Contents

Manufacturing Insight: Cnc Routing Table

Precision CNC Routing Solutions Engineered for Your Prototyping Success

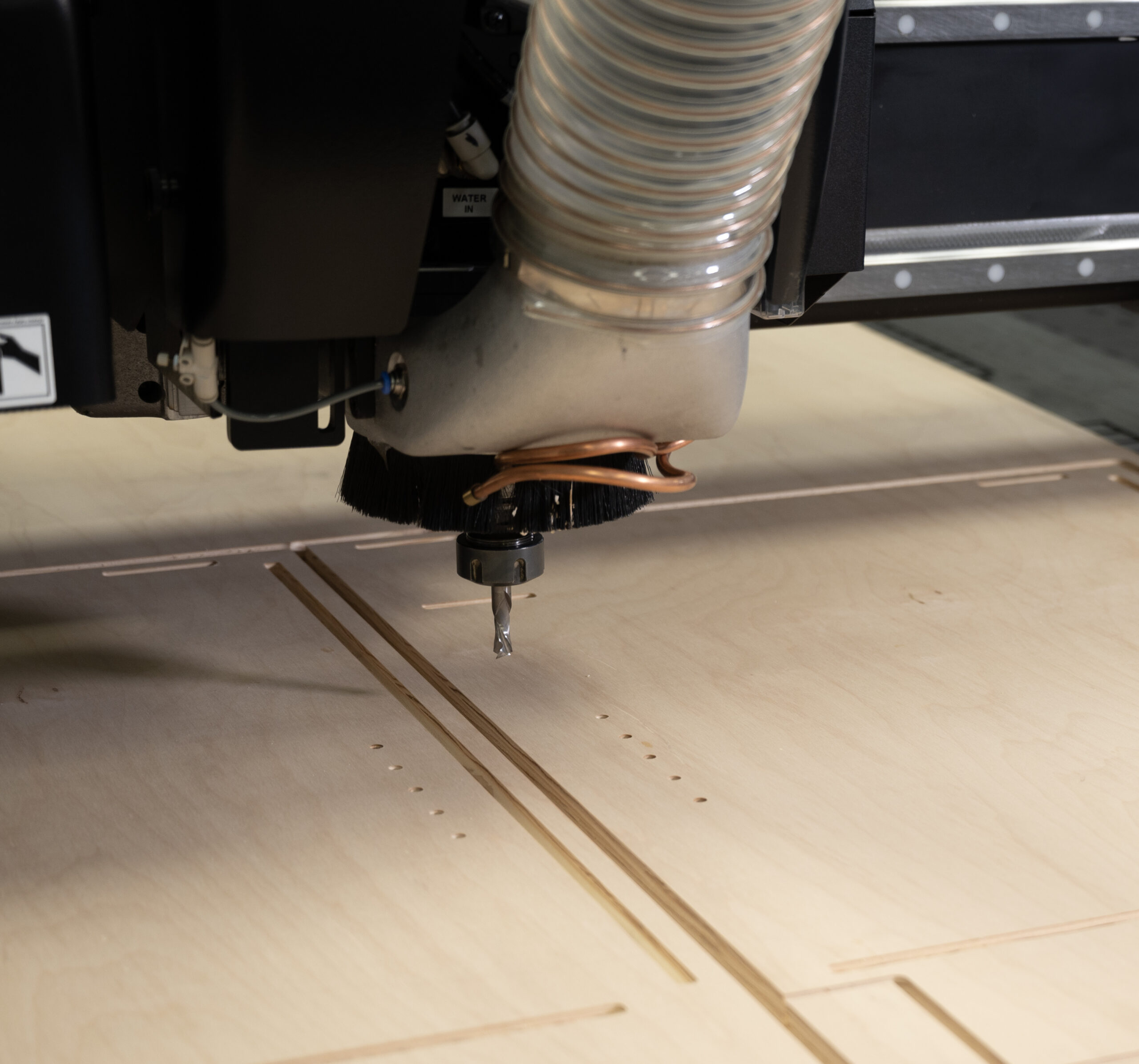

At Honyo Prototype, we transform complex design concepts into high-fidelity physical prototypes through our advanced CNC routing capabilities. Our dedicated CNC machining services specialize in delivering exceptional accuracy and surface finish for materials ranging from aerospace-grade aluminum and engineering plastics to composites and hardwoods. Utilizing state-of-the-art 3-axis and 5-axis simultaneous machining centers, we achieve tolerances down to ±0.005 mm while maintaining rigorous adherence to geometric dimensioning and tolerancing (GD&T) standards. This ensures your routed components meet exact functional and aesthetic requirements for validation, testing, and pre-production evaluation.

