investment. Cons: Limited cutting area, less powerful. |

| Industrial CNC Router | Heavy-duty construction, advanced technology integration | Aerospace, automotive, large-scale production | Pros: High precision, can handle tough materials. Cons: High cost, requires maintenance. |

| CNC Router Kits | Modular design, can convert other CNC machines | Sign making, cabinetry, artwork production | Pros: Cost-effective, customizable. Cons: May require additional setup, software compatibility issues. |

| Hybrid CNC Router | Combines routing and plasma cutting capabilities | Metal fabrication, complex designs | Pros: Multi-functional, versatile applications. Cons: Higher complexity, learning curve. |

What Are the Characteristics of Standard CNC Routers?

Standard CNC routers are renowned for their versatility and large working areas, typically ranging from 4’x4′ to 4’x8′. They are designed to handle a variety of materials, including wood, plastics, and metals, making them ideal for diverse applications like woodworking, furniture manufacturing, and signage production. B2B buyers should consider the initial investment and the need for skilled operators, as these machines often require a degree of technical knowledge to maximize their capabilities.

How Do Compact CNC Routers Fit in Small Workshops?

Compact CNC routers are designed for businesses with limited space, making them ideal for small workshops or educational institutions. These machines usually have a smaller cutting area but are still capable of performing intricate tasks. Buyers benefit from a lower initial investment and ease of use, although they may need to compromise on power and cutting capabilities compared to larger models.

What Makes Industrial CNC Routers a Top Choice for Heavy-Duty Applications?

Industrial CNC routers feature robust construction and advanced technology, making them suitable for heavy-duty applications like aerospace and automotive manufacturing. These machines provide high precision and can cut through tough materials, ensuring consistent quality in large-scale production. However, the high cost and maintenance requirements can be a barrier for some buyers, necessitating a careful evaluation of their long-term needs and budget.

Why Consider CNC Router Kits for Versatility?

CNC router kits offer a modular design that allows businesses to convert existing CNC machines into routing systems. This flexibility is particularly appealing for sign makers, cabinetry, and artwork production, as it enables users to maximize their existing equipment. While these kits can be cost-effective, buyers should be aware of potential compatibility issues and the need for additional setup time.

What Are the Advantages of Hybrid CNC Routers?

Hybrid CNC routers combine routing and plasma cutting capabilities, making them suitable for complex designs and a variety of materials, including metals and composites. This multi-functionality can be a significant advantage for businesses involved in metal fabrication and intricate projects. However, the complexity of these machines may lead to a steeper learning curve, which is an essential consideration for B2B buyers looking to invest in such technology.

Key Industrial Applications of cnc routing table

| Industry/Sector | Specific Application of CNC Routing Table | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Woodworking | Custom Furniture Production | Enhances precision and efficiency in creating unique designs | Look for machines with robust software integration and high spindle speeds for wood types. |

| Sign Making | Production of Custom Signs | Provides versatility in cutting various materials, increasing service offerings | Ensure compatibility with diverse substrates and tools for varied designs. |

| Cabinet Making | Mass Production of Cabinets | Streamlines manufacturing, reducing labor costs and turnaround time | Consider machines with large working areas and automated tool changers for efficiency. |

| Automotive Manufacturing | Creation of Prototype Parts | Facilitates rapid prototyping, allowing for quick design iterations | Source CNC routers that can handle metals and composites, ensuring durability. |

| Education and Training | Hands-on Learning in Technical Programs | Equips students with practical skills in design and manufacturing | Opt for systems with comprehensive training support and easy-to-use software for educational institutions. |

How is a CNC Routing Table Used in Custom Furniture Production?

In the woodworking industry, CNC routing tables are essential for custom furniture production. They allow manufacturers to produce intricate designs with high precision and repeatability. This capability addresses common challenges like material waste and inconsistent quality. International buyers should prioritize machines that offer robust software solutions and high spindle speeds to accommodate various wood types, ensuring optimal performance and versatility in design.

What Role Does a CNC Router Play in Sign Making?

CNC routing tables are pivotal in the sign-making industry, enabling the production of custom signs with varying materials such as wood, acrylic, and metal. They enhance operational efficiency by allowing for intricate designs and detailed engraving, which are crucial for modern signage needs. For businesses in Africa and South America, sourcing routers that can handle multiple substrates and offer compatibility with various tools is essential to meet diverse customer demands.

How Does CNC Routing Benefit Cabinet Makers?

Cabinet making heavily relies on CNC routing tables for mass production. These machines streamline the manufacturing process, significantly reducing labor costs and time while maintaining high-quality standards. Buyers should look for machines with expansive working areas and automated tool changers, which are vital for handling multiple cabinet designs efficiently. This is particularly important for businesses in competitive markets like Europe and the Middle East.

