Introduction: Navigating the Global Market for cnc router and engraver

In today’s competitive landscape, sourcing CNC routers and engravers presents a unique challenge for international B2B buyers. The need for precision machinery that can handle diverse applications—from woodworking to metal fabrication—while ensuring cost-effectiveness and reliability is paramount. This guide serves as a comprehensive resource, addressing the complexities involved in selecting the right CNC solutions. It covers various types of machines, their specific applications, supplier vetting processes, and cost considerations, enabling buyers to navigate the global market with confidence.

For businesses in regions like Africa, South America, the Middle East, and Europe—including emerging markets such as Vietnam and Saudi Arabia—understanding the nuances of CNC technology is crucial. This guide empowers buyers by providing insights into the latest innovations and trends, ensuring they make informed purchasing decisions. By focusing on key factors such as machine specifications, supplier reputation, and total cost of ownership, international buyers can streamline their procurement processes and enhance their operational capabilities.

As you delve deeper into this guide, you will uncover actionable strategies to evaluate and select CNC routers and engravers tailored to your unique business needs. Whether you’re a seasoned manufacturer or an emerging entrepreneur, this resource is designed to equip you with the knowledge to thrive in an increasingly globalized marketplace.

Understanding cnc router and engraver Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Router | High-speed cutting, versatility in materials, typically larger work area | Woodworking, cabinetry, signage, metalworking | Pros: Efficient for large projects; Cons: Initial cost can be high. |

| Laser Engraver | Uses laser technology for precise engraving and cutting | Personalization, signage, small-scale production | Pros: High precision; Cons: Limited material compatibility. |

| CO2 Laser Cutter | Powerful laser, good for thicker materials, large cutting area | Industrial manufacturing, prototyping | Pros: Handles diverse materials; Cons: Requires ventilation. |

| Fiber Laser Engraver | High speed, ideal for metal marking, compact size | Jewelry, electronics, metal fabrication | Pros: Fast and durable; Cons: Higher operational costs. |

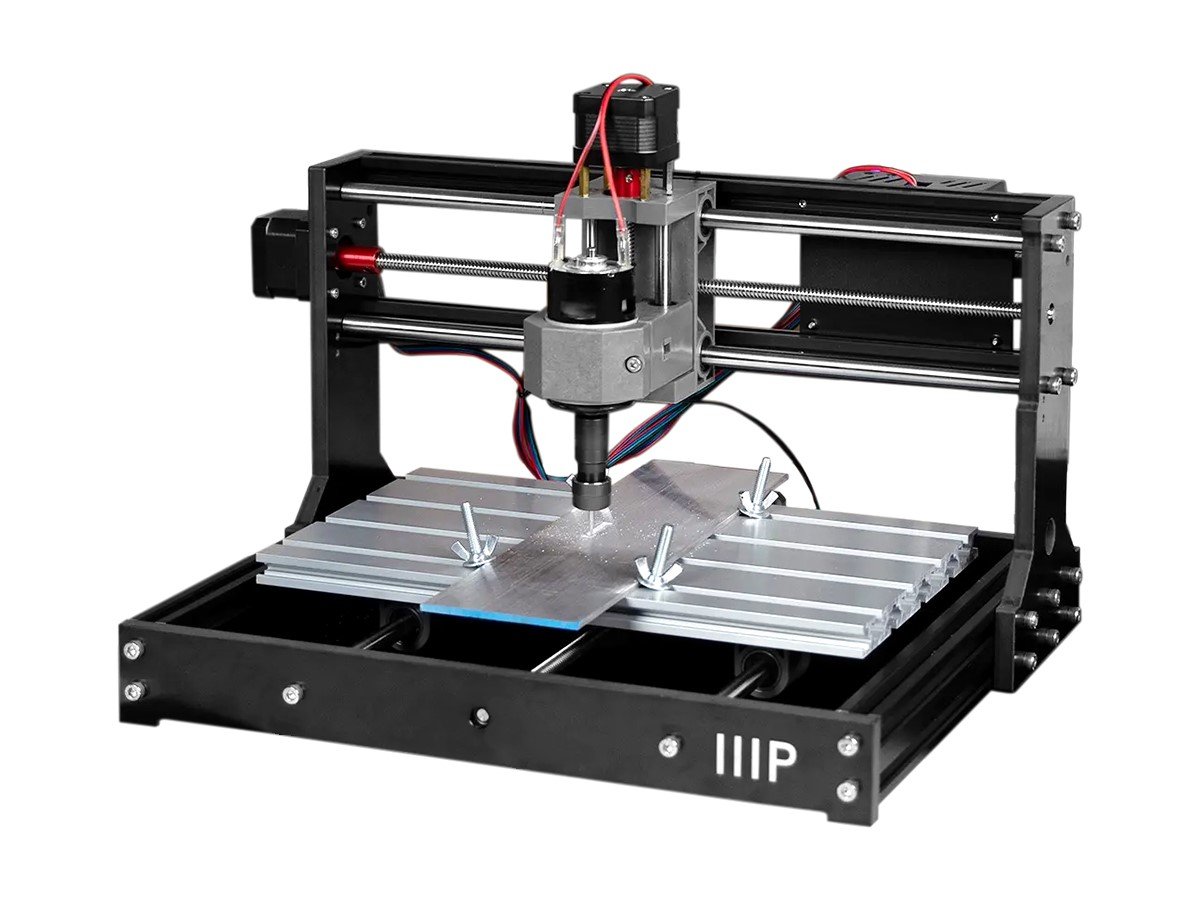

| Desktop CNC Router | Compact size, user-friendly, suitable for small workshops | Hobbyists, small businesses, prototyping | Pros: Affordable and easy to use; Cons: Limited cutting capacity. |

What are the Characteristics and Suitability of CNC Routers for B2B Buyers?

CNC routers are versatile machines that excel in high-speed cutting and can handle various materials, including wood, plastics, and metals. Their large work areas make them suitable for mass production in woodworking, cabinetry, and signage applications. B2B buyers should consider the initial investment, as the cost can be significant, but the long-term efficiency and productivity gains often justify the expense.

How Do Laser Engravers Meet the Needs of Various Industries?

