Contents

Manufacturing Insight: Cnc Programmes

Precision CNC Machining Programmes for Accelerated Prototyping and Low-Volume Production

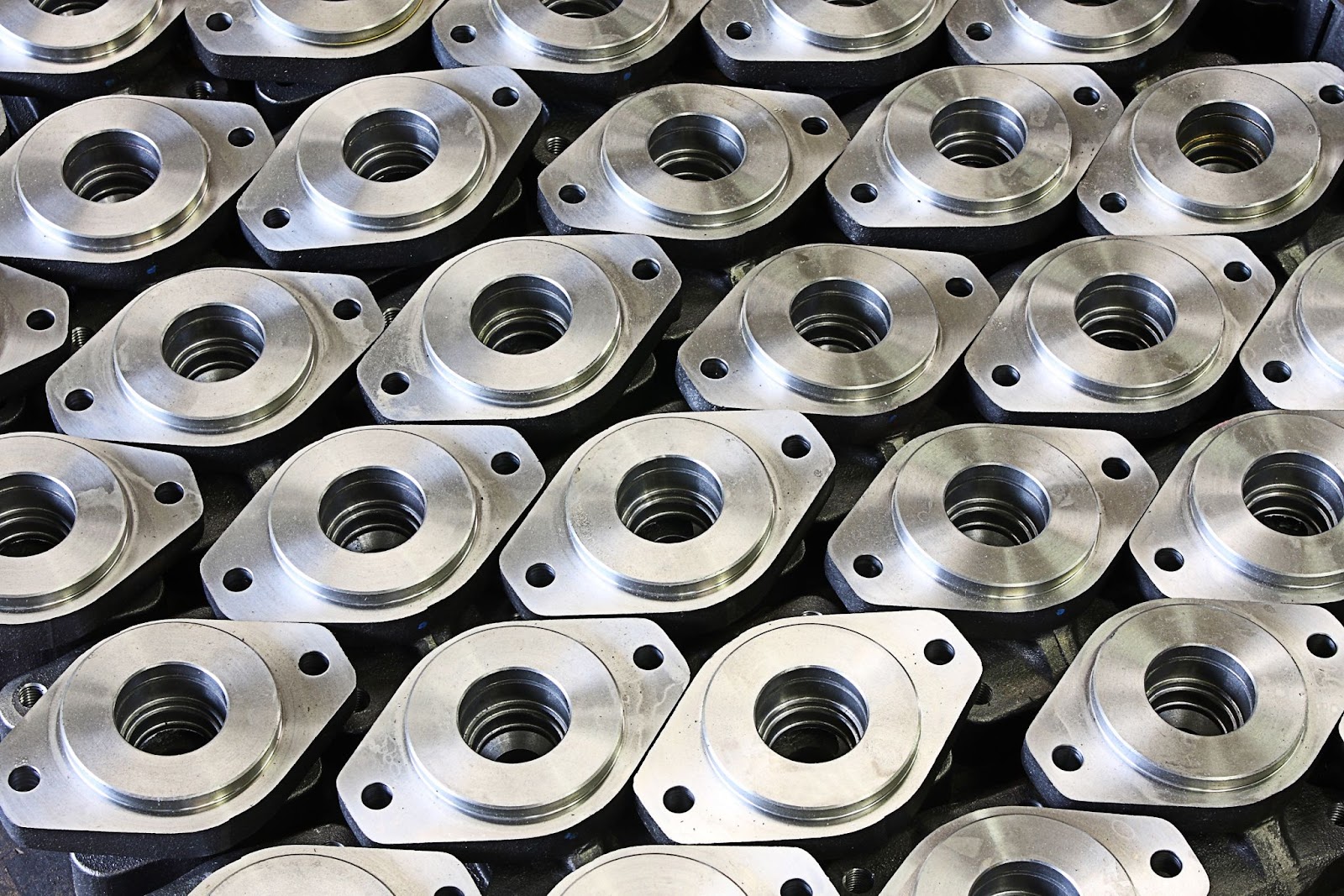

Honyo Prototype delivers advanced CNC machining services engineered to transform complex designs into high-integrity components with exceptional accuracy and repeatability. Our comprehensive CNC programming and manufacturing capabilities encompass 3-axis, 4-axis, and 5-axis milling, precision turning, and multi-tasking operations, supporting a broad spectrum of engineering-grade materials including aluminum alloys, stainless steels, titanium, plastics, and composites. Every programme is meticulously developed and optimized using industry-leading CAM software, rigorously validated through simulation, and executed on our modern, well-maintained Haas, DMG MORI, and Mazak equipment to consistently achieve tight tolerances down to ±0.005 mm and superior surface finishes. We adhere to stringent ISO 9001:2015 quality management protocols throughout the process, ensuring dimensional conformity and material integrity for critical applications across aerospace, medical, robotics, and industrial sectors.

