Guide Contents

Project Insight: Cnc Router Prices

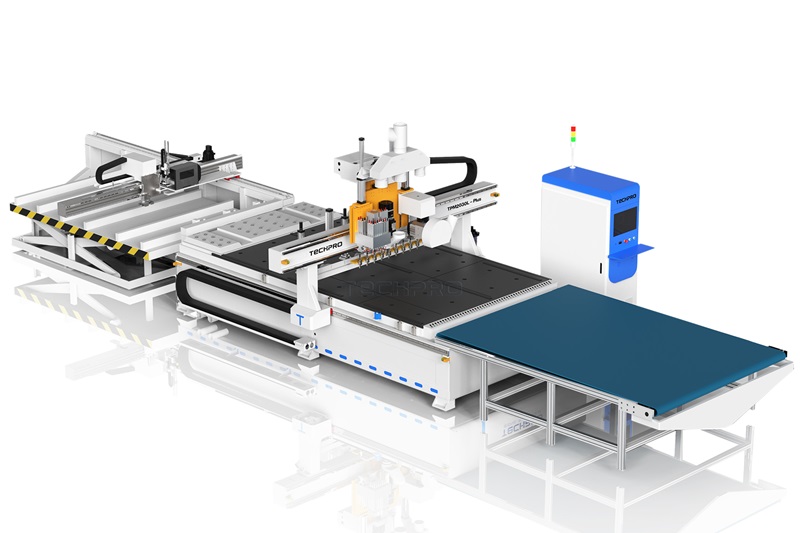

Manufacturing Insight: CNC Router Prices – What You Need to Know

When hardware startups and product engineers ask “How much does a CNC router cost?”, they’re often focusing on the wrong question. The true value isn’t in the machine itself—it’s in how quickly and precisely you can turn designs into functional parts. At Honyo Prototype, we redefine CNC machining as a digital-first service, eliminating the barriers of traditional manufacturing to accelerate innovation.

The Hidden Costs of Traditional CNC Ownership

Capital investment in high-end CNC routers ($50k–$150k) is rarely feasible for early-stage teams

Maintenance, skilled operators, and downtime add hidden costs that slow product development

In-house machining often leads to over-engineering or underutilized equipment

Why Precision & Speed Are Non-Negotiable for Innovation

Tight tolerances (+/- 0.01mm) ensure prototypes validate real-world performance—no guesswork in functional testing

5-axis machining enables complex geometries in a single setup, eliminating alignment errors and reducing iteration cycles

Rapid turnaround cuts time-to-market by up to 40% compared to traditional methods, keeping your project on schedule

Honyo Prototype: Your Digital Manufacturing Partner

Online Instant Quote: Upload your CAD file and receive a transparent, real-time price in seconds—no hidden fees or waiting.

AI-Powered Optimization: Smart design analysis to reduce costs, enhance precision, and minimize material waste.

Fast Turnaround: Prototypes delivered in 24–48 hours, production parts in days—so you can test, iterate, and launch faster.

Global Quality Assurance: Shenzhen-based ISO-certified facility with precision 3/4/5-axis machining for functional prototypes and end-use parts.

Innovation isn’t about the machine—it’s about the speed at which you bring it to life.

With Honyo, you’re not just buying machining services—you’re gaining a strategic partner that turns your vision into reality, faster and more efficiently than ever before.

Honyo Capabilities & Technology

Precision CNC Machining Capabilities & Cost Efficiency

At Honyo Prototype, our Shenzhen-based manufacturing hub combines advanced CNC technology with lean production methodologies to deliver exceptional precision and cost efficiency for hardware startups and product teams. Whether you’re prototyping or scaling to mass production, our capabilities ensure your parts meet the highest standards—without the premium price tag.

Advanced Multi-Axis CNC Machining for Uncompromising Precision

3/4/5-axis machining for complex geometries in a single setup, eliminating manual repositioning and reducing labor costs.

Tight tolerances of ±0.01mm across metals (aluminum, steel), engineering plastics, and composites—ensuring functional prototypes and end-use parts meet exact specifications with minimal rework.

