Contents

Manufacturing Insight: Cnc Optics

Precision CNC Optics Manufacturing at Honyo Prototype

Honyo Prototype delivers mission-critical CNC machining services specifically engineered for the demanding requirements of optical component fabrication. Our advanced 5-axis CNC milling and turning capabilities, combined with proprietary finishing protocols, enable the production of complex lenses, prisms, mirrors, mounts, and structural optics assemblies to exacting aerospace, defense, and scientific instrumentation standards. We specialize in achieving nanometer-level surface finishes, sub-micron positional tolerances, and exceptional form accuracy on challenging materials including fused silica, Zerodur, ULE, sapphire, and precision optical glasses. This mastery ensures optimal light transmission, minimal wavefront distortion, and thermal stability essential for high-performance optical systems.

Our integrated manufacturing process encompasses precision grinding, deterministic polishing, and metrology-grade inspection using Zygo interferometers and CMMs, guaranteeing components meet stringent λ/10 surface quality and geometric specifications. Material compatibility and process control are paramount, as demonstrated in the core capabilities below:

| Parameter | Capability Range | Typical Application |

|---|---|---|

| Surface Accuracy | λ/10 to λ/20 (RMS) | Laser Cavities, Telescopes |

| Surface Roughness | < 5 Å RMS (Optical Finish) | UV Optics, Interferometry |

| Material Removal | Fused Silica, Sapphire, Ge, Si, Metals | IR Systems, Sensor Housings |

| Geometric Tolerance | ±1.0 µm (Critical Features) | Beam Steering Assemblies |

Accelerate your optical prototyping and low-volume production cycles with Honyo Prototype’s Online Instant Quote system. This dedicated platform provides validated manufacturing feedback and binding price/lead time estimates for CNC optics within hours—not days—by analyzing your STEP/IGES files against our process capabilities and material databases. Eliminate procurement delays while ensuring design manufacturability from the earliest stages. For projects demanding uncompromising optical performance and rapid turnaround, our CNC machining expertise coupled with digital quoting efficiency delivers the technical reliability your program requires.

Technical Capabilities

CNC Optics Manufacturing – Technical Specifications

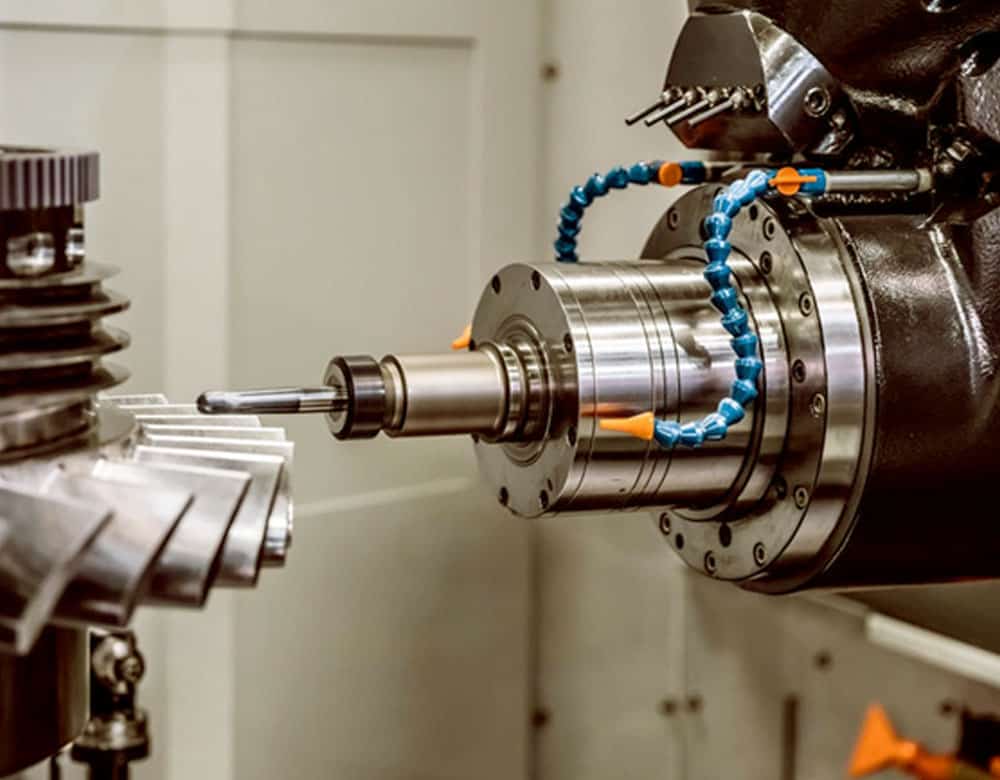

CNC optics refer to precision-machined components used in optical systems, including mounts, housings, lens barrels, and alignment fixtures. These parts require high dimensional accuracy, superior surface finish, and excellent material stability. At Honyo Prototype, we specialize in CNC machining of optical components using 3-axis, 4-axis, and 5-axis milling, as well as precision turning, to meet tight tolerance requirements essential for optical performance.

