Introduction: Navigating the Global Market for cnc router for beginners

In an increasingly competitive global market, sourcing the right CNC router for beginners can pose significant challenges, especially for international B2B buyers from regions like Africa, South America, the Middle East, and Europe. Understanding the various types of CNC routers, their applications, and the nuances of supplier vetting is essential for making informed purchasing decisions. This guide provides a comprehensive overview of CNC routers, catering specifically to newcomers looking to invest in this technology.

Within these pages, you’ll find insights into the different models available, from entry-level machines to more advanced options suitable for specific applications. We delve into the cost implications, helping you assess budget-friendly solutions without compromising on quality. Additionally, we provide actionable advice on how to vet suppliers effectively, ensuring that you partner with reputable manufacturers who can meet your needs.

By empowering you with critical knowledge and practical tips, this guide aims to simplify the selection process, enabling you to navigate the complexities of the CNC router market confidently. Whether you’re looking to enhance your manufacturing capabilities or explore new creative avenues, understanding the landscape of CNC routers will set you on the path to success.

Understanding cnc router for beginners Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Desktop CNC Routers | Compact size, lower cost, suitable for hobbyists | Prototyping, small-scale production | Pros: Affordable, easy to set up. Cons: Limited cutting depth and material types. |

| Mid-Range CNC Routers | Enhanced capabilities, larger work area | Signmaking, woodworking, light metal work | Pros: Versatile, good balance of price and features. Cons: Requires more technical skill. |

| Industrial CNC Routers | High precision, robust construction, larger size | Mass production, complex machining tasks | Pros: Exceptional accuracy, durable. Cons: High initial investment, requires skilled operators. |

| Hybrid CNC Routers | Combines routing with other processes (e.g., laser) | Multi-material projects, custom fabrication | Pros: Multifunctional, efficient for diverse tasks. Cons: Complexity in operation and maintenance. |

| DIY CNC Kits | Customizable, educational, lower cost | Prototyping, educational purposes | Pros: Cost-effective, hands-on learning. Cons: Time-consuming assembly, variable quality. |

What are the Characteristics and Suitability of Desktop CNC Routers for B2B Buyers?

Desktop CNC routers are compact and budget-friendly, making them ideal for small businesses or startups looking to prototype or produce small-scale items. They typically offer basic functionality for woodworking, engraving, and light plastic applications. B2B buyers should consider these machines for low-volume production or educational purposes, but be aware of their limitations in cutting depth and material variety.

How Do Mid-Range CNC Routers Meet Diverse Business Needs?

Mid-range CNC routers provide a versatile solution for businesses engaged in signmaking, woodworking, and light metal work. These machines feature a larger work area and enhanced capabilities compared to desktop models, making them suitable for small to medium-sized production runs. Buyers should evaluate their technical skills, as these routers require a greater understanding of software and machine operation, but they offer a valuable balance of cost and performance.

What Advantages Do Industrial CNC Routers Offer for Large Scale Production?

Industrial CNC routers are designed for high precision and robust performance, making them ideal for mass production and complex machining tasks. These machines can handle a wide range of materials with exceptional accuracy, which is crucial for industries such as aerospace, automotive, and furniture manufacturing. However, the significant initial investment and the need for skilled operators are key considerations for B2B buyers looking to adopt these systems.

How Can Hybrid CNC Routers Enhance Custom Fabrication Processes?

Hybrid CNC routers are versatile machines that integrate routing with other processes like laser cutting or engraving. This multifunctionality allows businesses to undertake diverse projects, particularly in custom fabrication and multi-material applications. While they increase efficiency and reduce the need for multiple machines, B2B buyers must be prepared for the complexity in operation and potential maintenance challenges.

Why Consider DIY CNC Kits for Educational and Prototyping Purposes?

DIY CNC kits are a cost-effective option for businesses interested in hands-on learning or prototyping. They allow users to customize their machines according to specific needs, fostering a deeper understanding of CNC technology. However, the assembly can be time-consuming, and the quality may vary based on the components used. B2B buyers should weigh the educational benefits against the investment of time and effort required to build and calibrate these machines.

Key Industrial Applications of cnc router for beginners

| Industry/Sector | Specific Application of CNC Router for Beginners | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Woodworking | Custom Furniture Design and Production | Increased design flexibility and reduced labor costs | Material compatibility, machine size, and precision needed |

| Signage | Creation of Custom Signs and Displays | Enhanced branding and marketing opportunities | Software compatibility, engraving capabilities, and size |

| Prototyping | Rapid Prototyping of Product Designs | Accelerated development cycles and reduced time-to-market | Material types, precision requirements, and software needs |

| Automotive | Fabrication of Custom Parts and Components | Improved accuracy and repeatability in manufacturing | Ability to work with metal, tooling options, and machine power |

| Arts and Crafts | Crafting Intricate Art Pieces or Decorative Items | Unique product offerings and differentiation in the market | Material versatility, precision, and design software support |

How Can CNC Routers Benefit the Woodworking Industry?

In the woodworking sector, CNC routers allow beginners to create custom furniture designs with high precision. These machines can cut, carve, and engrave various wood types, enabling woodworkers to produce intricate designs that would be difficult to achieve by hand. For international buyers, especially in regions like Africa and South America, sourcing CNC routers that accommodate local wood materials and provide adequate software support is crucial. Additionally, understanding the machine’s capacity to handle various sizes and complexities can significantly enhance production efficiency.

What Role Do CNC Routers Play in the Signage Industry?

CNC routers are pivotal in the signage industry, enabling the production of customized signs and displays that meet specific client needs. Beginners can utilize these machines to engrave logos, cut out letters, and create eye-catching designs that enhance branding efforts. For businesses in Europe and the Middle East, it’s essential to consider the compatibility of the CNC router with various materials, such as acrylic or wood, and the software used for design and production. This ensures that the signs produced are not only visually appealing but also durable.