In What Ways Can CNC Routers Facilitate Prototype Creation in Automotive Manufacturing?

In automotive manufacturing, CNC routing tables are used to create prototype parts quickly and accurately. This capability supports rapid prototyping, allowing designers to iterate on their concepts swiftly. When sourcing CNC routers for this application, companies should focus on machines capable of cutting metals and composite materials, ensuring they can meet the demands of automotive design. This is crucial for businesses looking to innovate while managing production costs effectively.

Why Are CNC Routers Important in Educational Settings?

CNC routing tables serve a significant role in educational institutions, providing students with hands-on experience in design and manufacturing. They help cultivate technical skills that are essential for modern careers. Institutions should consider sourcing systems that come with extensive training support and user-friendly software, making it easier for students to learn. This is particularly beneficial for schools in regions like Africa and the Middle East, where technical education is rapidly evolving.

3 Common User Pain Points for ‘cnc routing table’ & Their Solutions

Scenario 1: Difficulty in Material Versatility for Diverse Applications

The Problem: Many B2B buyers invest in CNC routing tables expecting them to handle a wide array of materials, from wood and plastics to metals and composites. However, they often encounter limitations due to either the machine’s specifications or the tooling options available. For instance, a furniture manufacturer may require precise cuts in hardwoods for custom pieces, but the CNC router table they purchased is only optimized for softer materials. This mismatch can lead to production delays, increased costs, and ultimately, dissatisfied customers.

The Solution: To address this pain point, B2B buyers should prioritize sourcing CNC routing tables that boast a modular design and compatibility with various tooling systems. When selecting a machine, ensure it supports a wide range of materials by checking the specifications for spindle capabilities and the type of cutting tools available. For example, investing in a router that can accommodate different spindle sizes and types, such as VFD spindles, can greatly enhance versatility. Additionally, incorporating a dedicated software solution like VCarve Pro can aid in adapting designs to various materials, enabling users to maximize their machine’s potential across different applications. Regular training for staff on how to adjust settings based on material type can further mitigate challenges.

Scenario 2: Technical Support and Maintenance Challenges

The Problem: B2B buyers often struggle with the maintenance and technical support aspects of CNC routing tables. Issues such as software glitches, mechanical failures, or improper calibration can halt production, leading to significant downtime. For instance, a sign-making business might experience a software crash during a critical project, causing delays that affect customer satisfaction and revenue. Without reliable support, resolving these issues can become a daunting task.

The Solution: To combat these technical challenges, it’s crucial for buyers to choose CNC routing table suppliers who offer robust support services, including lifetime technical assistance and comprehensive warranties. When evaluating potential vendors, inquire about their support channels—whether they provide phone support, online resources, or on-site assistance. Additionally, consider investing in maintenance contracts that cover regular check-ups and servicing. This proactive approach not only helps in identifying issues before they escalate but also ensures that the equipment remains in optimal working condition. Educating staff on basic troubleshooting techniques can empower them to resolve minor issues independently, thus minimizing production interruptions.

Scenario 3: The Complexity of Software Integration

The Problem: As CNC routing tables become increasingly sophisticated, the complexity of their software can pose a significant barrier for B2B buyers, particularly those with limited technical expertise. Users may face challenges in integrating the CNC machine with existing design software or in understanding the full capabilities of the routing software. For example, a cabinetry business might struggle to create intricate designs due to a lack of familiarity with the software’s advanced features, leading to wasted materials and time.

The Solution: To alleviate software integration challenges, buyers should seek CNC routing tables that come bundled with user-friendly software solutions and offer comprehensive training resources. When purchasing a machine, confirm that the included software supports file formats compatible with your design programs, and look for vendors that provide demo sessions or training workshops. Furthermore, utilizing platforms that feature a strong online community can also be beneficial. Engaging in forums or user groups allows businesses to share tips and tricks, learn from peers, and find solutions to common software hurdles. Investing time in training sessions for staff can ensure they are well-equipped to harness the full potential of the software, ultimately enhancing productivity and design capabilities.

Strategic Material Selection Guide for cnc routing table

What Are the Key Materials for CNC Routing Tables?

When selecting materials for CNC routing tables, understanding the properties, advantages, and limitations of each option is crucial for optimizing performance and ensuring compatibility with various applications. Below, we analyze four common materials used in CNC routing tables: aluminum, steel, MDF (Medium-Density Fiberboard), and phenolic resin.

How Does Aluminum Perform in CNC Routing Tables?

Aluminum is a lightweight metal known for its excellent strength-to-weight ratio and corrosion resistance. It typically has a temperature rating of up to 200°C, making it suitable for a variety of machining applications.

