Introduction: Navigating the Global Market for cnc router engraving machine

In today’s competitive landscape, sourcing a reliable CNC router engraving machine can present significant challenges for international B2B buyers. The demand for precision and efficiency in manufacturing processes has driven industries across Africa, South America, the Middle East, and Europe to seek out advanced machinery that not only meets their production needs but also adheres to budgetary constraints. This comprehensive guide is designed to equip buyers with the knowledge needed to navigate the complexities of selecting the right CNC router engraving machine.

Within these pages, you will discover a wealth of information covering various types of CNC machines, their applications in different industries, and essential criteria for vetting suppliers. We will delve into cost considerations, maintenance requirements, and the importance of after-sales support, ensuring you are well-prepared to make informed purchasing decisions.

By addressing the unique needs of diverse markets, including those in Saudi Arabia and Nigeria, this guide empowers you to streamline your sourcing process, enhance operational efficiency, and ultimately invest wisely in technology that propels your business forward. Whether you are expanding your manufacturing capabilities or replacing outdated equipment, understanding the global market landscape will be key to your success.

Understanding cnc router engraving machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Benchtop CNC Routers | Compact size, entry-level pricing, limited workspace | Prototyping, small-scale production | Pros: Affordable, easy to use. Cons: Limited cutting area, less powerful. |

| Industrial CNC Routers | High precision, large workspaces, robust construction | Mass production, complex designs | Pros: High efficiency, versatile. Cons: Higher investment, requires skilled operators. |

| Laser CNC Engravers | Uses laser technology for engraving and cutting | Sign making, intricate designs | Pros: Fine detail, minimal material waste. Cons: Limited to specific materials, higher maintenance. |

| Hybrid CNC Machines | Combines CNC routing with laser engraving capabilities | Versatile applications, multi-material | Pros: Multi-functional, saves space. Cons: More complex, potential for higher repair costs. |

| Portable CNC Routers | Lightweight, designed for on-site applications | Construction, custom installations | Pros: Mobility, flexibility. Cons: May sacrifice power and precision for portability. |