How Can CNC Routers Enhance Prototyping Processes?

In the realm of prototyping, CNC routers provide a fast and efficient method for creating product designs. Beginners can quickly turn digital designs into physical prototypes, allowing for rapid testing and iteration. This capability is particularly beneficial for businesses in dynamic markets like Brazil, where speed to market can be a competitive advantage. When sourcing CNC routers for prototyping, buyers should prioritize machines that offer versatility in material handling and precision cutting, as these factors significantly influence the quality of prototypes.

Why Are CNC Routers Important in the Automotive Sector?

The automotive industry increasingly relies on CNC routers for fabricating custom parts and components. Beginners can use these machines to create intricate designs that require high accuracy, which is essential for ensuring the functionality and safety of automotive parts. For international buyers, particularly in regions with developing automotive markets, it’s important to choose CNC routers that can handle metal materials and provide the necessary power for effective machining. Additionally, understanding tooling options is vital for achieving the desired specifications.

How Do CNC Routers Support Arts and Crafts?

CNC routers are transforming the arts and crafts sector by enabling the production of unique art pieces and decorative items. Beginners can explore creative possibilities by carving intricate designs and patterns into various materials. For businesses in Europe and the Middle East, sourcing CNC routers that offer versatility in material types and design software support is key to fostering creativity and innovation. This capability allows artisans to differentiate their products in a competitive market, appealing to consumers looking for unique handmade items.

3 Common User Pain Points for ‘cnc router for beginners’ & Their Solutions

Scenario 1: Overwhelming Complexity of Software Integration

The Problem: Many B2B buyers entering the CNC router space for the first time find themselves daunted by the software requirements. The integration of CAD (Computer-Aided Design), CAM (Computer-Aided Manufacturing), and CNC software can be incredibly complex, particularly for those without a technical background. This complexity often leads to frustration, wasted time, and ultimately, a reluctance to fully utilize the capabilities of their CNC router.

The Solution: To alleviate these concerns, buyers should consider investing in CNC routers that come with user-friendly software solutions or packages that offer comprehensive tutorials. Prioritize systems that provide an all-in-one solution where CAD, CAM, and CNC functions are seamlessly integrated. For example, opting for routers that support popular software like Easel or VCarve can simplify the learning curve. Additionally, participating in online forums or local workshops can provide valuable insights and hands-on experience. This approach not only builds confidence but also enhances the overall efficiency of utilizing the CNC router.

Scenario 2: Inadequate Understanding of Material Compatibility

The Problem: Beginners often struggle with selecting the appropriate materials for their CNC projects, leading to unsatisfactory results. Many buyers are unsure about which materials their CNC router can handle, especially when it comes to harder substances like aluminum or various types of wood. This lack of understanding can lead to damaged equipment and wasted resources, causing significant financial strain for businesses.

The Solution: Buyers should conduct thorough research before committing to a specific CNC router model, focusing on the machine’s specifications regarding material compatibility. It’s advisable to seek out machines with versatile capabilities, capable of handling a range of materials from soft woods to metals. Furthermore, manufacturers often provide material guidelines, which can be invaluable for beginners. Engaging with the manufacturer or supplier for recommendations on compatible materials and obtaining sample kits for testing can help mitigate risks. Additionally, investing in a machine with adjustable feed rates and tool options will allow for greater experimentation and adaptation as the user gains experience.

Scenario 3: Safety Concerns and Operational Risks

The Problem: Safety is a major concern for beginners operating CNC routers, especially in a B2B environment where the stakes are higher. Many new users are unaware of the necessary precautions to take, which can lead to accidents and injuries. This not only impacts employee morale but can also result in costly downtime and liability issues for the business.

The Solution: To address safety concerns, companies should prioritize training and education. Implementing a structured training program for all employees using the CNC router is essential. This program should cover the proper operation of the machine, safety protocols, and emergency procedures. Additionally, investing in safety equipment such as goggles, gloves, and dust masks should be mandatory. Establishing a culture of safety by encouraging regular safety audits and open discussions about best practices can further enhance workplace safety. Utilizing CNC routers equipped with advanced safety features, such as emergency stop buttons and protective enclosures, can provide an added layer of security for operators. This comprehensive approach not only promotes a safer working environment but also boosts productivity and employee confidence.

Strategic Material Selection Guide for cnc router for beginners

What Are the Key Materials for CNC Routers for Beginners?

When selecting materials for CNC routers, it’s crucial to understand the properties, advantages, and limitations of each material. This knowledge will help international B2B buyers make informed decisions based on their specific applications and regional compliance requirements. Below, we analyze four common materials suitable for beginners in CNC routing: wood, acrylic, aluminum, and MDF (Medium Density Fiberboard).

How Does Wood Perform in CNC Routing Applications?

Key Properties: Wood is a natural material known for its versatility and ease of machining. It typically has a temperature rating of up to 60°C and exhibits good resistance to corrosion, making it suitable for various indoor applications.

Pros & Cons: The durability of wood varies significantly based on the type used (e.g., hardwood vs. softwood). While hardwoods like oak and maple offer excellent durability, they can be more expensive and harder to source. Softwoods like pine are more affordable and easier to work with but may not withstand heavy use. The manufacturing complexity is relatively low, making wood a popular choice for beginners.

Impact on Application: Wood is ideal for creating furniture, decorative items, and prototypes. Its compatibility with various finishes allows for a wide range of end products.

Considerations for International Buyers: Buyers should be aware of local regulations regarding sustainable sourcing and certifications (e.g., FSC certification). Preferences for specific wood types may vary by region, influencing availability and cost.

What Are the Advantages of Using Acrylic in CNC Routing?