Laser engravers utilize advanced laser technology to achieve precise engraving and cutting, making them ideal for personalization and small-scale production tasks. They are widely used in signage and craft industries. While they offer high precision, buyers should be aware of their limitations regarding material compatibility, as not all materials can be effectively processed.

What Advantages Do CO2 Laser Cutters Offer for Industrial Applications?

CO2 laser cutters are renowned for their ability to cut through thicker materials, making them essential in industrial manufacturing and prototyping. Their powerful lasers and large cutting areas facilitate efficient processing of a wide range of materials, including wood, acrylic, and textiles. Buyers must consider the need for proper ventilation systems due to the fumes generated during operation, which can add to operational costs.

Why Choose Fiber Laser Engravers for Metal Fabrication?

Fiber laser engravers are specifically designed for high-speed marking and engraving on metals, making them invaluable in industries such as jewelry and electronics. Their compact size allows for easy integration into smaller workspaces. While they provide fast and durable results, the operational costs may be higher than other types, which is an essential consideration for budget-conscious buyers.

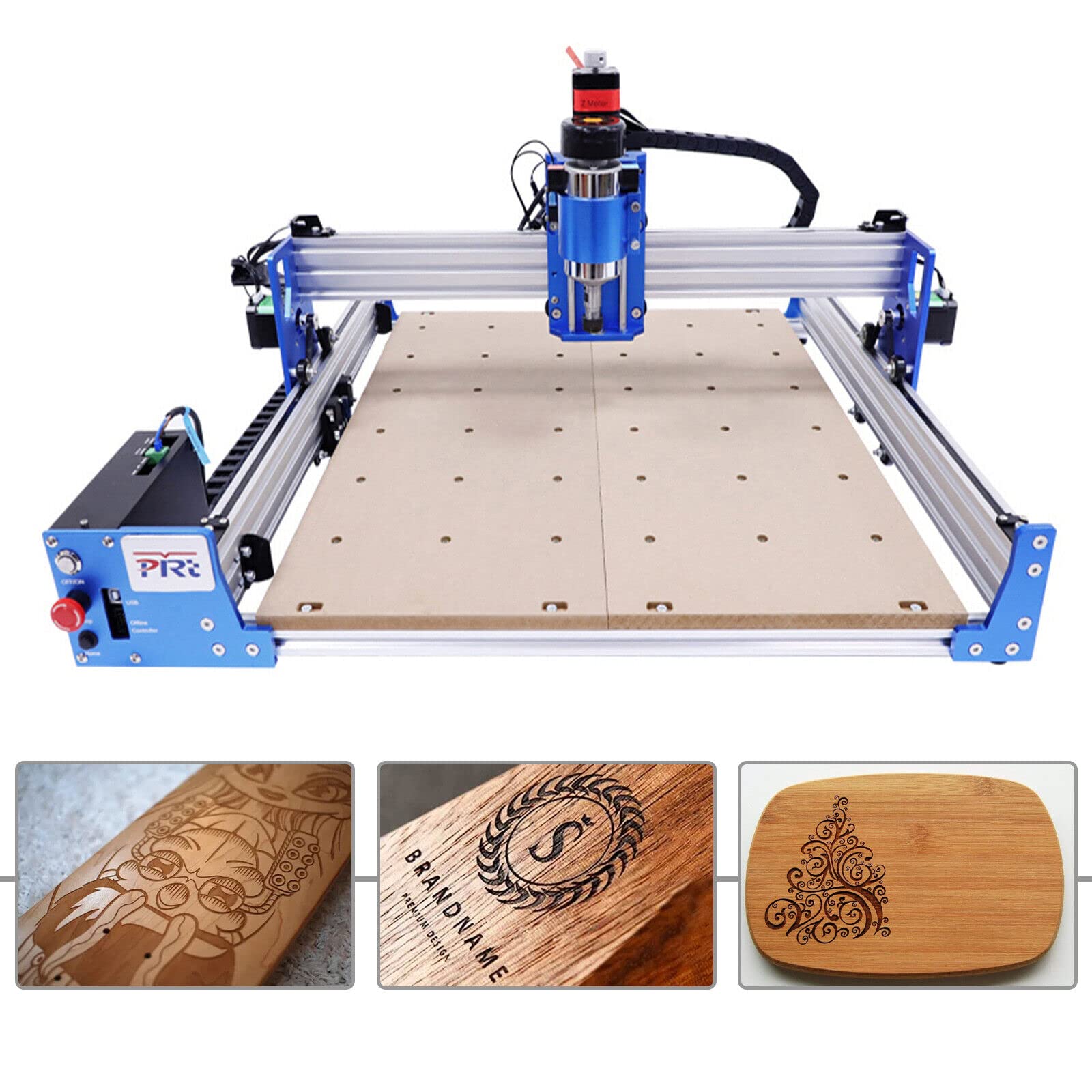

What Are the Benefits of Desktop CNC Routers for Small Businesses?

Desktop CNC routers are compact and user-friendly, making them an excellent choice for hobbyists and small businesses looking to prototype or produce small batches. Their affordability and ease of use make them accessible to a broader audience. However, their limited cutting capacity may restrict larger projects, so buyers should assess their specific needs before investing.

Key Industrial Applications of cnc router and engraver

| Industry/Sector | Specific Application of CNC Router and Engraver | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Woodworking | Custom furniture and cabinetry production | High precision and repeatability in designs | Material compatibility, machine size, and software support |

| Signage | Creating intricate signage and promotional displays | Enhanced brand visibility and custom designs | Durability of materials, engraving speed, and design software |

| Automotive | Component prototyping and custom parts manufacturing | Reduced lead times and cost-effective production | Tolerance specifications, material types, and machine capabilities |

| Jewelry | Detailed engraving and design of jewelry pieces | Unique designs and personalization options | Precision of engraving, material handling, and tooling options |

| Aerospace | Manufacturing parts with complex geometries | Lightweight, high-strength components | Compliance with industry standards, precision, and material sourcing |

How is CNC Router and Engraver Used in Woodworking?

In the woodworking industry, CNC routers are employed for the production of custom furniture and cabinetry. These machines allow manufacturers to achieve high precision in cutting and shaping various wood types, ensuring repeatability in designs. Buyers in this sector must consider the compatibility of their materials with the CNC router, the size of the machine relative to their workspace, and the software support available for design and operation. This technology not only streamlines production but also significantly enhances the quality of the finished products.

