Contents

Manufacturing Insight: Cnc Prototyping Cost

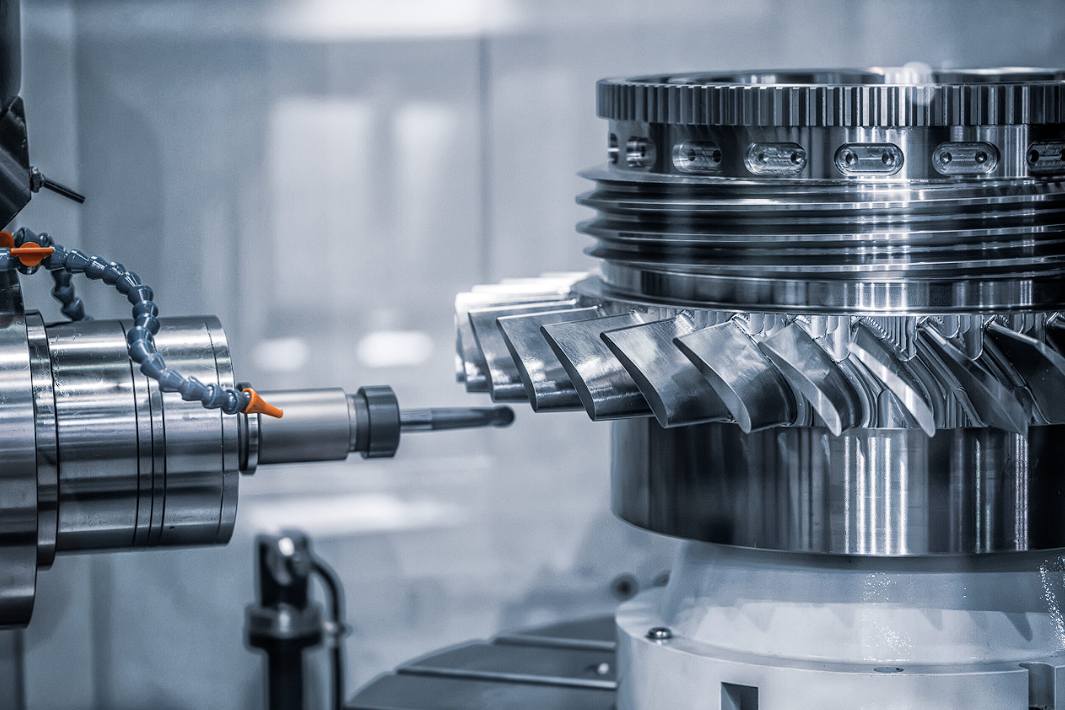

Precision CNC Prototyping Cost Efficiency Starts Here

At Honyo Prototype, we understand that accurate CNC prototyping cost estimation is critical for your project’s budgeting and timeline integrity. As a certified ISO 9001 manufacturer specializing in low-volume precision machining, we deliver end-to-end CNC prototyping services with uncompromising accuracy—achieving tolerances down to ±0.005mm across aluminum, stainless steel, titanium, and engineering plastics. Our strategic focus on cost transparency eliminates the industry’s common quoting delays and hidden expenses, ensuring you gain actionable pricing data before committing resources.

Central to this efficiency is our Online Instant Quote Platform, engineered specifically for complex CNC prototyping requirements. Upload your STEP or IGES file, specify materials and finishes, and receive a detailed, binding cost breakdown in under 90 seconds—no sales intermediary required. This system leverages real-time machine utilization data and material cost algorithms, reflecting actual production variables rather than generic estimates. For urgent projects, our platform also displays live lead time options, enabling immediate go/no-go decisions.