Pros: Aluminum is durable, easy to machine, and resistant to rust, which enhances the longevity of the routing table. Its lightweight nature allows for easier handling and installation.

Cons: The primary drawback is its cost; aluminum can be more expensive than other materials. Additionally, while it is strong, it may not withstand extreme pressure as well as steel.

Impact on Application: Aluminum is compatible with a wide range of materials, including plastics and composites, making it versatile for various industries.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure compliance with local standards for aluminum quality (e.g., ASTM B221). Understanding the specific grades of aluminum that are available locally can also affect procurement decisions.

What Are the Benefits of Steel in CNC Routing Tables?

Steel is renowned for its strength and durability, with a high temperature rating that can exceed 400°C. Its rigidity makes it an ideal choice for heavy-duty applications.

Pros: Steel’s high strength allows it to withstand significant stress and pressure, making it suitable for industrial applications. It also has a long lifespan when properly maintained.

Cons: The primary disadvantages of steel include its susceptibility to corrosion and its heavier weight, which can complicate installation and transport.

Impact on Application: Steel is particularly effective for machining harder materials, including metals and high-density plastics, but may require additional protective coatings to prevent rust.

Considerations for International Buyers: Compliance with standards such as ASTM A36 or DIN 17100 is essential for ensuring quality. Buyers should also consider the availability of corrosion-resistant coatings in their local markets.

Why Choose MDF for CNC Routing Tables?

MDF is a composite material made from wood fibers, wax, and resin, which makes it a cost-effective option for CNC routing tables. It typically has a temperature tolerance of up to 80°C.

Pros: MDF is easy to machine and provides a smooth surface finish, ideal for precision work. It is also relatively inexpensive compared to metals.

Cons: MDF is less durable than metal options and can be susceptible to moisture damage, which may limit its use in humid environments.

Impact on Application: MDF is commonly used in woodworking, sign making, and other applications where a smooth finish is crucial.

Considerations for International Buyers: Buyers should be aware of local regulations regarding the formaldehyde content in MDF, as some regions have strict limits to ensure safety.

How Does Phenolic Resin Compare for CNC Routing Tables?

Phenolic resin is a thermosetting plastic known for its high strength and resistance to moisture and chemicals. It can withstand temperatures up to 150°C.

Pros: Phenolic resin is highly durable and resistant to wear, making it suitable for high-traffic environments. Its non-porous nature helps prevent moisture absorption.

Cons: The primary limitation is its higher cost compared to MDF and potential difficulties in machining due to its hardness.

Impact on Application: This material is ideal for applications requiring a robust surface, such as in the automotive and aerospace industries.

Considerations for International Buyers: Buyers should verify compliance with international standards for phenolic resins, such as JIS K 7202, to ensure product quality.

Summary Table of Material Selection for CNC Routing Tables

| Material | Typical Use Case for CNC Routing Table | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | General machining, sign making | Lightweight and corrosion-resistant | Higher cost, less pressure resistance | Medium |

| Steel | Heavy-duty industrial applications | High strength and durability | Susceptible to corrosion, heavy weight | High |

| MDF | Woodworking, cabinetry | Cost-effective, smooth finish | Less durable, moisture-sensitive | Low |

| Phenolic Resin | Automotive, aerospace applications | High durability and moisture resistance | Higher cost, machining difficulties | Medium |

This analysis provides a comprehensive understanding of the materials available for CNC routing tables, allowing international B2B buyers to make informed decisions based on their specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc routing table

What Are the Main Stages in the Manufacturing Process of CNC Routing Tables?

The manufacturing of CNC routing tables involves several critical stages, each designed to ensure that the final product meets high standards of quality and performance. Understanding these stages is essential for B2B buyers looking for reliable suppliers.

Material Preparation: What Are the Key Steps?

The first step in the manufacturing process is material preparation. CNC routing tables are typically made from high-quality steel or aluminum for their structural components, while the work surface may involve MDF, plywood, or phenolic materials for optimal performance. Suppliers often source materials that meet specific industry standards to ensure durability and functionality.

During this stage, materials are cut to size and inspected for defects. This initial quality control (IQC) step is crucial, as any flaws in the material can lead to performance issues in the final product.

Forming: How Are Components Shaped?

Once the materials are prepared, the next step is forming. This involves processes such as welding, machining, and milling to create various components of the CNC routing table. Advanced techniques like laser cutting may be employed for precision, ensuring that all parts fit together seamlessly.

This stage is also where critical features, such as the gantry and support structures, are crafted. Manufacturers often use Computer Numerical Control (CNC) machines during this process to achieve high levels of accuracy and repeatability.

Assembly: What Does the Assembly Process Involve?

After forming, the components are assembled. This includes attaching the gantry, motors, and control systems. Skilled technicians conduct this assembly to ensure that each unit adheres to the design specifications.