Key Properties: Acrylic, also known as PMMA (Polymethyl methacrylate), is a thermoplastic with a high transparency rating and good UV resistance. It can withstand temperatures up to 80°C and is generally resistant to various chemicals.

Pros & Cons: Acrylic is lightweight and offers excellent aesthetic appeal, making it suitable for signage and displays. However, it can be more brittle than other materials, leading to potential cracking during machining. The cost of acrylic is moderate, and while it is easy to cut and engrave, achieving high-quality finishes may require additional post-processing.

Impact on Application: Acrylic is commonly used for decorative items, signage, and protective covers. Its clarity and ability to be dyed or painted enhance its applicability in various projects.

Considerations for International Buyers: Compliance with regional standards, such as ASTM for plastics, is essential. Buyers should also consider the availability of acrylic sheets in their region, as sourcing can vary significantly.

Why Choose Aluminum for CNC Routing Projects?

Key Properties: Aluminum is a lightweight metal with excellent strength-to-weight ratio and corrosion resistance. It can withstand high temperatures (up to 200°C) and is non-magnetic, making it suitable for various industrial applications.

Pros & Cons: The durability of aluminum is a significant advantage, allowing for the production of robust components. However, machining aluminum requires more powerful CNC routers and specialized tooling, which can increase initial investment costs. The complexity of working with aluminum is higher than with softer materials, requiring more skill and experience.

Impact on Application: Aluminum is ideal for creating parts that need to endure stress, such as brackets, housings, and custom components. Its versatility makes it suitable for both functional and aesthetic applications.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards like ASTM or DIN for aluminum products. Additionally, sourcing aluminum can be influenced by local market conditions, affecting pricing and availability.

What Makes MDF a Suitable Material for Beginners?

Key Properties: Medium Density Fiberboard (MDF) is an engineered wood product made from wood fibers, wax, and resin. It has a uniform density and can withstand moderate temperatures, typically up to 50°C.

Pros & Cons: MDF is cost-effective and easy to machine, making it a popular choice for beginners. However, it is less durable than solid wood and can be susceptible to moisture damage. The manufacturing complexity is low, and it can be easily painted or veneered for aesthetic purposes.

Impact on Application: MDF is commonly used for cabinetry, furniture, and decorative items. Its smooth surface allows for intricate designs and finishes.

Considerations for International Buyers: Buyers should be aware of the environmental impact of MDF production and ensure compliance with local regulations regarding formaldehyde emissions. Preferences for MDF quality may vary by region, influencing sourcing decisions.

Summary Table of Material Selection for CNC Routers

| Material | Typical Use Case for CNC Router for Beginners | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Furniture, decorative items, prototypes | Versatile and easy to work with | Durability varies by type | Medium |

| Acrylic | Signage, displays, protective covers | High transparency and UV resistance | Brittle and may crack | Medium |

| Aluminum | Brackets, housings, custom components | Excellent strength-to-weight ratio | Requires skilled machining | High |

| MDF | Cabinetry, furniture, decorative items | Cost-effective and easy to machine | Susceptible to moisture damage | Low |

This guide provides a comprehensive overview of materials suitable for CNC routing, enabling international B2B buyers to make informed decisions tailored to their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc router for beginners

What Are the Main Manufacturing Processes for CNC Routers Designed for Beginners?

The manufacturing of CNC routers, particularly those aimed at beginners, involves several critical stages. Understanding these stages can help B2B buyers make informed decisions when sourcing these machines.

Material Preparation: What Materials Are Typically Used?

The initial stage of manufacturing CNC routers involves selecting appropriate materials. Most CNC routers are constructed using aluminum and high-grade steel for their frames, providing strength and stability. The components such as the spindle, rails, and base are often made from these materials to ensure durability and performance.

In addition to metals, manufacturers may use composite materials for lighter-weight models, which can be advantageous for smaller workshops or mobile applications. Proper handling and storage of these materials are crucial to avoid warping or degradation, impacting the final product’s quality.

How Are CNC Routers Formed and Assembled?

Once the materials are prepared, the next phase is forming, which typically involves cutting, machining, and shaping the components. Advanced techniques such as laser cutting, CNC machining, and water jet cutting are often employed to ensure precision. The accuracy of these processes is vital, as even minor discrepancies can lead to significant issues in the machine’s operation.

After forming, the assembly process begins. This stage includes the installation of the frame, motors, electronics, and the control systems. Manufacturers often use modular assembly techniques, allowing for easier upgrades and repairs. Ensuring that components fit together seamlessly is critical, as misalignments can affect the machine’s performance and longevity.

What Finishing Techniques Are Applied to CNC Routers?

Finishing processes are essential for enhancing the aesthetic appeal and protective qualities of CNC routers. Typical methods include anodizing aluminum parts to increase corrosion resistance and powder coating to provide a durable, visually appealing surface. These techniques not only improve the router’s appearance but also extend its lifespan, making it more attractive to potential buyers.

Quality control during this phase is also crucial, as surface imperfections can lead to operational inefficiencies or compromise the machine’s durability.

How is Quality Assurance Implemented in CNC Router Manufacturing?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that each CNC router meets the required standards before reaching the market.

What International Standards Should Buyers Be Aware Of?

For CNC routers, adherence to international standards is paramount. ISO 9001 is the primary quality management standard that manufacturers should comply with, ensuring consistent quality in their products. Additionally, certifications like CE (Conformité Européenne) are essential for products sold in Europe, indicating compliance with safety and health requirements.

For buyers in Africa and South America, understanding local regulatory requirements is also important. Some countries may have specific certifications that are necessary for importation.

What Are the Key Quality Control Checkpoints in CNC Router Manufacturing?

