Contents

Manufacturing Insight: Cnc Production Machining

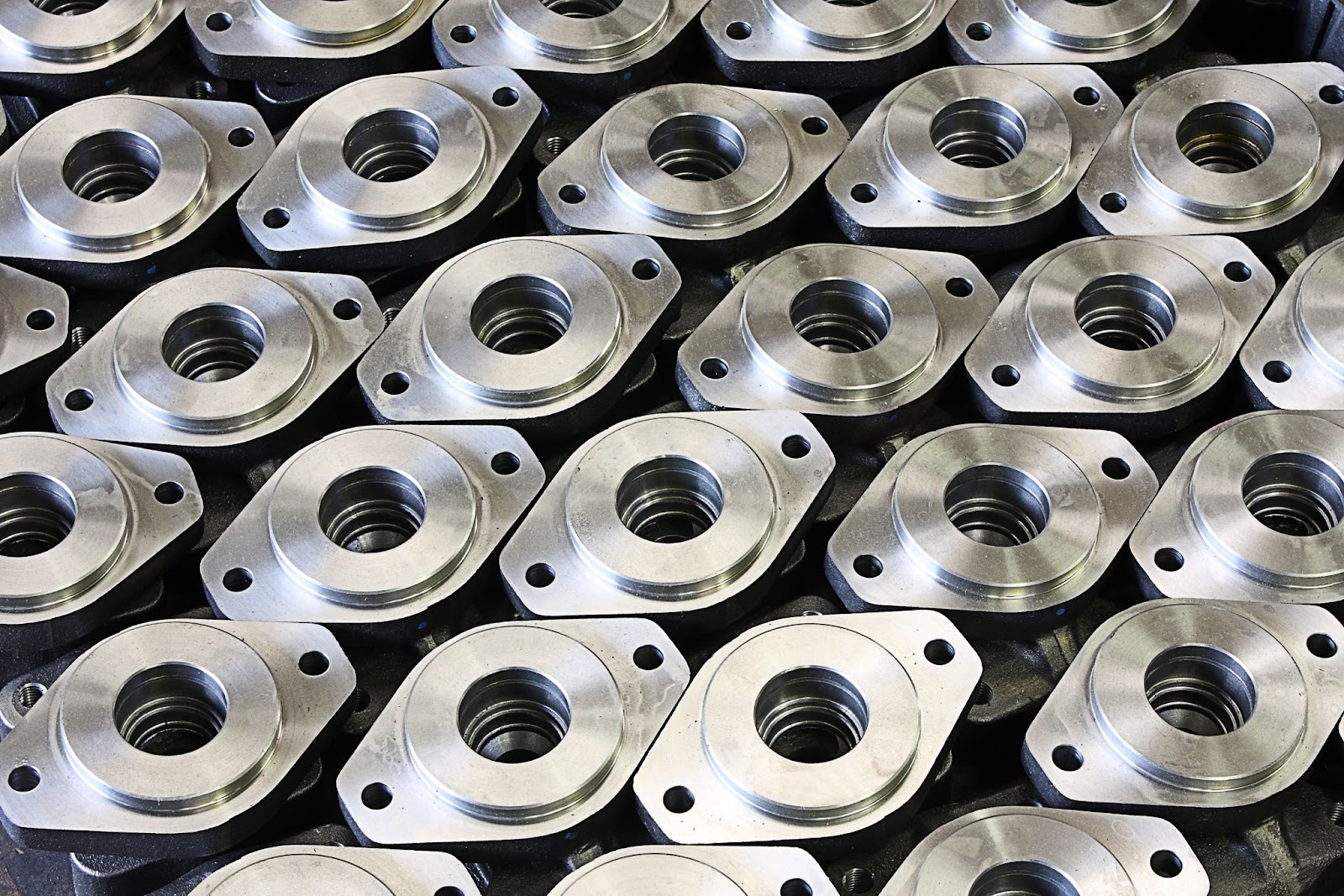

Precision CNC Production Machining for Demanding Industrial Applications

At Honyo Prototype, we deliver high-integrity CNC production machining services engineered to transform complex designs into mission-critical components with unwavering consistency. Our advanced manufacturing ecosystem integrates state-of-the-art multi-axis milling and turning centers with rigorous quality protocols, enabling scalable production runs from rapid prototypes to low-volume manufacturing. We specialize in machining aerospace alloys, medical-grade stainless steels, engineering plastics, and exotic materials to tight tolerances of ±0.005mm, ensuring every part meets stringent AS9100 and ISO 13485 requirements for performance and reliability.

