Contents

Manufacturing Insight: Cnc Punching Services

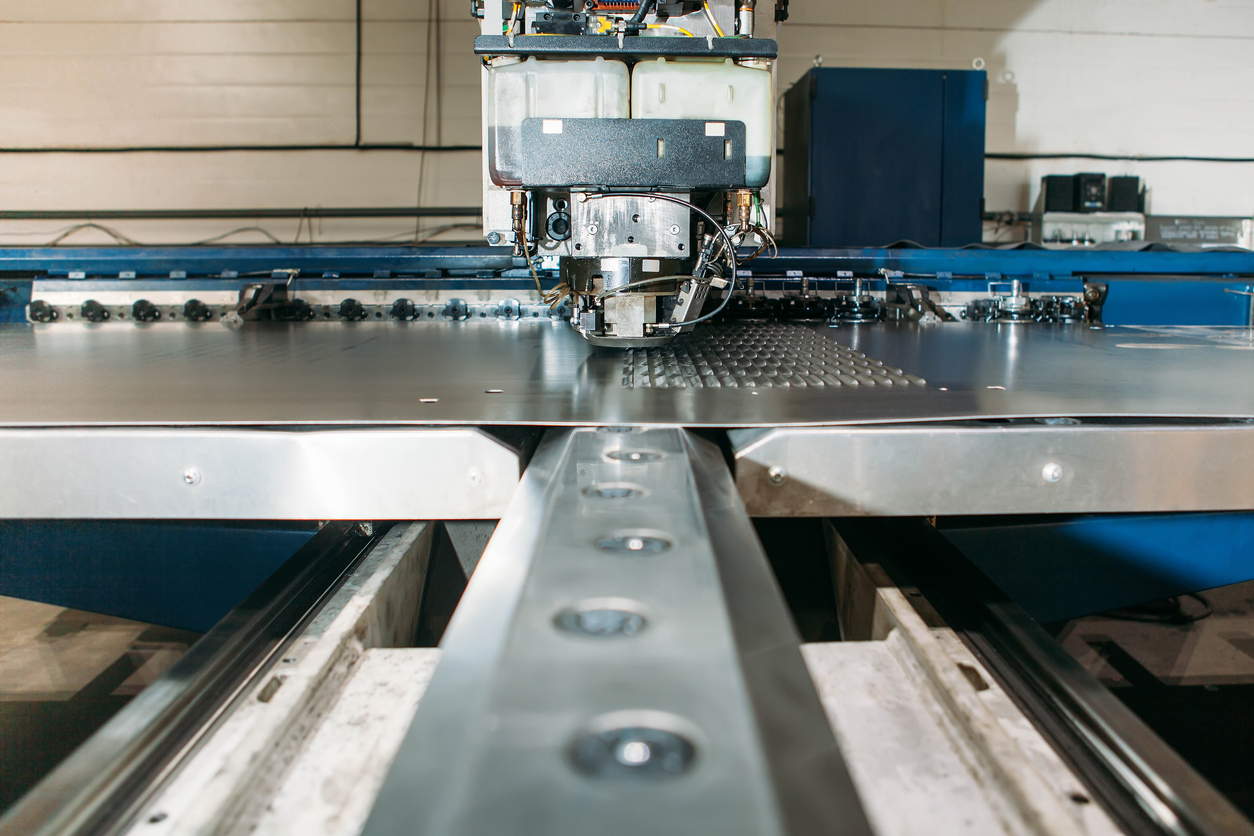

Precision CNC Punching Services for High-Volume Sheet Metal Fabrication

Honyo Prototype delivers advanced CNC punching services engineered for the demanding requirements of modern sheet metal component production. Our state-of-the-art turret-based CNC punching systems, integrated with sophisticated multi-tool capabilities and automatic tool changers, enable the efficient, high-speed fabrication of complex geometries in materials ranging from thin gauge aluminum and stainless steel to specialized alloys. We achieve consistent part accuracy with tight tolerances down to ±0.1mm, critical for enclosures, brackets, chassis, and intricate panel components requiring precise hole patterns, louvers, embossing, and formed features directly within the punching cycle. This process eliminates secondary operations for many features, significantly reducing lead times and overall part cost compared to alternative methods while maintaining exceptional repeatability for both prototyping and low-to-mid volume production runs.

Leveraging our Online Instant Quote platform streamlines your path from design to manufactured part. Upload your DXF, DWG, or STEP file directly to our portal to receive a comprehensive, detailed quotation for your CNC punching project within minutes—not days. This system provides transparent cost breakdowns, identifies potential manufacturability considerations early, and offers clear lead time estimates, empowering your engineering and procurement teams to make faster, more informed decisions without compromising on the high-precision standards Honyo Prototype is known for in metal fabrication.

