Contents

Manufacturing Insight: Cnc Plasma Cutting Services

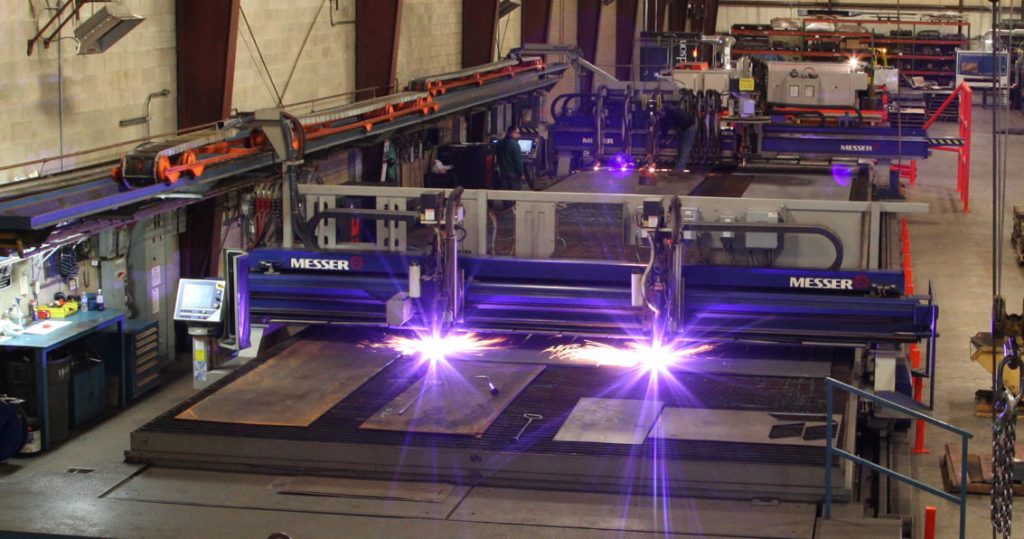

Precision Metal Fabrication Through Advanced CNC Plasma Cutting

Honyo Prototype delivers industrial-grade CNC plasma cutting services engineered for complex metal fabrication projects requiring tight tolerances and rapid turnaround. As an extension of our comprehensive CNC machining capabilities—including milling, turning, and multi-axis milling—we integrate plasma cutting into end-to-end production workflows to streamline prototyping and low-volume manufacturing. Our 5-axis CNC plasma systems leverage high-velocity ionized gas technology to achieve clean, burr-free cuts in conductive materials up to 1.5 inches thick, supporting carbon steel, stainless steel, aluminum, and copper with precision tolerances of ±0.010 inches.

This capability complements Honyo’s core CNC machining expertise, enabling seamless transitions from raw plate to finished component without outsourcing dependencies. We optimize cut paths using proprietary nesting software to minimize material waste while maintaining edge quality suitable for welding, painting, or direct assembly—critical for aerospace, automotive, and industrial equipment applications where dimensional accuracy impacts final product integrity.

Accelerate your project timeline with Honyo’s Online Instant Quote platform, designed specifically for CNC plasma cutting and machining services. Upload DXF, DWG, or STEP files to receive a detailed, no-obligation cost estimate in under 60 seconds, including material utilization analysis and lead time projections. This transparent, real-time quoting system eliminates traditional RFQ delays, allowing engineers to iterate designs and validate budgets before committing to production.

Partner with Honyo Prototype for CNC plasma cutting that meets the exacting standards of precision manufacturing, backed by our ISO 9001-certified processes and dedicated engineering support from quote to delivery.

Technical Capabilities

Honyo Prototype offers advanced CNC plasma cutting services integrated with precision 3/4/5-axis milling and turning capabilities to support high-complexity fabrication with tight tolerance requirements. While plasma cutting is typically used for primary cutting of conductive materials, it is often combined with secondary CNC machining operations to achieve final dimensional accuracy and surface finish. Below are the technical specifications for our integrated CNC plasma and machining services:

CNC Plasma Cutting & Precision Machining Technical Specifications

| Parameter | Specification Description |

|---|---|

| Cutting Process | High-definition CNC plasma cutting with automated torch height control |

| Compatible Materials | Mild Steel, Stainless Steel, Aluminum (up to 1.5” thick), other conductive metals |

| Material Compatibility (Machining) | Aluminum (6061, 7075), Steel (1018, 4140), Stainless Steel (303, 316), ABS, Nylon, and engineering plastics |

| Maximum Cutting Thickness | Up to 1.5 inches (38 mm) for steel; up to 1 inch (25 mm) for aluminum |

| Cutting Tolerance (Plasma) | ±0.010” (±0.25 mm) typical; edge prep for secondary machining |

| Machining Capabilities | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning (lathe) with live tooling |

| Machining Tolerance | ±0.0005” (±0.013 mm) for critical dimensions; tight tolerance features per GD&T standards |

| Surface Finish (Machined) | As low as 32 μin (0.8 μm) Ra; post-processing options available |

| Work Envelope (Milling) | Up to 20″ x 40″ x 20″ (508 x 1016 x 508 mm) for 3/4/5-axis systems |

| Work Envelope (Turning) | Maximum part diameter: 12” (305 mm); length up to 48” (1219 mm) |

| CAD/CAM Integration | Full 3D model import (STEP, IGES, SolidWorks, DXF/DWG); in-house programming and simulation |

| Quality Control | CMM inspection, first-article inspection (FAI), PPAP documentation available |

| Secondary Operations | Deburring, tapping, drilling, threading, anodizing, powder coating, welding support |

