Contents

Manufacturing Insight: Cnc Plastic Parts

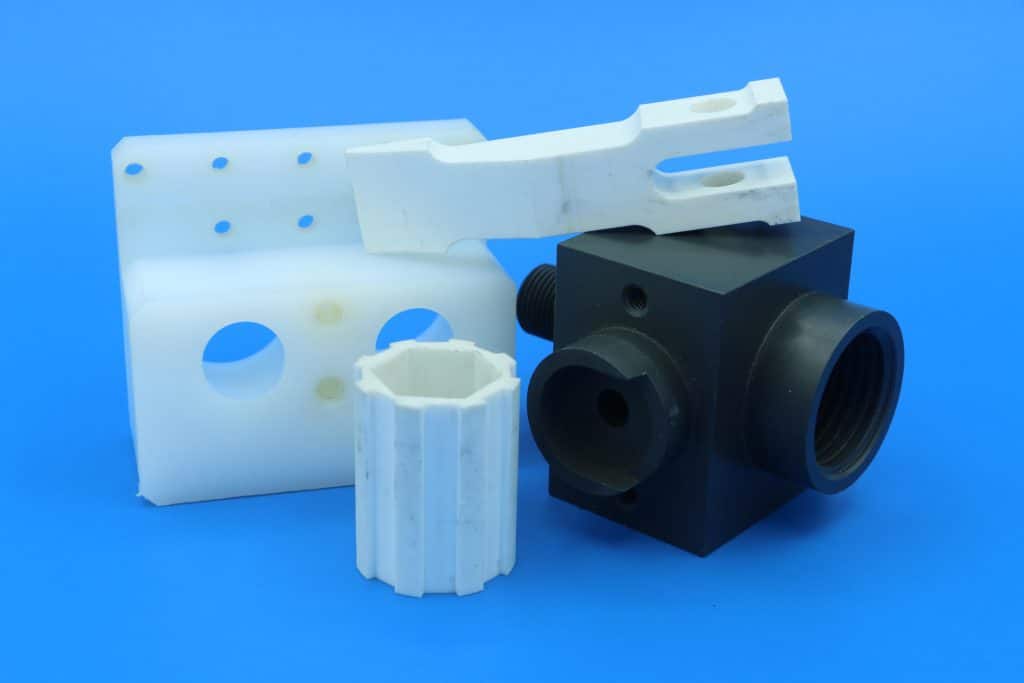

CNC Plastic Parts Precision Manufacturing at Honyo Prototype

Honyo Prototype delivers advanced CNC machining services specifically engineered for high-performance plastic components, serving the demanding requirements of industrial, medical, and aerospace sectors. Our expertise spans a comprehensive range of engineering-grade polymers including PEEK, Ultem, Delrin, PTFE, Nylon, and acrylics, ensuring material properties are optimized for your application’s thermal, chemical, and mechanical demands. We utilize state-of-the-art 3-, 4-, and 5-axis CNC machining centers with tight process controls to achieve exceptional dimensional accuracy, tight tolerances down to ±0.0002 inches, and superior surface finishes critical for functional prototypes and low-volume production runs.

Our dedicated team of manufacturing engineers applies deep material science knowledge to overcome inherent plastic machining challenges such as thermal expansion, chip evacuation, and part deflection. This technical proficiency guarantees consistent part integrity and repeatability across complex geometries and thin-walled features. All processes adhere to rigorous ISO-compliant quality management protocols, with comprehensive in-process and final inspection documentation provided.

Accelerate your development cycle with Honyo Prototype’s Online Instant Quote system. Upload your 3D CAD model (STEP, IGES, X_T, or native formats) to receive a detailed, no-obligation manufacturing assessment and competitive pricing within hours—not days. This streamlined digital workflow provides immediate cost transparency and manufacturability feedback, allowing engineering teams to iterate designs efficiently and move from concept to precision-machined plastic parts faster. Partner with us for CNC plastic machining where technical excellence meets operational agility.

Technical Capabilities

CNC Plastic Parts – Technical Specifications Overview

CNC machined plastic parts are manufactured using precision 3-axis, 4-axis, and 5-axis milling processes, as well as CNC turning, to achieve complex geometries and tight tolerances. While metals like aluminum and steel are common in CNC machining, engineering-grade plastics such as ABS and nylon are frequently used for lightweight, corrosion-resistant, or electrically insulating components. The following table outlines key technical specifications relevant to CNC plastic parts with emphasis on multi-axis milling, turning, and tight tolerance capabilities.

| Feature | Specification Detail |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (for rotational plastic components) |

| Tight Tolerance Capability | ±0.005 mm (±0.0002″) typical; achievable down to ±0.0025 mm (±0.0001″) with process control |

| Surface Finish (Typical) | 1.6 μm (63 μin) to 0.8 μm (32 μin) Ra; post-processing available for finer finishes |

| Common Plastic Materials | ABS (Acrylonitrile Butadiene Styrene), Nylon (PA6, PA66, reinforced grades) |

| Common Metal Materials | Aluminum (6061, 7075, 2024), Steel (1018, 4140, Stainless 303, 316) – for hybrid/metal-shelled assemblies |

| Material Suitability | ABS: Good impact resistance, moderate heat deflection; ideal for prototypes and housings. Nylon: High wear and chemical resistance; suitable for gears, bushings, and structural parts. |