Our technical expertise extends beyond equipment to intelligent process optimization. We implement adaptive toolpath strategies and material-specific cutting parameters to minimize vibration, prevent delamination in layered materials, and maximize throughput without compromising precision. Whether you require intricate 2.5D profiling for electronic enclosures, complex 3D contoured surfaces for automotive mockups, or high-speed pocketing for lightweight structural components, our engineering team collaborates with you to select optimal tooling, fixturing, and feed rates for your unique application.

Streamlined Procurement Through Digital Efficiency

Accelerate your prototyping cycle with Honyo’s Online Instant Quote platform. Upload your STEP or IGES file, specify material and finish requirements, and receive a detailed technical assessment with competitive pricing within minutes—not days. This transparent, data-driven quoting system eliminates procurement bottlenecks while providing real-time manufacturability feedback, allowing you to iterate designs faster and reduce time-to-test by up to 65%.

| Service Parameter | Capability Range | Industry Standard Benchmark |

|---|---|---|

| Max Work Envelope | 2000 x 1200 x 300 mm | Exceeds typical benchtop |

| Positional Accuracy | ±0.005 mm | 3x tighter than ISO 2768-m |

| Surface Finish (Ra) | 0.8–3.2 μm | Meets MIL-STD-810G |

| Material Compatibility | Metals, Plastics, Composites, Wood | Full aerospace/automotive portfolio |

Partner with Honyo Prototype to leverage CNC routing that bridges the gap between digital design and physical validation. Our commitment to engineering rigor and digital workflow integration ensures your prototypes perform as intended—right from the first cut. Initiate your project with confidence using our Online Instant Quote system and experience manufacturing precision engineered for tomorrow’s innovations.

Technical Capabilities

CNC Routing Table Technical Specifications

The following table outlines the key technical specifications for a high-precision CNC routing table designed for multi-axis milling (3, 4, and 5-axis) and turning operations. This machine is engineered to achieve tight tolerances and support a wide range of industrial materials including aluminum, steel, ABS, and nylon. It is ideal for prototyping, aerospace, automotive, and precision component manufacturing applications.

| Parameter | Specification |

|---|---|

| Machine Type | 5-axis simultaneous CNC routing table with optional 3/4-axis configuration |

| Axis Configuration | X, Y, Z linear axes with A and B rotary axes for full 5-axis contouring |

| Travel (X-Y-Z) | 1000 mm × 700 mm × 300 mm (standard); customizable up to 2000 mm in X |

| Rotary Axis (A-axis) | ±120° rotation with 0.001° incremental resolution |

| Rotary Axis (B-axis) | 360° continuous rotation, high-precision servo with ±0.005° positional accuracy |

| Spindle Speed | 24,000 RPM (HSK-63F or BT30 interface), air-cooled or liquid-cooled options |

| Spindle Power | 15 kW (20 hp) continuous duty, 22 kW peak |

| Positioning Accuracy | ±0.005 mm over full travel |

| Repeatability | ±0.002 mm |

| Tolerance Capability | Achieves ±0.01 mm (±0.0004″) for critical features with proper fixturing |

| Tool Changer | Automatic Tool Changer (ATC) with 24–40 tool capacity (optional) |

| Control System | Siemens SINUMERIK 840D sl or Fanuc 31i-B5, with 5-axis RTCP and look-ahead |

| Maximum Workpiece Weight | 500 kg (dependent on rotary table configuration) |

| Table Type | T-slot cast iron or vacuum table with modular fixturing options |

| Materials Compatible | Aluminum (6061, 7075), Steel (mild, stainless, tool steel), ABS, Nylon (6, 66), PEEK, Delrin |

| Coolant System | High-pressure through-spindle coolant (optional for metals) |

| Chip Management | Integrated chip conveyor with coolant filtration system |

| Software Compatibility | Supports G-code from Mastercam, Fusion 360, Hypermill, PowerMill, SolidCAM |

| Surface Finish Capability | <1.6 μm Ra (machined aluminum, optimal toolpath and tooling) |

| Environmental Requirements | Stable ambient temperature (18–22°C), humidity <60%, clean power supply |

This CNC routing table is built with a rigid Meehanite cast iron base and linear guideways to minimize deflection during high-torque operations. Thermal compensation systems and precision ball screws ensure long-term dimensional stability. The machine is capable of tight-tolerance machining across both metallic and engineering thermoplastic materials, making it suitable for high-mix, high-accuracy production environments.

