Contents

Manufacturing Insight: Cnc Router Metal Cutting

Precision Metal Fabrication Through Advanced CNC Router Technology

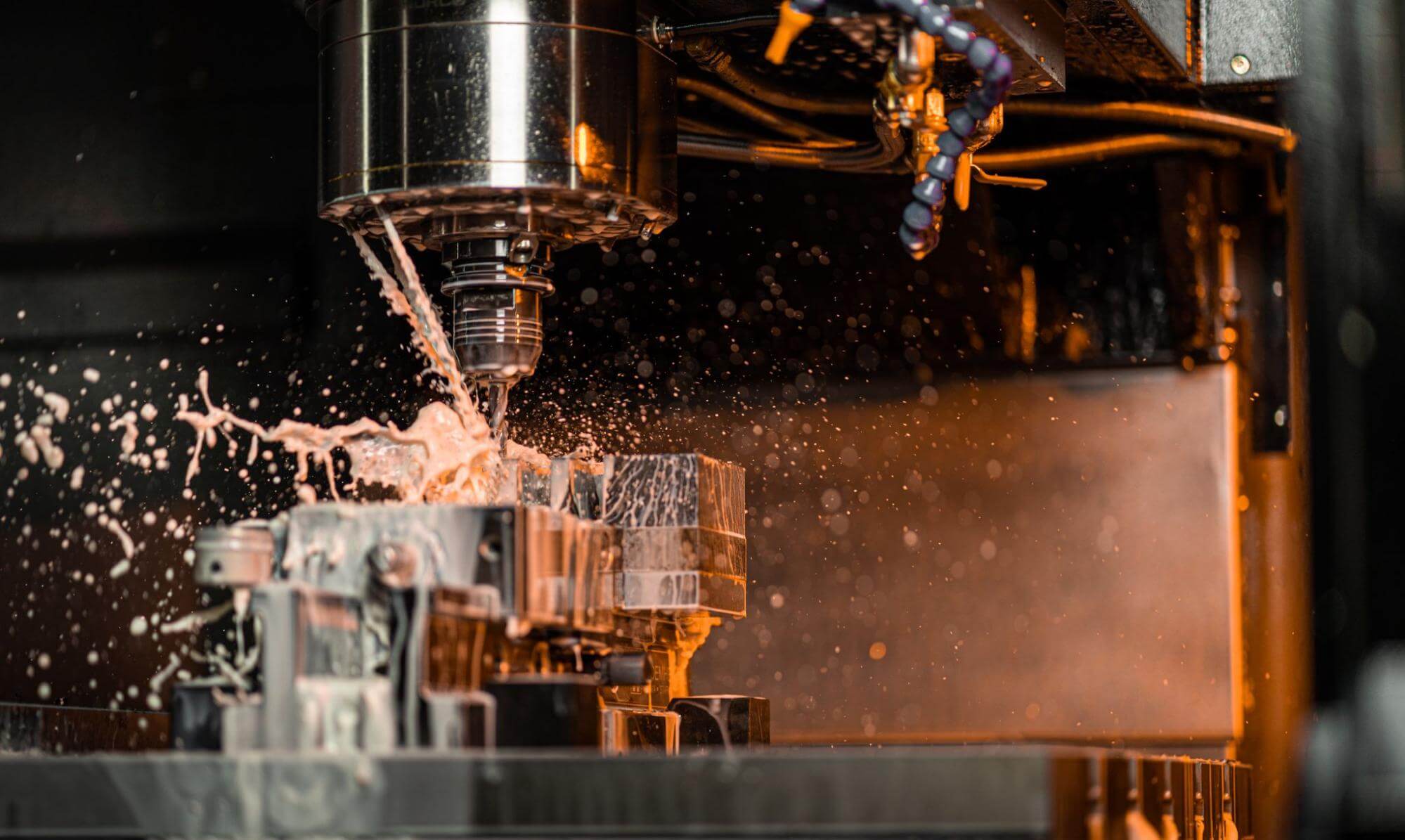

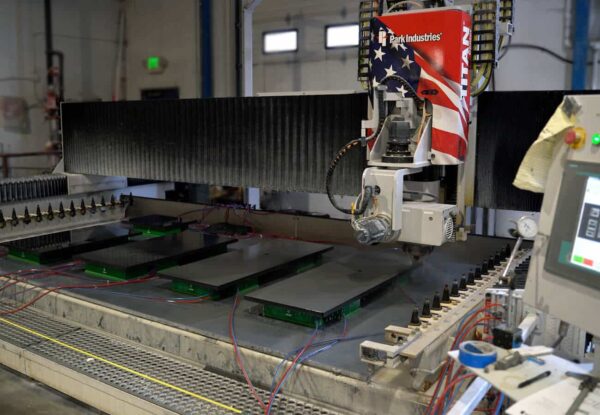

At Honyo Prototype, we engineer high-tolerance metal components using purpose-built CNC routing systems designed specifically for sheet metal applications. While conventional routers often target non-ferrous materials, our industrial-grade platforms integrate rigid spindles, high-pressure coolant systems, and optimized toolpath strategies to achieve consistent, burr-minimized cuts in aluminum, brass, and mild steel up to 1/2″ thickness. This capability bridges prototyping agility with production-grade repeatability, eliminating the need for secondary finishing in many low-to-medium volume runs.

Our Sheet Metal Fabrication suite extends beyond routing to encompass laser cutting, precision bending, welding, and surface treatment—all managed under a single quality-controlled workflow. Every process adheres to ISO 9001 standards, ensuring dimensional accuracy within ±0.005″ and material integrity for mission-critical applications across aerospace, medical, and industrial automation sectors.

Accelerate your procurement cycle with Honyo’s Online Instant Quote platform. Upload CAD files in minutes to receive detailed cost breakdowns, lead time projections, and design-for-manufacturability feedback—no sales intermediary required. This transparency empowers engineering teams to iterate faster while maintaining budgetary control from concept to shipment.

Explore how our integrated metal fabrication solutions reduce time-to-market without compromising precision. Visit Honyo Prototype’s instant quoting portal to initiate your project today.

Technical Capabilities