What Role Does CNC Technology Play in Signage Production?

CNC routers and engravers are essential tools in the signage industry, allowing for the creation of intricate designs for promotional displays and directional signs. The ability to customize shapes and engravings enhances brand visibility and helps businesses stand out. When sourcing equipment for this application, it’s crucial to assess the durability of materials used, the engraving speed of the machine, and the design software compatibility. Such considerations ensure that the signage produced is both appealing and long-lasting.

How are CNC Routers Beneficial in Automotive Manufacturing?

In the automotive sector, CNC routers and engravers are utilized for component prototyping and the manufacture of custom parts. This technology significantly reduces lead times and costs associated with traditional manufacturing methods. Buyers should focus on the tolerance specifications required for automotive components, the types of materials suitable for machining, and the capabilities of the CNC machines they are considering. Implementing CNC technology allows for more efficient production workflows and higher quality standards.

What Advantages Do CNC Engravers Offer to Jewelry Makers?

Jewelry makers leverage CNC engravers for detailed engraving and design work on various jewelry pieces. This technology enables artisans to create unique designs and personalization options that cater to customer preferences. When sourcing CNC equipment for jewelry applications, precision of engraving, material handling capabilities, and tooling options must be carefully evaluated. This ensures that jewelers can deliver intricate and high-quality pieces that meet market demand.

How Does CNC Technology Impact Aerospace Manufacturing?

The aerospace industry employs CNC routers and engravers for manufacturing parts with complex geometries, essential for lightweight yet high-strength components. This technology plays a crucial role in meeting stringent industry standards for precision and reliability. Buyers in this sector must prioritize compliance with aerospace regulations, the precision capabilities of the machines, and reliable material sourcing to ensure safety and performance. Utilizing CNC technology in aerospace manufacturing enhances efficiency and innovation in part design.

3 Common User Pain Points for ‘cnc router and engraver’ & Their Solutions

Scenario 1: Navigating Complex Specifications for CNC Machines

The Problem: Many B2B buyers, particularly those in emerging markets, face the daunting task of selecting the right CNC router and engraver due to the overwhelming variety of specifications and features available. This often leads to confusion about which machine best suits their specific material requirements and production needs. For instance, a company in South Africa looking to expand its woodworking business may be unsure whether to invest in a machine that supports dual Z-axis for greater precision or one with a higher spindle speed for faster production. Such indecision can result in costly mistakes and wasted resources.

The Solution: To effectively navigate this complexity, buyers should start by clearly defining their operational needs. This includes understanding the types of materials they will be working with (e.g., wood, metal, or composite materials) and the specific applications (like engraving, cutting, or 3D modeling). Once these parameters are established, it’s crucial to consult with manufacturers or suppliers who can provide tailored advice based on industry best practices. For example, investing in a CNC router with a robust ball screw drive system can enhance precision and durability for woodworking projects. Additionally, utilizing online resources and user forums can provide insights from other businesses with similar needs, helping buyers make informed decisions.

Scenario 2: Ensuring Machine Reliability and Maintenance

The Problem: Another significant challenge is maintaining the reliability and longevity of CNC routers and engravers. B2B buyers often encounter issues with machine downtime due to inadequate maintenance schedules or lack of access to replacement parts, which can severely impact production timelines. For example, a manufacturing firm in Brazil may find that frequent mechanical failures lead to lost contracts and dissatisfied customers, highlighting the need for reliable equipment.

The Solution: To combat these issues, companies should establish a proactive maintenance plan that includes regular inspections and timely replacements of wear-and-tear parts. This plan should be supported by a service agreement with the supplier or manufacturer, ensuring that technical support is readily available when needed. It’s advisable for buyers to consider machines that come with comprehensive warranties and reliable customer support, as this can mitigate the risks associated with unexpected failures. Additionally, investing in training for staff on proper machine operation and maintenance can significantly reduce the likelihood of operational disruptions.

Scenario 3: Integrating CNC Technology with Existing Workflows

The Problem: Integrating new CNC routers and engravers into existing workflows can be a complex and disruptive process for many businesses. Buyers often struggle with aligning new technology with their current production processes, leading to inefficiencies and potential confusion among staff. For instance, a company in Vietnam may find that its legacy systems are not compatible with the new CNC technology, resulting in a steep learning curve and decreased productivity.

The Solution: To facilitate a smooth integration, businesses should conduct a thorough analysis of their existing workflows and identify areas where CNC technology can enhance efficiency. Collaborating with the CNC machine supplier during the implementation phase is crucial; they can provide tailored integration solutions and training sessions for staff. Furthermore, establishing a phased approach to integration—whereby the CNC equipment is gradually introduced into production—can help mitigate disruption. Incorporating software solutions that support both the CNC machines and existing systems can also streamline operations, ensuring that all components work harmoniously together. This strategic approach not only maximizes the benefits of the new technology but also minimizes the risks associated with operational changes.

Strategic Material Selection Guide for cnc router and engraver

What Are the Key Materials for CNC Routers and Engravers?

When selecting materials for CNC routers and engravers, it is crucial to consider their properties, advantages, and limitations. This analysis focuses on four common materials: wood, acrylic, aluminum, and stainless steel. Understanding these materials will help international B2B buyers make informed decisions that align with their operational needs and market standards.

How Does Wood Perform in CNC Applications?

Wood is a versatile material widely used in CNC routing and engraving due to its availability and ease of machining. Key properties include a low density, which allows for high-speed machining, and natural variations in grain that can enhance aesthetic appeal.

Pros: Wood is generally cost-effective and offers good durability for interior applications. It is easy to source and can be finished in various ways, making it suitable for a wide range of end products, from furniture to decorative items.

Cons: However, wood can be sensitive to moisture, which may lead to warping or swelling. Additionally, the presence of knots and grain inconsistencies can complicate machining processes.

Impact on Application: Wood is compatible with various CNC operations, including routing, engraving, and carving. Buyers should consider local wood species and their availability, as well as any specific regulations regarding sustainable sourcing.

What Are the Advantages of Using Acrylic?

Acrylic is a popular choice for CNC engraving due to its clarity and aesthetic versatility. It has a high impact resistance and excellent weatherability, making it suitable for both indoor and outdoor applications.