The following table outlines the technical specifications for CNC-machined optical components across key parameters:

| Parameter | Specification Detail |

|---|---|

| Machining Capabilities | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including mill-turn) |

| Tolerance Range | ±0.001 mm to ±0.005 mm (±0.00004″ to ±0.0002″) for critical optical alignment features |

| Surface Finish (Ra) | 0.4 µm to 1.6 µm (16–63 µin); polishable grades available for reflective surfaces |

| Feature Accuracy | Positional accuracy within ±0.002 mm; angular tolerances ±0.05° on 5-axis platforms |

| Materials Supported | Aluminum (6061, 7075), Steel (303, 304, 4140), ABS, Nylon (6, 66), and specialty polymers |

| Aluminum Characteristics | Lightweight, excellent machinability, anodizable; ideal for optical mounts and frames |

| Steel Characteristics | High rigidity, thermal stability, corrosion resistance (with passivation); used in precision instrument bodies |

| ABS Characteristics | Good dimensional stability, low cost, suitable for non-load-bearing optical enclosures |

| Nylon Characteristics | High wear resistance, low friction, moisture-resistant; used in lens retainers and insulating components |

| Secondary Operations | Deburring, precision cleaning, metrology (CMM inspection), anodizing, plating, laser marking |

| Inspection Standards | Full first-article inspection reports (FAIR), GD&T compliance, ISO 2768 medium precision default |

| Typical Applications | Laser housing, sensor mounts, telescope components, medical imaging devices, aerospace optics |

All CNC optics components are machined under controlled environmental conditions to minimize thermal drift, ensuring repeatable accuracy. Multi-axis capabilities allow complex geometries—such as compound angles and undercuts—to be achieved in a single setup, reducing cumulative error and improving alignment integrity. Material selection is optimized based on thermal expansion, weight, and environmental exposure requirements of the optical system.

From CAD to Part: The Process

Honyo Prototype employs a rigorously controlled workflow for CNC optical component manufacturing, designed to ensure precision, reduce lead times, and maintain stringent quality standards from initial design to final delivery. Our process begins with the customer uploading a validated CAD file in STEP or IGES format through our secure customer portal. This file must include critical optical specifications such as surface form tolerances (e.g., λ/10 at 632.8 nm), surface roughness requirements (typically <5 Å RMS for laser optics), material grade (e.g., fused silica, Zerodur), and coating specifications. Incomplete or ambiguous CAD submissions trigger an automated notification for immediate resubmission to prevent downstream delays.

The AI-powered quoting system processes the CAD geometry within minutes, analyzing factors like part complexity, material utilization, machine time estimates, and secondary operations. Unlike generic quoting tools, our AI engine cross-references historical production data from over 12,000 optical components to predict manufacturability risks and generate accurate cost/time projections. This phase outputs a formal quotation with a guaranteed tolerance feasibility assessment and explicit lead time commitments based on current machine capacity.

Design for Manufacturability (DFM) review follows immediately upon quote acceptance. Our optical engineering team conducts a multi-stage analysis: First, geometric validation checks for undercuts, thin walls (<3mm), or features incompatible with diamond-turned toolpaths. Second, material suitability is verified against thermal stability requirements and stress-induced birefringence thresholds. Third, we propose actionable optimizations—such as adjusting edge thickness to prevent chipping during handling or modifying chamfer dimensions to accommodate metrology probe access—documented in a collaborative DFM report with annotated CAD markups. Customer approval of DFM recommendations is mandatory before proceeding.

