Introduction: Navigating the Global Market for cnc router hobbyist

In today’s rapidly evolving marketplace, sourcing CNC routers for hobbyist applications poses a significant challenge for international B2B buyers. With the growing popularity of CNC technology among enthusiasts in Africa, South America, the Middle East, and Europe, understanding the nuances of these machines is crucial for making informed purchasing decisions. This guide is designed to navigate the complexities of the CNC router market, providing insights into various types of routers, their applications, and essential supplier vetting processes.

From compact, entry-level models ideal for woodworking and crafting to advanced systems capable of handling intricate designs, this comprehensive resource covers the spectrum of CNC routers available to hobbyists. Buyers will gain a clear understanding of cost structures, including upfront investments and ongoing operational expenses, ensuring they can budget effectively. Additionally, the guide emphasizes the importance of selecting reputable suppliers that provide not only quality equipment but also robust customer support and training.

By leveraging this guide, B2B buyers will be empowered to streamline their purchasing processes, reduce risks, and ultimately enhance their production capabilities. Whether you’re looking to expand your workshop’s offerings or simply invest in a high-quality CNC router, this resource serves as an invaluable tool for making strategic decisions in the global market.

Understanding cnc router hobbyist Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Benchtop CNC Routers | Compact size, often plug-and-play, lower cost | Prototyping, small-scale production | Pros: Affordable, easy to use; Cons: Limited cutting area, less powerful. |

| Large Format CNC Routers | Extensive working area (e.g., 4×4 or larger) | Sign making, cabinetry, large projects | Pros: Handles large materials; Cons: Higher initial investment, requires more space. |

| Hybrid CNC Routers | Combines milling and laser cutting capabilities | Versatile applications in woodworking and metalworking | Pros: Multi-functional; Cons: Complexity in operation, higher maintenance. |

| DIY CNC Kits | Customizable, assembly required, cost-effective | Hobby projects, educational purposes | Pros: Tailored to specific needs; Cons: Requires technical skill for assembly. |

| Industrial CNC Routers | High precision, robust build, advanced features | Mass production, detailed engraving | Pros: Exceptional accuracy and durability; Cons: Significant investment, requires skilled operation. |

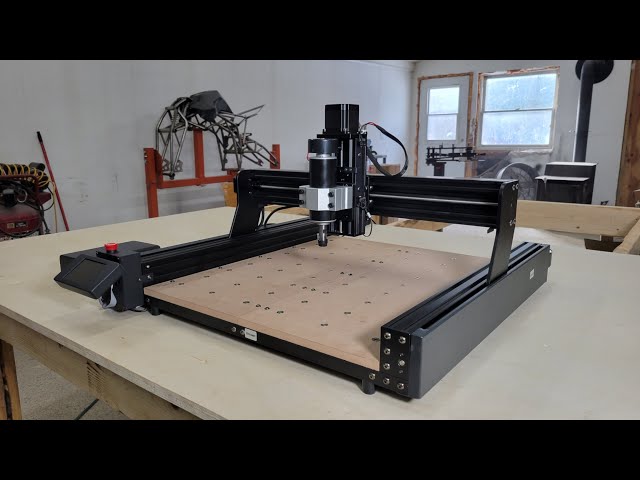

What Are Benchtop CNC Routers and Who Should Use Them?

Benchtop CNC routers are ideal for hobbyists and small businesses looking for a compact solution. With a plug-and-play design, they offer ease of use, making them suitable for those with little experience in CNC machining. Their affordability and versatility allow for various applications, such as prototyping and small-scale production. However, their limited cutting area and power may not meet the demands of larger projects.

How Do Large Format CNC Routers Benefit Businesses?

Large format CNC routers provide expansive working areas, allowing for the processing of larger materials, such as sheets of plywood. These machines are particularly beneficial for industries focused on sign making and cabinetry. While they enable the creation of intricate designs and large parts, the higher initial investment and space requirements may be a consideration for some businesses.

What Advantages Do Hybrid CNC Routers Offer?

Hybrid CNC routers are designed to perform both milling and laser cutting, making them highly versatile for various applications in woodworking and metalworking. They are perfect for businesses that require multi-functional capabilities without investing in multiple machines. However, their complexity can pose challenges in operation and maintenance, requiring a skilled operator to maximize their potential.

Why Consider DIY CNC Kits for Educational Purposes?

DIY CNC kits are an excellent choice for educational institutions and hobbyists who want to customize their machines. These kits offer a cost-effective way to delve into CNC technology while allowing users to tailor features to specific needs. However, buyers should be prepared for the assembly process, which requires technical skills and time investment.

What Makes Industrial CNC Routers a Smart Investment?

Industrial CNC routers are built for high precision and durability, making them suitable for mass production and detailed engraving tasks. These machines are essential for businesses that prioritize accuracy and efficiency in their operations. However, the significant investment and need for skilled operators can be barriers for smaller enterprises or startups.