Pros: Acrylic is lightweight and easy to cut, allowing for intricate designs. It also provides a polished finish that appeals to customers seeking high-quality visual products.

Cons: On the downside, acrylic can be more expensive than wood and may chip if not machined correctly. It also has lower heat resistance, which can limit its use in high-temperature environments.

Impact on Application: Acrylic is often used for signage, displays, and decorative elements. Buyers should ensure compliance with local regulations regarding plastic materials and consider the environmental impact of acrylic production.

Why Choose Aluminum for CNC Projects?

Aluminum is favored for its strength-to-weight ratio and corrosion resistance, making it ideal for structural applications. It can be machined to high tolerances, which is essential for precision engineering.

Pros: Aluminum offers excellent durability and can withstand harsh environments, making it suitable for outdoor applications. Its recyclability also appeals to environmentally conscious buyers.

Cons: The cost of aluminum is generally higher than wood and acrylic, and machining can be more complex due to its hardness. Additionally, it requires specific tooling to achieve optimal results.

Impact on Application: Aluminum is commonly used in industrial applications, automotive parts, and high-end consumer products. Buyers should be aware of the specific alloy grades and their compliance with international standards like ASTM and DIN.

What Makes Stainless Steel a Preferred Material?

Stainless steel is known for its exceptional strength and corrosion resistance, making it a top choice for applications requiring durability. It is often used in environments exposed to moisture or chemicals.

Pros: The longevity and robustness of stainless steel make it ideal for machinery parts, kitchen equipment, and medical devices. It can withstand high temperatures and is easy to clean, which is crucial for hygiene-sensitive applications.

Cons: However, stainless steel is relatively expensive and can be challenging to machine, requiring specialized tools and techniques.

Impact on Application: Stainless steel is suitable for high-value applications where performance and longevity are critical. Buyers should consider the specific grade of stainless steel and its compliance with international standards, particularly in industries like food processing and healthcare.

Summary of Material Selection for CNC Routers and Engravers

| Material | Typical Use Case for CNC Router and Engraver | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Furniture, decorative items | Cost-effective and easy to source | Sensitive to moisture | Low |

| Acrylic | Signage, displays, decorative elements | Aesthetic appeal and lightweight | More expensive, can chip | Medium |

| Aluminum | Structural applications, automotive parts | High strength-to-weight ratio | Higher cost, complex machining | High |

| Stainless Steel | Machinery parts, kitchen equipment | Exceptional durability and corrosion resistance | Expensive, challenging to machine | High |

This guide provides a comprehensive overview of material selection for CNC routers and engravers, enabling international B2B buyers to make informed decisions that align with their operational needs and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc router and engraver

What Are the Main Stages in the Manufacturing Process of CNC Routers and Engravers?

The manufacturing process for CNC routers and engravers involves several critical stages that ensure the final product meets the required specifications and quality standards. Here’s a breakdown of these stages:

Material Preparation

The first step in the manufacturing process is material preparation. This involves selecting high-quality materials, such as aluminum, steel, or composite materials, that will form the primary structure of the CNC machine. Manufacturers often conduct a thorough inspection of incoming materials to verify their quality and specifications. This step is crucial, as the durability and performance of the CNC router or engraver heavily depend on the quality of the materials used.

Forming Techniques

Once materials are prepared, the next stage is forming. This can include processes such as cutting, bending, and machining to shape components according to design specifications. Advanced CNC machining centers are often used in this phase, enabling precise cuts and shapes that meet tight tolerances. Techniques such as laser cutting and waterjet cutting may also be employed, especially for intricate designs or when working with harder materials.

Assembly Process

The assembly stage involves bringing together various components, including motors, control systems, and structural parts. This process often requires skilled labor to ensure that all parts fit together correctly and function as intended. Manufacturers typically utilize jigs and fixtures to enhance accuracy during assembly. Additionally, many companies adopt modular designs, allowing for easier upgrades and repairs in the future.

Finishing Touches

The final stage in the manufacturing process is finishing. This includes surface treatments, such as anodizing, painting, or powder coating, which not only enhance the aesthetic appeal but also improve corrosion resistance and durability. Quality control measures are applied during this phase to ensure that every unit meets the established standards before moving on to packaging and shipping.

How Do Manufacturers Ensure Quality Control in CNC Routers and Engravers?

Quality control (QC) is a vital component of the manufacturing process for CNC routers and engravers. It ensures that products meet international standards and customer expectations. Here are some of the key QC measures:

What International Standards Are Relevant for CNC Manufacturing?

Manufacturers of CNC routers and engravers often adhere to several international standards to ensure quality. ISO 9001 is one of the most recognized standards, focusing on quality management systems and continuous improvement. In addition to ISO standards, many manufacturers also comply with industry-specific certifications like CE marking in Europe, which signifies that products meet safety and health requirements.

What Are the Key Quality Control Checkpoints?

Quality control in CNC manufacturing typically involves three main checkpoints:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials and components upon arrival at the manufacturing facility to ensure they meet the required specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, various checks are performed to monitor the production. This includes verifying dimensions and tolerances at different stages of forming and assembly to catch any defects early.

-

Final Quality Control (FQC): Before products are packaged and shipped, a comprehensive final inspection is conducted. This may involve functional testing, performance checks, and visual inspections to ensure that the product is fully operational and meets quality standards.

What Common Testing Methods Are Used in QC?

Common testing methods for CNC routers and engravers include:

- Functional Testing: Ensures that all mechanical and electrical components operate as intended.

- Dimensional Inspection: Uses tools like calipers and gauges to verify that components meet specified dimensions.

- Performance Testing: Evaluates the machine’s performance under simulated operating conditions to ensure it meets speed, accuracy, and load capacity specifications.

- Durability Testing: Assesses the machine’s resistance to wear and tear through extended operation.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are several strategies to ensure supplier compliance with quality standards:

Conducting Supplier Audits

One of the most effective ways to verify a supplier’s quality control processes is to conduct on-site audits. During these audits, buyers can assess the manufacturing environment, review quality control documentation, and observe the manufacturing processes in action. This direct engagement helps establish trust and gives buyers confidence in the supplier’s capabilities.