The term “CNC router metal cutting” typically refers to CNC milling or plasma cutting for metals; however, for precision sheet metal fabrication involving Laser Cutting, Bending, and Welding, the processes are distinct from traditional routing. Below is a technical specification overview focused on Laser Cutting, Bending, and Welding for common materials including Aluminum, Steel, ABS, and Nylon. Note that ABS and Nylon are non-metallic and generally not processed via laser cutting in metalworking contexts unless using CO₂ lasers for cutting or engraving.

| Process | Parameter | Aluminum | Steel (Mild/Carbon) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (Polyamide) |

|---|---|---|---|---|---|

| Laser Cutting | Laser Type | Fiber Laser (preferred) | Fiber Laser | CO₂ Laser | CO₂ Laser (limited) |

| Thickness Range | 0.5 – 20 mm | 0.5 – 25 mm | 0.5 – 10 mm | 0.5 – 8 mm | |

| Power Requirement | 1 – 6 kW (depends on thickness) | 1 – 6 kW | 30 – 150 W | 50 – 100 W | |

| Edge Quality | Smooth, dross-free (with assist gas) | Smooth, minimal burr | Clean cut, slight charring possible | Tends to melt; poor edge quality | |

| Assist Gas | Nitrogen or Argon (high purity) | Oxygen (for mild steel), Nitrogen | Compressed air or inert gas | Compressed air | |

| Notes | Reflective; requires anti-reflection safeguards | High precision, fast cutting speeds | Not typical in metal shops; flammable | Melts easily; not recommended | |

| Bending | Process | Press Brake (CNC-controlled) | Press Brake (CNC-controlled) | Not applicable | Not applicable |

| Thickness Range | 0.8 – 12 mm | 0.8 – 15 mm | N/A | N/A | |

| Minimum Bend Radius | 0.8 × material thickness | 1.0 × material thickness | N/A | N/A | |

| Tooling | Punch and die sets (V-die bending) | Punch and die sets | N/A | N/A | |

| Springback Compensation | Required (5–15° depending on alloy) | Moderate (2–10°) | N/A | N/A | |

| Notes | Use radius tooling for thin sheets | High repeatability with CNC control | Not performed on thermoplastics in metal fab | Flexible; not suitable for press brake | |

| Welding | Process | TIG, MIG, or Laser Welding | MIG, TIG, Spot, Laser Welding | Ultrasonic, Vibration, or Solvent (not arc) | Vibration, Hot Plate, or Laser (low power) |

