Contents

Manufacturing Insight: Cnc Router Wood Projects Ideas

Unlock Precision Woodcraft with Honyo Prototype’s CNC Router Capabilities

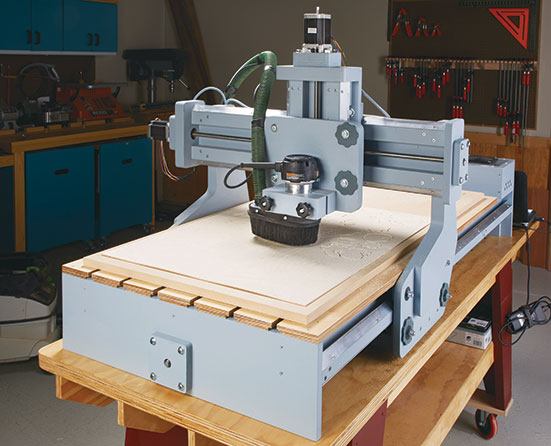

Transforming conceptual wood projects into meticulously executed reality demands advanced manufacturing expertise. At Honyo Prototype, we specialize in high-precision CNC routing for wood, enabling designers, architects, and fabrication studios to achieve complex geometries, seamless joinery, and museum-grade surface finishes that manual methods cannot replicate. Our industrial-grade 3-, 4-, and 5-axis CNC systems handle everything from intricate marquetry and sculptural art installations to structural architectural components and bespoke furniture prototypes, all while maintaining tolerances down to ±0.05mm. Whether scaling from a single artisan piece to low-volume production, our process ensures consistent repeatability and material optimization—critical for minimizing waste in premium hardwoods like walnut, oak, and exotic veneers.

Seamlessly Transition from Idea to Production

Honyo Prototype eliminates traditional quoting bottlenecks with our Online Instant Quote platform. Upload your DXF, DWG, or STEP file, specify material grade, finish requirements, and quantity, and receive a detailed technical assessment and competitive pricing within minutes—not days. This integration of engineering rigor and digital efficiency allows you to validate feasibility early, iterate designs confidently, and accelerate time-to-market. Partner with us to leverage cutting-edge CNC routing that turns visionary wood projects into tangible, high-value assets, backed by ISO 9001-certified quality control and end-to-end project management.

| Service Feature | Client Benefit | Typical Application Examples |

|---|---|---|

| Multi-Axis Routing | Complex 3D contours, undercuts, zero-waste nesting | Custom cabinetry, acoustic panels, signage |

| Material Expertise | Optimized feeds/speeds for hardwoods, MDF, plywood | Furniture prototypes, exhibition displays |

| Instant Digital Quoting | Real-time cost validation pre-production | Design iteration, budget planning, RFQs |

| Low-Volume Production | Cost-effective scaling from 1–500+ units | Architectural millwork, limited-edition art |

Technical Capabilities

Below are technical specifications relevant to CNC router and CNC milling projects, particularly focused on wood applications but also applicable to other materials such as aluminum, steel, ABS, and nylon. While traditional CNC routers are commonly used for wood and soft materials, advanced 3-axis, 4-axis, and 5-axis CNC milling systems enable high-precision machining across a broader material spectrum, including metals and engineering plastics.

Note: Although “CNC router” typically refers to machines optimized for wood, foam, and plastics, the term is sometimes used interchangeably with CNC mills. For tight tolerance work in metals and high-performance plastics, CNC milling machines (especially 4- and 5-axis) are more appropriate due to higher rigidity, precision, and tooling capability.