Key Industrial Applications of cnc router hobbyist

| Industry/Sector | Specific Application of CNC Router Hobbyist | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Woodworking | Custom Furniture Production | High precision in intricate designs, reducing waste | Machine size, spindle power, and software compatibility |

| Signage | Personalized Sign Creation | Unique branding options and rapid production | Material compatibility, engraving capabilities |

| Prototyping | Rapid Prototyping of Components | Accelerated design iterations and reduced time-to-market | Size of work area, software integration, and cost |

| Arts & Crafts | Decorative Art and Sculpture Production | Ability to create complex designs with minimal labor | Tooling options, ease of use, and customer support |

| Educational Institutions | Hands-on Learning Projects for Students | Engaging learning experiences through practical applications | Safety features, training support, and warranty terms |

How is CNC Router Hobbyist Used in Woodworking?

In the woodworking industry, CNC routers are instrumental in producing custom furniture. Hobbyists leverage these machines to create intricate designs with high precision, significantly reducing material waste. Buyers in this sector need to consider machine size, spindle power, and software compatibility to ensure that their projects can be executed efficiently. With the ability to handle various types of wood, CNC routers offer a versatile solution for businesses aiming to enhance their product offerings.

What Role Does CNC Router Hobbyist Play in Signage Production?

CNC routers are essential tools in the signage industry, where they facilitate the creation of personalized signs. These machines allow businesses to produce unique branding elements quickly, catering to specific customer needs. For international buyers, material compatibility and engraving capabilities become critical considerations, as different regions may have diverse preferences for sign materials. The ability to produce high-quality, customized signs in a timely manner enhances customer satisfaction and strengthens brand identity.

How Can CNC Router Hobbyist Accelerate Prototyping?

In prototyping, CNC routers enable rapid development of components, allowing businesses to iterate designs quickly. This capability is crucial for companies aiming to reduce their time-to-market. Buyers must evaluate the size of the work area and software integration options to ensure the router meets their specific prototyping needs. The investment in a CNC router can lead to significant cost savings and increased efficiency in product development cycles.

What Benefits Do Arts and Crafts Businesses Gain from CNC Router Hobbyist?

Arts and crafts businesses utilize CNC routers for decorative art and sculpture production, enabling them to create complex designs with minimal labor. This technology empowers artisans to push the boundaries of creativity while maintaining high-quality output. When sourcing CNC routers, businesses should prioritize tooling options, ease of use, and customer support to ensure a smooth operation. This investment not only enhances creativity but also improves overall production capabilities.

How Can Educational Institutions Leverage CNC Router Hobbyist?

Educational institutions can benefit from CNC routers by incorporating them into hands-on learning projects for students. These machines provide engaging experiences that enhance practical skills in design and manufacturing. Safety features, training support, and warranty terms are vital factors for educational buyers, ensuring that the equipment is safe and user-friendly for students. By integrating CNC technology into their curricula, institutions prepare students for the demands of modern industries.

3 Common User Pain Points for ‘cnc router hobbyist’ & Their Solutions

Scenario 1: Struggling with Material Size Limitations

The Problem: Many hobbyist CNC router users find themselves constrained by the size limitations of their equipment. For instance, a buyer may purchase a 4×4 CNC router, only to realize that their projects often require larger materials, such as 4×8 sheets of plywood. This limitation can result in frustration, as it affects production efficiency and can lead to additional costs associated with cutting materials into smaller sections or investing in more extensive machinery.

The Solution: To mitigate this issue, buyers should look for CNC routers that offer the ability to pass larger materials through the machine. For example, models like the Shapeoko 5 Pro are designed with an open front-to-back configuration, allowing users to cut parts of any length as long as the material is supported adequately. When sourcing a CNC router, it’s crucial to evaluate the machine’s specifications, ensuring it can accommodate the types of materials most commonly used in the buyer’s projects. Additionally, investing in clamping tools and workholding devices can help securely support larger pieces during the cutting process, enabling more efficient and versatile project execution.

Scenario 2: Overcoming Software Integration Challenges

The Problem: A common challenge faced by CNC router hobbyists is the integration of software tools necessary for design and operation. Buyers may encounter difficulties in finding software that is compatible with their CNC machinery, particularly if they are using a router from a lesser-known brand. This can lead to wasted time and resources, as well as a steep learning curve for those who are not technologically savvy.

The Solution: Buyers should prioritize CNC routers that come with comprehensive software packages included in the purchase. For example, brands like Carbide 3D offer advanced software compatible with their machines, easing the transition for users. When selecting a CNC router, inquire about the software’s usability, support, and training resources. It’s also beneficial to explore communities and forums dedicated to CNC machining, where users can share insights and troubleshoot common software-related issues. Additionally, consider routers that offer a plug-and-play experience, minimizing setup time and allowing users to focus on their creative projects rather than technical challenges.

Scenario 3: Navigating Quality vs. Cost in CNC Router Purchases

The Problem: B2B buyers often struggle to balance quality and cost when investing in CNC routers for hobbyist applications. They may find lower-priced options that promise high performance but ultimately lack durability or precision, leading to unsatisfactory results. This creates a dilemma: invest more upfront for a quality machine or risk frequent repairs and replacements with cheaper alternatives.

The Solution: To navigate this challenge, buyers should conduct thorough market research and look for CNC routers that offer a good balance of performance and value. It’s advisable to assess user reviews and testimonials from other hobbyists to gauge the reliability and quality of different machines. Furthermore, consider brands that provide warranties and customer support, such as Carbide 3D, which offers a one-year warranty and 60 days of damage coverage. This ensures that buyers have recourse in case of issues, thereby protecting their investment. Additionally, consider the long-term costs associated with maintenance and replacement parts when calculating the total cost of ownership, as this can significantly influence the overall value of the machine.