Our technical expertise spans 3-axis to 5-axis simultaneous machining, Swiss turning, and mill-turn operations, supported by in-house CMM validation and real-time process monitoring. This capability allows us to optimize geometries that challenge conventional manufacturing—such as thin-wall features, deep cavities, and micro-precision interfaces—while maintaining repeatable accuracy across batches. Whether producing production-intent prototypes for validation or bridging to full-scale manufacturing, Honyo’s end-to-end workflow eliminates supply chain bottlenecks through integrated design for manufacturability analysis and material sourcing.

Accelerate your path to production with our Online Instant Quote platform. Upload CAD files in STEP, IGES, or native formats to receive a detailed technical and commercial assessment within hours—not days—including manufacturability feedback, lead time projections, and cost breakdowns. This digital gateway streamlines procurement cycles while ensuring engineering alignment before order commitment, reducing time-to-market for your most time-sensitive projects. Partner with Honyo to convert design ambition into precision-engineered reality.

Technical Capabilities

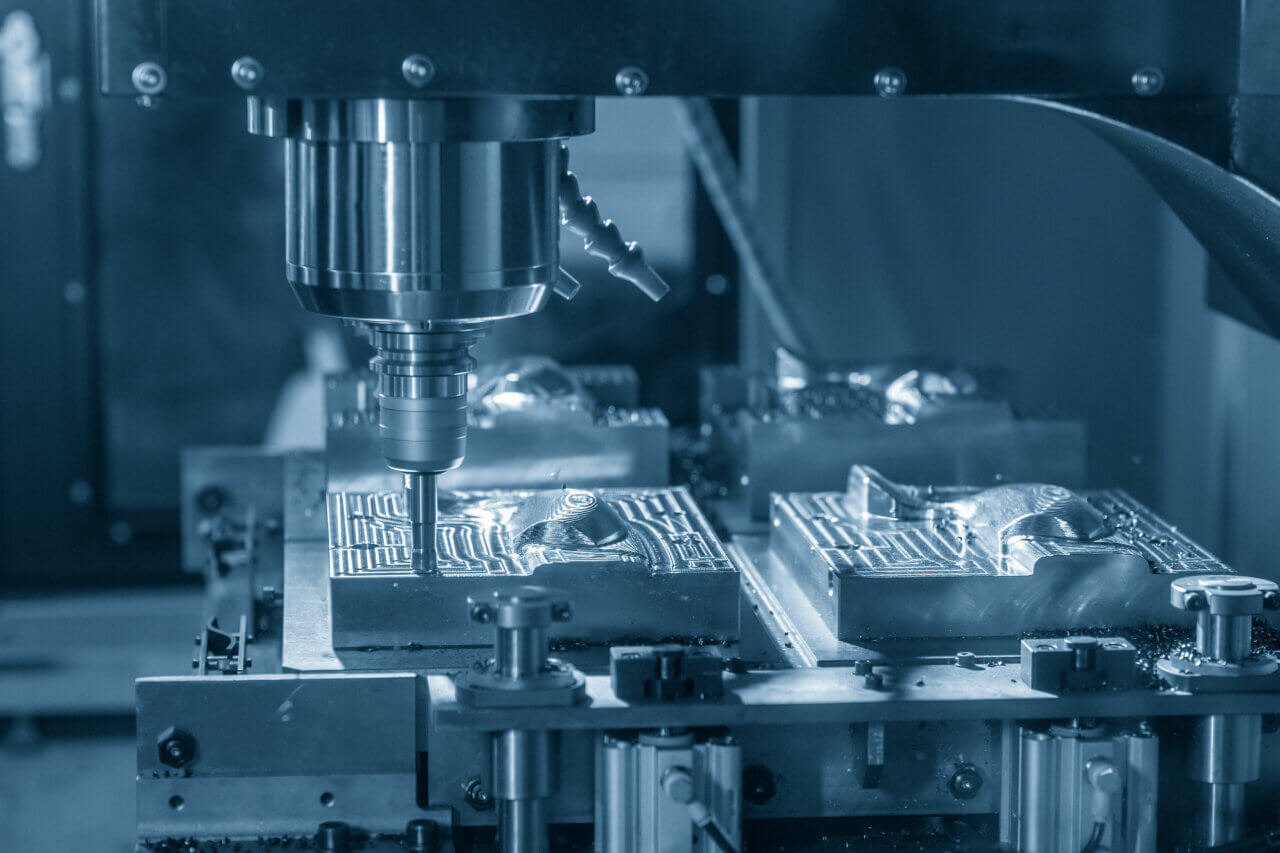

CNC production machining involves high-precision material removal processes used to manufacture complex parts with tight tolerances. At Honyo Prototype, our capabilities span 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, enabling us to support a wide range of production requirements across various materials including aluminum, steel, ABS, and nylon. These processes are ideal for both prototyping and low-to-high volume production runs where precision, repeatability, and surface finish are critical.

Our multi-axis milling systems provide enhanced flexibility for machining complex geometries without requiring multiple setups. 5-axis machining, in particular, allows tool access to intricate features and undercuts, significantly reducing lead times and improving accuracy. CNC turning is employed for cylindrical or rotationally symmetric components, often in combination with milling for fully finished parts.

