Introduction: Navigating the Global Market for cnc router mill

In the rapidly evolving landscape of manufacturing, sourcing a reliable CNC router mill can pose a significant challenge for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe strive for precision and efficiency, understanding the nuances of CNC technology becomes imperative. This comprehensive guide delves into the intricacies of CNC router mills, covering essential aspects such as types, applications, supplier vetting processes, and cost considerations.

By providing in-depth insights into the various models available—from entry-level machines to advanced industrial units—this guide equips decision-makers with the knowledge necessary to make informed purchasing decisions. Buyers will discover how to identify reputable suppliers, assess machine specifications, and evaluate total cost of ownership to ensure optimal returns on investment. Furthermore, we explore the unique needs of diverse markets, addressing regional challenges and opportunities that can impact sourcing strategies.

With this guide, B2B buyers can navigate the complexities of the CNC router mill market confidently, ensuring that their manufacturing processes are supported by reliable and efficient equipment tailored to their specific operational needs. Whether you are based in Vietnam or Nigeria, this resource is designed to empower you with the expertise needed to enhance your production capabilities and drive business growth.

Understanding cnc router mill Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard CNC Router | Versatile, typically used for wood, plastic, and soft metals. | Furniture, signage, prototypes, crafts. | Pros: Affordable, easy to use. Cons: Limited in cutting hard materials. |

| CNC Mill Router | Heavy-duty, designed for precision cutting of hard materials. | Aerospace, automotive, metal fabrication. | Pros: High precision, strong build. Cons: Higher cost, requires skilled operation. |

| Hybrid CNC Router | Combines milling and laser cutting capabilities. | Custom manufacturing, intricate designs. | Pros: Versatile, multi-functional. Cons: Complexity can lead to higher maintenance. |

| Desktop CNC Router | Compact size, ideal for small workshops and personal use. | Hobby projects, educational purposes. | Pros: Space-efficient, cost-effective. Cons: Limited working area and power. |

| Plasma CNC Router | Uses plasma cutting for metal, excellent for thick materials. | Metal art, construction, automotive parts. | Pros: Fast cutting of thick materials. Cons: Requires ventilation and safety measures. |

What Are the Key Characteristics of Standard CNC Routers?

Standard CNC routers are versatile machines primarily used for cutting wood, plastics, and soft metals. They are characterized by their ease of use, making them ideal for small to medium-sized businesses engaged in furniture making, signage production, and various crafts. B2B buyers should consider their budget, as these routers are generally more affordable than specialized machines, but they may lack the capability to handle harder materials.

How Do CNC Mill Routers Differ from Standard Models?

CNC mill routers are built for heavy-duty applications, providing high precision for cutting hard materials such as aluminum and brass. These machines are essential in industries like aerospace and automotive, where accuracy is paramount. B2B buyers must evaluate the cost versus the return on investment, as these machines are more expensive and require skilled operators, but they offer superior performance and durability for demanding tasks.

What Makes Hybrid CNC Routers a Smart Investment?

Hybrid CNC routers combine milling and laser cutting functionalities, making them suitable for custom manufacturing and intricate designs. These machines are highly versatile, allowing businesses to expand their service offerings without investing in multiple machines. However, the complexity of operation may necessitate additional training for staff, which is a key consideration for B2B buyers looking to maximize efficiency.

Why Choose a Desktop CNC Router for Smaller Operations?

Desktop CNC routers are compact and affordable, making them perfect for small workshops or educational environments. They are ideal for hobby projects and low-volume production runs. B2B buyers should note that while these machines are easy to operate and require less space, they have limitations in terms of working area and power, which may not meet the needs of larger projects.

What Are the Advantages of Plasma CNC Routers?

Plasma CNC routers are specialized for cutting metal, particularly thicker materials, using a plasma torch. They are widely used in metal art, construction, and automotive parts manufacturing. The speed and efficiency of plasma cutting make these machines attractive for B2B buyers focused on high-volume production. However, considerations regarding ventilation and safety equipment are crucial due to the nature of the cutting process.

Key Industrial Applications of cnc router mill

| Industry/Sector | Specific Application of cnc router mill | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Woodworking | Custom furniture manufacturing | Enhances design flexibility and precision in production | Ensure machine supports various wood types and has reliable software compatibility. |

| Signage | Creation of intricate signage and displays | Allows for high-quality, detailed outputs that attract customers | Look for machines with high precision and speed for efficient production. |

| Aerospace | Production of composite parts | Reduces waste and improves material utilization | Verify capabilities in machining lightweight and strong materials, such as carbon fiber. |

| Electronics | PCB milling and prototyping | Speeds up the development process and reduces costs | Ensure compatibility with various circuit board materials and sizes. |

| Metalworking | Fabrication of metal components | Increases accuracy and reduces manual labor | Assess the machine’s power and tooling options for diverse metal types. |

How is CNC Router Mill Used in Woodworking?

In the woodworking industry, CNC router mills are pivotal for manufacturing custom furniture and cabinetry. These machines enable precise cutting, engraving, and shaping of various wood types, allowing businesses to create intricate designs that meet customer demands. By automating the production process, companies can significantly reduce labor costs and material waste. For international buyers, it is crucial to select a CNC router that can handle local wood species and is compatible with the software used in design and production.