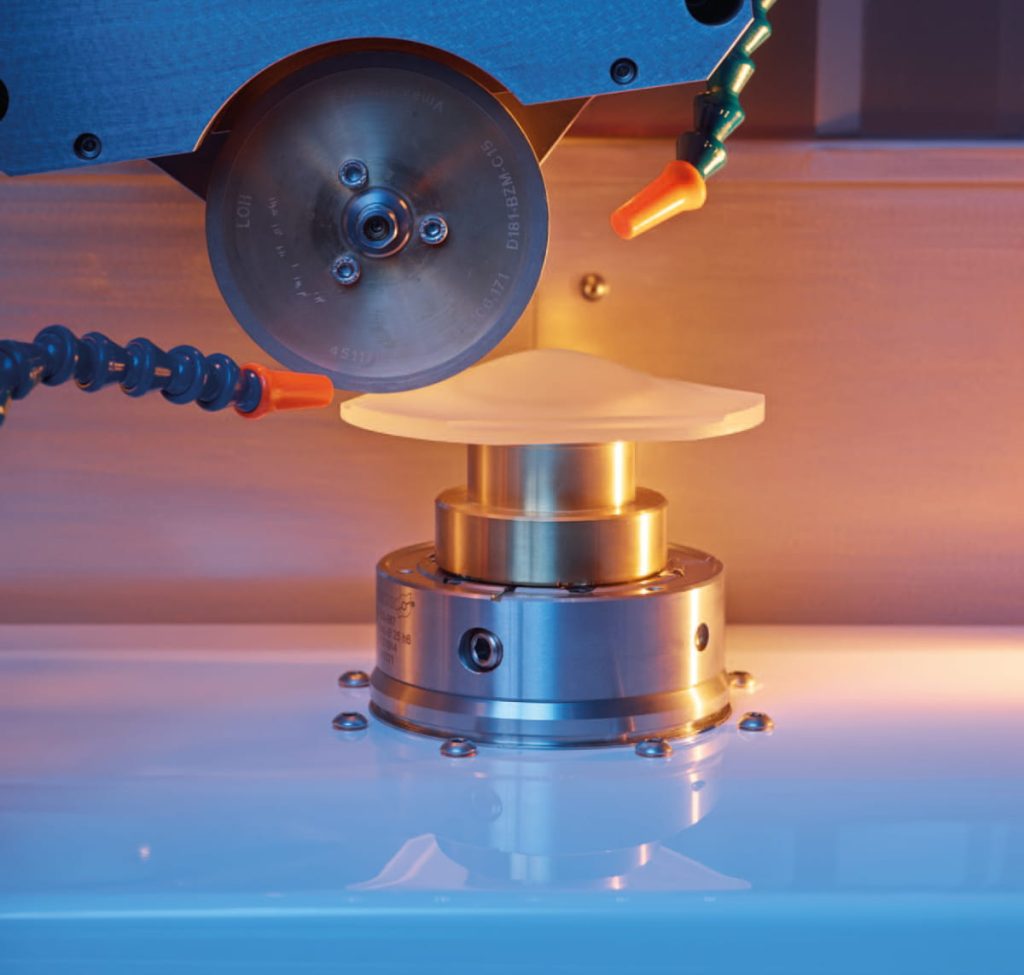

Production execution occurs in our ISO 14644-1 Class 7 cleanroom facility using dual-spindle CNC machines equipped with sub-micron linear encoders and air-bearing spindles. Key stages include: precision annealing to relieve internal stresses, deterministic micro-grinding for near-net shape formation, magnetorheological finishing for sub-angstrom surface smoothing, and interferometric in-process metrology at each critical stage. All optics undergo 100% post-process verification via Zygo GPI interferometers and Wyko optical profilers, with full test reports including Power, Irregularity, RMS roughness, and scratch-dig compliance archived to the component’s digital twin.

Final delivery includes the optical component in ESD-safe packaging with desiccant, accompanied by a comprehensive quality dossier containing first-article inspection reports, interferograms, material certificates, and coating spectral transmission data. We provide tracked global logistics with real-time shipment visibility and a 72-hour post-delivery technical support window for dimensional validation. Below summarizes typical optical tolerance capabilities for reference:

| Parameter | Standard Capability | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Surface Form | λ/4 @ 632.8 nm | λ/20 @ 632.8 nm | Phase-Shifting Interferometry |

| Surface Roughness | 10 Å RMS | 2 Å RMS | White Light Interferometry |

| Centration | 3 arcmin | 30 arcsec | Autocollimator |

| Thickness Tolerance | ±0.05 mm | ±0.005 mm | Capacitive Probe |

This integrated workflow ensures first-pass yield rates exceeding 95% for complex optical elements while maintaining full traceability from digital design to certified physical component.

Start Your Project

Interested in high-precision CNC optics manufacturing? Contact Susan Leo at [email protected] to discuss your project requirements.

Honyo Prototype operates a dedicated manufacturing facility in Shenzhen, equipped with advanced CNC machining capabilities tailored for optical components. Our expertise ensures tight tolerances, superior surface finishes, and fast turnaround times for prototyping and low-volume production.

Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.