Note: While CNC plasma cutting is not suitable for non-conductive materials such as ABS and Nylon, these materials are fully supported through our precision CNC milling and turning services. Plasma-cut metal components are often finish-machined on multi-axis CNC platforms to meet tight tolerance and surface quality requirements for prototyping and low-volume production.

From CAD to Part: The Process

Honyo Prototype CNC Plasma Cutting Service Workflow

Honyo Prototype delivers precision CNC plasma cutting through a streamlined, technology-driven workflow designed for speed, accuracy, and manufacturability. Our process begins with seamless digital integration and concludes with certified on-time delivery, ensuring minimal lead times and maximum part integrity.

CAD File Upload & Validation

Clients initiate the process by uploading native CAD files (DXF, DWG, STEP, or IGS) via our secure online portal. Our system automatically validates file geometry, layer integrity, and unit consistency to prevent downstream errors. Unsupported formats trigger an immediate notification for client correction, eliminating manual back-and-forth. This stage ensures dimensional accuracy aligns with plasma cutting tolerances (±0.5mm typical) and material constraints.

AI-Powered Instant Quoting

Uploaded files enter Honyo’s proprietary AI quoting engine, which analyzes geometry complexity, material type, thickness, and quantity against real-time machine availability, material costs, and labor rates. The AI cross-references our database of 10,000+ historical plasma cutting jobs to predict processing time within 95% accuracy. Clients receive a detailed quote—including cost breakdown, lead time, and material waste percentage—in under 90 seconds. Critical parameters like kerf width compensation and heat-affected zone mitigation are pre-calculated during this phase.

Engineer-Verified DFM Analysis

Every job undergoes mandatory Design for Manufacturability (DFM) review by our senior manufacturing engineers. The AI-generated quote is validated against practical constraints:

Minimum feature size vs. plasma torch capability

Material grade suitability for plasma cutting (e.g., carbon steel, stainless steel, aluminum)

Nesting optimization to maximize sheet utilization

Thermal distortion risk assessment for intricate geometries

Engineers provide actionable feedback within 4 business hours, suggesting modifications like adjusted hole sizes or bridge placements to reduce dross and prevent part warpage. This step typically reduces scrap rates by 18–22% versus industry averages.

Precision Production Execution

Approved jobs move to production on our CNC plasma cutting systems (Hypertherm Powermax45 XP or equivalent), featuring:

5m x 10m cutting beds with ±0.2mm repeatability

Automatic height control for consistent cut quality

Dual-gas (oxygen/nitrogen) capability for material-specific optimization

Parts undergo in-process inspection at 30% and 70% completion to verify dimensional compliance. All cut edges are deburred, and critical dimensions are CMM-verified per ASME Y14.5 standards. Material certifications (e.g., ASTM A36, EN 10025) are tracked digitally for full traceability.

Certified Delivery & Logistics

Finished parts are packaged with anti-corrosion protection and serialized labels for inventory management. Honyo provides:

Digital first-article inspection reports (FAIR)

Material test certificates (MTC)

Real-time shipment tracking via client-integrated logistics platforms

Standard lead time is 3–5 business days from DFM approval, with 99.2% on-time delivery rate. Rush services (24–72 hours) are available for emergency prototyping or production line support.

Material & Capability Summary

| Parameter | Specification |

|———————|—————————————-|

| Material Types | Carbon Steel, Stainless Steel, Aluminum |

| Thickness Range | 1mm – 50mm |

| Max. Cutting Area | 5,000mm x 10,000mm |

| Positional Accuracy | ±0.2mm |

| Edge Quality | ISO 9013 Class F1 (smooth, minimal dross) |

This integrated approach eliminates traditional quoting bottlenecks while ensuring manufacturability—transforming digital designs into production-ready metal components with engineering rigor. Honyo’s closed-loop system guarantees that every plasma-cut part meets both dimensional requirements and functional intent for immediate assembly.

Start Your Project

Looking for precision CNC plasma cutting services? Partner with Honyo Prototype for high-quality, efficient metal fabrication solutions. Our advanced CNC plasma cutting technology ensures tight tolerances, clean cuts, and fast turnaround—ideal for prototypes and production runs.

Located in Shenzhen, our modern factory supports a wide range of materials and thicknesses with consistent accuracy and repeatability. Whether you need simple 2D profiles or complex sheet metal components, we deliver reliable results tailored to your specifications.

Contact Susan Leo today to discuss your project requirements or request a quote.

Email: [email protected]

Let Honyo Prototype be your trusted manufacturing partner in China.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.