Strategic Material Selection Guide for cnc router hobbyist

What Are the Key Properties of Common Materials for CNC Routing?

CNC router hobbyists often work with a variety of materials, each with unique properties that influence performance and application suitability. Understanding these materials is crucial for international B2B buyers looking to optimize their production capabilities.

Wood: A Versatile Material for CNC Routing

Wood is one of the most popular materials for CNC routers, especially among hobbyists. Its key properties include a natural aesthetic appeal, ease of machining, and a wide range of densities and grain patterns. Wood is generally lightweight, making it easy to handle and transport.

Pros: Wood is relatively inexpensive and readily available in many regions, including Africa and South America. It offers excellent machinability and can be finished with various coatings to enhance durability.

Cons: However, wood is susceptible to moisture and can warp or swell, leading to dimensional instability. It may also require additional finishing processes to achieve a smooth surface.

Impact on Application: Wood is ideal for projects like furniture making, signage, and decorative items. Its compatibility with various finishes makes it suitable for both indoor and outdoor applications, provided proper treatment is applied.

Considerations for International Buyers: Compliance with local regulations regarding sustainable sourcing and treatment of wood is essential. Buyers should also consider the availability of specific wood types in their regions, as well as any standards related to wood products (e.g., ASTM D198 for structural wood).

Acrylic: A Popular Choice for Signage and Displays

Acrylic is another material frequently used in CNC routing, particularly for signage and displays. Its key properties include high clarity, UV resistance, and the ability to be easily cut and shaped.

Pros: Acrylic is lightweight and offers excellent optical clarity, making it suitable for applications that require visual appeal. It is also resistant to UV light, which helps maintain its appearance over time.

Cons: On the downside, acrylic can be more expensive than wood and is prone to scratching. It can also emit harmful fumes when cut, necessitating proper ventilation during machining.

Impact on Application: Acrylic is commonly used for creating signs, displays, and protective barriers. Its compatibility with various colors and finishes allows for creative designs.

Considerations for International Buyers: Buyers should be aware of the specific grades of acrylic available in their regions and ensure compliance with local safety standards regarding material handling and machining.

Aluminum: A Durable Option for Precision Applications

Aluminum is a favored material for CNC routing due to its strength-to-weight ratio and corrosion resistance. It is commonly used in applications requiring precision and durability.

Pros: Aluminum is highly durable, lightweight, and resistant to corrosion, making it suitable for both indoor and outdoor applications. It can be anodized or painted for additional protection and aesthetic appeal.

Cons: The main drawback of aluminum is its higher cost compared to wood and acrylic. Additionally, machining aluminum requires specialized tools and techniques to achieve the desired finish.

Impact on Application: Aluminum is ideal for parts in automotive, aerospace, and industrial applications where strength and precision are critical.

Considerations for International Buyers: Compliance with international standards such as ASTM B221 for aluminum extrusions is crucial. Buyers should also consider the availability of specific aluminum alloys in their regions.

MDF (Medium Density Fiberboard): Cost-Effective and Easy to Work With

MDF is a manufactured wood product made from wood fibers, wax, and resin. It is known for its smooth surface and uniform density, making it an excellent choice for CNC routing.

Pros: MDF is relatively inexpensive and easy to machine, allowing for intricate designs and smooth finishes. It is also free from knots and grain patterns, providing a consistent surface.

Cons: However, MDF is not as strong as solid wood or plywood and can be susceptible to moisture damage. It also produces fine dust during machining, which requires proper dust collection systems.

Impact on Application: MDF is commonly used for furniture, cabinetry, and decorative elements. Its smooth surface makes it ideal for painting and veneering.

Considerations for International Buyers: Buyers should be aware of local regulations regarding formaldehyde emissions from MDF and ensure compliance with standards such as CARB (California Air Resources Board).

Summary Table of Material Properties

| Material | Typical Use Case for CNC Router Hobbyist | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Furniture, signage, decorative items | Readily available, easy to machine | Susceptible to moisture, warping | Low |

| Acrylic | Signage, displays, protective barriers | High clarity, UV resistant | Prone to scratching, emits fumes | Medium |

| Aluminum | Precision parts in automotive, aerospace | Durable, corrosion resistant | Higher cost, requires specialized tools | High |

| MDF | Furniture, cabinetry, decorative elements | Smooth surface, easy to machine | Not as strong, moisture susceptible | Low |

This strategic material selection guide provides essential insights for B2B buyers in the CNC router hobbyist market, helping them make informed decisions based on material properties, application suitability, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc router hobbyist

What Are the Main Stages in the Manufacturing Process of CNC Routers for Hobbyists?

The manufacturing process of CNC routers designed for hobbyists typically involves several key stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves selecting high-quality materials that meet specific engineering standards. Common materials include aluminum, steel, and high-density plastics, chosen for their durability and machinability. Suppliers often perform initial tests to verify material integrity, including checks for impurities and physical properties.