Quality control typically involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This is where raw materials and components are inspected upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, various checks are performed to monitor the machining and assembly processes. This ensures that any deviations from the expected quality are caught early.

-

Final Quality Control (FQC): Once assembly is complete, the final product undergoes rigorous testing to verify its performance and safety. This may include operational tests, calibration checks, and inspections for surface defects.

What Testing Methods Are Commonly Used for CNC Routers?

Testing methods can vary but typically include:

-

Functional Testing: Verifying that all machine functions operate correctly.

-

Performance Testing: Assessing speed, accuracy, and repeatability of the CNC router.

-

Safety Testing: Ensuring that the machine meets safety standards to protect operators during use.

These testing methods are crucial for maintaining high quality and reliability, which are particularly important for B2B buyers looking for machines that can withstand rigorous use.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance processes is essential.

What Steps Should Buyers Take to Ensure Supplier Compliance?

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes, quality control measures, and adherence to international standards.

-

Requesting Quality Reports: Buyers should ask for documentation that details the quality control processes, including IQC, IPQC, and FQC results. This transparency can help identify any potential issues before making a purchase.

-

Third-party Inspections: Engaging independent third-party inspectors to evaluate the manufacturing process and final products can provide an unbiased assessment of quality.

-

Certifications and Compliance: Buyers should verify that suppliers hold relevant certifications, such as ISO 9001 or CE, ensuring that the manufacturer meets established industry standards.

What Are the Quality Control Nuances for International Buyers?

Different regions may have unique requirements and standards that affect quality control. For instance, while CE certification is crucial in Europe, African and South American countries may have their own sets of regulations that must be adhered to for imports.

Buyers should familiarize themselves with these regional standards and ensure that their suppliers are compliant. This knowledge can help prevent delays and additional costs associated with non-compliance.

In conclusion, understanding the manufacturing processes and quality assurance measures for CNC routers is vital for B2B buyers, particularly in international markets. By focusing on these aspects, buyers can make more informed purchasing decisions and ensure they select reliable and high-quality machines suitable for their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc router for beginners’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring CNC routers suitable for beginners. It outlines essential steps to ensure informed purchasing decisions that align with your operational needs and budget constraints. By following this checklist, businesses can minimize risks and maximize the potential of their CNC investment.

Step 1: Define Your Technical Specifications

Before exploring suppliers, it’s critical to clarify the technical specifications you require from a CNC router. Consider factors such as the machine’s cutting area, material compatibility (wood, plastics, aluminum), and desired precision.

– Key Considerations:

– What types of projects will you undertake?

– Do you need a machine with advanced features like a spindle or laser attachment for versatility?

Step 2: Set a Realistic Budget

Establishing a budget is vital to avoid overspending while ensuring you acquire a machine that meets your needs. Consider not only the initial purchase price but also ongoing costs for tools, maintenance, and software.

– Budget Breakdown:

– Initial costs: CNC router, computer software, and accessories.

– Long-term costs: Spare parts, tool replacements, and operational expenses.

Step 3: Research and Compare Brands

Take the time to research various CNC router brands that cater to beginners. Compare their features, reliability, and customer feedback. Look for brands with a solid reputation in the industry, especially those that offer robust customer support.

– Evaluation Criteria:

– User reviews and testimonials.

– Availability of parts and service in your region.

Step 4: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. Request detailed company profiles, customer references, and case studies from similar industries or regions to ensure credibility.

– Supplier Assessment:

– Check for certifications and compliance with industry standards.

– Ask about warranty terms and after-sales support.

Step 5: Examine Software Compatibility

Ensure that the CNC router is compatible with user-friendly CAD/CAM software suitable for beginners. The right software will streamline your design-to-production workflow and minimize learning curves.

– Software Considerations:

– Does the supplier offer training or resources for using the software?

– Are there community forums or support groups available for troubleshooting?

Step 6: Request Demonstrations or Samples

Whenever possible, request a demonstration of the CNC router in action or samples of completed projects. This will provide insight into the machine’s capabilities and ease of use, helping you assess if it meets your requirements.

– Demonstration Benefits:

– Observe the machine’s precision and speed.

– Evaluate the user interface and operational ease.

Step 7: Negotiate Terms and Conditions

Once you have selected a supplier, discuss terms and conditions, including payment options, delivery timelines, and installation support. Clear agreements will help prevent misunderstandings and ensure a smooth procurement process.

– Negotiation Points:

– Warranty coverage and service agreements.

– Return and refund policies in case the equipment does not meet expectations.

By following this structured checklist, B2B buyers can confidently navigate the procurement of CNC routers for beginners, ensuring a beneficial investment that supports their business objectives.

Comprehensive Cost and Pricing Analysis for cnc router for beginners Sourcing

What Are the Key Cost Components in Sourcing CNC Routers for Beginners?

When sourcing CNC routers for beginners, it’s essential to understand the various cost components that contribute to the overall pricing structure. The main cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materials comprise the bulk of production costs. The choice of components, such as the frame material (aluminum vs. steel), motor types (stepper vs. servo), and spindle quality, can significantly impact pricing. Higher-quality materials often lead to increased durability and performance, which may justify a higher initial investment.

Labor costs are influenced by the skill level required for assembly and programming. For entry-level machines, labor costs might be lower, but as the complexity increases, so does the expertise required, which can drive up costs.

Manufacturing overhead includes expenses related to facility operations, utilities, and equipment maintenance. These costs can vary widely based on the supplier’s location and operational efficiency.

Tooling refers to the specialized equipment needed for production. Custom tooling can add to the initial costs, especially if the manufacturer requires unique setups for specific models.

Quality Control measures ensure that the routers meet industry standards, which can add to the overall cost but is critical for maintaining product reliability and customer satisfaction.