All machining operations are performed under strict quality control, ensuring tight tolerances down to ±0.0002″ (±0.005 mm) depending on part geometry and material. We utilize high-performance cutting tools, advanced CAM programming, and in-process inspection to maintain dimensional accuracy and surface integrity.

Below is a summary of our technical specifications for CNC production machining:

| Parameter | Specification |

|---|---|

| Milling Capabilities | 3-Axis, 4-Axis, 5-Axis simultaneous |

| Turning Capabilities | CNC Turning (Swiss and standard), Mill-Turn with live tooling |

| Tolerance Range | ±0.0002″ (±0.005 mm) typical; up to ±0.0001″ (±0.0025 mm) with inspection |

| Maximum Work Envelope | Milling: 20″ x 40″ x 25″ (508 x 1016 x 635 mm); Turning: Ø16″ x 48″ (406 x 1219 mm) |

| Spindle Speed | Up to 24,000 RPM (high-speed options available) |

| Positioning Accuracy | ±0.0001″ (±0.0025 mm) |

| Repeatability | ±0.0001″ (±0.0025 mm) |

| Surface Finish | As low as 8 μin (0.2 μm) Ra, polishable to 2–4 μin (0.05–0.1 μm) Ra |

| Supported Materials | Aluminum (6061, 7075, 2024), Steel (1018, 4140, Stainless 303/316), ABS, Nylon (6/66), PEEK, Delrin |

| Fixturing | Custom soft jaws, modular vices, rotary tables (4/5-axis), CMM inspection |

| Software | Mastercam, Fusion 360, SolidWorks, Siemens NX |

| Inspection Tools | CMM, optical comparators, micrometers, calipers, bore gauges, surface testers |

We specialize in high-precision components for aerospace, medical, defense, and industrial automation sectors, where material performance and dimensional accuracy are mission-critical. Our shop supports both ferrous and non-ferrous metals as well as engineering-grade thermoplastics, ensuring optimal material selection for functional requirements such as strength, wear resistance, or chemical exposure.

From CAD to Part: The Process

Honyo Prototype executes CNC production machining through a rigorously defined workflow optimized for precision, efficiency, and client transparency. This integrated process ensures manufacturability from initial design through to certified delivery, leveraging both advanced technology and expert engineering oversight.