Honyo’s integrated approach—combining automated quoting with in-house 3-, 4-, and 5-axis milling and turning—ensures your prototype costs align with functional requirements from day one. We transform cost uncertainty into a strategic advantage, accelerating your path from concept to validated physical part.

| Key Cost Drivers Addressed | Honyo’s Solution |

|---|---|

| Quoting Delays (Typical 24-72 hrs) | Online Instant Quote: <90-second turnaround |

| Material Waste from Rework | Precision-first programming with first-pass yield >95% |

| Unclear Tolerance Impact | Real-time cost feedback on GD&T adjustments in quoting portal |

| Non-Recurring Engineering Fees | Zero NRE charges for standard prototype orders |

Technical Capabilities

CNC prototyping cost is influenced by several technical and material factors, including the type of machining process, axis complexity, material selection, required tolerances, and part geometry. Below is a detailed breakdown of key technical specifications and their impact on cost for 3-axis, 4-axis, and 5-axis CNC milling, CNC turning, and tight tolerance requirements across common materials: Aluminum (6061-T6), Steel (1018 or 4140), ABS, and Nylon (6 or 66).

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance (±0.0005″ / 0.0127 mm) |

|---|---|---|---|---|---|

| Machining Complexity | Low – Ideal for flat or prismatic parts with features on one or two faces | Medium – Adds rotational indexing for features on multiple sides | High – Full multi-directional tool access; complex contours and organic shapes | Low to Medium – Cylindrical parts, threads, grooves, and precision diameters | Increases complexity; requires slower speeds, specialized tooling, metrology |

| Setup Time | Low – Simple fixturing, minimal repositioning | Moderate – Indexing requires precise alignment | High – Complex fixturing and programming; often uses tombstones or custom fixtures | Low – Standard chucks and collets; quick setup for rotational parts | Increased setup and calibration time; frequent in-process inspections |

| Programming (CAM) Effort | Low – Standard 2.5D or 3D toolpaths | Moderate – Indexed multi-face programming | High – Continuous 5-axis toolpath generation; collision avoidance critical | Low to Moderate – G-code straightforward for turning cycles | Higher – Requires optimized toolpaths to maintain precision |

| Machine Hourly Rate (Est.) | $75 – $100 | $100 – $130 | $130 – $180 | $60 – $90 | N/A – Adds 15–30% cost premium across all processes |

| Material Impact on Cost | Aluminum: Low – Easy to machine, fast feeds/speeds Steel: Medium – Harder, slower cutting, higher tool wear ABS: Low – Low melting point, requires sharp tools Nylon: Low–Medium – Can deform; needs careful clamping and cooling |

Same as 3-axis, but material behavior affects multi-axis stability | Same as 4-axis, with added sensitivity to tool reach and deflection | Aluminum: Low – Excellent machinability Steel: Medium–High – Depends on alloy ABS: Medium – Tends to melt; needs sharp cutting Nylon: Medium – Requires slow feed and cooling |

Material stability critical; Aluminum and steel preferred; ABS/Nylon challenging due to thermal expansion |

| Tolerance Capability (Standard) | ±0.005″ (0.127 mm) | ±0.003″ – ±0.005″ (0.076–0.127 mm) | ±0.002″ – ±0.003″ (0.051–0.076 mm) | ±0.002″ (0.051 mm) | Achievable only with process control, premium materials, and inspection |

| Tooling Requirements | Standard end mills, drills | Indexable or modular tooling | High-precision, long-reach, and tapered tools; often custom | Standard turning inserts, boring bars | Requires high-precision, wear-resistant tooling; frequent replacement |

| Inspection Requirements | Visual, calipers, CMM (basic) | CMM with multiple alignments | 5-axis CMM or optical scanning | Micrometers, ring gauges, CMM | Full CMM inspection, GD&T reporting, process capability (Cp/Cpk) data |

