Contents

Manufacturing Insight: Cnc Router For Cutting Aluminum

Precision Aluminum Routing Solutions for Rapid Prototyping

Honyo Prototype delivers industry-leading CNC machining services engineered specifically for high-integrity aluminum component fabrication. Our advanced CNC router systems operate at 24,000 RPM with rigid spindle configurations and optimized chip evacuation pathways to eliminate work hardening and surface imperfections common in aluminum cutting. This technical capability ensures dimensional accuracy within ±0.001″ and superior surface finishes critical for aerospace, automotive, and electronics prototyping applications.

We specialize in low-volume, complex aluminum parts where traditional milling processes face cost or lead time constraints. Our vacuum table systems securely hold thin sheets and intricate geometries without mechanical clamping, preserving material integrity while accelerating production cycles. Every router workflow integrates real-time tool monitoring and coolant-through-spindle technology to maximize tool life and maintain thermal stability during extended runs.

For engineering teams under pressure to accelerate development timelines, Honyo eliminates quoting bottlenecks through our Online Instant Quote platform. Upload CAD files in STEP, IGES, or native formats to receive detailed manufacturability feedback and certified pricing within minutes—not days. This seamless integration between engineering intent and production execution reduces prototyping lead times by up to 65% while maintaining full ISO 9001:2015 traceability.

Partner with Honyo Prototype to transform aluminum design concepts into precision-engineered realities with unmatched speed and technical rigor. Initiate your project immediately through our digital quoting system at honyoprototype.com/quote.

Technical Capabilities

CNC Router for Precision Aluminum Cutting – Technical Specifications

The following table outlines the technical specifications for a high-performance CNC machining system designed for precision cutting of aluminum and other engineering materials. While traditionally referred to as a “CNC router,” this system is more accurately classified as a CNC milling machine (or machining center), given the required rigidity, accuracy, and capability for tight-tolerance work in metals such as aluminum and steel.

| Specification | Detail |

|---|---|

| Machine Type | 3-Axis, 4-Axis, or 5-Axis CNC Machining Center (Mill) |

| Primary Use | High-precision milling of aluminum, steel, engineering plastics (ABS, Nylon), and other non-ferrous/ferrous materials |

| Spindle Speed Range | 8,000 – 24,000 RPM (high-speed spindle with through-coolant option for aluminum) |

| Spindle Power | 7.5 – 15 kW (10 – 20 HP), air or liquid-cooled |

| Positioning Accuracy | ±0.005 mm (±0.0002 in) |

| Repeatability | ±0.002 mm (±0.0001 in) |

| Tolerance Capability | As tight as ±0.0125 mm (±0.0005 in) for critical features; achievable with proper fixturing and process control |

| Axis Travel (Typical) | X: 500–1000 mm, Y: 400–600 mm, Z: 300–500 mm (configurable based on model) |

| Tool Changer | Automatic Tool Changer (ATC) with 12–30 tool capacity (optional) |

| Control System | Fanuc, Siemens, or Heidenhain CNC with 5-axis interpolation and high-speed machining (HSM) capabilities |

| Coolant System | High-pressure through-spindle coolant (10–70 bar) optimized for chip evacuation in aluminum |

| Workholding | T-slots, vacuum tables (for plastics), or precision vices; 4th/5th axis rotary tables available |

| Materials Compatible | Aluminum (6061, 7075, etc.), mild and stainless steel, brass, titanium (limited), ABS, Nylon, PEEK, Delrin |

| Surface Finish (Typical) | 0.8 – 3.2 µm Ra (achievable with fine milling and proper parameters) |

| Rigidity & Frame | Cast iron or mineral casting base for vibration damping; linear guides with preloaded ball screws |

| Chip Management | Integrated chip conveyor and coolant filtration system |

| Optional Features | In-process probing, tool length breakage detection, thermal compensation, dry machining for plastics |

Notes on Application and Material Suitability

Aluminum is a primary target material due to its machinability, low cutting forces, and high thermal conductivity. The system is optimized for high-speed machining (HSM) strategies common in aluminum fabrication. For steel, lower spindle speeds and increased torque are required, but the same machine platform can handle both with appropriate tooling and parameters.

Engineering thermoplastics such as ABS and Nylon can be machined on the same platform, often with reduced spindle speeds and specialized tooling (e.g., polished carbide with high rake angles) to prevent melting or burring. Coolant may be replaced with air blast or mist in plastic machining.