Throughout the assembly process, manufacturers implement in-process quality control (IPQC) measures. This includes checking alignments, ensuring that all components operate correctly, and verifying that safety features are in place.

Finishing: What Techniques Are Used for Surface Treatment?

Finishing is the final stage of the manufacturing process. This may involve painting, powder coating, or anodizing the metal components to enhance durability and resistance to wear. The work surface may also receive treatments to ensure it is smooth and can handle various materials without damage.

Quality assurance during this stage includes visual inspections and testing for surface integrity. Buyers should inquire about the specific finishing techniques employed by suppliers, as these can significantly affect the table’s longevity and performance.

What Quality Assurance Measures Are Essential for CNC Routing Tables?

Quality assurance (QA) is a critical aspect of CNC routing table manufacturing, ensuring that the products meet international standards and client expectations.

Which International Standards Should Buyers Look For?

B2B buyers should be aware of relevant international standards, such as ISO 9001, which outlines requirements for quality management systems. This certification indicates that a manufacturer has established processes to consistently provide products that meet customer and regulatory requirements.

In addition to ISO certifications, regional certifications like CE (European Conformity) and API (American Petroleum Institute) may also apply, depending on the intended use of the CNC routing tables. Ensuring suppliers have these certifications can help mitigate risks associated with product quality and compliance.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integral to the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This occurs at the material preparation stage, where materials are inspected for defects before production begins.

-

In-Process Quality Control (IPQC): Conducted during the forming and assembly stages, this includes regular checks for alignment, functionality, and adherence to specifications.

-

Final Quality Control (FQC): This is the last step before the product is shipped, involving comprehensive testing of the CNC routing table’s functionality, including software integration and performance tests.

How Can B2B Buyers Verify Supplier Quality Assurance?

To ensure that suppliers maintain high-quality standards, B2B buyers should consider several verification methods:

What Documentation Should Buyers Request?

Buyers should request documentation related to the supplier’s quality assurance processes, including:

- Quality Management System (QMS) Reports: These documents outline how the supplier adheres to ISO standards and other regulations.

- Inspection Reports: Buyers can request records of inspections conducted at various checkpoints, providing transparency into the manufacturing process.

- Certificates of Compliance: Ensure that the supplier provides certificates that validate compliance with relevant standards.

Should Buyers Conduct Audits or Engage Third-Party Inspectors?

Conducting audits of potential suppliers can provide invaluable insights into their manufacturing processes and quality control measures. Alternatively, engaging third-party inspectors can offer an objective assessment of the supplier’s practices, ensuring that they meet the necessary standards.

What Are the Nuances of Quality Control for International Buyers?

For international buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential.

How Do Regional Regulations Impact Quality Assurance?

Different regions may have specific regulations that affect product standards. Buyers should familiarize themselves with local laws and industry standards relevant to CNC routing tables in their markets. For example, while CE certification is crucial in Europe, it may not hold the same weight in other regions.

What Should Buyers Know About Shipping and Compliance?

Lastly, when importing CNC routing tables, buyers must ensure that products comply with their country’s import regulations. This may involve additional quality checks and certifications, which can vary significantly from one region to another.

By understanding the manufacturing processes and quality assurance measures for CNC routing tables, B2B buyers can make informed decisions, ensuring they select suppliers that meet their operational needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc routing table’

In the competitive landscape of CNC routing, sourcing the right CNC routing table is critical for enhancing productivity and ensuring quality. This guide provides a structured checklist for international B2B buyers to streamline their procurement process.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. Consider factors such as the size of the work area, material compatibility (e.g., wood, plastics, metals), and the precision needed for your specific applications. A well-defined specification will help you communicate effectively with suppliers and ensure you select a machine that meets your operational needs.

Step 2: Research Market Trends and Technologies

Stay informed about the latest developments in CNC routing technology and market trends. Understanding the advancements in software compatibility, automation features, and energy efficiency can provide insights into which machines will best serve your business. This knowledge will empower you to make informed decisions and identify potential suppliers who align with current industry standards.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and quality. Request company profiles, product catalogs, and client references, particularly from businesses in your industry or region. Assess their experience, customer service reputation, and support offerings, as these factors can significantly impact your long-term satisfaction with the purchase.

- Check Certifications: Ensure suppliers hold relevant certifications (e.g., ISO) that indicate compliance with industry standards.

- Request Case Studies: Look for documented success stories that demonstrate the supplier’s capability in delivering effective solutions.

Step 4: Compare Pricing and Payment Terms

Obtain quotes from multiple suppliers and compare pricing structures. Look beyond the initial costs; consider the total cost of ownership, including maintenance, spare parts, and warranty terms. Understanding payment options and financing solutions can also help you manage cash flow more effectively.