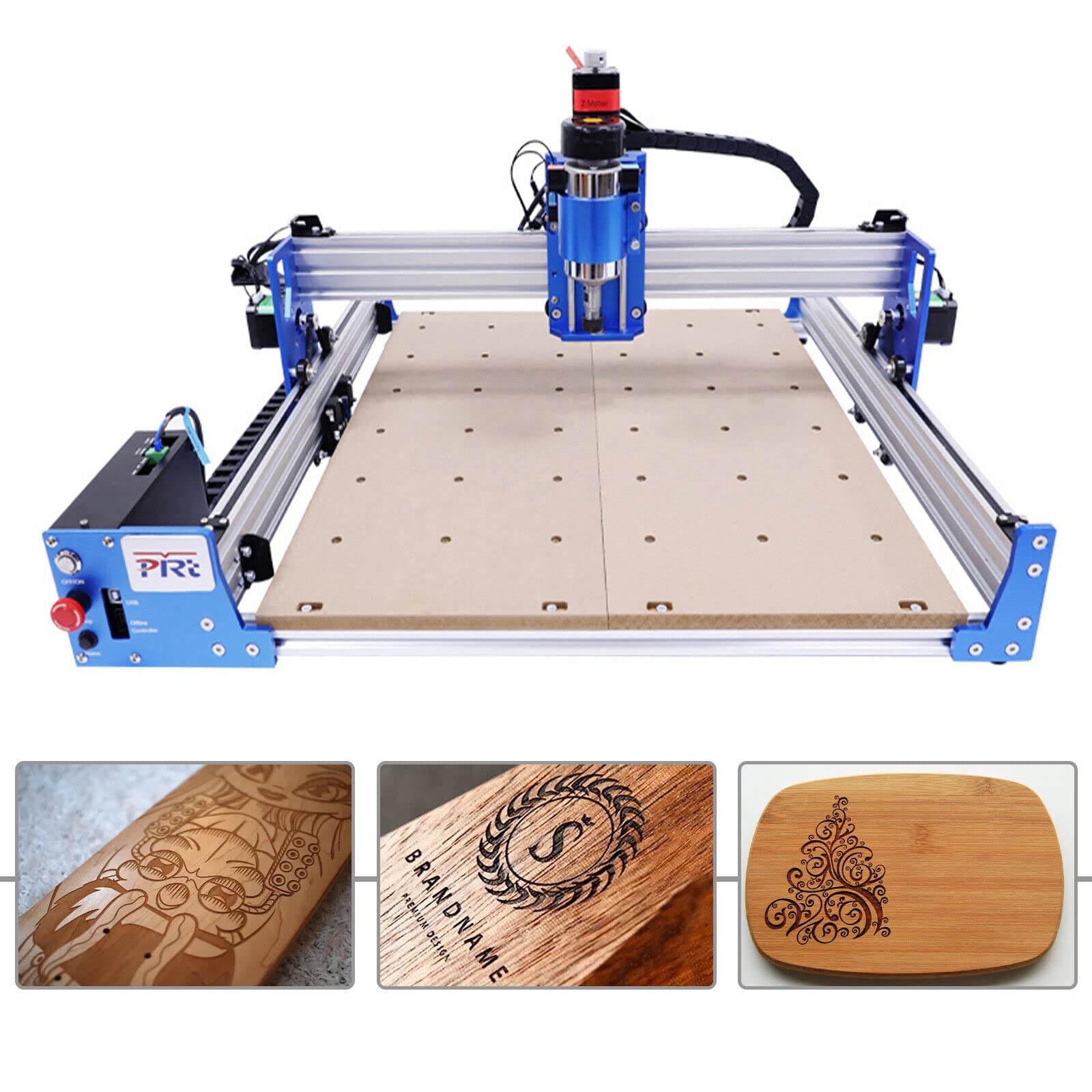

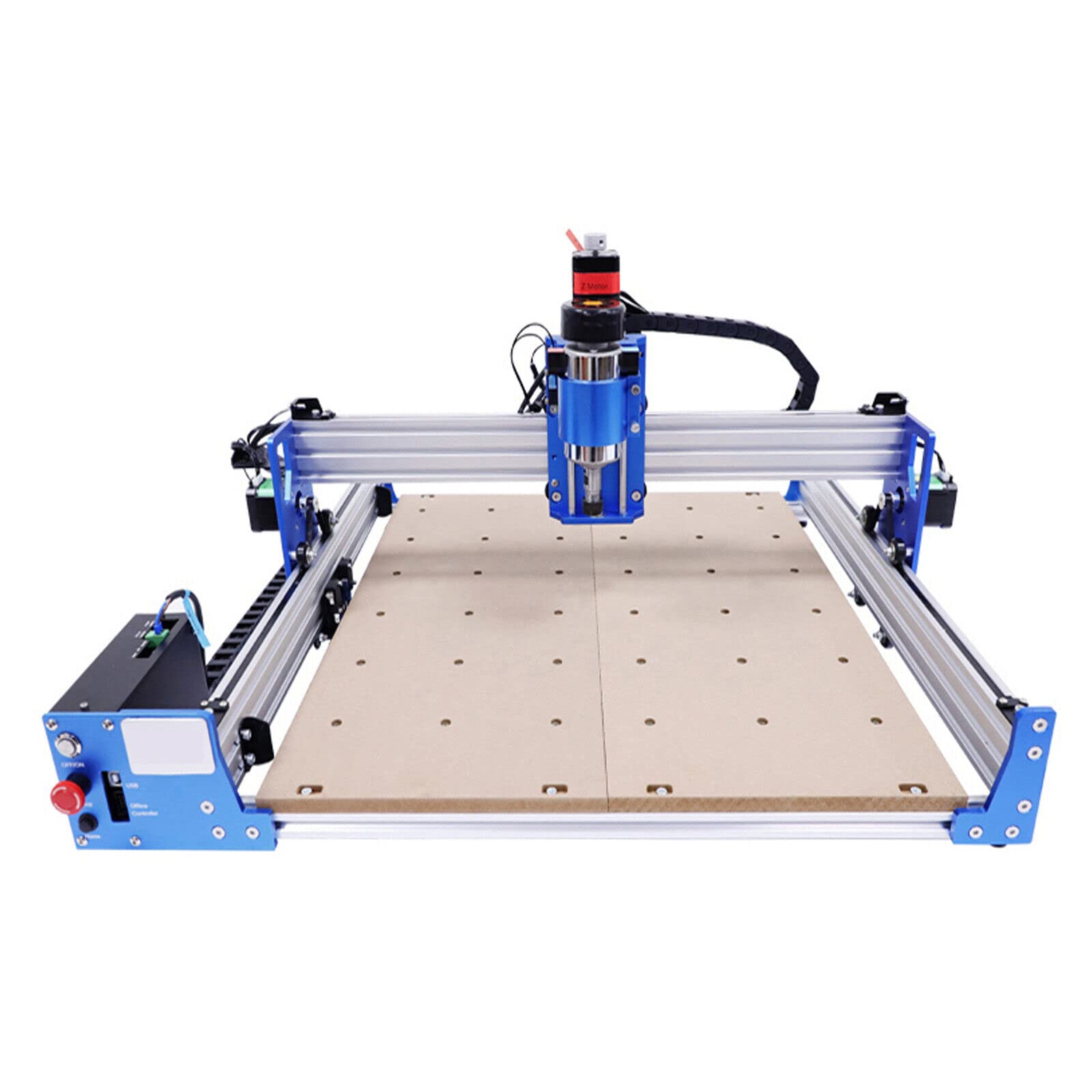

What Are Benchtop CNC Routers and Their B2B Relevance?

Benchtop CNC routers are compact, entry-level machines ideal for businesses looking to explore CNC technology without a hefty investment. They are perfect for prototyping and small-scale production, making them suitable for startups and hobbyists. When considering a benchtop router, B2B buyers should evaluate workspace limitations and the types of materials they intend to work with, as these machines often have reduced power and cutting areas compared to larger models.

How Do Industrial CNC Routers Meet High-Demand Production Needs?

Industrial CNC routers are designed for high-volume production with large workspaces and robust construction. They provide high precision and can handle complex designs, making them ideal for manufacturers needing consistent output. B2B buyers should consider the total cost of ownership, including maintenance and operator training, as these machines often require a skilled workforce and significant upfront investment.

What Advantages Do Laser CNC Engravers Offer for Detailed Work?

Laser CNC engravers utilize laser technology to achieve intricate designs and high-quality cuts, making them popular in sign-making and decorative applications. Their ability to work with various materials while minimizing waste is a significant advantage. However, B2B buyers should be aware of the limitations regarding material compatibility and the potential for increased maintenance costs due to the complexity of the laser systems.

Why Choose Hybrid CNC Machines for Versatile Applications?

Hybrid CNC machines combine the functionalities of routing and laser engraving, providing a comprehensive solution for businesses that require flexibility across multiple materials. This versatility can save space and reduce the need for multiple machines. However, B2B purchasers should consider the complexity of operation and potential higher repair costs when integrating such systems into their production lines.

What Are the Key Benefits of Portable CNC Routers for On-Site Work?

Portable CNC routers are designed for mobility, making them ideal for on-site applications such as construction and custom installations. Their lightweight design allows for easy transport, enabling businesses to offer services directly to clients. However, B2B buyers should weigh the trade-offs, including potential sacrifices in power and precision, against the benefits of flexibility and convenience.

Key Industrial Applications of cnc router engraving machine

| Industry/Sector | Specific Application of CNC Router Engraving Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Woodworking and Furniture | Custom furniture design and engraving | Enhances product differentiation and meets specific customer demands | Precision requirements, material compatibility, and software support |

| Signage and Advertising | Production of custom signs and promotional displays | Increases brand visibility and offers personalized marketing options | Machine size, engraving depth, and speed for high-volume production |

| Aerospace and Automotive | Component manufacturing and prototyping | Reduces production time and costs while ensuring high precision | Tolerance levels, material types (e.g., aluminum), and certification |

| Jewelry and Fashion | Engraving intricate designs on jewelry pieces | Adds value through customization and unique designs | Detail resolution, material handling, and finishing capabilities |

| Electronics and Electrical | Circuit board engraving and prototyping | Improves efficiency in product development and reduces waste | Software compatibility, engraving speed, and precision requirements |

How is CNC Router Engraving Machine Used in Woodworking and Furniture Industries?