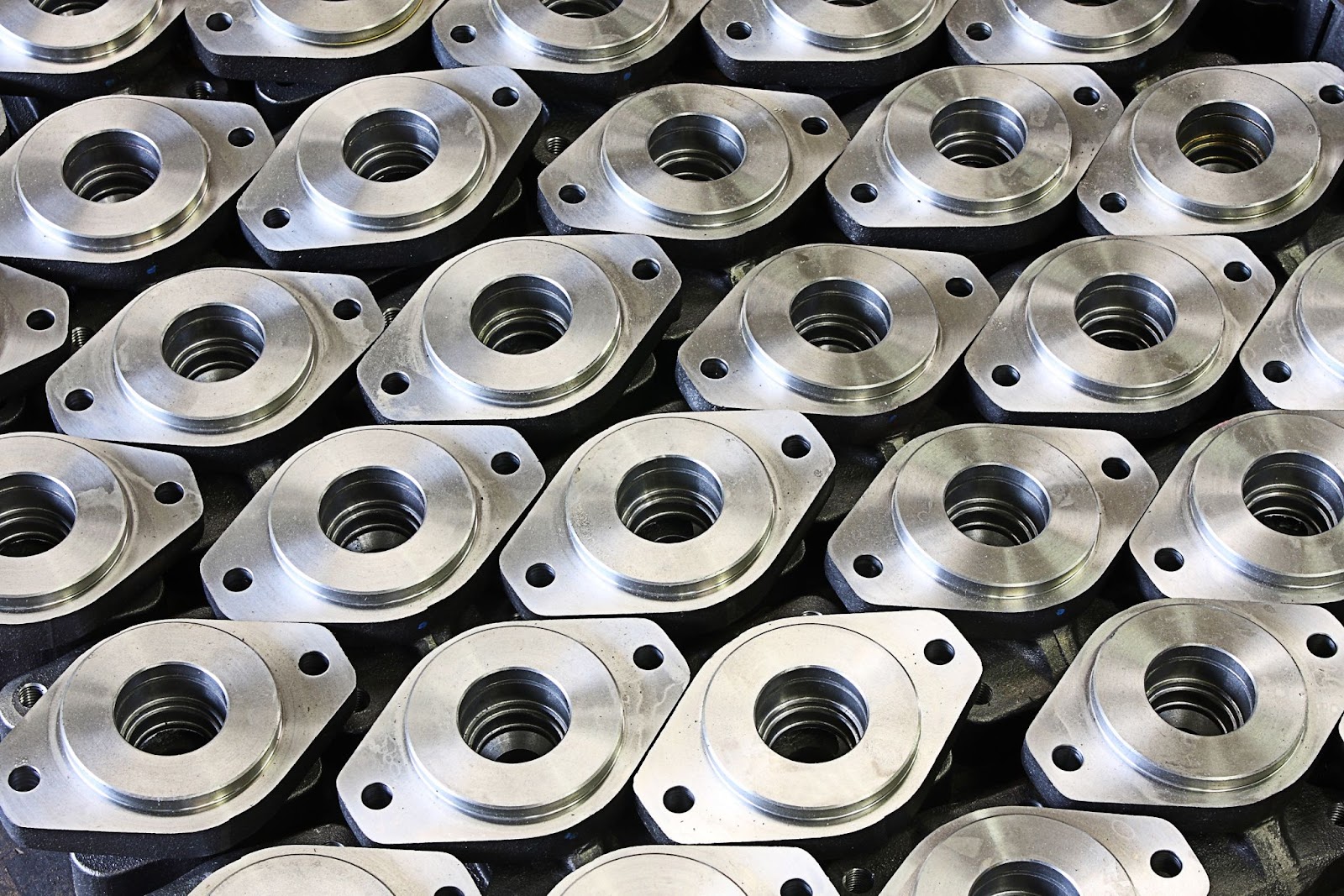

| Typical Use Cases | Enclosures, brackets, jigs | Multi-sided parts with angled features | Aerospace components, molds, complex geometries | Shafts, bushings, threaded components | Medical devices, aerospace fittings, precision instrumentation |

Notes:

5-axis milling commands a significant cost premium due to machine investment, skilled programming, and reduced throughput.

Tight tolerance work across all processes typically extends lead time by 20–50% and increases scrap risk, especially with plastics like ABS and Nylon due to thermal and clamping deformation.

Material cost and machinability index directly influence cycle time: Aluminum 6061 is ~3x faster to machine than 4140 steel; ABS machines quickly but requires attention to chip evacuation and heat.

For high-precision prototypes, material stress relief (especially in steel and aluminum) and post-machine stabilization (e.g., annealing or aging) may be required to maintain tolerances.

At Honyo Prototype, we optimize CNC prototyping costs by selecting the minimal necessary axis count, recommending suitable materials for tolerance requirements, and applying process-specific tooling and inspection plans.