Reviewing Quality Control Reports

Buyers should request quality control reports and documentation from suppliers. These documents should detail the quality assurance processes, test results, and any certifications the supplier holds. A thorough review of these reports can provide insights into the supplier’s commitment to quality.

Engaging Third-Party Inspections

Another effective strategy is to hire third-party inspection services to evaluate the supplier’s processes and products. These independent organizations can provide unbiased assessments of the supplier’s quality control measures, ensuring compliance with international standards. This is particularly valuable for buyers unfamiliar with local manufacturing practices.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers should be aware of the nuances associated with quality control and certifications. Different regions may have varying standards and regulations that affect product acceptance. For example, while CE marking is essential for products sold in Europe, other regions may prioritize different certifications. Understanding these regional requirements can help buyers avoid compliance issues and ensure smoother transactions.

Additionally, buyers should consider the political and economic stability of the supplier’s country, as these factors can impact manufacturing consistency and quality. Establishing clear communication and building a strong relationship with suppliers can help address potential issues proactively.

In conclusion, understanding the manufacturing processes and quality assurance practices for CNC routers and engravers is vital for B2B buyers. By focusing on material preparation, forming techniques, assembly, finishing, and robust quality control measures, buyers can make informed decisions and choose reliable suppliers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc router and engraver’

Introduction

This practical sourcing guide is designed to assist B2B buyers in effectively procuring CNC routers and engravers. Whether you are a manufacturer, artisan, or service provider, understanding the key steps in sourcing these machines can significantly impact your operational efficiency and project outcomes. This checklist will guide you through essential considerations to ensure you make informed decisions and secure high-quality equipment.

1. Define Your Technical Specifications

Establishing clear technical specifications is crucial for selecting the right CNC router or engraver for your needs. Consider factors such as the materials you will be working with, the dimensions of your projects, and the desired precision level. Specific features to look for include:

– Spindle power: Ensure it matches the material requirements.

– Work area size: Confirm it accommodates your largest expected projects.

2. Research and Compare Suppliers

Thorough research on potential suppliers will help you identify reliable manufacturers. Compare their product offerings, customer reviews, and industry reputation. Look for:

– Established experience: Suppliers with a long track record are often more trustworthy.

– Diverse product range: A supplier with a variety of models can provide tailored options for your specific needs.

3. Evaluate Potential Suppliers

Before finalizing a supplier, vet them thoroughly to ensure they can meet your requirements. Request company profiles, case studies, and references from buyers in similar industries or regions. Important considerations include:

– Certifications: Check for ISO certifications or compliance with international standards.

– After-sales support: Understand their warranty and maintenance services to avoid future complications.

4. Request Quotes and Negotiate Terms

Once you have shortlisted suppliers, request detailed quotes. Compare not only the prices but also the included services, such as installation and training. Pay attention to:

– Payment terms: Ensure the terms are favorable and align with your financial planning.

– Lead times: Clarify delivery timelines to avoid project delays.

5. Assess Shipping and Customs Considerations

Given the international nature of your procurement, understanding shipping and customs processes is vital. Ensure you are aware of:

– Shipping costs: Factor these into your total budget.

– Customs regulations: Research import duties and regulations in your country to avoid unexpected fees.

6. Review and Understand User Manuals and Documentation

Before finalizing your purchase, request user manuals and technical documentation. Familiarize yourself with the operation and maintenance requirements of the machines. Important aspects to verify include:

– Ease of use: Ensure the documentation is clear and comprehensive for training your staff.

– Maintenance guidelines: Understand the recommended maintenance schedule to prolong the lifespan of your equipment.

7. Plan for Installation and Training

Finally, consider the logistics of installation and training. Many suppliers offer installation services, which can help ensure that the machines are set up correctly. Additionally, training is essential for maximizing productivity. Look for:

– On-site training options: This can be invaluable for staff who will operate the machines.

– Online resources: Check if the supplier provides online tutorials or customer support for ongoing assistance.

By following this checklist, B2B buyers can navigate the complexities of sourcing CNC routers and engravers effectively, ensuring they choose the right equipment for their operational needs.

Comprehensive Cost and Pricing Analysis for cnc router and engraver Sourcing

What are the Key Cost Components in CNC Router and Engraver Manufacturing?

When sourcing CNC routers and engravers, understanding the breakdown of costs is essential for informed purchasing decisions. The primary components affecting the total cost include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margins.

How Do Material Choices Influence CNC Machine Pricing?

Materials account for a significant portion of total manufacturing costs. Common materials used in CNC machine construction include high-grade aluminum, steel, and composite materials. The choice of materials directly impacts durability and performance. For instance, while aluminum is lightweight and cost-effective, it may not offer the same sturdiness as steel. Additionally, specialty materials or coatings that enhance precision can increase costs.

What Role Does Labor and Manufacturing Overhead Play in CNC Router and Engraver Costs?

Labor costs vary considerably based on the location of manufacturing. Regions with lower labor costs, like parts of Africa and South America, may provide a competitive edge in pricing but could also raise concerns regarding quality and consistency. Manufacturing overhead, which encompasses utilities, facility costs, and equipment maintenance, is another crucial factor. Efficient production processes and lean manufacturing techniques can help mitigate these expenses.

Why Is Tooling and Quality Control Important for CNC Equipment?

Tooling costs, which entail the expense of creating custom tools or fixtures, can also significantly influence the final price. High-quality tooling leads to improved precision in production, reducing waste and increasing efficiency. Similarly, rigorous quality control processes ensure that products meet industry standards and certifications, particularly crucial for international buyers. Adhering to quality standards can raise initial costs but often results in higher value and longevity of the product.

What Logistics Factors Affect the Total Cost of CNC Routers and Engravers?

Logistics encompasses the costs associated with shipping, handling, and distribution of CNC machines. International shipping costs can vary based on distance, weight, and shipping method, particularly for buyers in remote areas of Africa or South America. Understanding Incoterms is vital, as they define the responsibilities of buyers and sellers concerning insurance, shipping, and responsibilities during transit. These terms can have substantial implications on the total landed cost of the machinery.

How Do Pricing Influencers Impact CNC Router and Engraver Sourcing Abroad?