In the woodworking and furniture sector, CNC router engraving machines are employed to design and create custom furniture pieces with intricate engravings. This technology allows manufacturers to produce unique designs that cater to specific customer preferences, thus enhancing product differentiation. Buyers in this sector should consider precision requirements, material compatibility, and the availability of software support for design modifications. The ability to work with various wood types is also crucial for international buyers, particularly in regions like Africa and South America where diverse materials are utilized.

What Are the Applications in the Signage and Advertising Industry?

CNC router engraving machines play a vital role in the signage and advertising industry by enabling the production of custom signs and promotional displays. These machines can engrave logos and messages on various materials, increasing brand visibility and offering personalized marketing solutions. For businesses looking to invest in this technology, key considerations include machine size to accommodate different sign dimensions, engraving depth for varied material thickness, and speed to meet high-volume production demands. This is especially relevant for companies in the Middle East and Europe, where competitive advertising is paramount.

How Do Aerospace and Automotive Industries Benefit from CNC Router Engraving?

In the aerospace and automotive industries, CNC router engraving machines are utilized for component manufacturing and prototyping. These machines provide the precision necessary to create complex parts, significantly reducing production time and costs. Buyers from these sectors must focus on tolerance levels and material types, such as aluminum, which require specific machining capabilities. Additionally, certification for aerospace components is critical, making it essential for international buyers to ensure that the machines meet industry standards.

What Role Does CNC Router Engraving Play in Jewelry and Fashion?

In the jewelry and fashion industries, CNC router engraving machines are used to engrave intricate designs on various jewelry pieces, adding value through customization. This technology allows jewelers to offer unique designs that appeal to specific consumer tastes, enhancing their market position. Buyers in this sector should prioritize detail resolution, material handling capabilities, and finishing options to ensure high-quality outputs. As these products often serve luxury markets, sourcing machines that can handle precious metals and provide exquisite detailing is vital, particularly for buyers in Europe and the Middle East.

How Are CNC Router Engraving Machines Used in Electronics and Electrical Applications?

CNC router engraving machines are essential in the electronics and electrical sectors for tasks such as circuit board engraving and prototyping. These machines improve efficiency in product development by allowing for precise cuts and engravings that reduce waste. Buyers need to consider software compatibility for design and production, engraving speed for quick turnarounds, and precision requirements to meet the high standards expected in electronics manufacturing. This is particularly important for international buyers in regions like South America and Africa, where technological advancements are rapidly evolving.

3 Common User Pain Points for ‘cnc router engraving machine’ & Their Solutions

Scenario 1: Difficulty in Material Compatibility and Tool Selection

The Problem: Many B2B buyers face challenges with selecting the right materials and tools for their CNC router engraving machines. For instance, a manufacturer might be unsure whether their machine can handle specific materials like aluminum or softer stones, leading to costly mistakes. Additionally, the process of selecting the appropriate bits for engraving can be overwhelming, especially for those new to CNC operations. This uncertainty can result in delays in production, increased costs, and frustration.

The Solution: To overcome this challenge, buyers should first consult the specifications of their CNC router engraving machine to understand its material capabilities. For instance, machines like the PROVerXL series are designed to handle a variety of materials, including wood, metal, and soft stone. Manufacturers should also invest in a selection of high-quality bits that are specifically designed for their material choices. It’s advisable to create a compatibility chart that outlines which bits work best with which materials, along with recommended feed rates and speeds. Furthermore, engaging with suppliers who provide detailed resources on material compatibility can help streamline the selection process and reduce trial-and-error practices.

Scenario 2: Software Integration and G-code Generation Challenges

The Problem: Many B2B users encounter difficulties with software integration and G-code generation for CNC operations. For example, a small business may struggle with programming their CNC router engraving machine using software like Fusion 360 or GRBL. This can lead to incorrect engravings, wasted materials, and the need for rework, which can be both time-consuming and costly.

The Solution: Buyers should prioritize investing in CNC machines that come with robust software support and user-friendly interfaces. Many manufacturers offer comprehensive software packages that simplify G-code generation and include tutorials for first-time users. For businesses already using software like Fusion 360, it’s crucial to ensure that the CNC router is compatible and that the necessary settings are configured correctly. Regular training sessions for staff on software updates and best practices can also enhance operational efficiency. Additionally, joining online forums or communities can provide valuable insights and troubleshooting tips from other experienced users.

Scenario 3: Maintenance and Technical Support Limitations

The Problem: A significant pain point for B2B buyers is the maintenance and technical support of CNC router engraving machines. For example, a company may experience unexpected machine downtimes due to mechanical issues, but they lack the technical expertise or resources to troubleshoot effectively. This situation can lead to production halts, missed deadlines, and dissatisfied clients, particularly in competitive markets.

The Solution: To mitigate this risk, businesses should develop a proactive maintenance schedule that includes regular inspections and servicing of their CNC equipment. Buyers should inquire about the availability of technical support from the machine manufacturer before purchasing. This includes understanding warranty terms and the speed of response times for support inquiries. Additionally, investing in a maintenance training program for employees can empower them to handle minor issues independently, reducing reliance on external support. Establishing a relationship with local technicians or service providers who specialize in CNC machinery can also ensure quick resolutions to more complex problems, minimizing downtime.

Strategic Material Selection Guide for cnc router engraving machine

What Are the Key Materials for CNC Router Engraving Machines?

When selecting materials for CNC router engraving machines, it is crucial to consider their properties, advantages, disadvantages, and compatibility with specific applications. This analysis focuses on four common materials: wood, acrylic, aluminum, and stone. Each material has unique characteristics that can influence the performance of CNC routers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe.

How Does Wood Perform in CNC Router Applications?

Wood is one of the most popular materials used in CNC router engraving due to its versatility and ease of machining. Key properties include a moderate hardness, which allows for smooth cutting and engraving without excessive wear on tools. Wood is generally cost-effective and widely available, making it a preferred choice for both small and large-scale production.

Pros: Wood offers excellent durability and aesthetic appeal, making it suitable for furniture, signage, and decorative items. It is relatively inexpensive and readily available in various types, allowing for a wide range of applications.