Step 5: Assess After-Sales Support and Warranty

Evaluate the after-sales support offered by suppliers. A robust warranty and dedicated customer support are vital for minimizing downtime and ensuring operational continuity. Ensure that the supplier provides training resources, technical support, and access to spare parts.

- Lifetime Support: Consider suppliers that offer lifetime technical support to address any issues that may arise during the machine’s lifespan.

- Warranty Terms: Look for warranties that cover critical components for an extended period.

Step 6: Request a Demonstration or Trial Period

Whenever possible, request a demonstration or trial period to evaluate the CNC routing table in action. This step allows you to assess performance, ease of use, and the machine’s suitability for your specific applications. Observing the machine’s operation firsthand can provide invaluable insights that are not apparent from specifications alone.

Step 7: Finalize the Contract and Delivery Terms

Once you have selected a supplier, carefully review and finalize the contract. Pay attention to delivery timelines, installation services, and any terms regarding training and support. Clear communication regarding these details can prevent misunderstandings and ensure a smooth procurement process.

By following this checklist, B2B buyers can approach the procurement of CNC routing tables with confidence, ensuring they make informed, strategic decisions that will enhance their operational capabilities.

Comprehensive Cost and Pricing Analysis for cnc routing table Sourcing

What Are the Key Cost Components in CNC Routing Table Manufacturing?

When sourcing CNC routing tables, understanding the cost structure is crucial. The primary components contributing to the overall cost include:

-

Materials: The type and quality of materials used significantly impact the price. High-grade steel frames, precision components, and durable electronics will elevate costs but also enhance performance and longevity.

-

Labor: Skilled labor is essential for assembly and quality control. Labor costs can vary significantly based on geographic location, skill levels, and labor laws.

-

Manufacturing Overhead: This encompasses utilities, facility costs, and indirect labor. Efficient manufacturing processes can reduce overhead, affecting the final pricing.

-

Tooling: The investment in specialized tooling for CNC routing tables can be substantial. Custom tools for specific applications can increase initial costs but may lead to better output quality.

-

Quality Control (QC): Implementing rigorous QC protocols ensures product reliability and consistency. This process adds to manufacturing costs but is vital for maintaining standards.

-

Logistics: Transportation and handling costs can vary widely, especially for international shipments. Factors such as distance, mode of transport, and shipping terms (Incoterms) play a role in final pricing.

-

Margin: Suppliers will typically add a profit margin to their costs. This margin can vary based on competition, brand positioning, and perceived value.

What Influences the Pricing of CNC Routing Tables for B2B Buyers?

Several key factors influence the pricing of CNC routing tables:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often leads to discounts. Understanding MOQ requirements can help buyers negotiate better prices.

-

Specifications and Customization: Custom features tailored to specific applications can significantly alter pricing. Buyers should be clear about their needs to avoid unnecessary costs.

-

Material Quality and Certifications: High-quality materials and industry certifications (like ISO) may increase initial costs but can lead to lower maintenance and replacement expenses over time.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established manufacturers may charge more due to their track record, but they often provide better support and warranties.

-

Incoterms: The chosen Incoterms can influence the total landed cost. Terms that require the buyer to handle freight and customs can lead to unexpected expenses.

How Can Buyers Negotiate Better Prices for CNC Routing Tables?

B2B buyers can implement several strategies to enhance their negotiation power:

-

Research and Benchmarking: Understanding market prices and competitor offerings can provide leverage during negotiations. Buyers should gather data on similar models to compare prices effectively.

-

Long-Term Partnerships: Building relationships with suppliers can lead to better pricing structures over time. Suppliers may offer discounts for repeat business or long-term contracts.

-

Volume Commitments: Committing to larger orders can incentivize suppliers to provide better pricing. This strategy works well for businesses planning to scale.

-

Total Cost of Ownership (TCO): Buyers should consider TCO, which includes initial costs, maintenance, and operational expenses. Emphasizing TCO during negotiations can justify a higher upfront price if it leads to lower overall costs.

What Unique Pricing Nuances Should International Buyers Consider?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face distinct challenges in sourcing CNC routing tables:

-

Currency Fluctuations: Variability in exchange rates can impact pricing and payment terms. Buyers should consider hedging strategies to mitigate this risk.

-

Import Duties and Taxes: Understanding local import regulations and tariffs is essential. These costs can significantly affect the total price of CNC routing tables.

-

Logistics and Shipping Challenges: Different regions may experience varying shipping costs and lead times. Buyers should factor in these elements when evaluating suppliers.

-

Cultural and Communication Barriers: Effective communication is crucial in negotiations. Buyers should be aware of cultural differences that may influence business practices and expectations.