-

Forming: In this phase, the selected materials undergo various forming techniques, such as machining, laser cutting, or water jet cutting. CNC machining centers are frequently employed to achieve precise dimensions, ensuring that components fit together seamlessly. Advanced techniques such as 3D printing may also be used for prototyping parts, allowing for rapid iterations and design adjustments before mass production.

-

Assembly: Once the components are formed, they are assembled into a cohesive unit. This may involve attaching the spindle, motors, and other electronic components. During assembly, manufacturers utilize jigs and fixtures to maintain alignment and accuracy. Automation is increasingly common at this stage, with robotic arms assisting in the assembly process to improve efficiency and reduce the likelihood of human error.

-

Finishing: The final stage involves surface treatments such as anodizing, powder coating, or painting to enhance aesthetics and corrosion resistance. Quality assurance during this stage is crucial, as it ensures that the finished product meets customer expectations in both functionality and appearance.

How Is Quality Assurance Implemented in CNC Router Manufacturing?

Quality assurance (QA) is essential in the manufacturing of CNC routers, ensuring that products meet international standards and customer requirements.

-

Relevant International Standards: Many manufacturers adhere to international quality management standards such as ISO 9001, which outlines criteria for establishing a quality management system. Compliance with CE marking requirements is also critical for ensuring that products meet safety and environmental standards in Europe. For specific industries, certifications like API (American Petroleum Institute) may be necessary, particularly for routers used in oil and gas applications.

-

Quality Control Checkpoints: Quality control (QC) involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial step checks raw materials and components upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify any deviations from quality standards before they escalate into larger issues.

– Final Quality Control (FQC): At this stage, the completed CNC router undergoes rigorous testing, including functional tests, safety checks, and performance evaluations. -

Common Testing Methods: Manufacturers employ various testing methods to ensure product integrity. These may include functional testing to verify operational capabilities, stress testing to evaluate durability, and dimensional inspections using precision measuring tools to confirm adherence to specifications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to verify the quality control processes of CNC router manufacturers. Here are several strategies to consider:

-

Audits and Inspections: Conducting on-site audits of potential suppliers allows buyers to assess the manufacturing processes and quality assurance practices firsthand. This can involve reviewing documentation, observing production lines, and assessing the overall cleanliness and organization of the facility.

-

Quality Reports: Requesting detailed quality reports can provide insights into a manufacturer’s compliance with international standards. These reports should outline results from various quality checks and any corrective actions taken in response to non-conformities.

-

Third-Party Inspections: Engaging independent third-party inspection services can add another layer of assurance. These organizations can perform unbiased evaluations of the manufacturing processes and product quality, providing an objective assessment that is crucial for international buyers.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When dealing with international suppliers, especially from regions such as Africa, South America, the Middle East, and Europe, B2B buyers should be aware of specific nuances related to quality control and certification:

-

Cultural Differences: Understanding local business practices and cultural differences can influence how quality control is prioritized and implemented. Buyers should approach negotiations with an appreciation for these differences to foster strong supplier relationships.

-

Regulatory Compliance: Different countries have varying regulatory requirements. For example, products sold in Europe must comply with CE marking standards, while in the Middle East, local certifications may be necessary. Buyers should ensure that suppliers are familiar with and adhere to the relevant regulations in their respective markets.

-

Communication and Transparency: Maintaining open lines of communication with suppliers is crucial. Buyers should seek transparency regarding production capabilities, quality standards, and any challenges the supplier may face. This dialogue can help mitigate risks associated with quality assurance and ensure that expectations are clearly understood.

Conclusion: Why Quality Assurance Matters for CNC Router Hobbyists

For B2B buyers in the CNC router market, understanding the manufacturing processes and quality assurance practices is vital for making informed purchasing decisions. By focusing on the key stages of manufacturing, implementing robust quality control measures, and verifying supplier practices, businesses can ensure they invest in high-quality CNC routers that meet their operational needs. As the market continues to evolve, prioritizing quality assurance will not only enhance product reliability but also contribute to long-term business success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc router hobbyist’

Introduction

This practical sourcing guide aims to assist B2B buyers in effectively procuring CNC routers tailored for hobbyists. As the market for CNC machines continues to grow, understanding the key factors in selecting the right equipment can enhance operational efficiency and product quality. This checklist will provide a structured approach to ensure informed purchasing decisions.

Step 1: Define Your Technical Specifications

Establishing your technical requirements is the first step in the sourcing process. Consider the dimensions of the projects you intend to undertake, as this will dictate the size of the CNC router you need.

– Key Considerations:

– Working area size (e.g., 4×4 or larger).

– Material types (wood, plastic, metal) and thickness.

Step 2: Research and Compare Different Models

Investigate various CNC router models available in the market, focusing on their capabilities and features. Different machines cater to different applications, so understanding these distinctions is essential for meeting your specific needs.

– Focus On:

– Accuracy and precision of the machine.

– Power requirements and spindle options.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and quality. Request detailed company profiles, product catalogs, and case studies that illustrate their expertise in the CNC router space.

– Action Points:

– Ask for references from previous customers.

– Review their warranty and support services.

Step 4: Verify Supplier Certifications and Compliance

Ensure that suppliers adhere to international quality standards and certifications relevant to CNC machinery. This is crucial for maintaining safety and operational efficiency in your workshop.

– Important Certifications:

– ISO certifications (e.g., ISO 9001).