Logistics costs encompass shipping and handling fees, which are particularly significant for international buyers. Factors such as freight forwarding, customs duties, and insurance should be considered when calculating total costs.

Finally, the margin represents the supplier’s profit and can vary based on market conditions and competition. Understanding these components helps buyers assess the price and value of CNC routers effectively.

How Do Price Influencers Affect CNC Router Pricing for Beginners?

Several factors influence the pricing of CNC routers, particularly for international B2B buyers. Volume and Minimum Order Quantity (MOQ) play a crucial role; purchasing in bulk often leads to discounts. Suppliers may offer better pricing for larger orders, making it essential for buyers to consider their long-term needs.

Specifications and customization can also impact costs. Basic models typically come at a lower price point, but adding features like enhanced cutting capabilities or advanced software can significantly increase the price. Buyers should weigh the benefits of customization against their budget constraints.

The choice of materials and the quality of components directly affect the durability and performance of the CNC router. Higher-quality routers may come with certifications, which can validate their reliability and justify a higher price.

Supplier factors, such as their reputation, production capabilities, and customer service, can influence pricing. Established suppliers may charge a premium for their experience and reliability, while newer entrants might offer lower prices to capture market share.

Incoterms should also be taken into account. Different shipping arrangements can affect total costs. For instance, choosing DDP (Delivered Duty Paid) can simplify logistics for buyers unfamiliar with international shipping processes.

What Are the Best Buyer Tips for Negotiating CNC Router Prices?

When negotiating prices for CNC routers, B2B buyers should focus on several strategies to maximize cost efficiency. Start by conducting thorough market research to understand typical pricing structures and identify competitive offers. This knowledge provides leverage during negotiations.

Consider discussing Total Cost of Ownership (TCO), which includes not just the purchase price but also operational costs, maintenance, and potential downtime. Emphasizing the long-term value can help negotiate better terms.

Buyers should also be clear about their specific needs and potential for future growth. This transparency can open discussions about tailored solutions that fit their budget while meeting their operational requirements.

Understanding pricing nuances for international transactions is critical, especially for buyers in Africa, South America, the Middle East, and Europe. Currency fluctuations, local regulations, and import duties can impact total costs, so it’s advisable to factor these elements into negotiations.

Lastly, maintaining a good relationship with suppliers can lead to better pricing and terms in future dealings. Building trust encourages suppliers to provide favorable conditions, such as extended warranties or better payment terms.

Disclaimer on Indicative Prices

Prices for CNC routers can vary widely based on numerous factors, including market conditions, specific supplier agreements, and regional economic influences. Buyers should always request detailed quotes and consider their unique requirements when evaluating costs.

Alternatives Analysis: Comparing cnc router for beginners With Other Solutions

Exploring Alternatives to CNC Routers for Beginners

When considering the best tools for woodworking or manufacturing, CNC routers for beginners stand out for their versatility and precision. However, there are several alternative solutions that may also meet the needs of new users in various industries. This section explores these alternatives, comparing their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Cnc Router For Beginners | Laser Cutter | Manual Tools |

|---|---|---|---|

| Performance | High precision; versatile for various materials | Excellent for detailed cuts; limited to thin materials | Varies widely; less precision and repeatability |

| Cost | $300 – $1,500 | $200 – $3,000 | $50 – $500 |

| Ease of Implementation | Moderate learning curve; requires software | Moderate; software learning required, but simpler than CNC | Minimal; no software needed |

| Maintenance | Moderate; requires regular calibration and upkeep | Low; generally requires lens cleaning | Low; basic tool maintenance |

| Best Use Case | Prototyping, woodworking, and custom manufacturing | Engraving and cutting thin materials like acrylic and wood | Simple projects, crafts, and repairs |

Detailed Breakdown of Alternatives

1. Laser Cutter

Laser cutters are an attractive alternative for beginners interested in precision cutting and engraving. They excel in creating intricate designs on materials like wood, acrylic, and even some metals. The primary advantage of laser cutters is their ability to produce detailed cuts quickly and cleanly. However, they typically have a higher upfront cost and are limited to thinner materials, which might not suit all projects. For businesses focused on detailed engraving or working with specific materials, investing in a laser cutter can be worthwhile.

2. Manual Tools

Manual tools, such as hand saws, chisels, and routers, represent a more traditional approach to woodworking and crafting. They are generally much cheaper and easier to acquire, making them accessible for beginners. The downside is that they require more skill and physical effort to achieve the precision and repeatability that CNC routers provide. Manual tools are best suited for simple projects, crafts, or repairs, where the ultimate goal is less about precision and more about skill development or hobbyist satisfaction.

Conclusion: Choosing the Right Solution for Your Needs

In evaluating these alternatives, B2B buyers should consider their specific needs, budget, and intended use. CNC routers for beginners offer a balance of precision and versatility, making them ideal for prototyping and custom projects. However, if the focus is on detailed engraving, a laser cutter may be more suitable. Alternatively, for those just starting out or with budget constraints, manual tools can provide a hands-on experience that develops essential skills. Ultimately, the decision should align with the buyer’s long-term goals and the types of projects they aim to undertake.

Essential Technical Properties and Trade Terminology for cnc router for beginners

What Are the Key Technical Properties of CNC Routers for Beginners?

Understanding the technical specifications of CNC routers is crucial for B2B buyers, particularly those new to the field. Here are several essential properties to consider:

1. Material Grade

The material grade of a CNC router refers to the quality of the components used in its construction, such as the frame, spindle, and rails. Common materials include aluminum, steel, and high-grade plastics. High-quality materials ensure durability and longevity, making them essential for businesses aiming to invest in reliable machinery. Lower-grade materials may reduce initial costs but can lead to increased maintenance and replacement expenses over time.