| Max Work Envelope (Milling) | 3-Axis: Up to 1000 x 600 x 500 mm; 5-Axis: Up to 800 x 500 x 400 mm (machine-dependent) |

| Max Turning Diameter | Up to Ø300 mm; length up to 500 mm (bar stock dependent) |

| Tooling | Carbide end mills, diamond-coated cutters for abrasive-filled plastics, sharp-tipped tools for clean plastic cuts |

| Cooling/Lubrication | Air blasting or dry cutting preferred; minimal coolant to prevent plastic warping or stress cracking |

| Secondary Operations | Deburring, tapping, heatstaking, ultrasonic welding, surface texturing, anodizing (for metal counterparts) |

| Quality Control | CMM inspection, optical comparators, laser scanning for GD&T validation |

Notes:

Tight tolerance machining of plastics requires careful consideration of material behavior, including thermal expansion and creep. Pre- and post-machining stress relief (e.g., annealing) is often applied to ensure dimensional stability. Multi-axis milling enables complex organic shapes and undercuts without manual re-fixturing, improving accuracy and repeatability. Turning is typically used for cylindrical plastic components such as seals, spacers, or insulators.

From CAD to Part: The Process

Honyo Prototype CNC Plastic Parts Manufacturing Process

Our end-to-end workflow for CNC machined plastic components integrates advanced digital tools with precision manufacturing expertise to ensure rapid turnaround without compromising on quality or functionality. This structured process minimizes iteration cycles and accelerates time-to-market for your prototypes and low-volume production parts.

CAD Upload and Initial Processing

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) or 2D engineering drawings via our secure customer portal. The system performs an immediate validation check for file integrity, unit consistency, and geometric completeness. Any detected anomalies such as missing datums, inconsistent units, or non-manifold geometry trigger an automated notification to the client for clarification before proceeding. This step ensures the digital foundation for quoting and manufacturing is technically sound.

AI-Powered Quoting Engine

Validated designs enter our proprietary AI quoting system, which analyzes over 200 geometric and material parameters. The engine cross-references our extensive database of 50+ engineering-grade plastics (including ABS, Delrin, Nylon, PEEK, and PMMA) with real-time material cost fluctuations, machine availability, and historical process capability data. Unlike basic surface-area calculators, our AI evaluates feature complexity—such as thin walls, undercuts, or tight tolerances—and dynamically applies machining time multipliers. Quotes include detailed cost breakdowns for material, machining, secondary operations, and finishing, typically generated within 2 business hours. Critical factors like moisture sensitivity for hygroscopic materials (e.g., Nylon 6/6) are flagged for client review.

Engineer-Led DFM Analysis

Following quote acceptance, Honyo’s manufacturing engineers conduct a formal Design for Manufacturability review. This is not an automated checklist but a collaborative assessment where our team evaluates material selection suitability against functional requirements, identifies potential stress concentrations or warpage risks in plastic components, and proposes actionable optimizations. For instance, we might recommend adjusting draft angles for easier ejection in multi-axis setups or modifying radii to prevent tool deflection in acrylic. Clients receive a marked-up DFM report with annotated CAD suggestions and tolerance stack-up analysis. Resolution of critical DFM issues occurs within 24 hours through direct engineer-client collaboration.

Precision CNC Production

Approved designs move to our climate-controlled machining floor housing 32 HAAS and DMG MORI 3-5 axis CNC centers. Key production protocols include:

Material conditioning: Plastics are acclimatized for 72 hours in a 22°C/45% RH environment to minimize post-machining dimensional drift

Toolpath optimization: High-speed machining strategies with specialized plastic-cutting tool geometries (e.g., polished carbide end mills with 40° helix angles) to prevent melting or burring

In-process metrology: First-article inspection using Zeiss CMMs verifies critical dimensions before batch continuation

Dedicated fixturing: Vacuum tables or custom soft jaws prevent part deformation during clamping

Typical lead times from DFM approval to shipment vary by complexity and material, as shown below:

| Part Complexity | Material Type | Standard Lead Time |

|---|---|---|

| Low (e.g., simple brackets) | Standard (ABS, HDPE) | 3-5 business days |

| Medium (e.g., housings with cavities) | Engineering (Delrin, Nylon) | 5-7 business days |

| High (e.g., optical lenses, fluidic manifolds) | High-Performance (PEEK, PVDF) | 7-10 business days |

Quality-Controlled Delivery

Every shipment undergoes final inspection against ASME Y14.5 GD&T standards. Dimensional reports, surface roughness measurements (Ra values), and material certification documents are provided digitally. Parts are packaged in anti-static containers with desiccant for moisture-sensitive polymers and shipped via tracked courier with real-time logistics visibility through our client portal. We maintain ISO 9001:2015-certified traceability from raw material lot to finished part, including machining parameter logs and calibration records for all inspection equipment. This closed-loop system ensures consistent repeatability for prototype validation and bridge production runs.

Start Your Project

Looking for high-precision CNC plastic parts manufactured to exact specifications? Honyo Prototype delivers consistent quality and fast turnaround for prototyping and low-volume production.

Our in-house CNC machining capabilities in Shenzhen ensure tight tolerances, excellent surface finishes, and rapid iteration for engineering-grade plastic components.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.