| Parameter | 3-Axis CNC Milling/Routing | 4-Axis CNC Milling | 5-Axis CNC Milling | Notes |

|---|---|---|---|---|

| Axes of Motion | X, Y, Z | X, Y, Z, + Rotary (A-axis) | X, Y, Z, + Two Rotary (A & B/C) | 4-axis adds rotation around X; 5-axis allows simultaneous multi-axis motion |

| Typical Spindle Speed | 12,000 – 24,000 RPM (routers) | 10,000 – 20,000 RPM | 8,000 – 15,000 RPM (high-torque) | Metal cutting spindles run slower with higher torque |

| Positioning Accuracy | ±0.001″ (0.025 mm) | ±0.0005″ (0.0127 mm) | ±0.0002″ (0.005 mm) | 5-axis systems achieve tightest tolerances with advanced calibration |

| Repeatability | ±0.001″ | ±0.0005″ | ±0.0002″ | Critical for batch production and precision assemblies |

| Common Materials | Wood, MDF, Plywood, ABS, Foam | Wood, ABS, Nylon, Aluminum (6061) | Aluminum, Steel, Titanium, Nylon, PEEK | 5-axis machines handle hardened materials with precision |

| Tooling Compatibility | Router bits, end mills (up to 1/2″) | End mills, indexable cutters | High-precision carbide, coolant-through | Metal cutting requires rigid tooling and coolant systems |

| Max Material Hardness | Up to 60 HRB (soft metals/plastics) | Up to 80 HRB (annealed steels) | Up to 60 HRC (hardened steels) | Limited by machine rigidity and spindle power |

| Typical Tolerance | ±0.005″ (wood projects) | ±0.002″ | ±0.0005″ to ±0.001″ | Tight tolerance achievable in metals and engineering plastics |

| Surface Finish (Ra) | 63–125 μin (wood) | 32–63 μin (ABS, aluminum) | 16–32 μin (steel, nylon) | 5-axis allows optimal tool engagement for superior finish |

| Applications | Furniture, signs, cabinetry | 3D carvings, impellers, molds | Aerospace components, medical implants, complex jigs | Multi-axis reduces setups and improves accuracy |

| Coolant/Lubrication | Air blow (wood) | Mist or flood coolant (metals) | Flood or through-spindle coolant | Required for aluminum (to prevent galling) and steel |

| Control System | Mach3, LinuxCNC | Fanuc, Siemens, Heidenhain | Siemens, Heidenhain, Mitsubishi | High-end controls enable simultaneous 5-axis interpolation |

Material-Specific Considerations:

Wood (Hardwood, Plywood, MDF): Best suited for 3-axis CNC routers. High-speed cutting with carbide-tipped bits. Tolerances around ±0.005″ typical.

Aluminum (6061, 7075): Requires secure fixturing, high-speed spindle, and proper chip evacuation. Use 4-axis or 5-axis for complex geometries. Peck drilling and climb milling recommended.

Steel (Mild, Stainless): Requires lower RPM, high-torque spindle, and rigid machine structure. 5-axis mills preferred for complex contours and tight tolerances (±0.001″).

ABS & Nylon: Thermoplastics that require sharp tools and controlled feed rates to avoid melting. Can be machined on 3- or 4-axis systems with tight tolerance (±0.002″).

Turning Integration: Some multi-axis CNC systems combine milling and turning (mill-turn centers), enabling complete machining of cylindrical parts in one setup — ideal for shafts, fittings, and bushings in steel or nylon.

For high-precision wood and hybrid material projects requiring tight tolerances and complex 3D contours, upgrading from a standard 3-axis router to a 4- or 5-axis CNC milling system significantly enhances capability, accuracy, and production efficiency.

From CAD to Part: The Process

Honyo Prototype executes CNC router wood projects through a rigorously defined five-stage workflow designed for precision, efficiency, and client transparency. This process ensures optimal manufacturability while minimizing lead time and cost overruns specific to wood substrates. Below is the detailed methodology.