When engaging with suppliers, several price influencers must be considered. The volume of order (MOQ) affects pricing; larger orders typically benefit from lower per-unit costs due to economies of scale. Additionally, specific customization requests can lead to higher costs, necessitating discussions about the balance between required features and budget constraints. Always consider the overall quality and certifications of the machinery, as international buyers may have different regulatory requirements.

What Negotiation and Cost-Efficiency Strategies Can International Buyers Employ?

B2B buyers should prioritize negotiation skills and conduct thorough market research to understand the standard pricing for CNC routers and engravers. Building long-term relationships with suppliers can lead to better pricing and conditions. Understanding the Total Cost of Ownership (TCO) is essential; this includes not only the purchase price but also operational costs, maintenance, and the expected lifespan of the machines.

How Should International Buyers Navigate Pricing Nuances in Different Regions?

When sourcing from regions like Europe or the Middle East, consider fluctuations due to local economic factors, tariffs, and trade agreements. Buyers from these areas might experience different pricing dynamics due to differing supply chains and demand levels. Building awareness around these factors will enable buyers to make more informed decisions.

Disclaimer on Indicative Pricing

As prices can vary drastically depending on configurations, suppliers, and shipping costs, all mentioned prices should be viewed as indicative. Prospective buyers should conduct comprehensive market analysis and engage directly with manufacturers for precise quotations tailored to their specific needs and requirements.

Alternatives Analysis: Comparing cnc router and engraver With Other Solutions

When evaluating the best manufacturing solutions for your business, it’s essential to consider various technologies that can fulfill similar roles to CNC routers and engravers. This analysis will compare CNC routers and engravers with two viable alternatives: laser cutters and traditional woodworking methods. Each option has unique characteristics that can affect performance, cost, and suitability for specific projects.

| Comparison Aspect | Cnc Router And Engraver | Laser Cutter | Traditional Woodworking |

|---|---|---|---|

| Performance | High precision for both carving and engraving across various materials. | Excellent for detailed cuts and engravings, especially on thinner materials. | Variable precision; highly dependent on skill level and tools used. |

| Cost | Initial investment ranges from $600 to $4,800 based on features. | Prices vary from $600 for basic models to $10,000+ for industrial versions. | Generally lower initial cost; however, skilled labor costs can add up. |

| Ease of Implementation | Requires some training and software familiarity. | User-friendly with intuitive software; easy to learn. | Labor-intensive, requiring extensive skill and experience. |

| Maintenance | Moderate; requires regular calibration and bit replacements. | Low; mainly lens cleaning and occasional part replacements. | High; continuous tool maintenance and skill development required. |

| Best Use Case | Versatile for custom signs, furniture, and prototypes. | Ideal for intricate designs on materials like acrylic, wood, and fabric. | Best for handcrafted items, bespoke furniture, and artistic projects. |

What Are the Advantages and Disadvantages of Laser Cutters Compared to CNC Routers and Engravers?

Laser cutters provide a unique advantage in producing intricate designs with high speed and precision, making them particularly effective for detailed engraving and cutting tasks. Their operational costs can be lower over time due to minimal maintenance and ease of use, which can be attractive for businesses with less skilled labor. However, they may not handle thicker materials as effectively as CNC routers, which can limit their application in heavy-duty manufacturing.

How Do Traditional Woodworking Methods Compare to CNC Routers and Engravers?

Traditional woodworking methods excel in craftsmanship and artistic expression, allowing for a unique, handcrafted quality that machines cannot replicate. The initial costs are generally lower, as the tools required can be less expensive. However, the reliance on skilled labor can lead to higher long-term costs and inconsistent quality in production. For businesses focusing on bespoke items or artisan products, traditional methods may be preferable, but they lack the efficiency and precision of CNC technology.

Conclusion: Which Solution Should a B2B Buyer Choose for Their Needs?

Choosing the right solution depends on the specific needs of your business. If high precision and versatility are critical, CNC routers and engravers are likely the best choice. For businesses focused on detailed designs and ease of operation, laser cutters may be more suitable. Conversely, if your company prioritizes craftsmanship and bespoke creations, traditional woodworking methods could provide the personal touch required. Ultimately, assessing your production requirements, budget, and skill availability will guide you to the most suitable technology for your operations.

Essential Technical Properties and Trade Terminology for cnc router and engraver

What Are the Key Technical Properties of CNC Routers and Engravers?

Understanding the essential technical properties of CNC routers and engravers is crucial for international B2B buyers looking to invest in machinery that meets their production needs. Here are some critical specifications to consider:

-

Material Grade

– The material grade of CNC machines, often indicated by the type of metals or alloys used in their construction, significantly affects durability and performance. Machines made from higher-grade materials tend to offer increased longevity and resistance to wear, which is essential for businesses prioritizing reliability and low maintenance costs. -

Tolerance

– Tolerance refers to the permissible limit of variation in a physical dimension. High precision in manufacturing is essential for industries such as aerospace and automotive, where even minute deviations can lead to product failure. A tolerance range of ±0.01 mm is typical in quality CNC machines, and understanding this can help buyers assess whether a machine meets their specific production requirements. -

Work Area Size

– The work area size defines the maximum dimensions of materials that can be processed by the CNC router or engraver. This specification is crucial for businesses that require the machining of large components or multiple items simultaneously. An adequately sized work area enhances productivity and minimizes the need for multiple setups, thereby saving time and labor costs. -

Spindle Power

– Spindle power, measured in watts or horsepower, indicates the machine’s ability to cut through various materials, including wood, metal, and plastics. A higher spindle power allows for faster and more efficient cutting, which is vital for businesses aiming to increase throughput without sacrificing quality. -

Drive System

– The drive system of a CNC machine determines how it moves along the axes during operation. Common types include ball screw drives and rack-and-pinion systems. Machines with ball screw drives offer higher precision and smoother operation, making them suitable for intricate designs and detailed work. -

Software Compatibility

– Compatibility with design software is essential for seamless operation. Many CNC routers and engravers come equipped with or support popular CAD/CAM software, enabling users to create complex designs easily. Understanding software compatibility can aid in selecting machines that integrate well with existing workflows.

What Are Common Trade Terms in the CNC Industry?