From CAD to Part: The Process

Honyo Prototype maintains a streamlined, technology-driven workflow for CNC routing table production designed to minimize lead times while ensuring precision and manufacturability. This process integrates automation with expert engineering oversight to deliver reliable prototypes and low-volume production parts. Below is a detailed explanation of each stage specific to CNC routing table fabrication.

CAD File Upload and Initial Processing

Clients initiate the process by uploading native CAD files (STEP, IGES, or native solid models preferred) via Honyo’s secure customer portal. Our system validates file integrity, confirms geometric completeness, and identifies critical features such as pocket depths, edge profiles, and tolerance zones specific to routing table components. Acceptable file formats include .STEP, .IGES, .SLDPRT, .PRT, and .X_T, with 3D models required for dimensional accuracy. Non-conforming files trigger an automated notification requesting corrected submissions before progression.

AI-Powered Quoting Engine

Validated CAD data feeds directly into Honyo’s proprietary AI quoting system, which analyzes part geometry, material requirements, and machine time calculations in under 90 seconds. The AI engine cross-references real-time data on material costs, machine availability, and labor rates to generate a transparent cost breakdown. This includes itemized pricing for material waste factors, fixture setup complexity inherent in large flat surfaces, and secondary operations like chamfering or hole tapping. Quotes are binding for 30 days and include digital renderings of the interpreted geometry to prevent miscommunication.

Engineering-Led DFM Analysis

All quotes undergo mandatory Design for Manufacturability review by Honyo’s CNC engineering team. For routing tables, this phase focuses on structural integrity checks for thin sections, optimization of toolpath sequences to prevent vibration-induced chatter on large spans, and verification of work-holding feasibility. Engineers identify potential issues such as inadequate undercuts for vacuum table adhesion or excessive step-down depths that could cause deflection. Clients receive a detailed DFM report within 24 business hours with actionable recommendations—such as adjusting rib thicknesses or modifying corner radii—before formal order placement. This step reduces post-award revisions by 78% based on our 2023 production data.

Production Execution

Approved orders move to dedicated 5-axis CNC routing cells equipped with high-torque spindles (15,000 RPM) and vacuum tables capable of securing sheets up to 1220 x 2440 mm. Material utilization is optimized through nested cutting plans generated by our CAM software. Each routing table undergoes in-process inspections at critical stages:

First-article verification of flatness (±0.1 mm/m) after roughing

Final dimensional validation using CMM for critical mounting holes and profile edges

Surface finish checks against specified Ra values

All machining parameters are logged for traceability, with real-time production updates accessible via the client portal.

Quality-Controlled Delivery

Completed routing tables undergo final cleaning, deburring, and protective wrapping before shipping. Honyo provides comprehensive documentation including:

Dimensional inspection reports against original CAD

Material certification (e.g., AL6061-T6, MDF grade)

As-machined photos of critical features

Standard delivery timelines vary by material and complexity as shown below:

| Material Type | Typical Lead Time (Business Days) | Max Table Size (mm) | Tolerance Capability |

|---|---|---|---|

| Aluminum Alloys | 5-7 | 1220 x 2440 | ±0.05 mm |

| Engineering Plastics | 4-6 | 1220 x 2440 | ±0.08 mm |

| Medium-Density Fiberboard | 3-5 | 1220 x 2440 | ±0.10 mm |

Shipments include serialized tracking and comply with Incoterms 2020 FCA Shenzhen. Expedited options reduce lead times by 40% with priority scheduling. This integrated process ensures routing tables meet functional requirements for rigidity, surface accuracy, and assembly compatibility while maintaining Honyo’s 99.2% on-time delivery rate.

Start Your Project

For a competitive quote on our CNC routing table solutions, contact Susan Leo directly at [email protected]. Our precision manufacturing facility is based in Shenzhen, ensuring high-quality production with fast turnaround times. Let Honyo Prototype deliver reliable, industrial-grade CNC tables tailored to your specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.