Turning operations are not performed on a CNC milling machine. If turning is required, a mill-turn center (C-axis live tooling lathe) would be recommended for combined milling and turning capabilities, especially for complex aluminum or steel components requiring tight tolerances.

This machine platform supports tight-tolerance manufacturing critical in aerospace, automotive, and medical industries, where repeatability and precision across aluminum and steel components are essential.

From CAD to Part: The Process

Honyo Prototype Aluminum CNC Routing Process Overview

Honyo Prototype executes a streamlined, technology-driven workflow for aluminum CNC routing projects, ensuring precision, cost efficiency, and rapid turnaround. Our process integrates advanced AI with rigorous engineering validation to address aluminum-specific challenges like thermal expansion, chip evacuation, and tool wear. Below is a detailed breakdown of each phase.

CAD File Upload and System Integration

Clients initiate the process by uploading native or neutral-format CAD files (STEP, IGES, Parasolid) via our secure customer portal. The system automatically validates file integrity, checks for unit consistency (millimeters preferred for metric aluminum stock), and confirms geometric completeness. For aluminum routing, the system specifically identifies features requiring attention, such as thin walls below 0.8mm, deep cavities exceeding 3x width, or sharp internal corners, which are prone to deflection or breakage in aluminum alloys like 6061-T6 or 7075-T6.

AI-Powered Quoting Engine

Our proprietary AI engine analyzes the validated CAD geometry against real-time production parameters to generate an instant quote. For aluminum, the algorithm factors in material-specific variables:

Alloy grade and temper (affecting machinability and tool selection)

Required surface finish (e.g., Ra 1.6µm vs. Ra 0.8µm for critical sealing surfaces)

Chip load and spindle speed constraints (e.g., max 18,000 RPM for 6061 to prevent work hardening)

Coolant requirements (flood coolant mandatory for aluminum to avoid built-up edge)

The AI cross-references historical data from 12,000+ aluminum jobs to predict scrap rates and machine time within 5% accuracy, providing transparent cost breakdowns for material, setup, and machining.

Automated DFM Analysis with Aluminum Optimization

Every aluminum part undergoes mandatory Design for Manufacturability (DFM) review via our digital twin platform. Engineers focus on aluminum-specific optimizations:

Converting sharp internal corners to ≥0.5mm radii to reduce tool stress

Adjusting wall thicknesses to ≥1.0mm for rigidity in large panels

Recommending pocketing strategies to minimize heat buildup in deep features

Flagging features requiring specialized tooling (e.g., carbide end mills with TiAlN coating)

DFM feedback is delivered within 4 business hours, including annotated 3D models and actionable revision suggestions. Critical aluminum considerations are highlighted in the report.

| DFM Checkpoint | Aluminum-Specific Threshold | Risk if Ignored |

|---|---|---|

| Minimum Wall Thickness | ≥0.8mm (structural) | Vibration-induced chatter |

| Internal Corner Radius | ≥0.3mm (non-critical) | Tool fracture at high RPM |

| Max Cavity Depth | ≤3x cavity width | Chip recutting and surface defects |

| Surface Finish | Ra ≤3.2µm (standard) | Built-up edge causing dimensional drift |

Precision Production Execution

Approved designs move to our dedicated aluminum CNC cell featuring 5-axis routers with high-frequency spindles (24,000 RPM), rigid tapping, and flood coolant systems. Key production protocols include:

Material clamping via vacuum tables with non-marring aluminum-compatible pods to prevent surface marring

Toolpath optimization using adaptive clearing for efficient chip evacuation in 6061/7075 alloys

In-process inspections at critical stages using Renishaw probes to compensate for thermal drift

Dedicated tool libraries with ZrN-coated carbide cutters specifically for aluminum to eliminate adhesion

All aluminum parts are machined under controlled humidity (45-55% RH) to minimize thermal distortion, with real-time machine data logged for traceability.

Quality-Controlled Delivery

Final inspection includes CMM verification of critical dimensions per ASME Y14.5, surface roughness testing, and deburring validation using optical comparators. Aluminum parts undergo post-machining cleaning with non-etching solvents to remove coolant residue. Parts ship with:

First-article inspection report (FAIR) showing actual vs. nominal dimensions

Material certification traceable to mill test reports

Packaging using anti-static VCI paper to prevent oxidation during transit

Standard lead time for aluminum routing is 5-7 business days from DFM approval, with expedited options available for prototyping. All deliveries include digital process documentation accessible via our client portal for future revisions.