What Role Does CNC Router Mill Play in Signage Production?

CNC router mills are extensively used in the signage sector to produce detailed and customized signs. These machines can cut and engrave a variety of materials, including acrylic, wood, and metal, allowing for unique branding solutions. The precision offered by CNC technology ensures that every sign meets exact specifications, which is vital for maintaining brand consistency. Buyers should consider sourcing machines that offer versatility in material handling and have strong customer support, especially when dealing with diverse projects across different regions.

How is CNC Router Mill Beneficial for Aerospace Applications?

In aerospace manufacturing, CNC router mills are employed to produce composite parts that are lightweight yet strong. The precision cutting capabilities of these machines allow for intricate designs that enhance aerodynamics and performance. By optimizing material usage and minimizing waste, companies can lower production costs while adhering to stringent industry standards. International buyers in the aerospace sector should prioritize sourcing machines that can handle advanced materials and ensure compliance with global manufacturing regulations.

How Does CNC Router Mill Improve Electronics Prototyping?

CNC router mills are invaluable in the electronics industry for milling printed circuit boards (PCBs) and rapid prototyping. These machines facilitate quick iterations and modifications, significantly shortening the product development cycle. By automating the milling process, companies can achieve consistent quality and reduce errors associated with manual methods. When sourcing CNC routers for electronics applications, buyers should focus on machine specifications that support various PCB materials and ensure compatibility with their design software.

What Advantages Does CNC Router Mill Offer in Metalworking?

In metalworking, CNC router mills are used for fabricating components with high precision. These machines can efficiently cut, engrave, and shape metals, enhancing production capabilities while minimizing manual labor. By integrating CNC technology, businesses can achieve consistent quality and reduce turnaround times for custom metal parts. International buyers should evaluate the machine’s power capacity and tooling options to ensure it meets the demands of various metal types, especially in regions with diverse industrial needs.

3 Common User Pain Points for ‘cnc router mill’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right CNC Router Mill for Specific Projects

The Problem: Many B2B buyers struggle to identify the most suitable CNC router mill for their particular applications. For instance, a furniture manufacturer in Nigeria may require a machine that can handle intricate designs in hardwoods, while a metalworking shop in Brazil might need a router capable of cutting through aluminum and mild steel. The vast array of options can lead to confusion, potentially resulting in costly purchasing mistakes or underutilized machinery that doesn’t meet production needs.

The Solution: To mitigate this issue, businesses should conduct a thorough assessment of their project requirements before making a purchase. This involves analyzing the materials they frequently work with, the complexity of designs they need to execute, and their production volume. Engaging with suppliers who provide comprehensive buyer’s guides or consultation services can also help in making informed decisions. Additionally, investing in machines that offer versatility, such as those that can handle wood, plastics, and light metals, can provide long-term value. Always ensure that the selected CNC router mill comes with robust support and warranty options to safeguard the investment.

Scenario 2: Challenges with Technical Support and Maintenance

The Problem: After investing in a CNC router mill, many businesses find themselves grappling with technical issues or maintenance challenges. A shop in South Africa, for example, may experience downtime due to a lack of accessible support when issues arise, leading to lost productivity and revenue. This is particularly problematic for smaller businesses that may not have in-house technicians or the expertise to troubleshoot equipment malfunctions.

The Solution: When sourcing a CNC router mill, it’s crucial to prioritize suppliers that offer comprehensive technical support and maintenance packages. Look for companies that provide lifetime technical assistance, as well as readily available replacement parts and repair services. Additionally, training programs for operators can enhance the team’s ability to handle minor issues independently, reducing reliance on external support. Establishing a preventive maintenance schedule can also help in identifying potential problems before they lead to significant downtime, ensuring that operations remain smooth and efficient.

Scenario 3: Cost Management and Financing Options for CNC Equipment

The Problem: For many international B2B buyers, particularly in developing regions, the upfront costs associated with purchasing a CNC router mill can be daunting. A manufacturer in Vietnam may wish to upgrade their machinery to stay competitive but faces financial constraints that limit their options. This situation often leads to either opting for subpar equipment or delaying essential upgrades that could enhance productivity and quality.

The Solution: To navigate this financial hurdle, businesses should explore financing options that align with their cash flow and investment strategy. Many suppliers offer financing plans tailored for businesses, which can ease the burden of upfront costs. Furthermore, consider leasing options for CNC machines, which allow for lower initial payments and the flexibility to upgrade as needed. Establishing a budget that includes not only the purchase price but also ongoing operational costs—such as electricity, maintenance, and tooling—will provide a clearer picture of the total investment. Engaging with local banks or financial institutions that understand the manufacturing sector can also yield beneficial financing solutions.

Strategic Material Selection Guide for cnc router mill

What Are the Key Properties of Common Materials Used in CNC Router Mills?

When selecting materials for CNC router mills, it is crucial to understand the properties that influence performance, durability, and suitability for various applications. Here, we analyze four common materials: wood, plastics, aluminum, and composite materials, focusing on their characteristics, advantages, disadvantages, and implications for international B2B buyers.