– CE marking for compliance with European safety standards.

Step 5: Assess After-Sales Support and Training

Consider the after-sales support offered by the supplier, as this can significantly impact your operational success. Comprehensive training and responsive customer service can ease the learning curve associated with new machinery.

– Look For:

– Availability of training sessions (online or in-person).

– Technical support response times.

Step 6: Request Quotes and Evaluate Pricing

Gather quotes from multiple suppliers to assess the market price range and identify competitive options. Be cautious of prices that seem too low, as they may indicate compromised quality.

– Considerations:

– Include potential additional costs (shipping, installation, training).

– Evaluate financing options if available.

Step 7: Make an Informed Decision

After evaluating all factors, make an informed purchasing decision based on the data collected. Ensure that your choice aligns with your operational needs and budget constraints.

– Final Checklist:

– Confirm the technical specifications meet project requirements.

– Ensure supplier reliability and support mechanisms are in place.

By following this step-by-step checklist, B2B buyers can confidently navigate the procurement process for CNC routers, ensuring they select the right machine to meet their hobbyist needs effectively.

Comprehensive Cost and Pricing Analysis for cnc router hobbyist Sourcing

What Are the Key Cost Components in CNC Router Hobbyist Sourcing?

When sourcing CNC routers for hobbyist applications, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality components, such as aluminum frames, precision motors, and advanced electronics, contribute to a higher price. Conversely, opting for lower-grade materials may reduce upfront costs but can lead to increased maintenance and replacement expenses over time.

-

Labor: Skilled labor is often required for assembly and testing, particularly for more complex CNC machines. Labor costs can vary based on geographic location, with regions that have a higher cost of living typically reflecting this in their pricing.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment depreciation. Efficient manufacturing processes can help minimize these costs, impacting the final price of the machine.

-

Tooling and Quality Control (QC): High-quality tooling and rigorous QC processes ensure that the machines meet performance and safety standards. Although these factors add to the initial cost, they can significantly reduce the likelihood of defects and failures, enhancing long-term value.

-

Logistics: Shipping and handling fees are crucial, especially for international buyers. Costs can escalate due to customs duties, taxes, and freight charges, particularly for larger machines.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and risks. Understanding the supplier’s market positioning can provide insights into pricing strategies.

How Do Price Influencers Affect CNC Router Hobbyist Costs?

Several factors can influence the pricing of CNC routers, including:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders can lead to significant discounts. Buyers should assess their needs and consider consolidating purchases with other hobbyists or businesses to achieve better pricing.

-

Specifications and Customization: Custom features or specifications often come at a premium. Buyers should evaluate whether these enhancements are necessary for their projects or if standard models suffice.

-

Materials and Quality Certifications: Machines built with certified materials and components typically carry a higher price tag. However, these certifications can enhance reliability and safety, which may justify the investment.

-

Supplier Factors: The reputation and reliability of the supplier can greatly influence price. Established suppliers may offer higher quality and better support but at a premium price. Newer or less established companies might provide lower prices but could lack in service or quality assurance.

-

Incoterms: Understanding the terms of trade (Incoterms) is essential for international buyers. Different terms can affect the total landed cost, including responsibilities for shipping, insurance, and customs clearance.

What Buyer Tips Can Help Achieve Cost-Efficiency in CNC Router Purchases?

International B2B buyers should consider several strategies to enhance cost-efficiency:

-

Negotiation: Always be prepared to negotiate terms and pricing. Suppliers may have flexibility, especially for larger orders or long-term contracts.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, repairs, and operational efficiency. A cheaper machine might lead to higher costs in the long run if it requires frequent repairs or has lower operational efficiency.

-

Pricing Nuances for International Buyers: When sourcing from different regions (e.g., Africa, South America, Middle East, Europe), be aware of currency fluctuations, import tariffs, and local market conditions that may impact pricing. Additionally, consider local suppliers who might offer better service or lower shipping costs.

-

Research and Comparison: Conduct thorough market research and compare different suppliers and models. Utilize online resources, reviews, and forums to gather insights from other hobbyists.

Disclaimer on Pricing

The prices mentioned in various sources can vary widely based on market conditions, supplier policies, and specific configurations. It is advisable for buyers to request quotes tailored to their specific needs and to verify all costs, including potential hidden fees related to shipping and customs.

Alternatives Analysis: Comparing cnc router hobbyist With Other Solutions

When evaluating options for precision cutting and engraving, businesses often consider various technologies that can fulfill similar roles as a CNC router designed for hobbyists. Understanding the strengths and weaknesses of each alternative is crucial for making an informed purchasing decision, especially for international B2B buyers looking for effective solutions tailored to their specific needs.

| Comparison Aspect | Cnc Router Hobbyist | Laser Cutter | Manual Milling Machine |

|---|---|---|---|

| Performance | High precision; ideal for wood, plastics, and light metals | Excellent for detailed cuts; suitable for a wide range of materials | Very precise but slower; best for metals and complex shapes |

| Cost | $1,000 – $4,500 | $2,000 – $15,000 | $3,000 – $10,000 |

| Ease of Implementation | User-friendly; often plug-and-play | Requires setup; software learning curve | Requires skilled operators; complex setup |

| Maintenance | Low maintenance needs; regular bit changes | Moderate; lens cleaning and alignment needed | High; requires regular upkeep and skilled maintenance |

| Best Use Case | Small-scale woodworking, sign-making, and prototyping | Intricate engraving, cutting thin materials, and industrial applications | Heavy-duty machining, prototyping, and production of complex parts |

How Does a Laser Cutter Compare to a CNC Router Hobbyist?