Conclusion

While CNC routing tables represent a significant investment, understanding the cost structure, pricing influences, and strategic negotiation techniques can empower buyers to make informed decisions. By focusing on total cost of ownership and being mindful of unique international factors, businesses can optimize their sourcing strategy effectively. Pricing will vary based on the aforementioned factors, and it is advisable to seek multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing cnc routing table With Other Solutions

Exploring Alternatives to CNC Routing Tables

In the world of precision manufacturing and woodworking, CNC routing tables are widely used for their ability to automate cutting and engraving tasks. However, buyers should consider alternative solutions that may offer different advantages depending on specific needs and applications. This section provides a comparative analysis of CNC routing tables against two viable alternatives: laser cutting machines and manual routing methods.

Comparison Table

| Comparison Aspect | CNC Routing Table | Laser Cutting Machine | Manual Routing Method |

|---|---|---|---|

| Performance | High precision for various materials | Excellent for thin materials | Dependent on operator skill |

| Cost | Moderate ($3,750 – $7,000) | High ($10,000 – $100,000+) | Low (tools under $500) |

| Ease of Implementation | Moderate (requires setup) | High (plug-and-play systems available) | Low (requires skilled labor) |

| Maintenance | Regular maintenance needed | Low (minimal parts wear) | High (manual tools require upkeep) |

| Best Use Case | Woodworking, cabinetry, sign making | Cutting acrylic, metals, and textiles | Small-scale projects, detailed work |

Detailed Breakdown of Alternatives

Laser Cutting Machines

Laser cutting machines utilize focused laser beams to cut or engrave materials. They excel in precision and can handle a wide range of materials, particularly thin substrates like acrylic and fabric. One of the main advantages of laser cutting is its speed and the ability to create intricate designs with minimal waste. However, the initial investment can be significantly higher compared to CNC routing tables, and they are not as effective for thicker materials. Additionally, laser cutting requires proper ventilation and safety measures, which can complicate setup and operation.

Manual Routing Methods

Manual routing involves using handheld routers to cut and shape materials. This method offers flexibility and is highly cost-effective, with basic tools available at a fraction of the price of CNC machines. Manual routing is ideal for small-scale projects or detailed work where artisan skill is paramount. However, performance is heavily reliant on the operator’s expertise, and the consistency of output can vary. This method can also be labor-intensive and time-consuming, making it less suitable for large-scale production runs.

Conclusion: Choosing the Right Solution for Your Business

When selecting the right solution for your manufacturing or woodworking needs, it’s crucial to assess your specific requirements and constraints. CNC routing tables are excellent for high-volume production and versatility across various materials, making them ideal for businesses focused on woodworking, cabinetry, and sign-making. In contrast, laser cutting machines are better suited for applications requiring high precision on thinner materials, while manual routing may appeal to smaller operations or craftspeople focused on detailed work.

Ultimately, the choice between these technologies will depend on factors such as budget, production scale, and the types of materials you intend to work with. By carefully evaluating these aspects, B2B buyers can make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for cnc routing table

What are the Key Technical Properties of CNC Routing Tables?

When selecting a CNC routing table, understanding its technical specifications is crucial for ensuring the machine meets your production needs. Here are some essential properties to consider:

1. Material Grade

The material used in the construction of CNC routing tables, typically steel or aluminum, affects durability and stability. A higher-grade material results in a sturdier machine that can handle heavy workloads and resist wear and tear over time. For B2B buyers, investing in a machine made from premium materials can lead to lower maintenance costs and increased longevity.

2. Tolerance Levels

Tolerance refers to the allowable deviation from a specified measurement. CNC routing tables typically offer tolerance levels ranging from ±0.005 inches to ±0.01 inches. High precision is vital for industries like aerospace and automotive, where even minor inaccuracies can lead to significant issues. Understanding tolerance levels helps businesses select machines capable of meeting their quality standards.

3. Spindle Power and Speed

The spindle is the heart of a CNC router, influencing cutting speed and material compatibility. Spindle power is measured in horsepower (HP) and affects the machine’s ability to cut through various materials, from soft woods to hard metals. Additionally, variable spindle speeds (measured in RPM) allow for customization based on the material being processed. For businesses, choosing a routing table with the appropriate spindle characteristics can enhance productivity and versatility.

4. Work Area Dimensions

The work area defines the maximum size of the material that can be processed. Common sizes range from 2′ x 3′ to 6′ x 12′. Selecting the right dimensions is crucial for meeting production demands without needing additional machines. B2B buyers must consider their typical project sizes to avoid limitations that could hinder operational efficiency.

