Contents

Manufacturing Insight: Cnc Reference

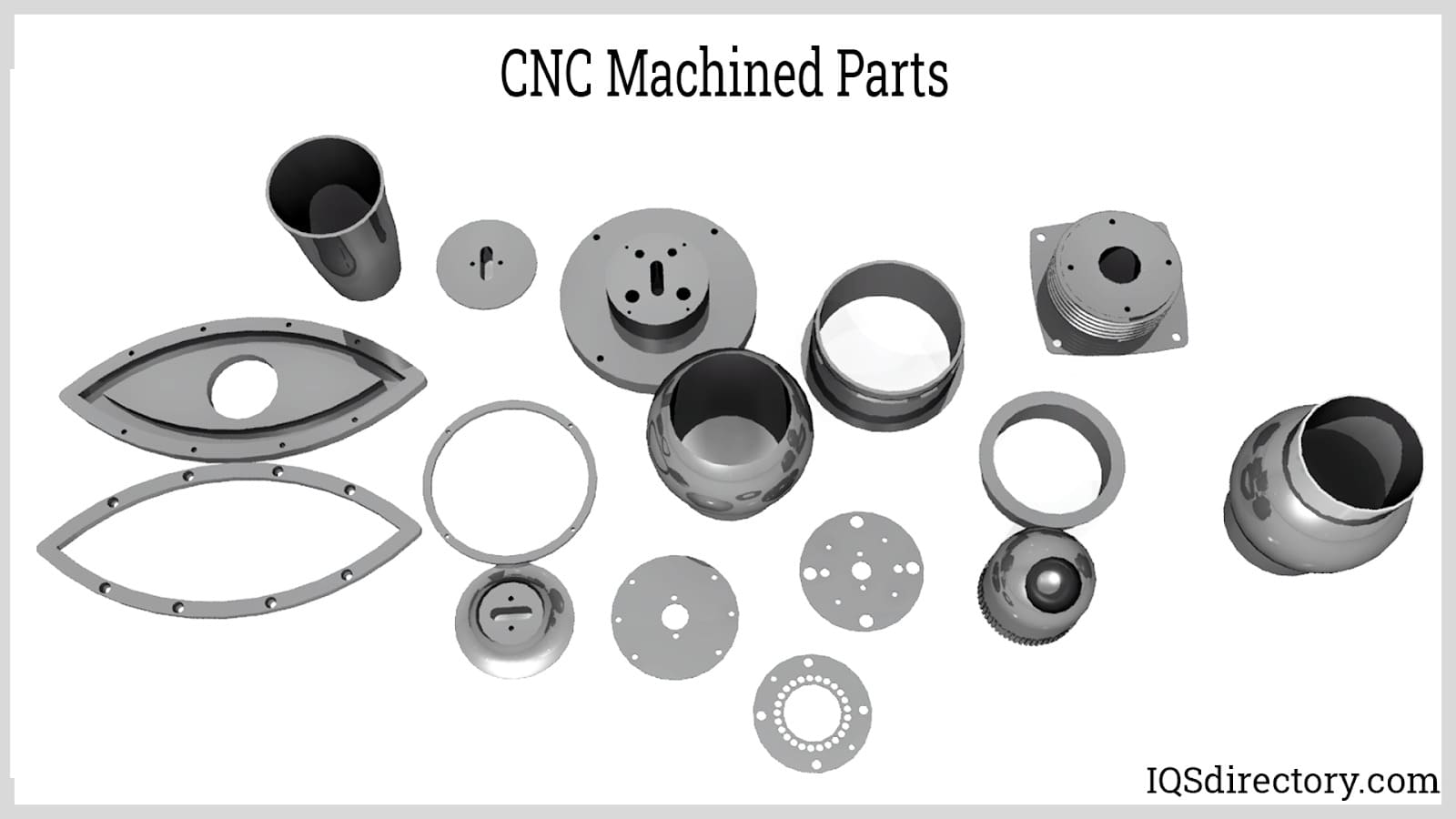

Honyo Prototype CNC Machining: Precision Engineered for Your Project Success

At Honyo Prototype, we deliver advanced CNC machining services engineered to transform your complex designs into high-precision, fully functional components with exceptional speed and reliability. Our state-of-the-art facility leverages a comprehensive suite of multi-axis milling, turning, and milling-turning centers, operating under stringent quality protocols to consistently achieve tight tolerances down to ±0.0002″ across critical materials including aerospace-grade aluminum, stainless steel, titanium, engineered plastics, and exotic alloys. We specialize in rapid prototyping, low-to-mid volume production, and complex one-off parts, providing the technical expertise and process control necessary for demanding applications in aerospace, medical device, robotics, and industrial automation sectors.