2. Cutting Area

The cutting area, often expressed in millimeters or inches, defines the maximum dimensions of the material that can be processed by the CNC router. For instance, a machine with a cutting area of 600mm x 600mm allows for a variety of projects but may limit larger applications. Understanding the cutting area is vital for businesses that require flexibility in project sizes, as it directly impacts production capabilities.

3. Tolerance

Tolerance indicates the precision of the CNC router, typically measured in millimeters or inches. A tolerance of ±0.1mm, for example, means that the machine can produce parts with a deviation of no more than 0.1mm from the intended design. High tolerance is critical for industries requiring precise components, such as automotive or aerospace. Buyers should assess their specific needs to determine the required tolerance for their applications.

4. Spindle Power

Spindle power, usually expressed in watts or horsepower, indicates the router’s ability to cut through various materials. A higher spindle power allows for more aggressive cutting and the ability to handle denser materials like aluminum or hardwood. For businesses focused on diverse manufacturing needs, selecting a CNC router with adequate spindle power can enhance productivity and reduce processing time.

5. Stepper Motors

The type and quality of stepper motors used in CNC routers directly affect their performance. Stepper motors convert electrical signals into precise mechanical movements, impacting the router’s speed and accuracy. High-quality stepper motors enable smoother operation and better control, making them crucial for projects requiring intricate designs. Understanding motor specifications helps buyers match the CNC router’s capabilities with their operational requirements.

6. Software Compatibility

CNC routers operate using specific software for design (CAD), manufacturing (CAM), and control (CNC). Compatibility with widely used software platforms ensures that businesses can integrate the machinery into their existing workflows seamlessly. Buyers should verify that the router supports standard file formats and is compatible with their preferred software to minimize setup time and learning curves.

What Are Common Trade Terms Associated with CNC Routers?

Familiarity with industry terminology is essential for effective communication and decision-making in B2B transactions. Here are several common terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components or products that are used in another company’s end products. In the CNC router market, understanding OEM relationships can help businesses identify reliable suppliers and ensure quality components are used in their machines.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for businesses to manage inventory and cash flow effectively, especially when sourcing CNC routers and related components.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers. It outlines the specifications and quantities required, allowing businesses to compare offers and make informed purchasing decisions regarding CNC routers.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping and delivery obligations. Understanding these terms is crucial for B2B buyers to navigate logistics and ensure smooth transactions when importing CNC routers from international suppliers.

5. G-code

G-code is a programming language used to control CNC machines. It provides instructions for the router, such as movement, speed, and tool changes. Familiarity with G-code is essential for businesses aiming to customize machining operations and optimize production efficiency.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when purchasing CNC routers, ensuring they select the right equipment for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the cnc router for beginners Sector

What Are the Current Market Dynamics and Key Trends in the CNC Router Sector for Beginners?

The CNC router market is witnessing significant growth, driven by advancements in technology and increased demand for precision manufacturing. As industries worldwide, including woodworking, metalworking, and prototyping, embrace automation, CNC routers are becoming essential tools for beginners looking to enter these fields. Emerging trends include the integration of user-friendly software, such as CAD and CAM systems, which simplify the design-to-production workflow. Additionally, the rise of online communities and resources has made knowledge sharing more accessible, allowing beginners in regions like Africa, South America, the Middle East, and Europe to upskill rapidly.

International B2B buyers are increasingly seeking affordable, yet robust, CNC router options that cater to various applications. There is a notable shift toward compact and desktop models, which are particularly appealing for small businesses and startups. Notably, vendors are focusing on enhanced customer support and training programs to help beginners navigate the complexities of CNC technology. As environmental concerns grow, buyers are also prioritizing machines that utilize energy-efficient components and sustainable materials, reflecting a broader trend towards responsible manufacturing practices.

How Is Sustainability and Ethical Sourcing Influencing the CNC Router for Beginners Market?

Sustainability is becoming a cornerstone of purchasing decisions in the CNC router market. The environmental impact of manufacturing processes, including energy consumption and waste generation, is prompting buyers to seek suppliers committed to sustainable practices. Ethical sourcing of materials is gaining traction, with an emphasis on suppliers who can demonstrate transparency in their supply chains.

Buyers are increasingly inquiring about certifications such as FSC (Forest Stewardship Council) for wood products and ISO 14001 for environmental management systems. These certifications not only assure quality but also signify a commitment to environmental responsibility. Furthermore, the use of biodegradable or recycled materials in the production of CNC routers and their components is becoming a selling point. This trend is particularly relevant for markets in Europe, where regulatory frameworks favor sustainable practices.

For B2B buyers, aligning with suppliers that prioritize sustainability not only enhances brand reputation but also meets the growing consumer demand for eco-friendly products. This shift is crucial for companies aiming to establish long-term partnerships in a competitive market.

What Is the Historical Context of CNC Routers and Their Evolution for Beginners?

The evolution of CNC routers dates back to the early 1950s when numerical control technology was first introduced in manufacturing. Initially designed for large-scale industrial applications, CNC routers have gradually become more accessible to smaller enterprises and individual users. By the late 20th century, advancements in computer technology and software development led to the creation of affordable desktop CNC routers, opening the market to hobbyists and beginners.

Today, CNC routers are equipped with sophisticated features such as advanced motion control, improved cutting speeds, and enhanced user interfaces, making them easier to operate. This evolution has democratized access to precision machining, allowing a broader audience to explore creative applications in various sectors. For international B2B buyers, understanding this historical context is vital in recognizing the potential of CNC routers as a versatile tool for innovation and production.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc router for beginners

-

How do I choose the right CNC router for my business needs?