5. Drive System Type

CNC routers can utilize different drive systems, including rack and pinion or ball screw systems. Each has its advantages in terms of speed, accuracy, and maintenance. For example, ball screw systems offer higher precision but may come at a higher cost. Understanding the differences helps buyers make informed decisions that align with their operational needs and budget.

What are Common Trade Terms Related to CNC Routing Tables?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the CNC industry, understanding OEM relationships can help buyers identify the quality and reliability of the machines they are purchasing, as OEMs often have established reputations.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant for businesses looking to purchase CNC routing tables or parts in bulk. Knowing the MOQ helps buyers manage their budgets and inventory effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products. For B2B buyers, issuing an RFQ can help in comparing different suppliers and negotiating better terms based on competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce. They outline the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for managing shipping costs, risks, and responsibilities effectively.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. In the CNC routing table market, lead times can vary significantly based on the manufacturer and customization options. Knowing the lead time helps businesses plan their production schedules and manage customer expectations.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring that their investments in CNC routing tables align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the cnc routing table Sector

What Are the Current Market Dynamics and Key Trends in the CNC Routing Table Sector?

The global CNC routing table market is experiencing significant growth, driven by advancements in technology and increasing demand across various industries. Key trends include the adoption of modular and versatile systems that allow for quick adaptations between CNC routing and plasma cutting. This flexibility is particularly appealing to B2B buyers in regions like Africa and South America, where businesses often seek cost-effective solutions that maximize utility without compromising quality. Additionally, the shift towards automation and smart manufacturing is reshaping the market landscape, enabling businesses to improve efficiency, reduce labor costs, and enhance production capabilities.

International buyers are also prioritizing sourcing from manufacturers that offer robust support and warranties, as these aspects are crucial for maintaining operational continuity. As economies in regions such as the Middle East and Europe become more integrated into global supply chains, the demand for high-performance, reliable CNC routing tables is expected to rise. Furthermore, the trend towards integrating advanced software solutions, such as VCarve Pro, into CNC systems is gaining traction, facilitating ease of use and enhancing design capabilities for users ranging from small workshops to large manufacturing facilities.

How Is Sustainability and Ethical Sourcing Influencing the CNC Routing Table Market?

Sustainability is increasingly becoming a focal point for B2B buyers in the CNC routing table sector. The environmental impact of manufacturing processes has led many businesses to seek suppliers who prioritize ethical sourcing and sustainable practices. This includes the use of eco-friendly materials and processes that minimize waste and energy consumption. Buyers are particularly interested in suppliers who can provide certifications for their products, such as FSC (Forest Stewardship Council) for wood materials or ISO 14001 for environmental management systems.

Moreover, the push for greener solutions is prompting manufacturers to invest in technology that reduces emissions and enhances energy efficiency in CNC routing operations. For instance, advancements in dust collection systems and the use of recyclable materials in machine construction are becoming standard. By sourcing from suppliers who adhere to these sustainable practices, international buyers not only align with global trends but also enhance their brand reputation and meet the growing consumer demand for environmentally responsible products.

What Is the Evolution of CNC Routing Tables in the B2B Sector?

The evolution of CNC routing tables can be traced back to the early days of computer-aided manufacturing (CAM), where the integration of computers into machining processes revolutionized production capabilities. Initially, CNC routers were primarily used for simple tasks in woodworking and sign-making. However, as technology advanced, so did the applications of these machines, expanding into diverse industries such as furniture making, aerospace, and automotive manufacturing.

The introduction of sophisticated software solutions and modular designs has further enhanced the functionality of CNC routing tables, allowing for a broader range of materials to be processed with increased precision and speed. Today, CNC routers are not only viewed as tools for mass production but also as essential components of custom fabrication and prototyping. This evolution reflects the growing demand for versatility and efficiency in manufacturing, making CNC routing tables indispensable for international B2B buyers looking to stay competitive in an increasingly dynamic market.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc routing table

-

How do I choose the right CNC routing table for my business needs?

Choosing the right CNC routing table involves assessing your specific requirements, including the materials you will be working with, the size of projects, and your production volume. Consider factors such as the table’s working area, spindle power, and the types of materials it can process (wood, plastics, metals, etc.). Additionally, evaluate the machine’s build quality, ease of use, and the availability of technical support. It may also be beneficial to consult with manufacturers or suppliers to gain insights into the best options for your specific application. -

What are the common applications for CNC routing tables in various industries?

CNC routing tables are versatile machines widely used across multiple industries. Common applications include woodworking, sign making, cabinetry, furniture manufacturing, aerospace components, and automotive parts. They excel in producing intricate designs, cutting various materials, and ensuring high precision in repetitive tasks. Understanding the specific needs of your industry will help you select a routing table that maximizes productivity and efficiency. -

What should I look for in a supplier of CNC routing tables?