Wood: A Versatile Choice for CNC Router Mills

Key Properties: Wood is generally lightweight, easy to machine, and offers good dimensional stability. It is not highly resistant to temperature fluctuations but performs well under moderate conditions.

Pros & Cons: Wood is widely available and relatively inexpensive, making it a popular choice for various applications, from furniture to decorative items. However, it can be prone to warping and splitting, which may affect the quality of the final product. Additionally, different wood species have varying densities, which can complicate machining processes.

Impact on Application: Wood is compatible with a wide range of CNC router mills, allowing for intricate designs and carvings. However, moisture content and wood type must be considered to avoid issues during machining.

Considerations for International Buyers: Compliance with local standards for wood products, such as those related to sustainability and treatment against pests, is essential. Buyers from regions like Africa and South America should be aware of the availability of specific wood types and their import regulations.

Plastics: Lightweight and Flexible

Key Properties: Plastics, including acrylic and PVC, are lightweight and resistant to moisture and chemicals. They can withstand moderate temperatures but may deform under excessive heat.

Pros & Cons: Plastics are easy to machine and can be produced in various colors and finishes, making them ideal for signage and decorative applications. However, they can be more expensive than wood and may require specialized tools for optimal machining.

Impact on Application: The versatility of plastics allows for a wide range of applications, from prototypes to end-use products. However, compatibility with specific CNC router mills must be ensured to avoid melting or chipping during machining.

Considerations for International Buyers: Buyers should consider the availability of specific plastic types and their compliance with local regulations, such as those related to recycling and environmental impact. Standards like ASTM for plastics are critical for ensuring quality.

Aluminum: Strength Meets Precision

Key Properties: Aluminum is lightweight yet strong, with excellent corrosion resistance and thermal conductivity. It can withstand higher temperatures compared to wood and plastics.

Pros & Cons: The durability of aluminum makes it suitable for high-precision applications, such as aerospace components. However, it can be more challenging to machine than softer materials, requiring specialized tools and techniques, which can increase manufacturing complexity.

Impact on Application: Aluminum’s strength and resistance to corrosion make it ideal for applications in harsh environments. Its compatibility with CNC router mills allows for intricate designs, but the need for precise machining can lead to increased costs.

Considerations for International Buyers: Compliance with international standards such as DIN and JIS for aluminum products is crucial. Buyers should also consider the availability of aluminum alloys and their specific properties in their local markets.

Composite Materials: The Best of Both Worlds

Key Properties: Composites, such as fiberglass and carbon fiber, offer high strength-to-weight ratios and excellent resistance to environmental factors. They can be engineered to meet specific performance criteria.

Pros & Cons: Composites are ideal for applications requiring lightweight and strong materials, such as in automotive and aerospace industries. However, they can be expensive and may require specialized machining techniques, increasing manufacturing complexity.

Impact on Application: The versatility of composites allows for a wide range of applications, but their compatibility with CNC router mills must be carefully assessed to avoid damage during machining.

Considerations for International Buyers: International buyers should be aware of the specific regulations regarding composite materials in their regions, including compliance with safety and environmental standards.

Summary Table of Material Selection for CNC Router Mills

| Material | Typical Use Case for CNC Router Mill | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Furniture, decorative items | Readily available and inexpensive | Prone to warping and splitting | Low |

| Plastics | Signage, prototypes | Easy to machine and versatile | Can be more expensive | Medium |

| Aluminum | Aerospace components, precision parts | Strong and corrosion-resistant | Challenging to machine | High |

| Composite Materials | Automotive, aerospace applications | High strength-to-weight ratio | Expensive and complex to machine | High |

This guide aims to equip international B2B buyers with the necessary insights to make informed material selections for CNC router mills, ensuring optimal performance and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc router mill

What Are the Key Stages in the Manufacturing Process of CNC Router Mills?

The manufacturing process for CNC router mills involves several critical stages, each designed to ensure that the final product meets the exact specifications required for precision machining. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step is sourcing high-quality raw materials, typically aluminum, steel, or composite materials. Suppliers must adhere to rigorous standards to ensure material integrity. Once the materials are obtained, they undergo cutting and shaping into manageable sizes, ready for further processing. This stage may also involve inspecting the raw materials for defects, which is crucial for maintaining product quality.

-

Forming: This phase encompasses various techniques such as CNC machining, laser cutting, and plasma cutting. CNC machining is particularly significant as it allows for high precision and complex geometries. The forming stage is where the components of the CNC router mill are shaped to the desired specifications, ensuring that they fit together correctly during assembly.

-

Assembly: After the parts are formed, they are assembled. This stage involves fitting together various components, such as the frame, motors, and electronic systems. Skilled technicians typically perform this process, ensuring that each part is securely fastened and aligned correctly. Quality checks are often conducted at this stage to catch any issues before moving to the next phase.

-

Finishing: The final stage includes surface treatment, painting, and coating to enhance durability and aesthetics. This may involve anodizing aluminum components or applying protective coatings to prevent corrosion. The finishing process not only improves the machine’s appearance but also contributes to its longevity and performance.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance is essential in the production of CNC router mills, ensuring that each machine meets international standards and customer expectations. Here are the key aspects of quality assurance that B2B buyers should consider:

-

International Standards Compliance: Many manufacturers adhere to ISO 9001, a globally recognized standard for quality management systems. This certification demonstrates a commitment to consistent quality and continual improvement. Other relevant certifications may include CE marking for European compliance or API standards for specific industrial applications.