CAD Upload and Validation

Clients initiate the process by securely uploading native or neutral CAD formats (STEP, IGES, Parasolid, native SOLIDWORKS) via our encrypted portal. Our system performs immediate validation for geometric integrity, unit consistency, and file completeness. Unsupported formats or corrupted files trigger automated notifications with specific remediation steps, minimizing project initiation delays. All data undergoes AES-256 encryption in transit and at rest per ISO 27001 protocols.

AI-Powered Quoting with Engineering Oversight

Uploaded geometry feeds into our proprietary AI quoting engine, which analyzes geometric complexity, feature density, material requirements, and tolerance stack-ups against real-time machine availability and shop floor data. The AI generates a preliminary cost and lead time estimate within 90 seconds, but crucially, this output is never final without human validation. A dedicated manufacturing engineer reviews the AI output, cross-referencing historical production data for similar geometries, validating material sourcing costs, and assessing fixturing complexity. Clients receive a formal quote within 4 business hours, including a detailed breakdown of machining operations, secondary processes, and critical path analysis.

Engineer-Led DFM Analysis

Upon quote acceptance, our DFM phase begins with a mandatory review by a senior CNC process engineer. Using Siemens NX CAM and custom tolerance analysis modules, we evaluate:

Machinability of specified materials (e.g., aluminum 7075-T6 vs. titanium Ti-6Al-4V)

Geometric feasibility of tight tolerances (±0.0002″ / ±0.005mm)

Optimal stock allowance and workholding strategies

Potential for feature consolidation to reduce setups

Secondary process integration (e.g., anodizing, heat treat)

We provide a formal DFM report within 24 hours highlighting manufacturability risks, cost-saving redesign suggestions, and tolerance justification per ASME Y14.5 standards. Client sign-off is required before proceeding.

Precision Production Execution

Approved designs enter production on our certified CNC equipment (DMG MORI, Haas, Makino), with strict adherence to documented work instructions. Key protocols include:

First-article inspection per AS9102 for aerospace/medical builds

In-process CMM checks at critical milestones using Zeiss CONTURA systems

Real-time machine monitoring via MTConnect for tool wear and process stability

Material traceability with full lot certification (e.g., EN 10204 3.1)

All operations follow documented control plans aligned with ISO 9001:2015 and IATF 16949 requirements. Complex multi-axis parts undergo iterative in-machine probing to ensure dimensional compliance before final release.

Certified Delivery and Logistics

Finished components undergo final inspection against all client-specified GD&T callouts, with comprehensive CMM reports provided. Parts are packaged per ESD-sensitive or corrosion-prone material requirements (e.g., VCI paper for steel, humidity-controlled containers for composites). We manage global logistics through vetted carriers with DDP/DDU flexibility, including customs documentation for international shipments. Real-time shipment tracking is accessible via client portal, with delivery confirmation including:

Dimensional inspection report (full FAI or AQL-based)

Material certification

Process nonconformance report (if applicable)

Packing list with serialized traceability

Typical Lead Time Benchmarks

Standard production timelines vary by material complexity and volume. Representative benchmarks for 10–50 piece runs include:

| Material Category | Standard Lead Time | Rush Option (30% surcharge) |

|---|---|---|

| Aluminum Alloys (6061, 7075) | 7–10 business days | 4–5 business days |

| Engineering Plastics (PEEK, Delrin) | 8–12 business days | 5–6 business days |

| Stainless Steel (17-4PH, 316L) | 10–14 business days | 6–8 business days |

| Titanium Alloys (Gr5) | 12–18 business days | 8–10 business days |

This structured workflow eliminates traditional prototyping bottlenecks while maintaining the rigor required for end-use production. Every phase incorporates feedback loops to our quoting and DFM systems, continuously refining accuracy for future projects. Clients receive full digital thread visibility via our secure portal, with all engineering data archived for 7 years to support reorders and quality audits.

Start Your Project

For high-precision CNC production machining, trust Honyo Prototype’s advanced manufacturing capabilities from our Shenzhen-based factory. With strict quality control, scalable production capacity, and fast turnaround, we deliver consistent, repeatable results for demanding industrial applications.

Contact Susan Leo to discuss your next production run.

Email: [email protected]

Leverage our expertise in CNC machining for volume production—engineered to spec, delivered on time.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.