A defining element of our service is the integration of our proprietary Online Instant Quote platform. This digital solution eliminates traditional procurement delays by providing fully transparent, geometry-based cost estimates and manufacturability feedback within seconds, directly from your CAD file upload. Engineers and procurement teams gain immediate visibility into lead times, material costs, and potential design optimizations, significantly streamlining the RFQ process and accelerating your time-to-market. Partner with Honyo Prototype for CNC programmes that combine technical excellence with operational efficiency, turning your precision component requirements into reality faster and more reliably.

Technical Capabilities

CNC Program Technical Specifications for 3/4/5-Axis Milling and Turning – Focus on Tight Tolerance Components

CNC programs for precision machining of tight tolerance components require detailed toolpath strategies, rigorous setup planning, and material-specific optimization. Below are the technical specifications relevant to 3-axis, 4-axis, and 5-axis milling, as well as CNC turning operations, across common engineering materials including Aluminum, Steel, ABS, and Nylon.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Notes |

|---|---|---|---|---|---|

| Degrees of Freedom | X, Y, Z | X, Y, Z, A (rotary about X) | X, Y, Z, and two rotary axes (e.g., A&B or B&C) | X, Z (rotary spindle + linear axes) | 5-axis enables simultaneous tool engagement from complex angles |

| Tolerance Capability | ±0.005 mm (±0.0002″) | ±0.005 mm | ±0.003 mm (±0.0001″) | ±0.005 mm (turning), down to ±0.002 mm with precision tooling | Tight tolerance programs require thermal stability, high rigidity, and compensated tool wear |

| Typical Surface Finish (Ra) | 0.8 – 3.2 µm | 0.8 – 1.6 µm | 0.4 – 1.6 µm | 0.8 – 1.6 µm (turning), 0.4 µm with fine cuts | Finish depends on material, tooling, and stepover/feed settings |

| Material Compatibility | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS | Aluminum, Steel (exotic alloys), Titanium | Aluminum, Steel, ABS, Nylon | Nylon and ABS require reduced cutting forces and chip evacuation control |

| Aluminum Machining Parameters | Spindle: 8,000–20,000 RPM; Feed: 1,000–3,000 mm/min; Tool: Carbide, 2–4 flute | Similar to 3-axis with indexed rotary positioning | Continuous toolpath optimization; Spindle: 12,000–25,000 RPM | Spindle: 1,500–4,000 RPM; Feed: 0.05–0.2 mm/rev | High-speed machining typical; coolant or air blast recommended |

| Steel Machining Parameters | Spindle: 2,000–8,000 RPM; Feed: 300–1,200 mm/min; Tool: Carbide or HSS with coating | Lower RPM than aluminum; indexed positioning for multi-face access | Spindle: 3,000–10,000 RPM; use of rigid toolholders and peck drilling | Spindle: 500–1,500 RPM; Feed: 0.1–0.3 mm/rev | Requires rigid setup and proper chip evacuation; tolerance maintained via tool wear compensation |

| ABS & Nylon Machining Parameters | Spindle: 10,000–18,000 RPM; Feed: 1,500–2,500 mm/min; Sharp tools, minimal rake | Use light cuts; avoid heat buildup | Climb milling, small stepdowns (≤1 mm) | Spindle: 2,000–4,000 RPM; Feed: 0.05–0.15 mm/rev | Thermoplastics prone to melting; sharp tools and air cooling essential |

| Toolpath Strategy | 2.5D and 3D contouring, pocketing, drilling | Indexed positioning (3+1), limited simultaneous motion | Full simultaneous 5-axis interpolation, swarf cutting, tilt optimization | OD/ID turning, grooving, threading, parting | Tight tolerance parts use adaptive clearing and high-precision finishing passes |

| Fixturing Requirements | Vises, clamps, vacuum tables (for plastics) | Rotary table integration, alignment critical | Custom fixtures or tombstones with angular access | Collets, chucks, steady/following rests | Minimize runout; alignment critical for sub-0.01 mm tolerances |

| Programming Software | Mastercam, Fusion 360, Siemens NX, Hypermill | Same as 3-axis, with 4-axis module | Advanced CAM with 5-axis simultaneous support | Fusion 360, Mastercam, Esprit | Simulation and G-code verification essential for collision avoidance |

| G-Code Standards | G00, G01, G02/G03, G17–G19, M03–M05 | Add G-code for A-axis (e.g., G1 A±) | Full 5-axis G-code (e.g., G43.4, RTCP supported) | G71–G76 cycles, G96 constant surface speed | High-end machines use RTCP (Rotational Tool Center Point) for accuracy |

| Applications | Flat plates, housings, jigs | Impellers, turbine blades (indexed), multi-face parts | Aerospace components, medical implants, molds | Shafts, bushings, connectors, threaded parts | Tight tolerance programs often used in aerospace, medical, and automation |