Laser cutters excel in providing detailed cuts and engravings on a variety of materials, including wood, acrylic, and metals. Their high precision and ability to create intricate designs make them suitable for applications in signage, jewelry making, and industrial parts. However, they come with a higher price tag and require more technical knowledge for operation and maintenance. Additionally, laser cutters may not be as effective for thick materials compared to CNC routers, which can handle larger and denser substrates.

What Are the Advantages of a Manual Milling Machine Over a CNC Router Hobbyist?

Manual milling machines offer exceptional precision and are particularly advantageous for machining metals. They allow for more control over the cutting process, making them ideal for complex shapes and detailed work. However, they require skilled operators and regular maintenance, which can drive up costs. Unlike CNC routers, manual mills are less user-friendly and have a steeper learning curve, making them less suitable for hobbyists or businesses looking for an easy-to-implement solution.

Conclusion: How to Choose the Right Solution for Your Business Needs?

Selecting the right technology hinges on understanding your specific business requirements, including the types of materials you work with, the precision needed, and your budget. For businesses focused on smaller-scale woodworking and prototyping, a CNC router hobbyist may offer the best value. Conversely, if your operations require intricate cuts on various materials, a laser cutter might be the more appropriate investment. For those in heavy-duty machining sectors, a manual milling machine could provide the precision and capability needed despite its higher operational demands. Evaluating these aspects will help B2B buyers make a choice that aligns with their operational goals and enhances productivity.

Essential Technical Properties and Trade Terminology for cnc router hobbyist

What Are the Key Technical Properties of CNC Routers for Hobbyists?

Understanding the essential technical properties of CNC routers is crucial for hobbyists looking to optimize their projects. Here are some of the most critical specifications to consider:

-

Working Area Dimensions

The working area refers to the maximum size of the material that can be processed by the CNC router. For example, a 4×4 CNC router has a working area of 48 inches by 48 inches. This specification is vital for B2B buyers as it determines the scale of projects that can be undertaken. A larger working area allows for more extensive and complex designs, making it a crucial factor for businesses involved in sign-making or custom woodworking. -

Spindle Power

The spindle power, measured in horsepower (HP) or kilowatts (KW), indicates the router’s cutting capability. For instance, a 1.25 HP spindle is suitable for softer materials, while a 3 HP spindle can handle tougher materials like hardwood or aluminum. B2B buyers should consider spindle power as it directly impacts the router’s performance and versatility in different applications. -

Material Compatibility

CNC routers can work with various materials, including wood, plastics, and metals. Understanding the material compatibility of a router is essential for buyers to ensure they can meet customer demands. A machine that can handle multiple material types increases marketability and expands project potential. -

Precision and Tolerance

Precision is typically indicated by the machine’s tolerance level, often expressed in millimeters (mm) or inches. For example, a tolerance of ±0.01 mm signifies high accuracy in cutting. This property is critical for businesses that require detailed and intricate designs, such as custom engraving or prototyping. -

Software Compatibility

The ability of a CNC router to integrate with various software programs, such as CAD/CAM applications, enhances its usability. Many routers come with proprietary software, but compatibility with industry-standard software is a significant advantage. Buyers should prioritize machines that offer flexibility in software use to streamline design processes.

What Are Common Trade Terms in the CNC Router Industry?

Familiarizing yourself with industry jargon is essential for effective communication and negotiation in the CNC router market. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the CNC router industry, understanding OEM relationships is crucial for sourcing quality parts and ensuring compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is vital for B2B buyers to understand, as it impacts inventory management and initial investment costs. Knowing the MOQ helps businesses plan their purchases effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and availability for specific products. This term is fundamental for B2B buyers seeking competitive pricing and understanding market rates for CNC routers and components. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in the shipping process. Familiarity with these terms is essential for international transactions, as they determine who bears the risk and costs of shipping. -

Lead Time

Lead time refers to the period between placing an order and receiving the goods. Understanding lead times is crucial for B2B buyers to manage project timelines and inventory effectively. -

CNC (Computer Numerical Control)

CNC refers to the automation of machine tools via computers executing pre-programmed sequences. This term is fundamental in the industry, as it describes the technology behind modern routing machines and their capabilities.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance their operational efficiency and product offerings in the competitive CNC router market.

Navigating Market Dynamics and Sourcing Trends in the cnc router hobbyist Sector

What Are the Key Market Dynamics and Trends Influencing the CNC Router Hobbyist Sector?

The CNC router hobbyist sector is experiencing notable growth, driven by several global factors. The rise in DIY culture and home-based crafting, particularly in regions such as Africa, South America, the Middle East, and Europe, has created a fertile ground for market expansion. As more individuals and small businesses seek to enhance their production capabilities with affordable technology, the demand for versatile CNC routers has surged. Key trends include the increasing availability of user-friendly machines, the integration of advanced software, and the growing popularity of hybrid models that combine CNC routing with laser cutting capabilities.