-

Quality Control Checkpoints: Quality control (QC) is integrated throughout the manufacturing process, with specific checkpoints established:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During the manufacturing process, QC personnel monitor production to catch defects early. This may include dimensional checks and functional testing of components.

– Final Quality Control (FQC): After assembly, each CNC router mill undergoes a thorough inspection and testing phase to verify that it meets all performance specifications before shipping. -

Common Testing Methods: Manufacturers utilize various testing methods, such as functional tests, load tests, and precision checks, to ensure that machines operate as intended. These tests help identify any potential issues that could affect performance in the field.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in international markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are effective strategies:

-

Conducting Audits: Buyers can perform on-site audits of potential suppliers. This allows them to assess the manufacturing processes, quality control measures, and overall operational standards firsthand.

-

Requesting Quality Reports: Suppliers should provide detailed quality reports, including results from IQC, IPQC, and FQC processes. These documents should outline any defects found and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s operations and product quality. These inspections can be particularly beneficial when dealing with suppliers in regions where local standards may vary.

What Are the Specific Quality Control Nuances for International Buyers?

International B2B buyers must navigate several nuances when it comes to quality control:

-

Regulatory Compliance: Different regions have varying regulatory requirements. Buyers should ensure that suppliers comply with local regulations and international standards relevant to their market. This includes understanding import/export regulations and compliance requirements in their respective countries.

-

Cultural and Communication Barriers: Language differences and cultural nuances can affect quality assurance processes. Establishing clear communication channels and protocols can help mitigate misunderstandings and ensure that quality expectations are met.

-

Logistical Considerations: Shipping and logistics can impact product quality. Buyers should work with suppliers to establish best practices for packaging and handling to minimize damage during transit.

-

Supplier Relationships: Building strong relationships with suppliers can enhance quality assurance. Regular communication and collaboration can lead to better understanding and alignment on quality expectations.

Conclusion: The Importance of Quality Assurance in CNC Router Mill Manufacturing

In conclusion, the manufacturing processes and quality assurance measures for CNC router mills are intricate and vital for ensuring product reliability and performance. B2B buyers must be diligent in evaluating suppliers, understanding their quality control practices, and ensuring compliance with international standards. By taking these steps, buyers can secure high-quality CNC router mills that meet their operational needs and contribute to their business success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc router mill’

When procuring a CNC router mill, especially for international business operations, it’s essential to follow a structured approach. This guide serves as a checklist to help B2B buyers navigate the complexities of sourcing a CNC router mill effectively.

Step 1: Define Your Technical Specifications

Start by outlining the technical specifications required for your projects. Consider factors such as the materials you will be working with (wood, metal, plastic), the size of the work area, and the precision needed for your applications. Clearly defined specifications will guide you in selecting a machine that meets your operational needs and budget.

Step 2: Research Potential Suppliers

Investigate various suppliers to identify those that align with your requirements. Look for manufacturers that specialize in CNC router mills and have a strong reputation in the market. Consider their experience, customer reviews, and product range. A well-established supplier is more likely to provide reliable products and support.

Step 3: Evaluate Supplier Certifications and Compliance

Ensure that potential suppliers comply with international quality standards and certifications. Look for certifications such as ISO 9001 or CE marking, which indicate adherence to quality management principles. Compliance not only assures product quality but also enhances safety and reliability, crucial for your operations.

Step 4: Request Quotes and Compare Pricing

Reach out to multiple suppliers to obtain detailed quotes. Compare pricing but also consider what is included in the price, such as warranties, technical support, and shipping costs. A lower price may not always translate to better value, so ensure you assess the overall package being offered.

Step 5: Assess After-Sales Support and Warranty Terms

Evaluate the after-sales support provided by suppliers, including technical assistance, availability of spare parts, and warranty terms. A robust support system is vital for minimizing downtime and ensuring smooth operations. Ensure you understand the warranty details, such as coverage duration and what it includes.

Step 6: Check Shipping and Logistics Options

Investigate the shipping options available from your chosen suppliers. Consider lead times, shipping costs, and delivery methods, especially if you are sourcing internationally. Ensure that the supplier can accommodate your location and that they have experience with international shipping, which can mitigate potential complications.

Step 7: Read Customer Reviews and Case Studies

Before finalizing your choice, read customer reviews and case studies to gauge the experiences of other buyers. Look for feedback on performance, reliability, and the quality of customer service. This insight can provide valuable information about the supplier’s reputation and the machine’s performance in real-world applications.

Following these steps will empower you to make informed decisions when sourcing a CNC router mill, ultimately enhancing your operational efficiency and productivity.

Comprehensive Cost and Pricing Analysis for cnc router mill Sourcing

When sourcing CNC router mills, understanding the comprehensive cost structure and pricing analysis is essential for making informed purchasing decisions. Here’s a breakdown of the critical cost components and price influencers that B2B buyers should consider.

What Are the Key Cost Components in CNC Router Mill Manufacturing?

