Contents

Manufacturing Insight: Cnc Prototype Machining

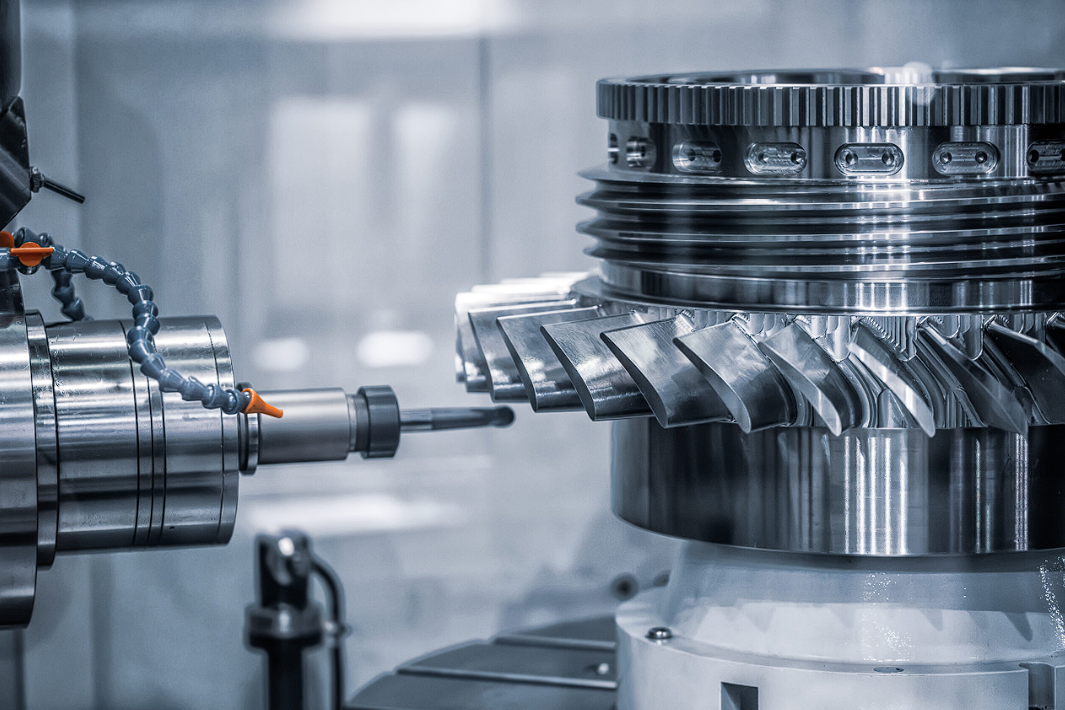

Precision CNC Prototype Machining: Accelerate Your Product Development with Honyo

When the accuracy and functionality of your prototype directly impact downstream engineering validation, tooling investment, and time-to-market, selecting the right manufacturing partner is critical. Honyo Prototype delivers industry-leading CNC machining services engineered specifically for rapid, high-fidelity prototyping and low-volume production. We leverage advanced 3-, 4-, and 5-axis milling and turning centers to transform complex CAD models into precise physical components with exceptional repeatability, meeting the stringent demands of aerospace, medical, automotive, and industrial equipment development.

Our technical capabilities span a wide range of engineering-grade materials including aluminum alloys (6061-T6, 7075), stainless steels (303, 304, 17-4 PH), titanium, plastics (Delrin, Nylon, PEEK), and brass. We consistently achieve tight tolerances down to ±0.005mm (±0.0002″) and surface finishes suitable for fit, form, and functional testing, ensuring your prototype accurately reflects final production intent. This precision minimizes design iteration cycles and de-risks your path to manufacturing.

Key technical specifications supported include:

| Parameter | Typical Capability Range |

|---|---|

| Tolerance | ±0.005mm (±0.0002″) standard |

| Max Work Envelope | 1000 x 600 x 500 mm (39″ x 24″ x 20″) |

| Materials | Metals, Engineering Plastics, Composites |

| Lead Time (Prototype) | As fast as 3-5 business days |

Streamlining your workflow begins with instant accessibility. Honyo’s proprietary Online Instant Quote system eliminates traditional quoting delays. Simply upload your STEP, IGES, or native CAD file directly to our secure portal, specify material and quantity requirements, and receive a detailed, transparent cost estimate within minutes – not days. This immediate feedback loop empowers faster design decisions and project initiation, giving your engineering team the agility required in today’s competitive development landscape. Partner with Honyo Prototype to convert your digital designs into mission-critical physical assets with speed, precision, and engineering confidence.

Technical Capabilities

CNC prototype machining is a high-precision subtractive manufacturing process used to produce functional prototypes with tight tolerances and complex geometries. At Honyo Prototype, we specialize in multi-axis milling and turning operations to meet demanding engineering requirements across a range of engineering-grade materials.

3/4/5-Axis Milling allows for the machining of complex 3D features with minimal setup. 3-axis is ideal for prismatic parts, while 4-axis (with rotational A-axis) and 5-axis (dual rotational axes) enable undercuts, angled features, and organic shapes without re-fixturing. CNC Turning is used for cylindrical or rotationally symmetric components, often in combination with milling for mill-turn parts.