| Thickness Range | 0.8 – 10 mm (TIG), up to 20 mm (MIG) | 0.8 – 25 mm | 1 – 6 mm | 2 – 8 mm | |

| Joint Preparation | Bevel edges for thick sections | Square or beveled edges | Clean, dry surfaces | Dry, clean surfaces (hygroscopic) | |

| Heat Input Control | Critical (distortion & HAZ) | Moderate to high | Low (to prevent warping) | Low to medium | |

| Post-Processing | Grinding, polishing, passivation | Grinding, painting, powder coating | Trimming, sanding | Machining, finishing | |

| Notes | Argon shielding gas for Al | Preheating may be needed for thick sections | Not arc welded; incompatible with metal welding | Requires pre-drying; sensitive to heat |

Important Notes

CNC routers are generally not used for cutting metals like aluminum or steel in high-volume or high-precision sheet metal environments—instead, fiber laser cutting systems are standard. CNC routers are more commonly used for plastics, wood, and composites. ABS and Nylon are typically machined, 3D printed, or thermoformed rather than processed using metal-centric techniques like press braking or arc welding. In integrated fabrication facilities, hybrid workflows may include laser cutting of metal parts and separate processing of plastics using CO₂ lasers or CNC routers.

From CAD to Part: The Process

Honyo Prototype CNC Metal Cutting Process Overview

Honyo Prototype utilizes CNC milling centers—not routers—for precision metal cutting, as routers lack the rigidity and tooling required for metals. Our streamlined workflow ensures accuracy, cost efficiency, and rapid turnaround for prototypes and low-volume production. Below is the detailed process flow.

CAD File Submission and Validation

Clients upload native CAD files (STEP, IGES, or native SolidWorks) via our secure portal. Our system performs automated geometry validation to check for gaps, non-manifold edges, or unit inconsistencies. Files failing validation trigger an immediate notification with specific error details, preventing downstream delays. Only validated CAD data proceeds to quoting.

AI-Powered Quoting Engine

Validated CAD files enter our proprietary AI quoting system, which analyzes geometric complexity, material requirements, tolerances, and feature density. The AI cross-references real-time machine availability, material costs, and historical production data to generate a technically accurate quote within 2 hours. This includes a manufacturability risk score (1–5 scale) highlighting potential cost drivers like thin walls or deep cavities.

Engineer-Led DFM Analysis

Before order confirmation, our manufacturing engineers conduct a manual Design for Manufacturability review. We identify opportunities to reduce costs or lead times—such as modifying non-critical radii, suggesting alternative stock sizes, or optimizing feature sequencing—without compromising functionality. Clients receive a DFM report with actionable recommendations and revised pricing. 87% of projects see a 15–30% cost reduction after DFM collaboration.

Precision CNC Metal Production

Approved orders move to production on Haas or DMG MORI 3–5 axis vertical machining centers. Key protocols include:

Material certification verification (e.g., 6061-T6 aluminum, 304 stainless steel)

In-process CMM checks for critical dimensions at 25% and 75% completion

Thermal compensation routines to maintain ±0.005mm accuracy

First-article inspection reports (FAIR) provided upon request

All metal cutting uses carbide tooling with high-pressure coolant for chip evacuation and surface integrity.

Quality-Controlled Delivery

Completed parts undergo final inspection per AS9102 standards, including dimensional verification and surface finish checks. Parts ship with material certificates, FAIR documentation, and a traceability tag linking to production logs. Standard lead time is 5–7 business days for 1–10 units, with 99.2% on-time delivery rate. Rush options (72-hour) are available for qualified geometries.

This integrated process eliminates quoting guesswork, reduces iteration cycles, and ensures metal components meet aerospace, medical, and industrial specifications on the first pass. Clients retain full visibility via our production dashboard from CAD upload to shipment.

Start Your Project

Looking for precision CNC router metal cutting services? Honyo Prototype offers high-accuracy machining for industrial applications, with our manufacturing facility based in Shenzhen.

Contact Susan Leo today to discuss your project requirements and receive a competitive quote.

Email: [email protected]

Trust Honyo Prototype for reliable, high-quality metal cutting solutions delivered on time.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.