When sourcing a supplier, prioritize their reputation, experience, and customer reviews. Ensure they offer comprehensive technical support and warranty services, as these are crucial for maintaining operational efficiency. Additionally, inquire about their manufacturing processes, customization options, and lead times. A supplier that provides training and post-sale assistance can significantly enhance your experience and help you maximize the use of your CNC routing table. -

What are the typical lead times for CNC routing table orders?

Lead times can vary significantly based on the supplier, the complexity of the machine, and whether it is a standard or customized model. Generally, expect lead times ranging from a few weeks to several months. It is advisable to confirm specific timelines with your supplier and factor in any potential delays caused by international shipping or customs processes, especially when sourcing from overseas manufacturers. -

What are the minimum order quantities (MOQ) for CNC routing tables?

Minimum order quantities can differ among suppliers and may depend on the type of CNC routing table you are interested in. Many suppliers offer flexibility in MOQs for larger businesses, while smaller companies may face higher MOQs. It’s essential to communicate your needs clearly with potential suppliers to understand their MOQ policies and negotiate terms that suit your purchasing capabilities. -

What payment terms should I expect when purchasing CNC routing tables?

Payment terms can vary based on the supplier and your relationship with them. Common arrangements include a deposit followed by the balance upon delivery, or payment in full before shipping. For international transactions, be prepared for wire transfers or letters of credit, especially if working with new suppliers. Discussing payment terms upfront can help avoid misunderstandings and facilitate a smoother purchasing process. -

How can I ensure quality assurance for my CNC routing table?

To ensure quality assurance, request detailed specifications and certifications from your supplier, such as ISO standards. Inquire about their quality control processes during manufacturing and whether they conduct final inspections before shipment. Additionally, consider asking for samples or visiting the manufacturing facility if feasible. Establishing clear communication with your supplier regarding your quality expectations will also help ensure that the final product meets your standards. -

What logistics considerations should I keep in mind when importing CNC routing tables?

When importing CNC routing tables, consider shipping methods, customs duties, and local regulations that may apply. Research the logistics providers your supplier uses and evaluate their reliability and experience with heavy machinery. Be aware of the necessary documentation required for customs clearance and ensure that your supplier is prepared to assist with this process. Planning ahead for potential delays at ports or during transit can help mitigate disruptions in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Cnc Routing Table Manufacturers & Suppliers List

1. Premier Plasma CNC – CNC Router Machines

Domain: premierplasmacnc.com

Registered: 2017 (8 years)

Introduction: This company, Premier Plasma CNC – CNC Router Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Grizzly – CNC Routers

Domain: grizzly.com

Registered: 1991 (34 years)

Introduction: This company, Grizzly – CNC Routers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. STV – STV-R8 CNC Router Table

Domain: stvcnc.com

Registered: 2018 (7 years)

Introduction: STV CNC STV-R8 CNC Router Table features a working area of 48″ x 48″, a maximum spindle speed of 24,000 RPM, and a robust aluminum frame for durability. It includes a 2.2 kW water-cooled spindle, a 4-axis capability, and is compatible with various software such as Mach3 and LinuxCNC. The machine is designed for precision cutting, engraving, and milling of materials like wood, plastic, and aluminum…

4. MultiCam – CNC Cutting Tables

Domain: multicam.com

Registered: 1996 (29 years)

Introduction: MultiCam CNC tables are computer-controlled cutting platforms designed for precision and versatility across various materials including wood, plastic, metal, and composites. Key features include:

– Precision: Repeatability down to 1/1000th of an inch for accurate cuts.

– Material Compatibility: Capable of cutting standard substrates like wood, MDF, plywood, as well as industrial-grade plastics a…

Strategic Sourcing Conclusion and Outlook for cnc routing table

The strategic sourcing of CNC routing tables is pivotal for businesses aiming to enhance their manufacturing capabilities and efficiency. By selecting high-quality, reliable equipment, companies can significantly improve their production processes, reduce waste, and increase output. It’s essential to consider not just the initial purchase price, but also the total cost of ownership, including maintenance, software compatibility, and long-term support. Investing in versatile machines that can adapt to various applications—such as woodworking, signage, and furniture making—will provide greater returns in diverse markets.

As international B2B buyers from regions like Africa, South America, the Middle East, and Europe navigate their sourcing strategies, it is crucial to prioritize suppliers who offer robust warranty programs and lifetime technical support. Building relationships with manufacturers that understand local market needs can lead to better pricing and tailored solutions.

Looking ahead, the demand for CNC routing tables is expected to grow as industries seek automation and precision. Embrace this opportunity by evaluating your sourcing options today, ensuring that your business remains competitive in an evolving global landscape. Reach out to trusted suppliers to explore the latest technologies and secure the best solutions for your manufacturing needs.