The cost structure for CNC router mills comprises several components:

-

Materials: The type of materials used significantly impacts the cost. High-quality metals, plastics, and composite materials increase production expenses. The choice of materials should align with the intended application and desired durability.

-

Labor: Skilled labor is essential for the manufacturing process. Labor costs can vary depending on the region, with countries offering lower wages potentially providing cost advantages. However, quality should not be compromised for lower labor costs.

-

Manufacturing Overhead: This includes expenses related to utilities, facility maintenance, and equipment depreciation. Overhead costs can vary widely based on the manufacturer’s location and operational efficiency.

-

Tooling: Specialized tooling is required for CNC machining, which can add to the initial investment. Buyers should inquire about the tooling included in the pricing and any additional costs for custom tooling.

-

Quality Control (QC): Rigorous QC processes ensure that the machines meet industry standards. The cost of implementing QC measures should be factored into the overall pricing.

-

Logistics: Shipping and handling costs can significantly affect the total price, especially for international buyers. Consideration of freight costs, insurance, and customs duties is crucial for accurate budgeting.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the typical margins in the CNC industry can help buyers assess if they are getting a fair deal.

How Do Price Influencers Affect CNC Router Mill Costs?

Several factors influence the pricing of CNC router mills, including:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to reduced per-unit costs. Buyers should negotiate for better pricing based on larger order commitments.

-

Specifications and Customization: Customized machines tailored to specific applications may incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: The quality of materials used and certifications (e.g., ISO) can affect pricing. Higher-quality machines with certifications typically come at a premium but offer better performance and reliability.

-

Supplier Factors: The manufacturer’s reputation, location, and supply chain efficiency can influence pricing. Established suppliers may charge more due to their reliability and track record.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. These terms dictate who bears the costs and risks associated with shipping, affecting the overall price.

What Are the Best Buyer Tips for Cost-Efficiency in CNC Router Mill Sourcing?

To maximize value when sourcing CNC router mills, consider the following strategies:

-

Negotiation: Engage in negotiations with suppliers. Leverage your purchasing power, especially if committing to a larger volume, to secure better pricing or payment terms.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes initial purchase price, operational costs, maintenance, and potential downtime. This holistic view helps in comparing suppliers effectively.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, and the Middle East should account for additional factors such as currency fluctuations, local tariffs, and shipping delays. Building strong relationships with suppliers can facilitate smoother transactions and better pricing.

-

Research and Compare: Conduct thorough research and compare multiple suppliers to understand the market pricing. Utilize online resources and industry contacts to gather information on the best deals.

In conclusion, a comprehensive understanding of the cost structure and pricing influencers in CNC router mill sourcing empowers B2B buyers to make informed decisions. By leveraging negotiation strategies and considering total costs, buyers can optimize their investments in CNC technology. Always remember that prices can vary widely based on numerous factors, and it’s advisable to seek multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing cnc router mill With Other Solutions

Understanding Alternatives to CNC Router Mills

In the realm of manufacturing and machining, CNC router mills are a popular choice for their versatility and precision. However, there are several alternative solutions available that may better meet specific business needs. This analysis will compare CNC router mills with other viable options, such as traditional milling machines and laser cutting systems, providing B2B buyers with actionable insights to make informed decisions.

Comparison Table

| Comparison Aspect | CNC Router Mill | Traditional Milling Machine | Laser Cutting System |

|---|---|---|---|

| Performance | High precision in wood, plastics, and soft metals | Excellent for hard materials and complex shapes | Exceptional speed and accuracy for thin materials |

| Cost | Moderate ($1,000 – $8,000) | High ($5,000 – $100,000+) | Moderate to high ($2,000 – $50,000) |

| Ease of Implementation | User-friendly, requires basic training | Requires skilled operators and setup | Typically easy to set up, but software can be complex |

| Maintenance | Low to moderate | High, frequent calibration needed | Low, but lens and optics require regular cleaning |

| Best Use Case | Prototyping, signage, furniture | Heavy machining, automotive parts | Cutting thin metals, intricate designs |

Detailed Breakdown of Alternatives

Traditional Milling Machines

Traditional milling machines are known for their robustness and ability to handle hard materials like steel and titanium. They excel in producing intricate parts with high accuracy, making them ideal for industries such as aerospace and automotive. However, the cost of acquiring and maintaining these machines can be prohibitive, often requiring significant investment in skilled labor for operation. Furthermore, the setup and calibration process can be time-consuming, which may not be suitable for businesses looking for quick turnaround times.

Laser Cutting Systems

Laser cutting systems offer unparalleled speed and precision when working with thin materials, particularly metals and plastics. They are highly effective for creating intricate designs and can operate with minimal operator intervention once set up. However, the initial cost can be substantial, and while maintenance is generally low, the equipment requires careful handling, especially the lenses and optics. Laser systems are best suited for businesses focused on detailed cutting tasks, but they may not be as versatile as CNC router mills when it comes to material types and thicknesses.

