Contents

Manufacturing Insight: Cnc Routering

Precision CNC Routing Solutions from Honyo Prototype

At Honyo Prototype, we transform complex design concepts into high-precision physical components through advanced CNC routing capabilities. Our industrial-grade 3-, 4-, and 5-axis machining centers deliver exceptional accuracy, surface finish, and repeatability for prototypes and low-to-mid volume production runs. Specializing in intricate geometries across diverse materials—from aerospace-grade aluminum and engineering plastics to composites and hardwoods—we ensure your parts meet stringent dimensional tolerances and functional requirements.

Our integrated CNC machining services bridge the gap between rapid prototyping and scalable production, supported by in-house engineering expertise that optimizes toolpaths, material utilization, and cycle times. This commitment to technical excellence minimizes waste and accelerates time-to-market without compromising quality.

A cornerstone of our client-centric approach is the Online Instant Quote platform. Upload your CAD file, specify materials and quantities, and receive a detailed, binding cost estimate within minutes—24/7. This transparent, no-obligation system eliminates procurement delays, empowering engineering and procurement teams to make agile, data-driven decisions.

Partner with Honyo Prototype to leverage precision CNC routing backed by responsive engineering support and seamless digital workflows. Begin your next project with confidence: access our Online Instant Quote system today and experience manufacturing efficiency redefined.

Technical Capabilities

CNC routing encompasses a range of subtractive manufacturing processes that utilize computer-controlled tools to shape materials with high precision. At Honyo Prototype, we specialize in multi-axis CNC milling (3, 4, and 5-axis configurations) and CNC turning, enabling complex geometries and tight tolerances across a variety of engineering materials. Our systems are optimized for rapid prototyping and low-to-mid volume production runs with consistent accuracy and surface finish.

Multi-axis capabilities allow for reduced setup times and improved part accuracy. 3-axis milling is ideal for prismatic parts with features on a single plane, while 4-axis (with rotary indexing) and 5-axis (simultaneous motion on three linear and two rotary axes) support complex contours, undercuts, and organic shapes without manual repositioning. CNC turning is used for cylindrical components, often in combination with milling for mill-turn operations.

We maintain tight tolerances down to ±0.005 mm (±0.0002″) depending on geometry, material, and feature type, with surface finishes as fine as Ra 0.8 µm achievable through precision toolpaths and post-processing.

Below is a summary of technical specifications and material capabilities:

| Parameter | Specification Detail |

|---|---|

| Machining Types | 3-Axis Milling, 4-Axis Indexing Milling, 5-Axis Simultaneous Milling, CNC Turning |

| Positioning Accuracy | ±0.005 mm (±0.0002″) |

| Repeatability | ±0.002 mm (±0.0001″) |

| Tolerance Range | Standard: ±0.025 mm (±0.001″) Tight: ±0.005 mm (±0.0002″) with process control |

| Surface Finish (Typical) | Ra 3.2 – 0.8 µm (125 – 32 µin); achievable via fine finishing passes |

| Max Work Envelope (Milling) | 1000 × 600 × 500 mm (39 × 23.6 × 19.7 in) – varies by machine |

| Max Work Envelope (Turning) | Ø 300 mm × 500 mm length (12 in × 19.7 in) |

| Spindle Speed (Milling) | Up to 24,000 RPM (high-speed options available) |

| Spindle Power | 15 – 22 kW depending on machine configuration |

| Tool Changer Capacity | 24 – 30 tools (ATC) |

| Control System | Fanuc, Siemens, or Heidenhain with full tool path verification |

| Material | Machinability | Max Tolerance Capability | Notes |

|---|---|---|---|

| Aluminum (6061, 7075) | Excellent | ±0.005 mm | High material removal rate; ideal for prototypes and lightweight parts |

| Steel (4140, 1018) | Good | ±0.01 mm | Requires rigid setup; used for high-strength components |

| Stainless Steel (303, 316) | Moderate | ±0.01 mm | Work-hardening tendency; optimized feeds/speeds required |

| ABS | Excellent | ±0.025 mm | Low melting point; sharp tools and light cuts recommended |

| Nylon (6, 66) | Good | ±0.025 mm | Prone to deflection; needs secure fixturing and controlled feeds |

All processes are supported by CAD/CAM integration, in-process inspection (via touch probes), and first-article inspection (FAI) reporting upon request. Material certifications and traceability are available for aerospace and medical applications.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined CNC routing workflow designed to ensure manufacturability, cost efficiency, and rapid turnaround for prototype and low-volume production parts. Our process integrates automated intelligence with expert engineering oversight at critical stages.