Moreover, the international market is witnessing a shift towards modular and scalable CNC systems that can accommodate a wide range of materials, from wood to plastics and metals. This trend is particularly beneficial for B2B buyers who are looking for machinery that can grow alongside their business needs. Additionally, e-commerce platforms are facilitating easier access to CNC router products, enabling buyers from diverse geographical regions to compare options and make informed purchasing decisions.

Emerging technologies, such as automation and smart manufacturing, are also influencing sourcing trends. Companies are increasingly focusing on integrating IoT solutions to enhance operational efficiency and product monitoring. This technological advancement allows hobbyists and small businesses to optimize their workflow, reduce waste, and improve overall productivity.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in the CNC Router Hobbyist Sector?

Sustainability is becoming a crucial consideration in the CNC router hobbyist sector, especially as consumers and businesses alike demand more environmentally responsible practices. The environmental impact of manufacturing processes and materials is under scrutiny, prompting companies to adopt greener alternatives. B2B buyers are encouraged to look for suppliers who prioritize sustainable materials and manufacturing techniques.

Ethical sourcing is also paramount, as it reflects a company’s commitment to social responsibility. Suppliers that demonstrate transparency in their supply chains and adhere to fair labor practices are increasingly favored by conscientious buyers. Certifications such as FSC (Forest Stewardship Council) for wood products or ISO 14001 for environmental management systems can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Moreover, eco-friendly materials, such as recycled plastics and sustainably sourced woods, are gaining traction among hobbyists. B2B buyers should seek out products that highlight their environmental credentials, as this not only meets consumer demand but also enhances brand reputation. By prioritizing sustainability and ethical sourcing, businesses can differentiate themselves in a competitive market while contributing to a healthier planet.

What Is the Historical Context of the CNC Router Hobbyist Market?

The CNC router hobbyist market has evolved significantly over the past few decades. Initially, CNC technology was largely confined to industrial applications due to its high cost and complexity. However, advancements in technology and manufacturing processes have democratized access to CNC routers. The introduction of more affordable, user-friendly models has opened the door for hobbyists and small businesses to leverage CNC technology for creative projects.

In the early 2000s, the rise of online communities and forums dedicated to DIY projects further fueled interest in CNC routers. As enthusiasts shared their experiences and designs, a vibrant ecosystem emerged, promoting knowledge exchange and innovation. Today, the CNC router hobbyist sector is characterized by a diverse range of products that cater to various skill levels, from novice users to seasoned professionals.

This historical context is essential for understanding the current dynamics of the market, as it highlights the increasing accessibility of technology and the growing community of passionate hobbyists and small-scale entrepreneurs.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc router hobbyist

-

How do I select the right CNC router for my hobbyist business?

When choosing a CNC router, consider the size of your projects and the materials you’ll be using. Look for a machine with a suitable working area; for example, a 4×4 router can handle larger materials while maintaining a compact design. Evaluate the router’s specifications, such as spindle power, accuracy, and software compatibility. Additionally, assess the manufacturer’s support services, warranty, and training options to ensure you can maximize the machine’s potential for your business. -

What is the best CNC router for woodworking projects?

The best CNC router for woodworking projects typically combines precision, power, and user-friendliness. Models like the Shapeoko 5 Pro are highly regarded due to their robust construction and advanced software compatibility. They offer a large working area and the ability to cut various materials, including plywood and hardwood. Additionally, consider routers with a strong community and support network, which can enhance your learning experience and troubleshooting capabilities. -

What are the typical minimum order quantities (MOQs) for CNC routers?

Minimum order quantities for CNC routers can vary significantly based on the manufacturer and the model. Many suppliers may offer single units for hobbyist models, while commercial-grade machines often have higher MOQs. It’s essential to communicate your needs directly with the supplier to negotiate terms that suit your purchasing strategy. In some cases, bulk purchases can yield discounts, which may be beneficial for businesses looking to scale operations. -

How can I verify the credibility of a CNC router supplier?

To verify a CNC router supplier’s credibility, start by checking their business history, customer reviews, and certifications. Look for suppliers with a solid track record in international trade and positive testimonials from other B2B buyers. It’s also advisable to request references and inquire about their after-sales support and warranty policies. Trade shows and industry events are excellent opportunities to assess suppliers in person and establish direct connections. -

What payment terms should I expect when purchasing CNC routers internationally?

Payment terms for international CNC router purchases can vary widely but often include options like upfront payment, 30/60/90-day terms, or letters of credit. It’s crucial to discuss these terms during negotiations to ensure they align with your cash flow capabilities. Additionally, consider using secure payment methods and contracts that protect your investment and ensure product delivery as agreed. -

What customs and import regulations should I be aware of when buying CNC routers?

When importing CNC routers, familiarize yourself with your country’s customs regulations, including tariffs, taxes, and required documentation. Each country has specific import duties that can significantly affect the overall cost. Engage with a customs broker to navigate these complexities, ensuring compliance with local laws and regulations. Understanding these aspects can help you avoid unexpected costs and delays during shipping. -

How do I ensure quality assurance (QA) for my CNC router purchase?