Start Your Project

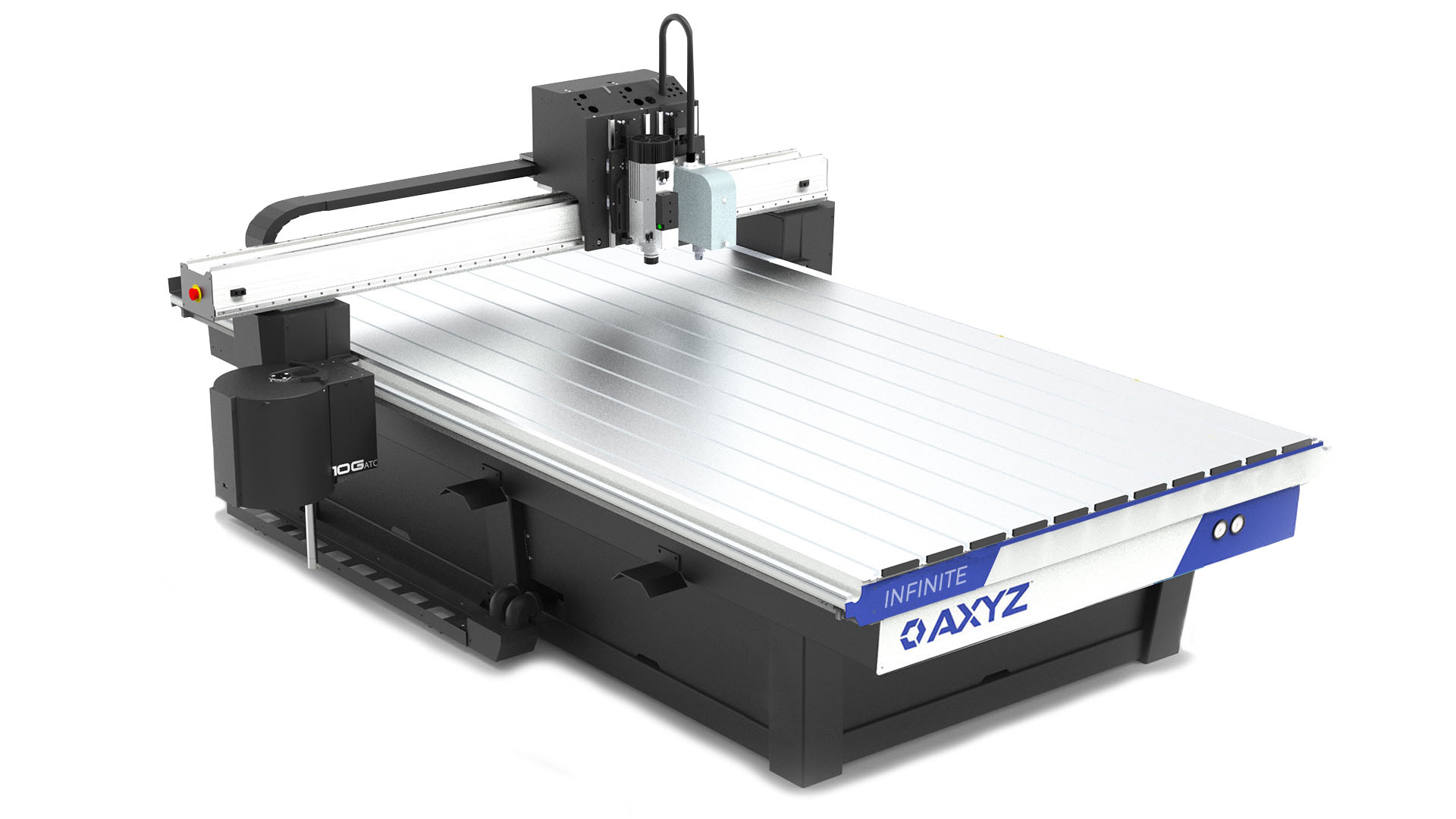

Looking for a high-performance CNC router specifically designed for cutting aluminum? Our precision-engineered machines are built to deliver accuracy, speed, and durability for demanding industrial applications.

Manufactured in our Shenzhen factory, each CNC router is optimized for aluminum machining with rigid construction, powerful spindles, and advanced cooling systems to ensure long tool life and consistent results.

Contact Susan Leo today at [email protected] to discuss your requirements and receive a tailored solution for your production needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.