Cons: Wood can be sensitive to moisture and temperature changes, which may lead to warping or splitting. Additionally, the quality of the end product can vary significantly based on the type of wood used.

Impact on Application: Wood is compatible with various engraving techniques, including 2D and 3D designs. However, international buyers should consider local standards for wood treatment and sustainability, especially in regions with strict environmental regulations.

What Are the Benefits of Using Acrylic in CNC Routing?

Acrylic, or polymethyl methacrylate (PMMA), is a lightweight and shatter-resistant plastic that is commonly used in CNC routing. Its key properties include high clarity, UV resistance, and good chemical stability, making it suitable for both indoor and outdoor applications.

Pros: Acrylic provides a high-quality finish and can be easily colored, making it ideal for signage, displays, and decorative items. It is also relatively easy to machine, allowing for intricate designs.

Cons: While acrylic is durable, it can be prone to scratching and may not withstand high temperatures as effectively as other materials. Its cost is generally higher than wood, which may impact budget considerations.

Impact on Application: Acrylic is compatible with laser engraving and cutting, making it a versatile option for various applications. Buyers should be aware of international standards for plastic materials, including compliance with regulations like REACH in Europe.

How Does Aluminum Compare in CNC Router Engraving?

Aluminum is a lightweight metal known for its excellent machinability and corrosion resistance. Its key properties include a high strength-to-weight ratio and good thermal conductivity, making it suitable for a wide range of industrial applications.

Pros: Aluminum is highly durable and can be used for both functional and aesthetic parts, such as machine components, signage, and architectural features. It also has a longer lifespan compared to wood and acrylic.

Cons: The cost of aluminum is generally higher than that of wood and acrylic, which may affect project budgets. Additionally, machining aluminum requires specialized tools and techniques to prevent tool wear and achieve a clean finish.

Impact on Application: Aluminum’s compatibility with various CNC machining processes makes it a popular choice in industries such as aerospace and automotive. International buyers should be aware of material standards like ASTM for metals and consider sourcing from reputable suppliers.

What Are the Considerations for Using Stone in CNC Routing?

Stone, including materials like granite and marble, is increasingly used in CNC routing for applications such as countertops, sculptures, and memorials. Its key properties include high durability and resistance to heat and chemicals.

Pros: Stone offers a unique aesthetic appeal and can withstand harsh environmental conditions, making it ideal for outdoor applications. It can also be polished to achieve a high-gloss finish.

Cons: The weight and density of stone can complicate machining processes, requiring specialized equipment. The cost of stone materials can also be significantly higher than other options.

Impact on Application: Stone is suitable for both engraving and cutting, but buyers should consider the availability of skilled labor and equipment in their region. Compliance with local regulations regarding mining and stone processing is also essential.

Summary of Material Properties for CNC Router Engraving Machines

| Material | Typical Use Case for cnc router engraving machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Furniture, signage, decorative items | Durable and cost-effective | Sensitive to moisture and temperature | Low |

| Acrylic | Signage, displays, decorative items | High clarity and easy to color | Prone to scratching, higher cost | Med |

| Aluminum | Machine components, signage, architectural features | High durability and strength | Higher cost, requires specialized tools | High |

| Stone | Countertops, sculptures, memorials | Unique aesthetic and durability | Heavy, requires specialized equipment | High |

This strategic material selection guide aims to equip international B2B buyers with the necessary insights to make informed decisions when sourcing materials for CNC router engraving machines. Understanding the properties and implications of each material can significantly enhance operational efficiency and product quality in diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc router engraving machine

What are the Main Stages in the Manufacturing Process of CNC Router Engraving Machines?

The manufacturing process of CNC router engraving machines involves several critical stages, each designed to ensure the final product meets high standards of performance and quality. Understanding these stages is essential for B2B buyers seeking reliable machines that deliver consistent results.

Material Preparation: Selecting and Sourcing Quality Components

The first stage in manufacturing CNC routers involves the careful selection and preparation of raw materials. Common materials used include aluminum, steel, and high-grade plastics. Suppliers often source these materials from certified vendors to ensure quality. The raw materials undergo cutting, machining, and treatment processes to achieve the required specifications. This stage is crucial as the quality of the materials directly influences the durability and performance of the CNC machine.

Forming: Utilizing Advanced Techniques for Precision

The forming stage involves various machining processes, including milling, turning, and laser cutting, to shape the components of the CNC router. Advanced CNC machining centers are often employed to achieve high precision and repeatability. Techniques such as CNC milling allow for complex geometries and tight tolerances, which are vital for the machine’s operational accuracy. Each component, such as the frame, gantry, and spindle, is crafted with meticulous attention to detail to ensure compatibility and functionality.

Assembly: Ensuring Structural Integrity and Functionality

Following the forming stage, the assembly of the CNC router takes place. This process typically involves the integration of various components, including motors, drive systems, and control units. Skilled technicians perform the assembly, often using specialized tools and jigs to ensure that all parts fit correctly. This stage also includes the installation of wiring and electronics, which are essential for the machine’s operation. Proper assembly is critical, as any misalignment can lead to operational inefficiencies and increased wear on the components.

Finishing: Enhancing Performance and Aesthetics

The final stage of manufacturing involves finishing processes such as painting, anodizing, or powder coating. These techniques not only enhance the aesthetic appeal of the CNC router but also provide protective coatings that increase resistance to corrosion and wear. Additionally, this stage may include the calibration of the machine’s components to ensure optimal performance. Quality assurance checks are often conducted during this phase to confirm that the machine meets the specified performance standards.

How is Quality Assurance Implemented in CNC Router Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for CNC routers. It ensures that the machines produced meet international standards and customer expectations. For B2B buyers, understanding the QA processes can help in selecting reliable suppliers.

What International Standards Govern CNC Router Quality?

Manufacturers of CNC routers typically adhere to various international quality standards, with ISO 9001 being one of the most recognized. This standard focuses on quality management systems and emphasizes continuous improvement and customer satisfaction. Additionally, specific industry certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for certain applications may also apply. These certifications demonstrate compliance with safety, health, and environmental regulations.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated into several checkpoints throughout the manufacturing process. Key QC checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to detect defects early.

- Final Quality Control (FQC): Comprehensive testing and inspection of the completed CNC router before shipping.