To ensure quality assurance for your CNC router, request detailed specifications and certifications from the supplier, including ISO certifications. It’s beneficial to inquire about their QA processes, such as testing protocols and quality control measures. Consider requesting a sample or demo of the machine before finalizing your order. Establishing clear communication about your quality expectations can help align your standards with the supplier’s capabilities. -

What logistics considerations should I keep in mind when ordering CNC routers?

Logistics considerations include shipping methods, lead times, and freight costs. Assess whether the supplier offers door-to-door delivery or if you’ll need to arrange transportation from a port. Additionally, consider the size and weight of the CNC router, as these factors can impact shipping costs and delivery timelines. Planning for potential delays and ensuring proper handling during transit can help mitigate risks and ensure your equipment arrives in optimal condition.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Cnc Router Hobbyist Manufacturers & Suppliers List

1. Reddit – Hobbyist CNC Routers

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Hobbyist CNC routers discussed include: 1. Shapeoko 4 XL – known for its community support and reliability. 2. SainSmart ProVerXL 4030 – praised for its performance but may require a spindle upgrade. 3. QueenAnt Pro V.2 – offers a working area of 600X600 mm and can handle metal without torsion issues. 4. Used Shapeoko 3 – a more affordable option for beginners. Budget is around $1000 for a full se…

2. Carbide 3D – Shapeoko 5 Pro CNC Router

Domain: shop.carbide3d.com

Registered: 2013 (12 years)

Introduction: Product Name: Shapeoko 5 Pro CNC Router

Sizes Available: 2×2, 4×4

Working Area: 4×4 feet

Price: Starting from $3,250.00

Key Features:

– Capable of passing larger materials through the work area (e.g., 4×8′ plywood)

– Precision engineering for accuracy, speed, and durability

– User-friendly design suitable for beginners and experienced users

– Ideal for woodworking, sign-making, plastic fabricatio…

3. MillRight CNC – Alpha Arc Plasma Table

Domain: millrightcnc.com

Registered: 2016 (9 years)

Introduction: {“products”:[{“name”:”Alpha Arc Plasma Table”,”price”:”$8,000.00″,”cutting_area”:”50×50″”,”capabilities”:”Cuts 26 gauge to 1/2″ steel plate, edge start for up to 5/8″ steel plate, sever 1″ steel plate with Hypertherm Powermax 45 Sync.”,”lead_time”:”Approximately 5 weeks”},{“name”:”Mega V 2″,”price”:”$2,299.00″,”capabilities”:”CNC machine for hobbyists and businesses.”},{“name”:”MillRight CNC Power…

4. Maker Hacks – CNC Machines

Domain: makerhacks.com

Registered: 2014 (11 years)

Introduction: CNC machines are categorized mainly into CNC Mills and CNC Routers. CNC Mills have a high-torque spindle and more vertical (Z) and horizontal (Y) travel, making them suitable for metal work and precise machine parts. CNC Routers, on the other hand, are designed for cutting softer materials like acrylic and wood, often used in cabinet making. Key considerations for purchasing a CNC machine include …

5. STYLECNC – CNC Routers for Every Need

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: CNC Routers for Every Need & Budget – STYLECNC offers a variety of CNC routers including CNC Wood Routers, ATC CNC Routers, Hobby CNC Routers, Metal CNC Machines, Stone CNC Machines, and more. Key features include:

– Computer-controlled machine tools for cutting, carving, milling, and shaping materials like wood, plastic, metal, stone, and composites.

– Available in 3-axis, 4-axis, 5-axis, and m…

6. Sienci – LongMill Benchtop CNC MK2.5

Domain: sienci.com

Registered: 2016 (9 years)

Introduction: LongMill Benchtop CNC MK2.5

– Rated 4.77 out of 5 based on 457 customer reviews

– Price: $1,359.00 – $1,879.00

– Shipping: Orders ship in 2 – 5 days

– Available Sizes: 12×30, 30×30, 48×30 (cutting area in inches)

– Z-axis travel: 125mm (~4.9″)

– Features:

– SuperLongBoard Spring Loaded Anti-Backlash Nuts

– Large extruded aluminum rails

– Fully supported Y-axes

– 1/4″ steel gantries on all…

7. Facebook – CNC Router Solutions

Strategic Sourcing Conclusion and Outlook for cnc router hobbyist

As the CNC router hobbyist market continues to expand, strategic sourcing emerges as a crucial factor for international B2B buyers. Understanding the variety of options, from compact models like the Shapeoko 5 Pro to larger systems such as the FoxAlien Vasto XL, allows businesses to tailor their purchasing decisions to specific project needs. Key takeaways include the importance of evaluating machine capabilities, ensuring compatibility with software, and considering after-sales support and warranty options.

Investing in high-quality CNC routers not only enhances production capabilities but also positions businesses to capitalize on the growing demand for custom woodworking, sign-making, and fabrication services. With competitive pricing and robust training resources available, now is an ideal time for buyers in Africa, South America, the Middle East, and Europe to explore these opportunities.

Looking ahead, the future of CNC routing for hobbyists is bright, driven by technological advancements and increased accessibility. We encourage international buyers to leverage strategic sourcing to enhance their operational efficiencies and product offerings. Engage with trusted suppliers, assess market trends, and seize the opportunity to innovate within this dynamic sector. Your next step could redefine your business capabilities—don’t miss out.