Conclusion: Choosing the Right Solution for Your Business

When deciding between a CNC router mill and its alternatives, B2B buyers should consider their specific needs, including the types of materials they will be working with, the complexity of the projects, and their budget constraints. CNC router mills offer a balanced solution for various applications, particularly for businesses in woodworking and prototyping. Traditional milling machines are better suited for heavy-duty tasks, while laser cutting systems excel in precision cutting of thin materials. By carefully evaluating these factors, businesses can select the most appropriate solution to enhance their operational efficiency and meet their production goals.

Essential Technical Properties and Trade Terminology for cnc router mill

What Are the Key Technical Properties of CNC Router Mills That B2B Buyers Should Know?

Understanding the technical specifications of CNC router mills is crucial for B2B buyers looking to invest in machinery that meets their operational needs. Here are some essential properties to consider:

-

Material Compatibility

CNC router mills can process a variety of materials, including wood, plastics, aluminum, and even mild steel. Knowing the material compatibility helps businesses select the right machine for their specific applications. For example, if a company primarily works with hardwoods and aluminum, a CNC router capable of handling both will enhance productivity and reduce the need for multiple machines. -

Working Area Size

This specification refers to the maximum dimensions of the material that can be processed by the machine. A larger working area allows for the processing of bigger sheets, which can be advantageous for industries such as furniture manufacturing or signage. Buyers should assess their production requirements to ensure that the working area aligns with their project sizes. -

Tolerance and Precision

Tolerance indicates how closely a machine can reproduce dimensions and is typically expressed in millimeters or inches. High precision is essential in industries like aerospace and automotive, where exact measurements are critical. Understanding the tolerance levels of a CNC router mill allows buyers to ensure that their selected equipment can meet the demands of their specific projects. -

Spindle Power

The spindle power, measured in watts or horsepower, determines the cutting capability of the machine. Higher spindle power is necessary for cutting harder materials or for more complex operations. Buyers should consider the types of materials they will be working with and choose a machine with adequate spindle power to avoid performance issues. -

Feed Rate

The feed rate is the speed at which the machine moves the material during cutting. This can affect both the quality of the cut and the overall production time. A higher feed rate may lead to faster processing but could compromise cut quality, so balancing speed and quality is essential for effective operations. -

Software Compatibility

CNC router mills require compatible software for design and operation. This can include CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) programs. Understanding the software requirements and compatibility ensures seamless operation and integration with existing systems, which can reduce training times and operational disruptions.

Which Trade Terms Are Commonly Used in the CNC Router Mill Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers evaluate the quality and reliability of components used in CNC router mills. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This is crucial for budgeting and inventory management, as higher MOQs may lead to increased upfront costs for businesses with limited production needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. Utilizing RFQs can help buyers compare prices and terms from different suppliers, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers for the delivery of goods. Understanding these terms helps buyers clarify shipping responsibilities, risks, and costs, which is particularly important in international transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. Recognizing lead times is critical for project planning and inventory management, especially in industries with tight production schedules. -

TCO (Total Cost of Ownership)

TCO encompasses all costs associated with purchasing and operating a CNC router mill, including initial purchase price, maintenance, training, and operating costs. Understanding TCO helps buyers evaluate the long-term financial implications of their investment.

By grasping these technical properties and industry terms, B2B buyers can make more informed decisions when selecting CNC router mills that fit their operational needs and business goals.

Navigating Market Dynamics and Sourcing Trends in the cnc router mill Sector

What Are the Current Market Dynamics and Key Trends in the CNC Router Mill Sector?

The CNC router mill sector is experiencing robust growth, driven by the increasing demand for precision machining across various industries, including woodworking, metal fabrication, and prototyping. The global market is expected to expand due to several key factors: the rise of automation, advancements in technology such as IoT and AI, and the growing need for customized solutions. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to enhance their production capabilities, the focus is shifting towards machines that offer versatility, reliability, and cost-effectiveness.

Emerging trends in sourcing highlight the importance of online platforms for procurement, enabling buyers to compare options and access a wider range of suppliers. Additionally, financing options are becoming increasingly relevant as businesses look to invest in high-quality CNC machines without compromising cash flow. The introduction of advanced features in CNC routers, such as enhanced software compatibility and improved cutting technologies, is also attracting attention. Companies are now prioritizing suppliers who provide comprehensive support, including training and technical assistance, to ensure a seamless integration of CNC solutions into their operations.

How Does Sustainability and Ethical Sourcing Impact the CNC Router Mill Sector?

Sustainability is becoming a cornerstone of business strategy in the CNC router mill sector, driven by growing environmental concerns and regulatory pressures. Companies are increasingly aware of the environmental impact of their operations, leading to a push for sustainable practices in sourcing materials and manufacturing processes. Buyers are now looking for suppliers that prioritize eco-friendly materials and production methods, thereby reducing waste and energy consumption.

Ethical sourcing is equally significant, as companies strive to ensure that their supply chains are transparent and responsible. Certifications such as ISO 14001 for environmental management and FSC (Forest Stewardship Council) for wood products are gaining traction among buyers who seek to validate the sustainability claims of their suppliers. By choosing manufacturers committed to ethical practices, businesses not only contribute to environmental conservation but also enhance their brand reputation, appealing to a growing base of environmentally conscious consumers.

What Is the Brief Evolution and History of CNC Router Mills Relevant to B2B Buyers?