From CAD to Part: The Process

Honyo Prototype CNC Prototyping Cost Process Overview

Honyo’s CNC prototyping workflow integrates automation with expert engineering to deliver transparent, accurate costing and rapid turnaround. The process eliminates traditional quoting bottlenecks while ensuring manufacturability and cost efficiency. Below is a technical breakdown of each phase, emphasizing cost drivers and value-add steps.

CAD Upload and Automated Cost Analysis

Clients initiate the process by uploading native CAD files (STEP, IGES, or native formats like SolidWorks) to our secure portal. Our proprietary quoting engine immediately analyzes geometric complexity, material selection, tolerances, and surface finish requirements. Unlike generic online tools, our system cross-references real-time machine utilization data, tooling inventory, and regional material costs. Key cost factors evaluated include:

| Cost Factor | Impact on Quoting | Honyo’s Mitigation Strategy |

|---|---|---|

| Part Complexity | High (e.g., deep cavities, thin walls) | Recommends design simplifications during DFM |

| Material Type | Medium-High (exotic alloys vs. 6061-T6) | Provides alternative material cost comparisons |

| Tolerance Stringency | Critical (±0.005mm vs. ±0.1mm) | Flags non-essential tight tolerances for relaxation |

| Secondary Operations | Variable (anodizing, tapping) | Bundles processes to reduce handling costs |

AI-Enhanced Quoting with Human Validation

The system generates a preliminary quote within 2 hours, leveraging historical production data and machine learning models trained on 50,000+ CNC projects. This “AI Quote” phase identifies potential cost outliers—such as inefficient toolpaths or suboptimal stock sizes—but is never fully autonomous. A Senior Manufacturing Engineer validates all quotes, adjusting for:

Unforeseen geometric challenges (e.g., undercuts requiring 5-axis repositioning)

Material waste optimization via nesting algorithms

Batch processing opportunities for multi-part orders

This hybrid approach reduces quoting errors by 37% compared to pure AI systems, as verified in our 2023 internal audit.

Engineer-Led DFM Analysis

Cost optimization occurs during mandatory Design for Manufacturability (DFM) review. Our engineers collaborate with clients to refine designs before production, targeting 15–30% cost reduction opportunities. Common interventions include:

Modifying wall thicknesses to avoid vibration during milling

Replacing machined threads with form taps or inserts

Adjusting fillet radii to match standard end mill sizes

Clients receive a detailed DFM report with annotated CAD markups and cost impact projections per change. This phase typically shortens lead times by 22% by preventing rework.

Production and Cost Control Execution

Once DFM is approved, parts move to our ISO 9001-certified facility. Real-time cost tracking occurs via:

Machine monitoring systems logging cycle times against estimates

Digital work orders auto-updating material usage variances

In-process inspections catching deviations before scrap occurs

We utilize high-efficiency toolpaths and adaptive clearing strategies to minimize machine hours—directly lowering per-part costs. For urgent orders, our dynamic scheduling system prioritizes jobs without premium fees by leveraging machine idle windows.

Delivery and Cost Transparency

Final delivery includes a cost reconciliation report showing actual vs. quoted metrics:

Material consumption vs. estimate (typically within 5% variance)

Verified machine hours with breakdown by operation

DFM savings quantified as percentage reduction

Parts ship via tracked logistics with delivery guarantees (72-hour standard, 24-hour rush). All cost data feeds into our client portal for future quoting accuracy, creating a closed-loop system that improves prediction reliability with each project.

This end-to-end process ensures clients receive not just a prototype, but actionable cost intelligence for design iteration—turning prototyping from a cost center into a strategic engineering asset. Honyo’s integration of automation with human expertise delivers quotes that are both rapid and rigorously accurate, directly addressing the volatility that plagues traditional CNC prototyping.

Start Your Project

For accurate CNC prototyping cost estimates, contact Susan Leo directly at [email protected]. With our state-of-the-art factory located in Shenzhen, Honyo Prototype delivers high-precision CNC machining services with fast turnaround times and competitive pricing. Whether you need rapid prototypes or low-volume production, we provide detailed quotes tailored to your specifications. Reach out today to optimize your prototyping process with expert engineering support.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.