Each checkpoint involves specific testing methods, including dimensional inspections, functional testing, and performance evaluations. These measures ensure that any defects are identified and rectified before the product reaches the customer.

What Common Testing Methods Are Used in CNC Router Quality Assurance?

Common testing methods employed in quality assurance include:

- Dimensional Inspection: Utilizing precision measurement tools to verify that components meet specified tolerances.

- Functional Testing: Operating the CNC machine to assess its performance, including speed, accuracy, and responsiveness.

- Load Testing: Simulating operational conditions to evaluate the machine’s performance under stress.

These testing methods are essential to confirm that the CNC router is capable of performing its intended functions reliably.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, ensuring that suppliers maintain robust quality control processes is crucial. Here are several strategies to verify supplier QC:

What Steps Can Buyers Take for Supplier Audits?

Conducting supplier audits is one effective way to assess a manufacturer’s quality control systems. Buyers can request on-site audits to evaluate the manufacturing processes, QC checkpoints, and compliance with international standards. During these audits, buyers should look for documentation of quality control processes and records of previous inspections.

How Can Buyers Request Quality Assurance Reports?

Buyers should also request quality assurance reports from suppliers. These reports typically include details about the QC measures in place, results from testing, and any corrective actions taken in response to identified defects. Reviewing these reports can provide insights into the supplier’s commitment to quality.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control practices. These independent organizations can conduct inspections and provide detailed reports on compliance with industry standards. This additional layer of verification is particularly valuable for international buyers who may face challenges in assessing suppliers directly.

What Are the QC and Certification Nuances for International Buyers?

International B2B buyers must navigate various nuances when evaluating quality control and certifications. Different regions may have specific regulatory requirements, and understanding these can help buyers make informed decisions. For instance, products exported to Europe must often meet CE marking requirements, while products intended for the Middle East may need to adhere to specific local standards.

Additionally, buyers should be aware of the importance of supplier relationships. Establishing strong partnerships with suppliers can facilitate better communication regarding quality expectations and compliance with international standards.

By understanding the manufacturing processes and quality assurance protocols of CNC router engraving machines, B2B buyers can make informed decisions that align with their operational needs and quality expectations. This knowledge is crucial for sourcing reliable machines that will enhance productivity and performance in their respective industries.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc router engraving machine’

Introduction

This practical sourcing guide aims to assist B2B buyers in procuring CNC router engraving machines effectively. By following this checklist, you can ensure that your investment meets your operational requirements while adhering to quality standards. Each step is designed to guide you through the critical aspects of the sourcing process, from defining specifications to evaluating suppliers.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical specifications needed for your CNC router engraving machine. Consider factors such as the materials you intend to engrave, the maximum thickness, and the precision required for your projects.

– Key specifications to include:

– Work area dimensions

– Type of materials (wood, metal, plastic)

– Desired spindle speed and power

Step 2: Research Market Trends and Technologies

Understanding current market trends and technological advancements is essential for making an informed purchase. Research various types of CNC routers available, such as those with dual Z-axis capabilities or advanced software integration.

– Focus on:

– User reviews and case studies

– Innovations in CNC technology that enhance productivity

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request detailed company profiles, product samples, and references from other businesses in your industry. This ensures that you are partnering with a reputable manufacturer.

– Assess:

– Supplier certifications (ISO, CE, etc.)

– Experience in your specific market or application

Step 4: Request Quotes and Compare Pricing

Once you have shortlisted potential suppliers, request detailed quotes that outline pricing, shipping costs, and payment terms. Comparing quotes helps you understand the market rate and ensures you are getting a fair deal.

– Consider:

– Volume discounts for bulk orders

– Warranty and after-sales support included in the pricing

Step 5: Verify Compliance with Local Regulations

Ensure that the CNC router engraving machine complies with local regulations and safety standards in your region. This is particularly important for international purchases, as regulations can vary significantly.

– Check for:

– CE marking for European buyers

– Compliance with local electrical and safety standards

Step 6: Assess Support and Training Options

Evaluate the level of technical support and training provided by the supplier. This is crucial for ensuring that your team can operate the machine effectively and troubleshoot any issues that arise.

– Look for:

– Availability of training programs or manuals

– Access to customer support and technical assistance

Step 7: Finalize the Purchase Agreement

Once you have chosen a supplier, finalize the purchase agreement. Ensure all terms are clear, including delivery timelines, payment schedules, and any contingencies for delays or product issues.

– Key elements to include:

– Clear definition of product specifications

– Terms for returns and exchanges in case of defects

By following this checklist, B2B buyers can navigate the complexities of sourcing CNC router engraving machines confidently, ensuring a successful procurement process tailored to their specific needs.

Comprehensive Cost and Pricing Analysis for cnc router engraving machine Sourcing

Understanding the cost structure and pricing dynamics of CNC router engraving machines is crucial for international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe. This analysis delves into the various cost components, pricing influencers, and buyer tips to help organizations make informed purchasing decisions.

What Are the Key Cost Components in CNC Router Engraving Machines?

-

Materials: The primary materials used in CNC routers include aluminum, steel, and plastic components. High-quality materials lead to better durability and performance, which can significantly impact the cost. For instance, a machine with a robust frame and high-grade motors will naturally be more expensive than a lightweight, lower-grade version.

-

Labor: Labor costs encompass the wages of skilled technicians involved in manufacturing, assembly, and quality control. Regions with lower labor costs may offer more competitively priced machines, but this can also correlate with lower quality.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these costs, allowing suppliers to offer better pricing.

-

Tooling: The equipment and tools used in the production of CNC machines also affect costs. Specialized tools may increase initial costs but can lead to higher quality and efficiency in production.

-

Quality Control (QC): Rigorous QC processes ensure that machines meet specified standards. While this adds to the cost, it provides assurance of performance and reliability, which is crucial for buyers.

-

Logistics: Shipping and handling costs can vary significantly based on the origin of the machine and the destination. International buyers should consider these expenses when evaluating total costs.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the industry standard margins can help buyers identify reasonable pricing.

How Do Pricing Influencers Impact CNC Router Engraving Machine Costs?

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk purchases. Buyers should evaluate their needs and consider negotiating for better rates when ordering larger quantities.