The evolution of CNC router mills traces back to the 1950s when numerical control (NC) systems were first developed. Initially, these systems were limited in functionality and primarily used in industrial settings. However, the introduction of computer technology in the 1970s transformed CNC machines into more sophisticated tools, allowing for greater precision and versatility in machining.

By the 1990s, advancements in software and hardware led to the widespread adoption of CNC technology across various sectors, including woodworking, metalworking, and aerospace. Today, CNC router mills are integral to modern manufacturing processes, offering unparalleled capabilities for customization and efficiency. As B2B buyers navigate this landscape, understanding the historical context can provide insights into the technological advancements that continue to shape product offerings and market dynamics.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc router mill

-

How do I select the right CNC router mill for my business needs?

Choosing the right CNC router mill involves assessing your specific applications, materials, and production volume. Evaluate the machine’s capabilities regarding material compatibility (wood, plastics, metals), cutting area size, and precision levels. Additionally, consider the machine’s ease of use, availability of technical support, and warranty terms. It’s beneficial to consult with suppliers and review case studies or testimonials from similar businesses to ensure the chosen machine aligns with your operational requirements. -

What are the key features to look for in a CNC router mill?

When sourcing a CNC router mill, prioritize features such as cutting area dimensions, spindle power, and the machine’s ability to handle various materials. Look for advanced features like automated tool changers, software compatibility, and safety measures. Additionally, consider the machine’s durability and maintenance requirements, as well as the availability of replacement parts and technical support from the supplier to minimize downtime in your operations. -

What is the typical lead time for CNC router mills when ordering internationally?

Lead times for CNC router mills can vary significantly depending on the manufacturer and shipping logistics. Typically, you can expect a lead time of 2 to 8 weeks for production and an additional 1 to 4 weeks for international shipping, depending on the destination and shipping method. It’s advisable to confirm lead times during the procurement process and factor in potential delays due to customs clearance or local regulations. -

What payment terms should I expect when purchasing CNC router mills?

Payment terms for CNC router mills can differ by supplier and region. Common arrangements include upfront payment, partial payments with the balance upon delivery, or financing options. Ensure you clarify the terms before finalizing the purchase, and consider using secure payment methods that provide buyer protection. Additionally, inquire about any applicable taxes, duties, or fees associated with international transactions to avoid unexpected costs. -

How can I vet suppliers of CNC router mills effectively?

To vet suppliers, start by researching their reputation within the industry through reviews, testimonials, and case studies. Verify their experience with international shipments and specific markets like Africa, South America, or Europe. Request references from previous clients and inquire about their after-sales support, including warranty and technical assistance. Additionally, consider visiting their facility or attending trade shows to assess their manufacturing capabilities firsthand. -

What customization options are typically available for CNC router mills?

Many manufacturers offer customization options for CNC router mills, including modifications to cutting area size, spindle type, and additional features such as laser engraving capabilities or automated tool changers. Discuss your specific requirements with potential suppliers to explore available configurations. Customization can enhance the machine’s performance for your unique applications, but be aware that it may also affect lead times and pricing. -

What quality assurance measures should I look for when sourcing CNC router mills?

When sourcing CNC router mills, inquire about the supplier’s quality assurance processes, including material sourcing, manufacturing standards, and inspection protocols. Look for certifications such as ISO 9001, which indicates adherence to quality management systems. Additionally, request information on warranty terms and the availability of technical support, as these factors can impact the long-term reliability and performance of the equipment. -

What logistics considerations should I keep in mind for international shipping of CNC router mills?

Logistics for international shipping of CNC router mills include understanding shipping methods (air vs. sea), customs regulations, and potential tariffs. Work with suppliers who have experience in international logistics to ensure proper documentation and compliance with local laws. It’s also important to consider the installation and setup process upon arrival, so confirm whether the supplier offers on-site assistance or remote support for your team during installation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Cnc Router Mill Manufacturers & Suppliers List

1. MillRight CNC – Alpha Arc Plasma Table

Domain: millrightcnc.com

Registered: 2016 (9 years)

Introduction: {“products”:[{“name”:”Alpha Arc Plasma Table”,”price”:”$8,000.00″,”cutting_area”:”50×50″”,”capabilities”:”Cuts 26 gauge to 1/2″ steel plate; edge start up to 5/8″; sever 1″ steel plate; cuts steel, stainless steel, and aluminum with Hypertherm Powermax 45 Sync.”,”lead_time”:”Approx. 5 weeks”},{“name”:”Mega V 2″,”price”:”$2,299.00″,”capabilities”:”CNC machine for hobby or business use.”},{“name”:”M…

2. SainSmart – Genmitsu CNC Router

Domain: sainsmart.com

Registered: 2011 (14 years)

Introduction: This company, SainSmart – Genmitsu CNC Router, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Shaper Tools – Origin CNC Router

Domain: shapertools.com

Registered: 2015 (10 years)

Introduction: Origin is a handheld CNC router that allows users to cut, carve, and engrave materials with precision. It features a real-time tracking system, a built-in camera for alignment, and a user-friendly interface. Origin is designed for both professionals and hobbyists, enabling them to create complex designs easily. The tool is compatible with various materials, including wood, plastic, and metal, and …