CAD Upload and Initial Validation

Customers submit native or neutral CAD files (STEP, IGES, Parasolid, DWG, DXF) via our secure online portal. Our system performs an immediate geometric validation check to confirm file integrity, unit consistency, and basic manufacturability. Unsupported formats or corrupted files trigger an automated notification for resubmission, preventing downstream delays. This initial scan verifies critical parameters such as closed solids and proper surface continuity.

AI-Powered Quoting Engine

Validated CAD data enters our proprietary AI quoting system. This engine analyzes part geometry, material selection (from our certified stock database), tolerance requirements, and secondary operations. It cross-references real-time machine availability, tooling libraries, and historical production data to generate a detailed cost breakdown within minutes. The quote includes material waste calculations, machine time estimates based on toolpath complexity, and identification of potential high-cost features requiring DFM review. Customers receive transparent pricing with clear rationale for cost drivers.

Engineering-Led DFM Analysis

All quotes undergo mandatory Design for Manufacturability review by our senior CNC engineering team. This is not an automated step but a critical human-in-the-loop process where engineers evaluate the AI’s findings and assess practical manufacturability. Key focus areas include:

| Parameter | Standard Capability | Critical Consideration |

|---|---|---|

| Minimum Feature | 0.8mm end mills | Undercuts require specialized tooling |

| Wall Thickness | ≥1.5mm (plastics) | Thin walls necessitate reduced cutting speeds |

| Internal Radii | ≥0.4mm | Sharp corners increase tool wear and cycle time |

| Draft Angles | 0.5° minimum | Essential for deep cavities in composites |

| Material Thickness | Up to 100mm | Thick materials require multi-side fixturing |

Engineers provide specific, actionable feedback through our portal—highlighting necessary design modifications, suggesting alternative materials for cost reduction, or proposing tolerance relaxations. Customer approval of the DFM report is required before production release.

Precision CNC Routing Execution

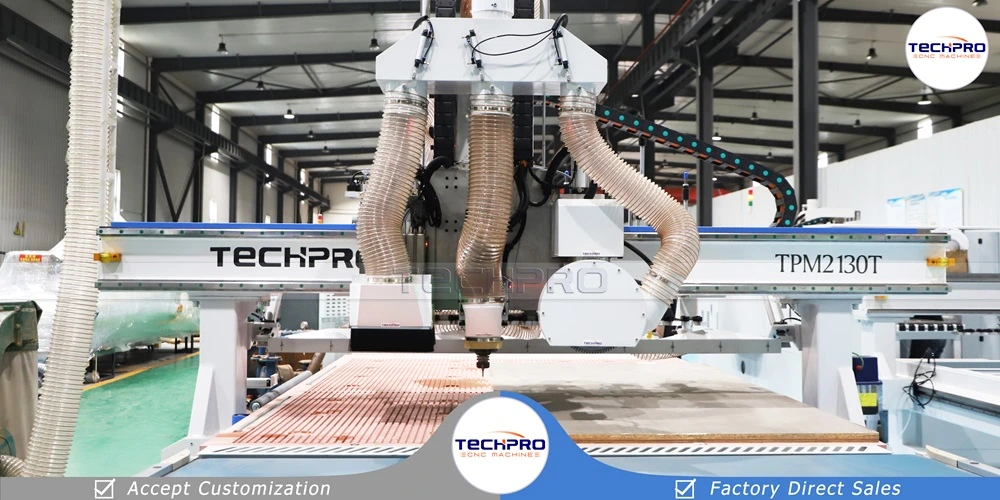

Approved jobs are scheduled on our network of 3-, 4-, and 5-axis CNC routers (ShopSabre, AXYZ, and custom-configured machines). Our process includes:

Material verification against certified mill certificates and batch tracking

Custom fixture design to minimize setup changes and ensure part stability

Simulated toolpath validation using Mastercam and Fusion 360 to prevent collisions

In-process CMM checks for critical first-article features

Real-time machine monitoring with automated spindle load and vibration analysis

All operations adhere to ISO 9001:2015 quality protocols with documented inspection records for each work order.

Quality-Controlled Delivery

Completed parts undergo final dimensional verification against the original CAD model using Zeiss CMMs or optical comparators where specified. We provide comprehensive documentation including:

First-article inspection report (FAIR) with critical dimensions

Material certification and traceability documentation

As-built photographs highlighting surface finish and edge quality

Packaging designed for secure transit of delicate routed components

Standard lead time is 3-5 business days from DFM approval, with expedited 24-72 hour options available. Parts ship with full customs documentation for international clients, and we maintain a digital audit trail of all process steps accessible to customers via our portal. This closed-loop system ensures traceability from initial CAD file to delivered part while maintaining our industry-leading 99.2% on-time delivery rate.

Start Your Project

For precision CNC routing services, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen delivers high-quality, custom machining solutions tailored to your prototyping and production needs. Reach out today to discuss your project and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.