-

Specifications and Customization: Custom features such as enhanced motor types, software compatibility, and additional tooling can affect the price. Buyers should clearly define their requirements to avoid unexpected costs.

-

Material Quality and Certifications: Machines built with certified materials or those that comply with international standards may command higher prices. However, such investments can lead to greater longevity and reliability.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with proven track records may charge more but often provide better after-sales support and warranty options.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) can help buyers negotiate better pricing and avoid hidden costs related to shipping and customs duties.

What Are the Best Buyer Tips for Sourcing CNC Router Engraving Machines?

-

Negotiate Pricing: Don’t hesitate to negotiate with suppliers. Highlighting your potential for future business can lead to better pricing and terms.

-

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, operational costs, maintenance, and potential resale value. Cheaper machines may incur higher costs in the long run due to lower durability or efficiency.

-

Understand Pricing Nuances for International Markets: For buyers from Africa, South America, the Middle East, and Europe, be aware of currency fluctuations, import duties, and regional market conditions that can affect pricing.

-

Request Detailed Quotations: Always ask for a breakdown of costs in quotations to understand the pricing structure better. This transparency can aid in negotiation and help identify any unnecessary costs.

-

Research and Compare: Conduct thorough research and compare multiple suppliers. Look for reviews and testimonials from other buyers to gauge the quality and reliability of the machines and the supplier.

By understanding these cost components and pricing influencers, B2B buyers can make strategic decisions when sourcing CNC router engraving machines, ensuring they select the best option for their specific needs while optimizing their investment.

Alternatives Analysis: Comparing cnc router engraving machine With Other Solutions

Exploring Alternatives to CNC Router Engraving Machines for B2B Buyers

In the landscape of manufacturing and engraving solutions, CNC router engraving machines stand out for their precision and versatility. However, several alternative technologies can also achieve similar results, each with unique advantages and limitations. This section compares CNC router engraving machines with two viable alternatives: laser engraving machines and traditional hand engraving.

| Comparison Aspect | CNC Router Engraving Machine | Laser Engraving Machine | Traditional Hand Engraving |

|---|---|---|---|

| Performance | High precision and speed; capable of cutting various materials | Excellent detail; faster than CNC for intricate designs | Varies greatly; depends on the artisan’s skill |

| Cost | Moderate initial investment; ongoing costs for bits and maintenance | Higher upfront costs; lower maintenance | Low initial cost; skilled labor can be expensive |

| Ease of Implementation | Requires software and setup; some training needed | User-friendly; often includes software | Requires significant skill and practice |

| Maintenance | Regular maintenance needed; replaceable parts | Low maintenance; infrequent part replacements | Minimal maintenance; depends on tools used |

| Best Use Case | Ideal for large-scale production and diverse materials | Best for intricate designs on smaller items | Suitable for custom, one-off pieces and artistic projects |

What Are the Pros and Cons of Laser Engraving Machines Compared to CNC Router Engraving Machines?

Laser engraving machines utilize focused beams of light to etch or cut materials, providing high detail and speed, particularly for intricate designs. They excel in applications involving softer materials like wood, acrylic, and certain metals. However, their initial investment tends to be higher than CNC routers, and they may not be as effective for thicker materials. Maintenance is minimal compared to CNC machines, making them an attractive option for businesses focused on detailed engraving and less on heavy cutting.

How Does Traditional Hand Engraving Compare to CNC Router Engraving Machines?

Traditional hand engraving involves skilled artisans using manual tools to create designs on various surfaces. This method allows for exceptional craftsmanship and unique touches that machines cannot replicate. However, the performance is highly variable and relies heavily on the engraver’s skill level. Additionally, while the initial costs for tools are low, the labor costs can be significant, especially for complex projects. Hand engraving is best suited for custom work or artistic pieces, where individuality and craftsmanship are paramount.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right engraving solution depends on several factors, including production scale, material types, design complexity, and budget. For businesses aiming for high volume and versatility, CNC router engraving machines offer an excellent balance of performance and cost-effectiveness. In contrast, if detailed designs on smaller items are the priority, laser engraving machines may prove to be the better investment. Meanwhile, for artisan-focused projects where uniqueness is valued, traditional hand engraving remains an irreplaceable option. By evaluating these aspects, B2B buyers can align their choice with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for cnc router engraving machine

What Are the Key Technical Properties of CNC Router Engraving Machines?

Understanding the essential technical properties of CNC router engraving machines is crucial for B2B buyers. These specifications directly impact performance, capability, and suitability for various applications. Here are some key properties to consider:

1. Material Compatibility

CNC routers can work with various materials, including wood, plastics, soft metals, and even some stone types. Knowing the machine’s compatibility helps buyers select the right equipment for their specific needs. For instance, a machine that can handle aluminum is essential for businesses in metalworking sectors.

2. Tolerance and Precision

Tolerance refers to the allowable deviation from a specified measurement. For CNC routers, precision is typically measured in millimeters or microns. High precision is vital for applications requiring intricate designs or tight-fitting components. Businesses should assess the tolerance level to ensure it aligns with their production standards and quality requirements.

3. Spindle Speed

The spindle speed, measured in RPM (revolutions per minute), indicates how fast the cutting tool spins. A higher spindle speed allows for faster cutting and engraving, which can improve production efficiency. Buyers must consider the spindle speed to match their material processing needs and desired finish quality.

4. Working Area Dimensions

The working area defines the maximum size of the material that can be processed. Machines with larger working areas can accommodate bigger workpieces, making them suitable for larger projects or batch productions. Understanding the dimensions helps buyers choose a machine that fits their operational space and project requirements.

5. Drive System

CNC routers utilize various drive systems, such as belt, rack and pinion, or ball screw drives. Each system has its advantages in terms of speed, accuracy, and maintenance. A ball screw drive, for example, offers high precision and is ideal for detailed engraving tasks. Buyers should evaluate the drive system to ensure it meets their performance expectations.

6. Control Software

The control software is essential for operating CNC routers, as it dictates how designs are translated into machine movements. Software compatibility can affect the learning curve and operational efficiency. Buyers should ensure that the machine supports user-friendly software that integrates well with their existing design tools.

What Are Common Trade Terms Associated with CNC Router Engraving Machines?