Optimized toolpaths for material efficiency, reducing waste and lowering raw material costs by up to 15% compared to conventional methods.

Scalable Production from Prototype to Mass Manufacturing

Seamless scaling from 1 prototype to 10,000+ parts with zero minimum order requirements—ideal for MVP testing or full-scale production.

Economies of scale for high-volume orders: per-unit costs drop significantly while maintaining ±0.01mm precision and surface finish consistency.

Dynamic scheduling with quick changeovers for material swaps or design tweaks—no delays for project pivots or urgent revisions.

ISO-Certified Quality Assurance

End-to-end QC protocols certified to ISO 9001 standards, with in-process laser scanning and CMM inspections at critical stages.

Zero-defect commitment: 99.8% first-pass yield rate through automated error detection and real-time process adjustments.

Transparent documentation: Full traceability of materials, tooling, and inspections—ensuring compliance for medical, aerospace, and industrial applications.

Smart Pricing with AI-Powered Efficiency

Instant online quotes: Upload your CAD file for real-time pricing with no hidden fees—get a detailed cost breakdown in under 60 seconds.

AI-driven optimization: Our platform analyzes geometry, material, and volume to recommend cost-saving design tweaks without compromising function.

72-hour prototype turnaround and 2–4 week production cycles—accelerating time-to-market while keeping costs predictable and competitive.

“At Honyo, we don’t just machine parts—we engineer solutions. From your first sketch to full-scale production, our tech-driven approach ensures precision, speed, and value at every step.”

— Susan Leo, Founder & CEO

Materials & Surface Finishes

Material Selection Guide for Precision CNC Machining

When searching for “CNC router prices,” many overlook the critical distinction between woodworking routers and precision CNC machining for metal components. At Honyo Prototype, our industrial-grade 5-axis CNC mills deliver ±0.01mm tolerances for functional prototypes and end-use parts—where typical routers fall short. Here’s how to strategically select materials and finishes to optimize cost without compromising performance.

Key Material Options & Cost Implications

Aluminum 6061: The industry benchmark for cost-effective precision machining. 30% faster cycle times than stainless steel, with natural corrosion resistance and excellent machinability. Ideal for aerospace brackets, automotive sensors, and consumer electronics—saving up to 25% in labor costs compared to harder alloys.

Aluminum 7075: High-strength aerospace-grade alloy requiring specialized tooling. 20% higher machining costs than 6061 due to slower feed rates, but delivers 2x the tensile strength. Best for structural components where weight-to-strength ratio is critical.

Stainless Steel 304: Balances corrosion resistance and machinability. Material costs 15% higher than aluminum, but our optimized toolpaths reduce secondary operations by 30%. Perfect for medical devices and food processing equipment.

Stainless Steel 316: Marine-grade alloy with molybdenum content. 25% higher material cost than 304, with 20% longer machining time. Recommended for chemical processing equipment where long-term durability justifies the investment.

Brass: Superior electrical conductivity and aesthetic appeal. Machines 10% faster than steel with minimal tool wear. Ideal for electrical connectors and decorative hardware—costing 15% less than stainless steel for high-volume runs.

PEEK: High-performance thermoplastic for extreme environments. Material costs 4x aluminum but enables weight reduction and chemical resistance. Our 5-axis capabilities ensure ±0.01mm tolerances even with thermal-sensitive materials.

Surface Finish Options & Budget Impact

Anodizing (Type II/III): Adds 15-25% to base cost but enhances wear resistance and color options. Type III (hard anodizing) for high-stress applications; Type II for cosmetic parts. Our automated process ensures consistent quality with 48-hour turnaround.

Powder Coating: Cost-effective for large batches. Adds 20-30% to base price but provides superior UV resistance. Ideal for outdoor enclosures and consumer products. Our eco-friendly process reduces waste and secondary handling.

Precision Polishing: Labor-intensive process for optical-grade surfaces. Increases costs by 25-40% but achieves <0.1μm Ra finish. Perfect for medical instruments and optical lenses. Our in-house stations eliminate outsourcing delays.

