Contents

Manufacturing Insight: Cnc Quality Control

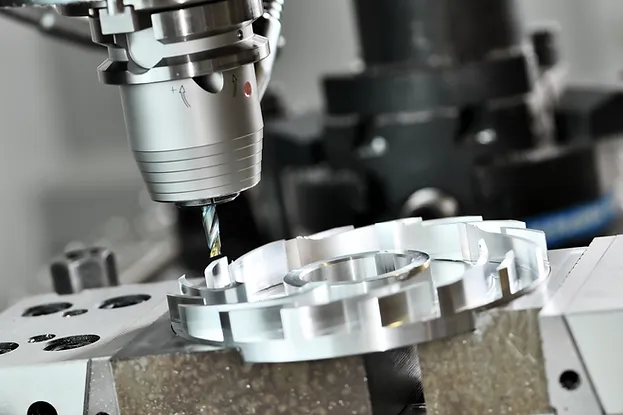

Precision CNC Machining with Integrated Quality Assurance at Honyo Prototype

In high-precision manufacturing, dimensional accuracy and material integrity are non-negotiable. Honyo Prototype delivers rigorously controlled CNC machining services where quality is engineered into every process stage, not merely inspected at the endpoint. Our ISO-compliant quality management system spans material certification, real-time in-process monitoring, and final inspection using calibrated CMMs, optical comparators, and surface roughness testers. This ensures adherence to tight tolerances (±0.0002″) and complex GD&T requirements critical for aerospace, medical, and automotive applications.

Every component undergoes documented verification against AS9102 or PPAP standards where required, with traceable metrology reports provided. Our technical team leverages statistical process control to preempt deviations, minimizing waste and ensuring repeatability across prototypes to low-volume production. This disciplined approach eliminates costly rework and accelerates time-to-market without compromising reliability.

Ready to experience precision manufacturing with transparent pricing? Honyo’s Online Instant Quote platform provides detailed cost and lead-time estimates within minutes—simply upload your CAD file to begin.

Technical Capabilities

CNC quality control ensures dimensional accuracy, surface finish, and material integrity across complex machining operations including 3-axis, 4-axis, and 5-axis milling, as well as precision turning. Critical for tight tolerance applications, the process involves systematic inspection using calibrated metrology equipment and adherence to engineering specifications. Below are the technical specifications for CNC quality control across key machining capabilities and materials.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Common Materials (Typical Use) |

|---|---|---|---|---|---|

| Positional Accuracy | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | Aluminum, Steel, ABS, Nylon |

| Repeatability | ±0.002 mm (±0.00008″) | ±0.002 mm (±0.00008″) | ±0.002 mm (±0.00008″) | ±0.002 mm (±0.00008″) | |

| Typical Tolerance Range | ±0.0125 mm (±0.0005″) | ±0.0125 mm (±0.0005″) | ±0.0125 mm (±0.0005″) | ±0.010 mm (±0.0004″) | Tight tolerance features held to ±0.005 mm |

| Surface Roughness (Ra) | 0.8–3.2 µm (32–125 µin) | 0.8–3.2 µm (32–125 µin) | 0.4–1.6 µm (16–63 µin) | 0.4–1.6 µm (16–63 µin) | Varies with toolpath and material |

| Inspection Equipment | CMM, OGP Vision System, Micrometers, Height Gauges, Bore Gauges | CMM, OGP Vision System, Micrometers, Height Gauges, Bore Gauges | 5-Axis CMM, OGP, Probe Scanning, Laser Scanners | CMM, OD/ID Micrometers, Roundness Tester | All materials inspected per ASTM/ASME |

| Material-Specific Notes | Aluminum: prone to burring; controlled tooling and deburring required. Steel: higher tool wear; monitored via tool life management. ABS: low melting point; optimized speeds/feeds. Nylon: hygroscopic; stabilized pre/post-machining. | ||||

| GD&T Compliance | Full ASME Y14.5 or ISO 1101 | Full ASME Y14.5 or ISO 1101 | Full ASME Y14.5 or ISO 1101 | Full ASME Y14.5 or ISO 1101 | Critical for aerospace and medical parts |

| In-Process Inspection | Available (probing) | Available (probing) | Standard (on-machine probing with touch-trigger or laser) | Available (laser tool setting, probing) | Ensures early deviation detection |

| First Article Inspection (FAI) | AS9102 or PPAP compliant | AS9102 or PPAP compliant | AS9102 or PPAP compliant | AS9102 or PPAP compliant | Required for production release |

| Final Reporting | Full dimensional report, material certs, traceability logs | Full dimensional report, material certs, traceability logs | Full dimensional report, material certs, traceability logs | Full dimensional report, material certs, traceability logs | Provided per customer requirement |

Quality control protocols are maintained through ISO 9001:2015-certified processes, with environmental controls to minimize thermal drift during inspection. For tight tolerance components, especially in aluminum and steel, thermal stabilization and precision fixturing are employed to ensure measurement validity. Plastic materials such as ABS and nylon are conditioned to ambient lab conditions prior to inspection to mitigate dimensional variance due to moisture or temperature.