Familiarity with industry-specific terminology can significantly enhance communication and negotiation processes in B2B transactions. Here are some essential terms to know:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding this term is important for buyers looking for reliable suppliers that can provide high-quality components or complete machines tailored to their specifications. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest number of units a supplier is willing to sell. This term is critical for businesses to grasp, as it impacts inventory management and cost-efficiency. Knowing the MOQ helps buyers plan their purchases according to production needs and budget constraints. -

RFQ (Request for Quotation)

– An RFQ is a document that companies send to suppliers to request pricing and availability for specific products or services. Using RFQs allows businesses to compare offers from multiple vendors and negotiate better terms, ensuring they secure the best value for their investment. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in the shipping process. Familiarity with these terms helps businesses understand shipping costs, risks, and responsibilities, facilitating smoother transactions across borders. -

Lead Time

– Lead time refers to the time taken from placing an order to its delivery. Understanding lead times is crucial for effective supply chain management, as it influences production schedules and inventory levels. -

After-Sales Support

– After-sales support encompasses services provided to customers following their purchase, including installation, maintenance, and troubleshooting. Recognizing the importance of after-sales support can help businesses choose suppliers that prioritize customer satisfaction and product longevity.

By equipping themselves with knowledge about these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational goals and enhance their competitive edge in the market.

Navigating Market Dynamics and Sourcing Trends in the cnc router and engraver Sector

What Are the Current Market Dynamics and Key Trends in the CNC Router and Engraver Sector?

The CNC router and engraver market is experiencing a transformative phase driven by several global factors. Key trends include the increasing adoption of automation and smart technology, which enhance operational efficiency and precision in manufacturing processes. B2B buyers are increasingly looking for machines that integrate seamlessly with design software and automation systems, allowing for streamlined workflows. Moreover, the demand for personalized and customized products is rising, particularly in regions like Africa and South America, where local artisans and small businesses are leveraging CNC technology to create unique offerings.

Emerging technologies, such as cloud-based software solutions and IoT connectivity, are reshaping sourcing strategies. Buyers can now utilize data analytics to optimize machine performance and predict maintenance needs, thus reducing downtime. Additionally, sustainability is becoming a central theme, with companies focusing on sourcing eco-friendly materials and energy-efficient machines. As a result, international buyers, particularly in the Middle East and Europe, are prioritizing suppliers that demonstrate a commitment to innovation and sustainability.

How Important Is Sustainability and Ethical Sourcing in the CNC Router and Engraver Market?

Sustainability and ethical sourcing are critical considerations for B2B buyers in the CNC router and engraver sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, has prompted a shift towards greener practices. Companies are increasingly seeking suppliers that offer energy-efficient machines and utilize sustainable materials in their production.

Moreover, ethical supply chains are becoming non-negotiable for many businesses. Buyers are looking for transparency in sourcing practices, ensuring that materials are obtained responsibly and that labor practices adhere to ethical standards. Certifications such as ISO 14001 for environmental management and FSC for sustainable wood sourcing can significantly influence purchasing decisions. By prioritizing sustainability, companies not only enhance their brand image but also align with the growing consumer demand for environmentally responsible products.

How Has the CNC Router and Engraver Industry Evolved Over Time?

The evolution of the CNC router and engraver industry is marked by significant technological advancements and shifts in market demand. Initially, these machines were primarily used in industrial settings for mass production. However, with the advent of more affordable and user-friendly models, the market has expanded to include small businesses and hobbyists.

The introduction of advanced software and automation technologies has further transformed the landscape, enabling greater precision and versatility in applications. Today, CNC routers and engravers are utilized across various sectors, including woodworking, metalworking, and even in artistic endeavors. This diversification has opened new avenues for international B2B buyers, allowing them to tap into a broader range of applications and industries, ultimately driving innovation and growth in the sector.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc router and engraver

-

How do I choose the right CNC router or engraver for my business needs?

Choosing the right CNC router or engraver depends on various factors, including the materials you plan to work with, the size of your projects, and your specific applications (e.g., engraving, cutting, or milling). Consider the machine’s specifications, such as spindle power, work area dimensions, and supported materials. Additionally, evaluate the software compatibility and ease of use. Engaging with suppliers to discuss your unique requirements can help you identify the best options tailored to your operational needs. -

What is the best CNC router for small to medium-sized businesses?

For small to medium-sized businesses, the ideal CNC router combines affordability, precision, and versatility. Models like the PROVerXL 4030 or Yora 3018-Pro are popular choices due to their compact design and ability to handle various materials, including wood and metal. Look for features such as user-friendly software, robust construction, and good customer support to ensure a smooth operational experience. Conducting a cost-benefit analysis based on your production volume can also aid in making the best selection. -

How can I ensure the quality and reliability of CNC machines from international suppliers?

To ensure quality and reliability, conduct thorough due diligence on potential suppliers. Verify their certifications (ISO, CE, etc.), review customer testimonials, and request samples of their products. Establish communication to gauge their responsiveness and willingness to provide technical support. Additionally, consider visiting the supplier’s facility if possible, or ask for virtual tours to observe their manufacturing processes and quality control measures. -

What are the typical payment terms when sourcing CNC routers and engravers internationally?

Payment terms can vary significantly among suppliers, but common options include a deposit upon order confirmation, followed by the balance before shipping. Some suppliers may offer flexible terms, such as letter of credit or payment through escrow services for added security. Always clarify terms in advance and ensure they are documented in the purchase agreement to avoid misunderstandings later. Understanding local regulations regarding international transactions is also crucial. -

Are there minimum order quantities (MOQs) for CNC routers and engravers?

Many suppliers set minimum order quantities (MOQs) based on manufacturing capabilities and costs. MOQs can vary widely; some suppliers may allow single-unit purchases, while others might require multiple units to offer competitive pricing. Discussing your specific needs with suppliers can sometimes lead to flexibility on MOQs, especially if you’re a first-time buyer or if you’re considering a long-term partnership. -

What should I consider regarding logistics and shipping when importing CNC machines?

Logistics is a crucial aspect of importing CNC machines. Consider factors such as shipping methods, lead times, and customs clearance procedures. Engage with suppliers who have experience in international shipping to ensure they can handle the logistics efficiently. Additionally, familiarize yourself with import regulations in your country, including tariffs and taxes, as these can impact overall costs. Using a reliable freight forwarder can also facilitate smoother logistics. -

How can I customize my CNC router or engraver to fit my specific production needs?