Familiarity with industry jargon is important for effective communication and decision-making in B2B transactions. Here are several common terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the CNC industry, OEMs provide machines and components that can be customized for specific applications. Understanding OEM relationships can help buyers evaluate product quality and support.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it influences inventory management and pricing. Knowing the MOQ can help businesses plan their purchases effectively and avoid overstocking.

3. RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers for specific products or services. This term is commonly used in procurement processes to gather competitive pricing and terms. Buyers should prepare detailed RFQs to ensure they receive comprehensive responses that meet their specifications.

4. Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps businesses navigate shipping, insurance, and risk management when sourcing CNC routers from global suppliers.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. This term is vital for project planning, as longer lead times can impact production schedules. Buyers should inquire about lead times to align their procurement processes with operational timelines.

6. Warranty and Service Agreements

These agreements outline the terms of repair and maintenance services provided by the manufacturer or supplier. Understanding warranty terms is crucial for ensuring long-term machine performance and minimizing downtime. Buyers should carefully review these agreements before making purchasing decisions.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when selecting CNC router engraving machines that best suit their operational needs.

Navigating Market Dynamics and Sourcing Trends in the cnc router engraving machine Sector

What Are the Current Market Dynamics and Key Trends in the CNC Router Engraving Machine Sector?

The CNC router engraving machine sector is witnessing significant growth, driven by the increasing demand for precision manufacturing across various industries such as woodworking, metalworking, and signage. Key global drivers include the rise of automation and digital fabrication, which streamline production processes and improve accuracy. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe (e.g., Saudi Arabia, Nigeria), look to enhance operational efficiency, they increasingly seek CNC routers that can handle diverse materials and complex designs.

Emerging trends include the integration of IoT technologies into CNC machinery, enabling real-time monitoring and predictive maintenance. This shift allows businesses to minimize downtime and optimize production schedules. Furthermore, there is a growing preference for machines that offer flexibility, such as multi-purpose routers that can engrave, cut, and carve. Buyers are also showing interest in CNC routers that are compatible with advanced software, facilitating seamless design-to-production workflows.

Additionally, the market is becoming more competitive, with manufacturers emphasizing not only the technical capabilities of their machines but also their ease of use and customer support services. As global supply chains evolve, buyers should prioritize suppliers who offer transparent sourcing practices and reliable logistics, particularly for international shipments.

How Are Sustainability and Ethical Sourcing Shaping the CNC Router Engraving Machine Market?

Sustainability has become a critical consideration for B2B buyers in the CNC router engraving machine sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to adopt more sustainable practices. Buyers are increasingly looking for machines made from recyclable materials and those that consume less energy during operation.

Ethical sourcing is also gaining traction, as businesses recognize the importance of maintaining responsible supply chains. Certifications such as ISO 14001 and other green labels can indicate a manufacturer’s commitment to environmental stewardship. Buyers should seek out suppliers who demonstrate compliance with these standards, as it reflects their dedication to minimizing negative impacts on the environment.

Moreover, the use of eco-friendly lubricants and cutting fluids in CNC operations is becoming more common. These products not only reduce environmental harm but also improve machine longevity and performance. By prioritizing sustainability and ethical sourcing, international B2B buyers can enhance their brand reputation and appeal to environmentally conscious consumers.

What Is the Evolution and Historical Context of CNC Router Engraving Machines?

CNC router engraving machines have evolved significantly since their inception in the mid-20th century. Initially, these machines were primarily used for woodworking and simple engraving tasks. However, advancements in computer technology and software have transformed them into versatile tools capable of cutting, carving, and engraving a wide range of materials, including metals and plastics.

The introduction of CAD/CAM software in the 1980s revolutionized the industry, allowing designers to create intricate designs that could be directly translated into machine instructions. This evolution has paved the way for modern CNC routers to integrate with various design tools, making them indispensable in industries ranging from manufacturing to art.

As international B2B buyers navigate this dynamic market, understanding the historical context of CNC technology can provide valuable insights into the capabilities and innovations that drive the sector today. By leveraging these advancements, businesses can enhance their production processes and meet the growing demands of diverse markets.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc router engraving machine

-

How do I solve compatibility issues with software when using a CNC router engraving machine?

To address compatibility issues, first verify the software specifications provided by the manufacturer. Many CNC routers operate on specific software versions or protocols (like GRBL). Ensure you have the correct drivers and software installed, which are often included in the product manual or available for download from the manufacturer’s website. If problems persist, consider reaching out to the supplier’s technical support for assistance, as they can provide tailored advice based on your specific setup. -

What is the best CNC router engraving machine for small to medium-sized businesses?

The ideal CNC router for small to medium-sized businesses often depends on the materials you plan to work with and the complexity of the projects. For versatile applications, a mid-range model with a robust spindle and a good work area, such as the PROVerXL series, is recommended. These machines usually come with software support and can handle various materials, including wood, plastics, and soft metals, making them a cost-effective solution for diverse engraving tasks. -

How do I evaluate a supplier for CNC router engraving machines?

When evaluating a supplier, consider their reputation in the market, customer reviews, and their experience with international shipping. Check if they provide technical support and warranty terms, as these are critical for machine longevity. Additionally, assess their response time and transparency during negotiations. Request references or case studies from other international buyers, especially those from your region, to gauge reliability and service levels. -

What are the typical minimum order quantities (MOQ) for CNC router engraving machines?

Minimum order quantities can vary significantly among suppliers. Some may offer machines as single units, while others may require a minimum of five or more for bulk pricing. When negotiating, inquire about flexibility in MOQ, especially if you’re a startup or a small business. Suppliers might be willing to accommodate lower quantities for first-time buyers or offer discounts for larger orders, so it’s essential to clarify your needs upfront. -

What payment terms should I expect when purchasing a CNC router engraving machine?

Payment terms can vary widely based on supplier policies and your negotiation strength. Common terms include a deposit upfront (often 30-50%) with the balance due before shipping. Some suppliers may offer financing options or payment upon delivery, particularly for long-term relationships. Always ensure to clarify payment methods accepted, including international transaction fees, and get everything in writing to avoid future disputes. -

How can I ensure quality assurance (QA) when sourcing CNC router engraving machines?