Choosing the right CNC router depends on several factors, including the materials you plan to work with, the size of the projects, and your budget. Assess the types of materials (wood, plastic, aluminum) you will be cutting, as some machines are more suited for specific materials. Consider the machine’s cutting area, precision, and power. Additionally, research different brands and models, and read reviews from other users. If possible, request demonstrations or samples to evaluate performance before making a purchase. -

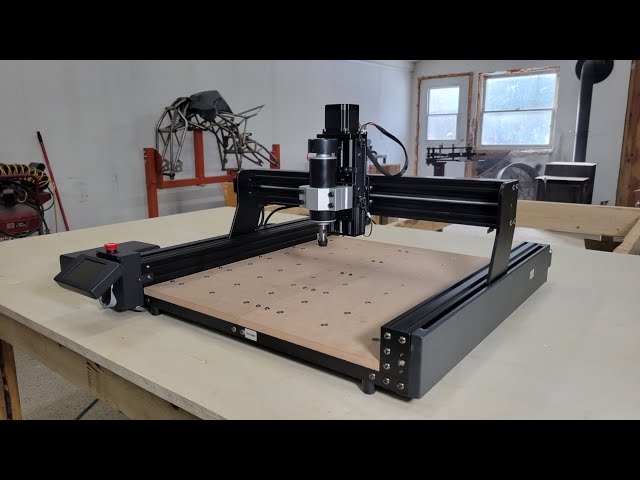

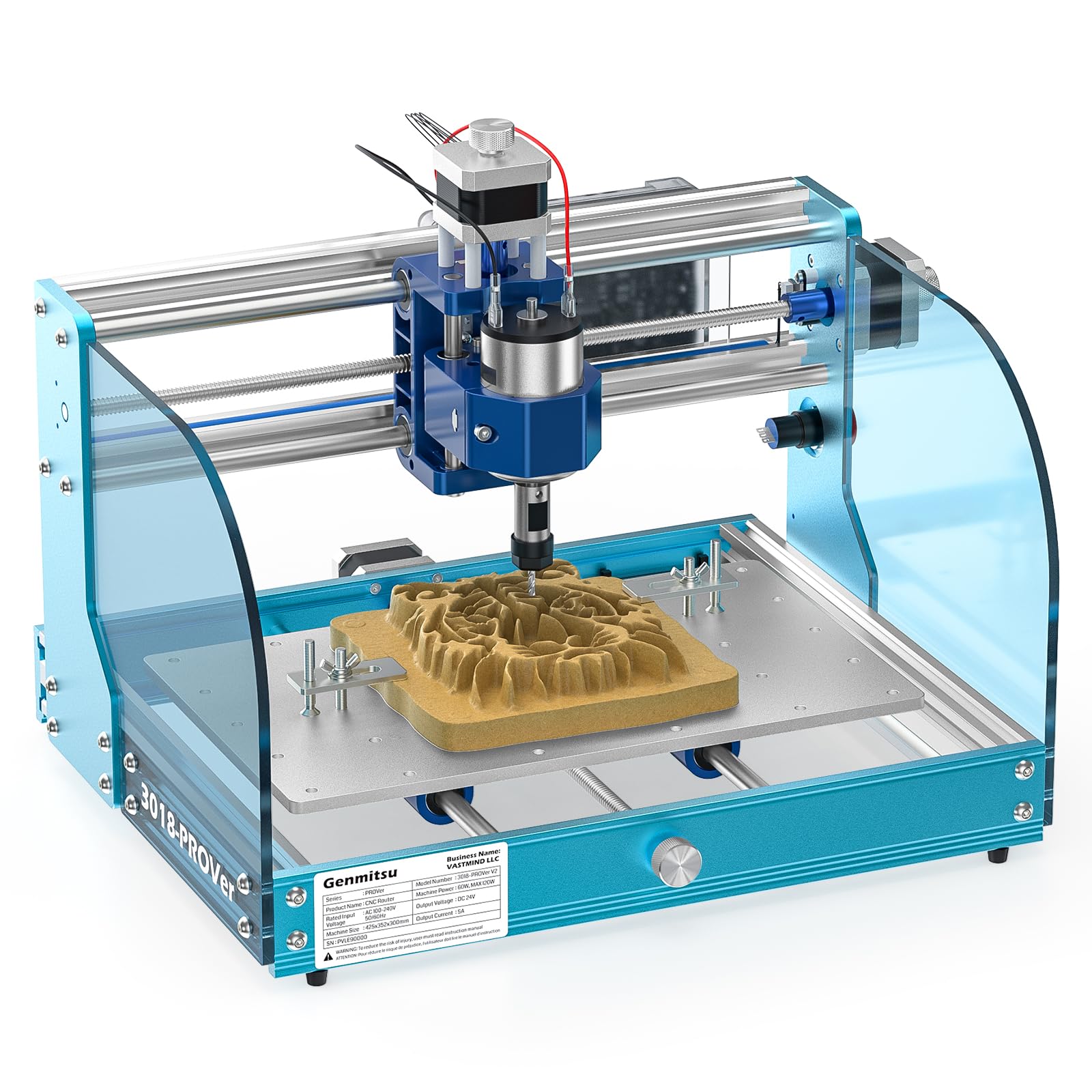

What is the best CNC router for beginners?

For beginners, models like the SainSmart 3018-proVer and Genmitsu 4040 are highly recommended due to their affordability, ease of use, and strong community support. These machines offer a good balance between functionality and price, allowing newcomers to learn the ropes without significant financial investment. Look for machines that come with user-friendly software and have a solid online support community to assist with troubleshooting and learning. -

What are the common customization options available for CNC routers?

Most CNC router manufacturers offer customization options, including different spindle types, motor configurations, and additional features like automatic tool changers or larger cutting areas. When considering a purchase, inquire about available upgrades or modifications that can enhance performance. Customization can also include software packages tailored to your specific needs, such as CAD/CAM integration. Make sure to communicate your requirements clearly to suppliers to ensure compatibility. -

What should I consider when vetting suppliers for CNC routers?