Customization options for CNC routers and engravers may include alterations in size, additional tooling capabilities, or software modifications to meet specific production requirements. When discussing with suppliers, provide detailed specifications of your needs, including types of materials and desired features. Many manufacturers offer tailored solutions or can recommend compatible accessories to enhance the machine’s functionality. -

What are the common quality assurance (QA) practices to look for in CNC machine suppliers?

Quality assurance practices can vary by supplier, but key indicators include adherence to international standards (like ISO 9001), routine machine inspections, and comprehensive testing before shipping. Inquire about their QA processes, including how they handle defects or malfunctions post-sale. A solid warranty and responsive customer service are also critical components, as they reflect the supplier’s commitment to maintaining quality and supporting their products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 10 Cnc Router And Engraver Manufacturers & Suppliers List

1. SainSmart – Affordable CNC Solutions

Domain: sainsmart.com

Registered: 2011 (14 years)

Introduction: This company, SainSmart – Affordable CNC Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. YoraHome – CNC Routers and Laser Engravers

Domain: yorahome.com

Registered: 2017 (8 years)

Introduction: YoraHome offers a range of CNC routers, laser engravers, and accessories. Key products include:

1. CNC Routers:

– 3018-Pro Desktop CNC

– SilverBack Benchtop 6060 CNC

– SilverBack Benchtop 1X1 CNC

– CrossRiver Benchtop 6060 CNC

2. Laser Engravers:

– 6550 Diode Laser Engraver Cutter

– Toocaa L2 Diode Laser Engraver Cutter (10W, 20W, or 40W options, 430x400mm workspace)

…

3. Monoprice – 44220 HDMI Cable

Domain: monoprice.com

Registered: 2001 (24 years)

Introduction: {“product_name”: “Monoprice 44220”, “category”: “Audio/Video”, “type”: “HDMI Cable”, “length”: “6 feet”, “features”: [“High-speed HDMI”, “Supports 4K resolution”, “Gold-plated connectors”, “Flexible PVC jacket”], “color”: “Black”, “warranty”: “1 year”}

4. Carbide 3D – Nomad Desktop CNC

Domain: carbide3d.com

Registered: 2013 (12 years)

Introduction: CNC engraving is the process of making shallow cuts to create fine detail, commonly for personalization, branding, and measurements. Ideal machines include high-speed spindles (over 12,000 RPM) and precise, flat surfaces. Suitable CNC machines for engraving include Carbide 3D’s Nomad Desktop CNC for small items and Shapeoko CNC Router for larger items, particularly wood. Engravable materials are w…

5. OMIO – CNC Router Series

Domain: omiocnc.com

Registered: 2014 (11 years)

Introduction: OMIO CNC Router X3 Series: X3-300-USB, 21D-USB; X4 Series: X4M-USB, X4-800L-USB, X4-800EPL; X6 Series: X6M-USB, X6-1500L-USB, X6-2200L-USB, X6-2200EPL; X8 Series: X8M-USB, X8-2200L-USB, X8-2200EPL; Accessories: High-precision Vise, 4th-Axis Collet; Discounts: US $5.00 – US $100.00; Shipping: International shipping to 56 countries, fast shipping via DHL/FEDEX/UPS, orders accepted 24/7, shipping on …

6. Vision Engraving & Routing Systems – Engraving Machines & CNC Routers

Domain: visionengravers.com

Registered: 1999 (26 years)

Introduction: Vision Engraving & Routing Systems manufactures engraving machines, CNC routers, and accessories in the USA since 1983. They offer a range of machines including small, medium, and large engravers, specialty engravers, CNC routers, and laser engravers. Their products cater to various applications such as ADA/Braille, badge and tag making, control panels, custom car parts, firearms marking, gift and…

7. Reddit – CNC Routers vs. Lasers

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: CNC routers are more versatile than lasers, capable of deep relief work and handling various materials such as wood, leather, and metals. They can perform tasks that lasers cannot, particularly in terms of depth and texture. Lasers primarily do surface engraving and require specific types (CO2, fiber) for metal engraving. The learning curve for operating CNC machines is higher compared to lasers, …

8. Twotrees – TTC3018 CNC Router Machine

Domain: twotrees3dofficial.com

Registered: 2021 (4 years)

Introduction: {“product_name”: “Twotrees TTC3018 CNC Router Machine”, “regular_price”: “$299.00”, “sale_price”: “$129.00”, “discount”: “57%”, “availability”: “23 in stock”, “shipping”: “Free Shipping”, “support”: “24/7 Support”, “return_policy”: “14 Days Free Return”, “warranty”: “1-year After-sale Guarantee”, “plug_type”: [“EU”, “US”], “bundles”: [“Machine”, “Machine & End Mills”, “Machine & Vacuum Cleaner”]}

9. Woodcraft – Laser Engravers & CNC Routers

Domain: woodcraft.com

Registered: 1995 (30 years)

Introduction: This company, Woodcraft – Laser Engravers & CNC Routers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

10. Rockler – Quality CNC Machines

Domain: rockler.com

Registered: 1997 (28 years)

Introduction: This company, Rockler – Quality CNC Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for cnc router and engraver

In the ever-evolving landscape of CNC routers and engravers, strategic sourcing has emerged as a vital practice for international B2B buyers. By understanding market dynamics and supplier capabilities, businesses can effectively reduce costs, enhance product quality, and improve delivery timelines. Key considerations include evaluating technological advancements, such as closed-loop systems and high-speed engraving capabilities, which can significantly impact production efficiency and output quality.

Buyers from Africa, South America, the Middle East, and Europe must prioritize partnerships with suppliers that offer not only competitive pricing but also robust support and service networks. Investing in CNC technologies is not merely a transaction; it is a step towards innovation and operational excellence. By leveraging local warehouses and diverse shipping options, buyers can ensure timely access to essential equipment and accessories, minimizing downtime and maximizing productivity.

Looking ahead, the potential for growth in the CNC market is substantial. As industries increasingly embrace automation and precision manufacturing, now is the time for international buyers to engage in strategic sourcing initiatives. Explore partnerships that align with your operational goals and capitalize on the advancements in CNC technology to drive your business forward.