All processes are optimized for tight tolerance machining, typically holding ±0.005 mm (±0.0002″) for critical dimensions, with surface finishes down to Ra 0.8 µm (32 µin) achievable.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Max Work Envelope | 1000 x 600 x 500 mm | 800 x 500 x 400 mm | 600 x 400 x 350 mm | Ø300 x 500 mm length |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.005 mm | ±0.005 mm |

| Repeatability | ±0.003 mm | ±0.003 mm | ±0.003 mm | ±0.003 mm |

| Typical Tolerance | ±0.01 mm | ±0.01 mm | ±0.01 mm | ±0.01 mm |

| Tight Tolerance Capability | ±0.005 mm | ±0.005 mm | ±0.005 mm | ±0.005 mm |

| Surface Finish (Typical) | Ra 1.6 – 3.2 µm | Ra 1.6 – 3.2 µm | Ra 0.8 – 1.6 µm | Ra 0.8 – 1.6 µm |

| Spindle Speed (Max) | 24,000 rpm | 20,000 rpm | 20,000 rpm | 6,000 rpm |

| Tool Changer Capacity | 24 tools | 24 tools | 30 tools | 12 stations |

Compatible Materials:

Aluminum: 6061-T6, 7075-T6 – excellent machinability, high strength-to-weight ratio, ideal for aerospace and automotive prototypes.

Steel: 4140, 1018, Stainless 303/316 – high strength and wear resistance; suitable for high-load or corrosive environments.

ABS: Good impact resistance and dimensional stability; commonly used for functional plastic prototypes and fit-check models.

Nylon (PA6, PA66): High toughness, low friction, and good chemical resistance; used in wear-prone or structural plastic components.

All materials are machined using optimized toolpaths, high-precision carbide tooling, and in-process inspection (via CMM or probe) to ensure dimensional accuracy and repeatability. First-article inspection reports (FAIR) and material certifications are available upon request.

From CAD to Part: The Process

Honyo Prototype employs a streamlined, technology-driven workflow for CNC prototype machining designed to accelerate time-to-part while ensuring manufacturability and quality. Our defined process eliminates traditional bottlenecks through integrated digital tools and engineering expertise.

CAD Upload and Initial Processing

Clients initiate the process by uploading native or neutral format CAD files (STEP, IGES, Parasolid, SolidWorks) via our secure customer portal. The system performs immediate geometric validation, checking for file integrity, unit consistency, and basic topology errors. This step ensures the digital model is production-ready before proceeding to quotation, reducing downstream delays.

AI-Powered Quoting Engine

Uploaded geometry is processed by our proprietary AI quoting system, which analyzes part complexity, material requirements, machine time estimates, and fixture strategies. The algorithm cross-references real-time data from our machine shop floor, including current workload, tooling availability, and material stock levels. Clients receive a detailed quote with cost breakdown and estimated lead time within minutes, not days. The system flags potential high-risk geometries requiring immediate engineering review.

Engineer-Led DFM Analysis

Every project undergoes mandatory Design for Manufacturability (DFM) review by our senior CNC engineers, even after AI validation. This critical phase identifies opportunities to optimize geometry for machining efficiency, reduce secondary operations, and prevent costly errors. Key DFM considerations include:

| DFM Factor | Analysis Focus | Typical Resolution |

|---|---|---|

| Feature Geometry | Undercuts, thin walls, deep cavities | Suggest draft angles, wall thickness adjustments |

| Tolerance Stack-Up | Interdependent GD&T callouts | Recommend relaxed tolerances where function allows |

| Material Utilization | Stock size vs. part envelope | Propose alternative billet dimensions |

| Setup Minimization | Feature accessibility | Redesign for single-setup machining |

Engineers collaborate directly with clients to discuss findings, providing annotated CAD markups and formal DFM reports. Client approval is required before production release, ensuring alignment on any necessary design modifications.

Precision CNC Production

Approved designs move to our climate-controlled machine shop featuring 3-axis, 4-axis, and 5-axis milling centers alongside precision turning centers. Each job receives:

Material certification documentation for aerospace/medical grades

First-article inspection (FAI) per AS9102 standards for critical features

In-process CMM verification at defined checkpoints

Real-time production tracking via client portal with machine telemetry

Our closed-loop quality system captures tool wear compensation data and thermal drift corrections, maintaining ±0.005mm tolerances across production runs.

Logistics and Delivery

Completed prototypes undergo final cleaning, deburring, and protective coating as specified. Parts are packaged in anti-static foam within crush-resistant containers with humidity indicators. Every shipment includes:

Dimensional inspection report (PDF and physical copy)

Material traceability documentation

Process validation records

Certificate of Conformance

We offer global delivery via DHL/FedEx with real-time tracking, typically achieving 5-7 business day turnaround from DFM approval for standard prototypes. Expedited services (72-hour) are available for qualifying geometries. All deliverables include full digital traceability for audit compliance.

Start Your Project

Looking for precision CNC prototype machining? Partner with Honyo Prototype for fast, high-quality manufacturing solutions. Our advanced CNC capabilities ensure tight tolerances, rapid turnaround, and consistent accuracy—ideal for functional prototypes and low-volume production.

Based in Shenzhen, our state-of-the-art factory supports global clients with seamless prototyping-to-production workflows.

Contact Susan Leo at [email protected] to discuss your next project and get a quote today.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.