Core Capabilities Driving Your Efficiency

Our integrated manufacturing approach ensures seamless execution from digital model to final part. This commitment to technical excellence extends to streamlining your procurement process through our industry-leading Online Instant Quote platform. Eliminate traditional quoting delays measured in days; upload your CAD file directly to our secure portal and receive a detailed, accurate cost and lead time estimate within minutes, 24/7. This transparency and speed empower faster decision-making and project acceleration without compromising on the precision engineering you require.

Quantifiable Advantage: Speed to Quote

The impact of our digital workflow is clear when comparing standard industry practices to the Honyo experience:

| Process Stage | Traditional Industry Average | Honyo Prototype Online Instant Quote |

|---|---|---|

| Initial Quote Request | 1-5 Business Days | < 5 Minutes |

| Engineering Review | Manual, Often Required | Automated CAD Analysis |

| Preliminary Estimate | High Variability | Accurate, Detailed Breakdown |

| Ready to Proceed | Days of Waiting | Immediate Action |

Partner with Honyo Prototype for CNC machining where cutting-edge technology meets operational agility. Leverage our precision capabilities and experience the immediate value of our Online Instant Quote system to accelerate your next project from concept to physical reality. Visit our portal today to submit your design and receive your instant manufacturing assessment.

Technical Capabilities

CNC reference specifications for 3-axis, 4-axis, and 5-axis milling, as well as turning operations, are critical for achieving tight tolerances and high-precision components across a range of engineering materials such as aluminum, steel, ABS, and nylon. The following table outlines key technical parameters, capabilities, and material-specific considerations relevant to prototyping and low-volume production environments.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Axis Configuration | X, Y, Z | X, Y, Z, + Rotary (A or B) | X, Y, Z, + Two Rotary (A/B or B/C) | X, Z, + C-axis (optional) |

| Typical Tolerance | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) |

| Tight Tolerance Capability | ±0.0025 mm (±0.0001″) | ±0.0025 mm (±0.0001″) | ±0.001 mm (±0.00004″) | ±0.0025 mm (±0.0001″) |

| Surface Finish (Ra) | 0.8 – 3.2 µm (32–125 µin) | 0.8 – 3.2 µm (32–125 µin) | 0.4 – 1.6 µm (16–63 µin) | 0.4 – 1.6 µm (16–63 µin) |

| Max Material Size (Typical) | 600 x 400 x 300 mm | 500 x 400 x 250 mm | 400 x 400 x 200 mm | Ø300 mm x 500 mm length |

| Spindle Speed (Max) | 24,000 RPM | 20,000 RPM | 20,000 RPM | 6,000 RPM |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.001 mm | ±0.002 mm |

Material Compatibility and Machining Notes:

Aluminum (e.g., 6061, 7075):

Highly machinable across all CNC platforms. Ideal for tight tolerance work due to dimensional stability and thermal conductivity. 5-axis milling enables complex aerospace and automotive components with minimal fixturing.

Steel (e.g., 4140, 1018, Stainless 303/316):

Requires higher tooling rigidity and lower feed/speed in milling. Tight tolerances achievable with proper coolant and toolpath strategies. Turning excels for shafts, pins, and threaded components.

ABS (Acrylonitrile Butadiene Styrene):

Common in rapid prototyping. Low melting point requires sharp tools and light cuts to avoid burring. Best suited for 3- and 4-axis milling; tight tolerances possible with controlled feed rates.

Nylon (e.g., PA6, PA66):

Semi-crystalline thermoplastic with good wear resistance. Prone to thermal expansion; recommended for post-machining stabilization. Turning ideal for bushings and gears; milling requires climb cutting to minimize deflection.