All CNC programs for tight tolerance work must include tool deflection compensation, thermal drift considerations, in-process probing routines (where available), and post-process CMM validation protocols. Material-specific tooling and feeds are critical to maintaining dimensional accuracy and surface integrity, especially when transitioning between metals and engineering plastics.

From CAD to Part: The Process

Honyo Prototype employs a streamlined, technology-driven workflow for CNC machining projects designed to maximize efficiency, reduce lead times, and ensure manufacturability from initial concept to final delivery. Our integrated process leverages proprietary AI systems and engineering expertise at critical decision points.

CAD Upload and Initial Processing

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, or native formats like SolidWorks) via our secure customer portal. Our system performs an immediate validation check for file integrity, unit consistency, and geometric completeness. Invalid or incomplete submissions trigger an automated notification requesting correction, preventing downstream delays. Validated files proceed directly to the AI quotation engine without manual intervention.

AI-Powered Quotation Generation

Honyo’s proprietary AI engine analyzes the validated CAD geometry to generate an instant, data-driven quotation within minutes. This system evaluates over 200 parameters including part complexity, feature density, material requirements, required tolerances, and surface finish specifications. The AI cross-references real-time machine availability, historical production data from our CNC fleet (Haas, DMG MORI, Makino), and current material market pricing. Clients receive a detailed quote containing estimated lead time, cost breakdown by operation, and recommended material options. This eliminates traditional quotation bottlenecks while providing unprecedented transparency.

Engineering-Led DFM Analysis and Optimization

Following quote acceptance, our manufacturing engineering team conducts a rigorous Design for Manufacturability (DFM) review. This is not an automated step but a value-added engineering service where senior CNC programmers and process engineers collaborate with the client to optimize the design for production. Critical DFM checks include:

| DFM Check Category | Specific Parameters Verified | Impact Mitigated |

|---|---|---|

| Geometric Feasibility | Minimum wall thickness, undercuts, internal radii | Prevents part failure during machining |

| Tool Access & Clearance | Tool reach requirements, collision risks | Eliminates non-productive machine stops |

| Tolerance Realism | GD&T feasibility, stacked tolerances | Avoids excessive inspection/scrap |

| Material Utilization | Stock size optimization, nesting efficiency | Reduces material waste by 15-30% |

| Secondary Operations | Deburring complexity, fixturing requirements | Minimizes post-CNC handling time |

Engineers provide actionable feedback through our portal with annotated 3D models, suggesting design modifications that maintain functional intent while improving machinability. Client approval is required before programming commences, ensuring alignment.

CNC Programming and Production Execution

Upon DFM sign-off, our CAM programming team generates optimized toolpaths using Mastercam and Fusion 360. Programs undergo virtual machine simulation (Vericut) to verify collision avoidance and cycle time accuracy. Critical processes utilize in-process probing for first-article validation. Production occurs in our climate-controlled facility on certified equipment with documented SPC tracking for critical dimensions. All CNC operations follow AS9100-aligned procedures with real-time monitoring of spindle load, tool wear, and dimensional conformance via integrated sensors.

Finishing, Quality Control, and Delivery

Post-machining operations include precision deburring, bead blasting, or anodizing as specified. Each part undergoes CMM inspection against the original CAD model with full FAIR documentation. Final packaging uses custom-designed anti-static, shock-absorbing materials meeting IPC-1601 standards. We provide clients with real-time shipment tracking through our logistics partners (DHL, FedEx) and guarantee on-time delivery via our production scheduling system, which dynamically adjusts for machine utilization and priority workflows. All deliveries include comprehensive documentation: inspection reports, material certifications, and process validation records accessible via the client portal.

Start Your Project

For expert CNC programming services, contact Susan Leo at [email protected]. Our precision manufacturing facility is located in Shenzhen, ensuring high-quality production with fast turnaround times. Reach out today to discuss your project requirements and receive a tailored solution for your CNC machining needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.