When vetting suppliers, focus on their reputation, experience, and customer feedback. Look for suppliers with a proven track record in your region, especially those familiar with international shipping regulations. Request references and examine their after-sales support, warranty policies, and technical assistance. Additionally, assess their response times and willingness to answer questions, as strong communication is crucial for a successful business relationship. -

What are the typical minimum order quantities (MOQs) for CNC routers?

Minimum order quantities can vary significantly based on the supplier and the specific model of the CNC router. For entry-level machines, some suppliers may offer units with no MOQ, while others may require a minimum of two or more units to ensure cost-effectiveness. Always discuss MOQs during negotiations, especially if you are looking to purchase multiple machines for a larger operation. Additionally, inquire about bulk pricing options to maximize your investment. -

What payment terms should I expect when purchasing CNC routers internationally?

Payment terms can vary by supplier and region. Common terms include a deposit upfront (often 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer financing options or payment via letters of credit for larger purchases. Ensure to clarify all payment methods accepted and any potential fees associated with international transactions. It is advisable to use secure payment channels to protect against fraud. -

How do I ensure quality assurance (QA) when sourcing CNC routers?

To ensure quality assurance, request detailed specifications and certifications for the CNC routers you’re considering. Ask suppliers about their QA processes, including pre-shipment inspections and testing protocols. It is also beneficial to visit the manufacturing facility, if feasible, or to work with third-party inspection companies that can verify product quality before shipment. Establishing clear communication regarding your quality standards will help align expectations. -

What logistics considerations should I keep in mind when importing CNC routers?

When importing CNC routers, consider shipping methods, customs regulations, and potential tariffs in your country. Research the best shipping options to minimize costs and ensure timely delivery. Work closely with your supplier to understand packaging requirements to prevent damage during transit. Additionally, be aware of lead times for production and shipping, and plan your inventory accordingly to avoid disruptions in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Cnc Router For Beginners Manufacturers & Suppliers List

1. Carbide 3D – Shapeoko 4 and 4 Pro

Domain: community.carbide3d.com

Registered: 2013 (12 years)

Introduction: This company, Carbide 3D – Shapeoko 4 and 4 Pro, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. FoxAlien – Masuter 4040 CNC Router

Domain: lumberjocks.com

Registered: 2005 (20 years)

Introduction: FoxAlien Masuter 4040 CNC Router Machine; SainSmart 3018-proVer with 12x8x2 cutting volume; Genmitsu 4040; Genmitsu CNC Machine 4040-PRO for Wood Acrylic MDF Nylon Carving Cutting, GRBL Control, 3 Axis CNC Router Machine, Working Area 400 x 400 x 84mm (15.7” x 15.7” x 3.31”); Price range under $1000; Genmitsu available for $649 with free shipping; Amazon price for Genmitsu at $599 with free shippi…

3. Genmitsu – ProverXL 4030 V2

Domain: skool.com

Registered: 1997 (28 years)

Introduction: Genmitsu ProverXL 4030 V2, price around $1500, issues with Y2 motor (blinks red, does not move), considering returning for a better machine.

4. Hobby Machinist – High Strength Steel 2030 CNC Router

Domain: hobby-machinist.com

Registered: 2010 (15 years)

Introduction: 1. High Strength Steel 2030 400W DC Desktop CNC Router Engraver Machine AC110V/220V – Features fixed rails and fixed gantry for rigidity, affordable option for beginners. 2. Linear Guide Rails 1.5KW 2.2KW 4 Axis CNC Router MACH3 USB 3040 – Suitable for metal, aluminum, iron, and steel engraving/milling, higher price point. 3. Desktop CNC Router with 4th Axis Rotary Table – Offered by stylecnc.com,…

5. Avid – CNC Routers for Custom Furniture

Domain: woodweb.com

Registered: 1995 (30 years)

Introduction: CNC routers suitable for a small custom furniture shop, specifically for cutting sheet goods and solid wood parts (up to 2″ thick). Recommendations include Avid, CAMaster, DB CNC, and Shop Sabre. Users suggest looking for a machine with a 10 horsepower minimum and high rigidity for machining solid wood. Desired size is 4′ x 8′ with a small footprint. Emphasis on quality and the importance of visit…

6. OpenBuilds – CNC Router for Beginners

Domain: builds.openbuilds.com

Registered: 2012 (13 years)

Introduction: CNC Router for Beginners, suitable for cutting wood, plastic, and soft metals. Suggested builds include the Makesmith (noted as an educational project) and C-Beam XL for more advanced use. Users recommend starting with a Dremel for cutting, but caution that it may lack torque for heavier projects. The C-Beam design is highlighted for its robustness and capability to handle more demanding tasks. Th…

Strategic Sourcing Conclusion and Outlook for cnc router for beginners

In the rapidly evolving landscape of CNC technology, strategic sourcing is essential for international B2B buyers looking to invest in CNC routers, especially beginners. Understanding the various hardware and software requirements, alongside the capabilities of different models, can significantly impact operational efficiency and product quality. Prioritizing established suppliers with proven track records ensures access to reliable equipment, technical support, and ongoing education—key components for mastering CNC routing.

For buyers in regions such as Africa, South America, the Middle East, and Europe, the ability to source machines that align with local manufacturing needs is paramount. As markets grow and diversify, investing in adaptable CNC solutions will not only enhance productivity but also foster innovation within your operations.

In conclusion, as you embark on your journey into CNC routing, leverage strategic sourcing to build a robust foundation for your business. Explore partnerships with reputable suppliers, engage in community discussions, and continuously educate yourself on the latest trends and technologies. By doing so, you position your enterprise for long-term success and competitiveness in the global market.