From CAD to Part: The Process

Honyo Prototype implements a rigorous, multi-stage CNC quality control process integrated across the entire workflow from initial design upload through final delivery. This systematic approach ensures dimensional accuracy, material integrity, and compliance with client specifications at every phase, minimizing rework and guaranteeing part functionality. Below is a detailed explanation of quality control activities within each designated stage.

Upon CAD file upload, our system initiates automated geometric validation and file integrity checks. This initial quality gate verifies unit consistency, non-manifold geometry, and proper solid body construction to prevent downstream manufacturing errors. Files failing validation trigger immediate client notification with specific error diagnostics, ensuring only manufacturable designs progress to quoting. This step eliminates common design submission errors before resource allocation.

The AI Quote phase incorporates predictive quality analysis using machine learning algorithms trained on historical production data. The system cross-references the CAD model against material databases, machine capabilities, and tolerance libraries to identify potential manufacturability risks such as thin walls, excessive aspect ratios, or non-standard tolerances. Risk flags generated here inform both the quote accuracy and the subsequent DFM review focus areas, providing clients with upfront visibility into quality-critical design considerations.

During the DFM analysis stage, our engineering team conducts a formal quality review that builds upon the AI insights. This human-led evaluation assesses geometric dimensioning and tolerancing (GD&T) applicability, fixture strategy feasibility, and surface finish requirements against ISO 2768 or client-specified standards. We provide actionable feedback on critical-to-quality features, recommending modifications to prevent chatter, deflection, or measurement uncertainty. All DFM findings are documented in a client-facing report with annotated CAD markups, establishing a shared quality baseline prior to production.

Production execution employs layered quality verification protocols. First article inspection (FAI) is mandatory for all new part numbers, utilizing calibrated coordinate measuring machines (CMM) for complex geometries, optical comparators for profile verification, and surface roughness testers per ISO 4287. In-process checks occur at 25%, 50%, and 75% production milestones using go/no-go gauges for high-volume runs or statistical process control (SPC) charting for critical dimensions. All measurement equipment undergoes quarterly calibration per ISO 17025 standards with NIST-traceable certificates.

Final quality validation precedes shipment through comprehensive dimensional reporting against the original CAD model. Our quality management system generates AS9102-compliant FAI reports including ballooned drawings, measurement results with uncertainty analysis, and material certification. Non-conforming parts trigger our corrective action workflow with root cause analysis documented in our enterprise resource planning (ERP) system. Only upon client approval of quality documentation is the order released for delivery with serialized traceability tags.

The following table summarizes key quality control methods applied at each process stage:

| Process Stage | Primary Quality Control Method | Purpose and Outcome |

|---|---|---|

| CAD Upload | Automated Geometric Validation | Ensures file integrity and manufacturable geometry; rejects invalid submissions pre-quoting |

| AI Quote | Predictive Risk Analysis | Identifies potential tolerance conflicts and material-process mismatches; informs DFM focus |

| DFM | Engineering Tolerance Review | Validates GD&T application and fixture strategy; provides actionable design-for-quality feedback |

| Production | First Article Inspection (CMM/Optical) | Verifies critical dimensions against CAD; establishes baseline for in-process checks |

| Production | In-Process SPC Monitoring | Maintains statistical control of critical features; prevents batch non-conformances |

| Delivery | AS9102 Documentation Package | Provides auditable proof of conformance; includes material certs and dimensional reports |

This integrated quality framework ensures Honyo Prototype delivers CNC machined components meeting stringent aerospace, medical, and industrial standards. Our process exceeds baseline ISO 9001 requirements through proactive defect prevention rather than end-of-line inspection, resulting in first-pass yield rates above 98.5% across our client portfolio. All quality records remain accessible through our client portal for full production traceability.

Start Your Project

Ensure precision and consistency in your CNC manufacturing with Honyo Prototype’s rigorous quality control processes. Our in-house facility in Shenzhen is equipped with advanced inspection equipment and staffed by expert technicians who perform comprehensive checks at every stage of production.

For inquiries about our CNC quality control protocols or to discuss your project specifications, contact Susan Leo at [email protected]. Trust Honyo Prototype for reliable, high-accuracy components built to meet strict industry standards.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.