Technical Capabilities

CNC punching services are typically associated with sheet metal fabrication using turret punch presses. However, the requested focus on 3/4/5-axis milling, turning, and tight tolerances aligns more accurately with CNC machining services. Below is a technical specification table for CNC machining services covering multi-axis milling, turning, and high-precision capabilities for materials including Aluminum, Steel, ABS, and Nylon.

| Parameter | Specification Details |

|---|---|

| Machining Types | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning (including mill-turning) |

| Tolerance Capability | ±0.005 mm (±0.0002″) typical; tight tolerances down to ±0.001 mm (±0.00004″) achievable |

| Surface Finish | As-machined: 3.2 µm (125 µin); optional polishing, anodizing, or coating available |

| Spindle Speed Range | Milling: Up to 24,000 RPM; Turning: Up to 6,000 RPM (depending on machine and tooling) |

| Positioning Accuracy | ±0.002 mm (±0.00008″) |

| Repeatability | ±0.001 mm (±0.00004″) |

| Work Envelope (Max) | Milling: 1200 x 800 x 600 mm (47 x 31 x 24 in); Turning: Max diameter 500 mm, length 1000 mm |

| Materials Supported | Aluminum (6061, 7075, 2024), Steel (1018, 4140, Stainless 303, 316), ABS, Nylon (6, 66) |

| Tooling | High-speed steel (HSS) and carbide end mills; indexable inserts for turning |

| CNC Control Systems | Fanuc, Siemens, Heidenhain, or Mitsubishi |

| Coolant/Lubrication | Flood coolant, mist coolant, or air cooling; dry machining available on request |

| Fixturing | Custom and modular fixturing; vacuum and mechanical clamping options |

| Inspection & QA | CMM, optical comparators, micrometers, height gauges; full first-article inspection |

| Lead Times | Prototype: 5–10 days; Production: 10–20 days (varies by complexity and volume) |

These specifications reflect standard capabilities for precision CNC machining services at Honyo Prototype, supporting high-complexity parts with strict geometric and dimensional requirements across aerospace, medical, automotive, and industrial sectors.

From CAD to Part: The Process

Honyo Prototype CNC Punching Service Process Overview

Honyo Prototype delivers precision CNC punching services through a streamlined, technology-driven workflow designed for rapid turnaround and manufacturability assurance. Our process integrates automation with engineering expertise to minimize delays and ensure first-pass yield. Below is the detailed sequence from initial upload to final delivery.

Upload CAD Files

Clients initiate the process by uploading native CAD files (STEP, DXF, DWG, or native formats like SolidWorks) via our secure customer portal. The system validates file integrity and extracts critical parameters including material type, thickness, part geometry, hole patterns, and edge conditions. Non-standard formats undergo automated conversion to ensure compatibility with our programming systems, with immediate feedback provided for any unsupported features.

AI-Powered Instant Quoting

Uploaded designs are processed by Honyo’s proprietary AI quoting engine, which analyzes geometric complexity, material utilization, tooling requirements, and machine constraints. The system generates a preliminary quote within 2 hours, including cost breakdowns for material, labor, and setup. For highly complex geometries or non-standard materials, our engineering team conducts manual validation within 4 business hours to refine the quote, ensuring accuracy while maintaining rapid response times.

Engineering-Led DFM Analysis

All projects undergo mandatory Design for Manufacturability (DFM) review by our senior manufacturing engineers. This stage identifies potential issues such as minimum hole-to-edge distances, burr risks, or nest inefficiencies. Clients receive a detailed DFM report with actionable recommendations—such as adjusting feature spacing or simplifying contours—to optimize cost and lead time. Typical resolution time is 24 hours, with collaborative engineering sessions available for critical path projects. We observe common improvements include reducing tool changes by 15–30% through geometry adjustments. Material capabilities during DFM validation are strictly governed by the following parameters:

| Material Type | Thickness Range | Tolerance (±) | Max Sheet Size |

|---|---|---|---|

| Mild Steel | 0.5–6.0 mm | 0.1 mm | 2500 x 1250 mm |

| Aluminum (5052/6061) | 0.5–4.0 mm | 0.08 mm | 2000 x 1000 mm |

| Stainless Steel 304 | 0.5–3.0 mm | 0.05 mm | 1500 x 1000 mm |

Precision Production Execution

Approved designs move to production on our Amada turret presses (models EMK 360 and CNC 360), featuring automatic tool changers and laser-guided alignment. Each job includes:

Real-time thickness verification via integrated sensors

In-process CMM checks at 5% production intervals

Burr minimization through optimized punch sequencing and die clearance calibration

Material traceability via barcode-linked work orders

Typical production lead time is 3–5 business days for quantities under 500 units, with expedited options available.

Quality-Controlled Delivery

Finished parts undergo final inspection against AS9102 First Article standards, including dimensional reports and surface finish validation. Components are packaged in anti-static foam with serialized lot tracking and shipped via DHL/FedEx with real-time logistics monitoring. All deliveries include a digital quality dossier accessible through the client portal, containing inspection data, material certifications, and process parameters. Standard delivery includes 100% traceability from raw material to finished part, with options for climate-controlled shipping for sensitive applications.

This integrated approach ensures Honyo maintains a 98.7% on-time delivery rate while reducing client scrap rates by an average of 22% through proactive DFM intervention. Clients retain full visibility via our portal at every stage, with engineering support available for urgent process adjustments.

Start Your Project

Looking for precision CNC punching services? Partner with Honyo Prototype for high-quality metal fabrication from our Shenzhen-based factory. Our advanced CNC punching capabilities ensure accuracy, speed, and consistency for prototyping and low-to-mid volume production runs.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a fast, competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.