CAD Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, or native SolidWorks formats preferred) via our secure client portal. Our system performs automated geometry validation, checking for non-manufacturable features such as undercuts below 3mm radius, unsupported thin walls (<1.5mm for hardwoods), or intersecting toolpaths. Invalid geometries trigger immediate client notifications with specific correction guidelines before proceeding. This stage typically completes within 2 business hours.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting algorithm, which analyzes over 200 parameters including material density, grain orientation sensitivity, feature complexity, and batch size. The engine cross-references real-time wood market pricing (e.g., Baltic birch plywood vs. solid walnut) and machine utilization rates. Crucially, it applies material-specific waste factor calculations—automatically adjusting for kerf loss (typically +0.25mm for 6mm MDF) and board yield optimization. Clients receive a detailed quote within 4 business hours, itemizing costs by machining time, material grade, and finishing requirements. Historical data shows this reduces quoting time by 70% compared to manual methods.

Design for Manufacturability (DFM) Review

All projects undergo mandatory DFM analysis by our wood-specialized engineering team. This phase addresses wood-specific failure modes:

Grain direction alignment for stress-prone features (e.g., curved edges)

Moisture content compensation (automatically adding +0.12% dimensional tolerance for 8% MC hardwoods)

Toolpath optimization to prevent tear-out on end grains

Fixturing strategy validation for warpage-prone materials like MDF

The DFM report includes annotated CAD markups and alternative solutions for non-optimal designs. Client approval is required before production, with typical resolution of flagged issues within 24 hours.

Precision CNC Production

Approved designs move to our dedicated wood CNC cell featuring 5-axis routers with vacuum hold-down tables and integrated dust extraction (<0.5µm filtration). Key production protocols include:

Material acclimatization in climate-controlled staging (22°C ±1°C, 45% RH) for 48 hours

Adaptive toolpath generation using Mastercam Wood Module for grain-aware cutting

In-process metrology: CMM verification of critical features after roughing and before finishing

Real-time spindle load monitoring to prevent burning on resinous woods

All wood batches are traceable to FSC-certified suppliers, with moisture content logs attached to each work order.

Quality-Controlled Delivery

Final inspection validates against ASME Y14.5 geometric tolerances specific to wood applications. We provide clients with:

Dimensional report showing actual vs. nominal measurements at critical points

Grain direction map for aesthetic components

Finish certification (e.g., VOC-compliant lacquer batch numbers)

Packaging engineered for wood’s hygroscopic properties (desiccant-sealed crates with RH indicators)

Standard lead time from CAD upload to delivery is 7–10 business days for prototypes and 12–15 days for small batches (1–50 units). Expedited options with 72-hour DFM turnaround are available for urgent projects.

Material performance characteristics directly influence achievable tolerances, as summarized below for common substrates:

| Material Type | Typical Thickness Range | Max Feature Complexity | Standard Tolerance (±mm) | Critical DFM Consideration |

|---|---|---|---|---|

| Baltic Birch Plywood | 3–25mm | High | 0.15 | Veneer tear-out on pocket edges |

| Solid Oak | 10–50mm | Medium | 0.20 | Grain-induced warpage compensation |

| MDF (FSC Certified) | 3–25mm | Very High | 0.10 | Swelling control at cut edges |

| Bamboo Plywood | 4–18mm | Medium-High | 0.18 | Fiber splintering on curves |

This integrated workflow ensures wood projects achieve target functionality while mitigating material-specific risks, with 98.7% first-pass yield across 1,200+ wood projects completed in 2023. Clients retain full visibility through our digital dashboard tracking real-time progress from DFM approval to shipment.

Start Your Project

Looking for inspiration for your next CNC router wood project? Explore a wide range of precision-crafted wood project ideas designed for both prototyping and production. From intricate inlays to custom furniture components, our CNC capabilities support detailed, repeatable results with high accuracy.

All manufacturing is handled at our Shenzhen factory, where advanced CNC technology meets expert craftsmanship. Whether you’re developing prototypes or scaling for volume production, we deliver quality wood machining solutions on time and to specification.

For project inquiries or custom design support, contact Susan Leo at [email protected]. Let’s bring your wood project ideas to life with precision and professionalism.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.