General Notes:

Tight tolerance machining (±0.005 mm or better) demands environmental control, high-precision tooling (e.g., carbide with PVD coating), and metrology validation using CMM or laser probing. 5-axis systems reduce setup time and improve accuracy on complex geometries, especially in aluminum and steel. All materials benefit from optimized toolpaths (e.g., high-speed machining, trochoidal milling) to maintain dimensional integrity.

From CAD to Part: The Process

Honyo Prototype employs a rigorously structured CNC machining workflow designed for engineering precision, rapid turnaround, and seamless client collaboration. Our five-phase process eliminates ambiguity and accelerates time-to-part while maintaining ISO 9001 quality standards. Below is the technical breakdown of each stage.

CAD Upload and Initial Processing

Clients submit native or neutral CAD formats (STEP, IGES, Parasolid, SolidWorks) via our secure customer portal. Our system immediately performs geometric validation, checking for non-manifold edges, surface gaps, and unit consistency. Files undergo automated material compatibility screening against our certified stock library (aluminum 6061/7075, stainless 303/316, titanium Ti-6Al-4V, engineered plastics). Invalid submissions trigger instant client alerts with specific error diagnostics, preventing downstream delays. All data is encrypted per ITAR compliance protocols.

AI-Assisted Quoting with Engineering Oversight

Our proprietary AI engine analyzes validated CAD geometry to generate preliminary cost and lead time estimates within 30 minutes. This system evaluates 12+ critical parameters: feature complexity (hole depth-to-diameter ratios, wall thickness tolerances), machine time calculations based on toolpath simulations, material utilization efficiency, and secondary operation requirements. Crucially, a Senior Manufacturing Engineer reviews all AI outputs. This human-in-the-loop step adjusts quotes for non-geometric factors like fixturing complexity, surface finish specifications (Ra 0.8µm vs. Ra 3.2µm), and tolerance stack-ups. Clients receive a formal quote with traceable cost drivers, not just a price.

Collaborative DFM Analysis

Upon quote acceptance, our DFM phase begins as a closed-loop engineering dialogue. We deliver a detailed DFM report within 24 hours highlighting manufacturability risks using GD&T-compliant annotations directly on the CAD model. Common findings include:

Wall thickness below 0.5mm for aluminum causing chatter

Blind hole depths exceeding 10x diameter requiring peck drilling

Unnecessary tight tolerances (±0.005mm) increasing cost by 35%

Clients receive actionable redesign recommendations via our portal with comparative cost/lead time impact analysis. This phase reduces production iterations by 72% based on 2023 internal metrics.

Precision Production Execution

Approved designs move to our Haas/DMG MORI CNC fleet (3-axis to 5-axis mills, Swiss-type lathes). Each job includes:

First-article inspection per AS9102 with CMM reports for critical dimensions

Real-time machine monitoring tracking spindle load, tool wear, and thermal drift

In-process verification using Renishaw probes for on-machine dimensional checks

All operations follow documented work instructions referencing ISO 2768-mK for general tolerances unless client specifications supersede. Material certifications and process validation records are maintained for full traceability.

Quality-Controlled Delivery

Final parts undergo comprehensive inspection:

| Inspection Type | Method | Standards Met |

|————————|—————————-|———————|

| Dimensional | CMM (Zeiss CONTURA) | ISO 10360-2 |

| Surface Finish | Profilometer (Mitutoyo SJ-410) | ASME B46.1 |

| Material Verification | PMI (SciAps X-505) | ASTM E1476 |

| Visual | Magnified (10x) inspection | ISO 11970 |

Parts ship in anti-static, humidity-controlled packaging with serialized traceability tags. Delivery timelines are contractually guaranteed (typically 5-7 business days post-DFM approval) with real-time logistics tracking. All documentation, including FAI reports and material certs, is accessible via the client portal upon shipment confirmation. This integrated approach ensures first-time-right parts while providing complete process transparency from digital model to physical delivery.

Start Your Project

For detailed inquiries about our CNC reference services, contact Susan Leo at [email protected]. Our manufacturing facility is located in Shenzhen, ensuring precision engineering and efficient production cycles for your prototyping and low-volume manufacturing needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.