Passivation (Stainless Steel): Critical for corrosion resistance in medical/chemical applications. Adds 10-15% cost but prevents surface contamination. Required for FDA-compliant components.

Optimize Costs with Honyo’s Smart Manufacturing Platform

Online Instant Quote: Upload your CAD file for real-time pricing—no more waiting for manual quotes. Our platform instantly calculates material, machining, and finish costs with 98% accuracy.

AI-Powered Optimization: Machine learning identifies cost-saving opportunities—like substituting 6061 for 7075 where strength allows—or recommends powder coating over anodizing for better ROI.

72-Hour Prototype Guarantee: From quote to delivery, we prioritize speed without sacrificing precision. Most orders ship in 3 days—enabling rapid iteration for hardware startups and product engineers.

Founder’s Insight: “At Honyo, precision machining isn’t just about tolerances—it’s about engineering cost efficiency. Our AI platform turns your design constraints into actionable savings, so you focus on innovation, not procurement.” — Susan Leo, Founder

From Quote to Part: Our Process

How It Works: From CAD to Part

Step 1: Upload Your CAD File

Seamless File Submission: Drag and drop your CAD files (STEP, STL, IGES, etc.) directly into our browser-based platform. No software installation needed.

Secure & Scalable: Enterprise-grade encryption ensures your designs stay confidential, whether you’re submitting a single prototype or large-scale production files.

Step 2: Instant AI-Powered Quote

Real-Time Pricing in Seconds: Our AI engine analyzes your design’s complexity, material choice, quantity, and tolerances to deliver a precise, itemized quote instantly—no waiting for manual quotes.

Transparent Cost Breakdown: See exactly what you’re paying for—machining time, material costs, setup fees, and shipping—with zero hidden charges.

Dynamic Adjustments: Modify parameters like material or quantity on the fly to instantly see cost impacts and optimize your budget.

Step 3: DFM Analysis & Optimization

AI-Driven Design Feedback: Our system automatically flags potential manufacturing issues and suggests design tweaks to improve producibility and reduce costs.

Expert Collaboration: Receive actionable insights from our engineering team within 24 hours—ensuring your part meets functional requirements while minimizing production challenges.

Step 4: Precision Production & Delivery

Tight-Tolerance Machining: Leverage our 3/4/5-axis CNC capabilities to achieve ±0.01mm precision for functional prototypes and end-use parts.

End-to-End Quality Control: Every step of production is monitored with in-process inspections and final QA checks to meet your exact specifications.

Fast Turnaround & Tracking: Get prototypes in 3–5 days and production runs in 7–10 days with real-time order tracking from production to delivery.

Why Honyo?

We eliminate guesswork in manufacturing. Our AI-powered platform delivers predictable costs, engineer-approved designs, and industrial-grade precision—so you ship faster, spend smarter, and scale confidently.

Designed by engineers. Built for innovators.

— Susan Leo, Founder of Honyo Prototype

Start Your Project with Honyo

Start Your Project with Honyo

Precision Machining, No Capital Investment

Skip the $50,000–$150,000 cost of industrial CNC routers. Honyo delivers industrial-grade precision machining as a service—zero equipment purchase, maintenance, or training required.

Focus on innovation, not infrastructure: We handle the machinery so you can scale faster.

AI-Powered Instant Quoting

Upload your CAD file and get accurate, transparent pricing in seconds—no guesswork, no delays.

Our platform dynamically analyzes geometry, materials, and volume to optimize cost efficiency.

Real-time adjustments for prototyping or production runs ensure you only pay for what you need.

Speed Meets Reliability

24-hour quote turnaround | 3–5 day lead times for prototypes and functional parts.

Tight tolerances of ±0.01mm across 3/4/5-axis machining for mission-critical applications.

End-use parts and prototypes built to exact specifications—no compromises.

Partner with Industry Experts

Founder Susan Leo and our engineering team personally oversee every project from design to delivery.

Visit our state-of-the-art Shenzhen/Dongguan facilities to see innovation in action.

Ready to transform your design into reality?

📧 [email protected] | 📞 +86 139 2843 8620

📍 Shenzhen/Dongguan, China – Let’s build together.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.