To ensure quality assurance, request detailed specifications and certifications for the machine from the supplier. Many reputable manufacturers conduct pre-shipment inspections, which you can request. Consider visiting the factory or using third-party inspection services to verify quality before shipping. Additionally, inquire about warranty terms and after-sales support to ensure that any issues can be promptly addressed. -

What logistics considerations should I keep in mind when importing CNC router engraving machines?

Logistics play a crucial role in the successful importation of CNC machines. Consider shipping methods (air vs. sea), transit times, and customs regulations in your country. Calculate total landed costs, including shipping, duties, and taxes. Collaborating with a freight forwarder experienced in machinery imports can help navigate these complexities. Also, ensure that the supplier can provide all necessary documentation for smooth customs clearance. -

Can I customize a CNC router engraving machine to fit my specific needs?

Yes, many manufacturers offer customization options for CNC router engraving machines. You can often request modifications such as different spindle sizes, enhanced software capabilities, or specific tooling setups to cater to your production requirements. It’s essential to communicate your needs clearly during the negotiation phase and verify whether there are additional costs or extended lead times associated with custom builds. Always request a detailed quote and timeline for any modifications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Cnc Router Engraving Machine Manufacturers & Suppliers List

1. Monoprice – CNC Router Machine

Domain: monoprice.com

Registered: 2001 (24 years)

Introduction: This company, Monoprice – CNC Router Machine, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. SainSmart – Genmitsu CNC Routers & Laser Engravers

Domain: sainsmart.com

Registered: 2011 (14 years)

Introduction: Genmitsu CNC & Engraving products include various CNC routers and laser engravers such as the Cubiko 4040-PRO, MAX PROVerXL 4×4, Kiosk 2.5W~10W, Falcon A1 10W, and L8 40W/20W. The collection also features parts and accessories like laser upgrade parts, spindle and stepper motors, extension kits, spoilboard clamps, controllers, and dust collection replacements. Additionally, there are Flexi-Packs, …

3. Vision Engraving – Engraving Machines & CNC Routers

Domain: visionengravers.com

Registered: 1999 (26 years)

Introduction: Vision Engraving & Routing Systems manufactures a variety of engraving machines and CNC routers in the USA, offering small to large engravers, specialty engravers, CNC routers, and laser engravers. They provide solutions for various applications including ADA/Braille, badges/tags, control panels, custom car parts, firearms marking, gift/jewelry engraving, glass engraving, government engraving, met…

4. Carbide 3D – CNC Engraving Machines

Domain: carbide3d.com

Registered: 2013 (12 years)

Introduction: CNC Engraving is a process that creates shallow cuts for fine detail, often used for personalization, branding, and markers. Ideal CNC machines for engraving include the Nomad Desktop CNC for small items and the Shapeoko CNC Router for larger items. Key features for engraving machines are a high-speed spindle (over 12,000 RPM) and accuracy for shallow cuts. Materials suitable for engraving include…

5. Automation Technologies Inc – 3 Axis CNC 3040T Router Engraver

Domain: automationtechnologiesinc.com

Registered: 2011 (14 years)

Introduction: Product Name: 3 Axis CNC 3040T Router Engraver/Engraving Drilling and Milling Machine UC100 USB Connection

Price: $699.95

Power: 300W Hobby Spindle

Control Box: USB UC100 Connection

Compatibility: Windows 32 bit or 64 bit, Mach3 USB UC100

Specifications:

– Driving Unit: X/Y/Z axis: 1204 trapezoidal screws, Chrome plate shaft

– Maximum Speed: 0-200 inch/min

– Carving Speed: 120 inch/min

– Structure…

6. OMIO – X4M-USB CNC Router

Domain: omiocnc.com

Registered: 2014 (11 years)

Introduction: Product Name: OMIO CNC X4M-USB CNC Router | Desktop Engraving Machine

Price: US$1,199.00

Availability: In stock

Spindle Options: 800W Water-Cooling, 800W Air-Cooling (220V-240V only), 1500W Air-Cooling (+US$40.00), 1500W Water-Cooling (+US$45.00)

Voltage Options: 100V~120V, 220V~240V

Axis Options: 3-axis version, 4-axis version (with H60-TB80T 4th-axis + US$315.00)

Wireless Control: Optional wirel…

7. Rockler – CNC Machines

Domain: rockler.com

Registered: 1997 (28 years)

Introduction: This company, Rockler – CNC Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Bravo Prodigy – BE3000 Desktop CNC Router

Domain: bravoprodigy.com

Registered: 2009 (16 years)

Introduction: {“product_name”: “Desktop CNC Router / Desktop CNC Engraving Machine”, “model”: “BE3000”, “table_size”: {“X”: “450 mm”, “Y”: “440 mm”, “dimensions_in_inches”: “17.7 × 17.3 inches”}, “max_table_load_weight”: “5 kgs (11 lbs)”, “engraving_area”: {“X”: “300 mm”, “Y”: “300 mm”, “Z”: “100 mm”, “dimensions_in_inches”: “12 × 12 × 4 inches”}, “max_engraving_speed”: “2500 mm/min (98 inches/min)”, “engraving…

9. Genmitsu – 3020-PRO MAX V2 CNC Router

Domain: walmart.com

Registered: 1995 (30 years)

Introduction: This company, Genmitsu – 3020-PRO MAX V2 CNC Router, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for cnc router engraving machine

In summary, strategic sourcing of CNC router engraving machines presents significant opportunities for international B2B buyers seeking to enhance their production capabilities. By understanding the diverse range of available machines, including budget-friendly options and advanced systems, buyers can align their investments with specific operational needs. Factors such as compatibility with existing software, ease of setup, and after-sales support are critical considerations that can influence purchasing decisions.

Moreover, leveraging volume pricing and exploring partnerships with reliable suppliers can yield substantial cost savings and ensure access to high-quality equipment. As industries across Africa, South America, the Middle East, and Europe continue to evolve, the demand for precision machining solutions will only increase.

Looking ahead, now is the opportune moment for businesses to invest in CNC technology that not only meets current demands but also scales with future growth. International buyers are encouraged to conduct thorough market research, evaluate supplier reliability, and seize the chance to enhance their operational efficiency through strategic sourcing. Embrace the future of manufacturing by making informed choices today.