4. Tormach – Compact CNC Mills

Domain: tormach.com

Registered: 2002 (23 years)

Introduction: This company, Tormach – Compact CNC Mills, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. American Micro Inc – CNC Milling Machine & Router

Domain: americanmicroinc.com

Registered: 2001 (24 years)

Introduction: CNC Milling Machine: Designed for heavy-duty materials (Aluminum, Brass, Fiberglass, Steel, Titanium), delivers precise cuts within 1,000th of an inch, operates by moving the workpiece, uses over five axes for control, suitable for industries like Medical, Military, Aerospace. CNC Router: Best for softer materials (foam, plastic), faster RPM than CNC mills, uses rotational speed for cutting, typic…

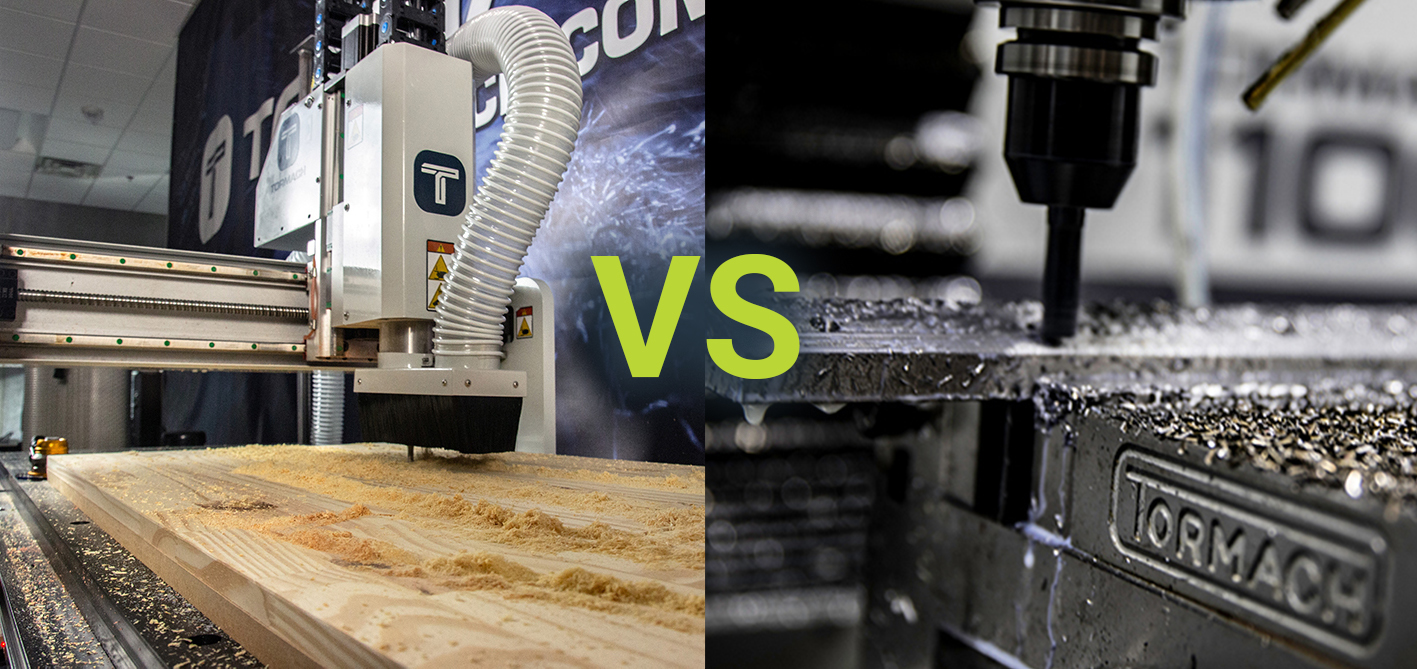

6. CNC Machines – Routers vs. Mills

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: CNC routers and mills differ primarily in their cutting mechanisms and structural designs. A mill uses torque for cutting, while a router relies on rotational speed. Mills typically have a heavier structure and finely grained speed control, making them more rigid and capable of cutting tougher materials. In contrast, routers are lighter and often used for cutting sheet materials. The workpiece mov…

Strategic Sourcing Conclusion and Outlook for cnc router mill

In the dynamic landscape of CNC router mills, strategic sourcing has become pivotal for international B2B buyers seeking competitive advantage. The key takeaways emphasize the importance of aligning machine capabilities with specific project requirements, thereby enhancing operational efficiency and reducing costs. As manufacturers increasingly innovate, options range from entry-level machines for small-scale projects to robust systems suited for heavy industrial applications. This diversity allows businesses in regions like Africa, South America, the Middle East, and Europe to select machines that not only fit their budget but also meet their production demands.

Investing in high-quality CNC routers can lead to significant returns, especially when considering factors such as durability, technical support, and financing options. As global supply chains continue to evolve, the ability to source machines that offer both performance and reliability will be a defining factor for success.

Looking ahead, international buyers are encouraged to leverage these insights and explore the diverse offerings available in the market. By doing so, they can position themselves at the forefront of innovation and efficiency in their respective industries. Engage with trusted suppliers today to secure the best solutions tailored to your unique business needs.